Material för ytbeläggning

Innehållsförteckning

När man tänker efter ytbeläggningsmaterial, vad tänker jag på? Är det den blanka kromen på en bilstötfångare, den fjädrande färgen på en köksmaskin, eller kanske det skyddande lagret på en byggnads exteriör? Ytbeläggningsmaterial spelar en avgörande roll för att förbättra hållbarheten, estetiken och funktionaliteten hos olika produkter och strukturer. Den här artikeln kommer att dyka djupt in i världen av ytbeläggningsmaterial, utforska deras typer, tillämpningar, fördelar och mer. Så låt oss ge oss ut på denna resa och avslöja allt du behöver veta om ytbeläggningsmaterial.

Översikt över ytbeläggningsmaterial

Ytbeläggningsmaterial är ämnen som appliceras på ytan av föremål för att skydda dem från miljöskador, förbättra deras utseende eller ge ytterligare funktioner. Dessa beläggningar kan sträcka sig från enkla färger till komplexa flerskiktssystem utformade för att motstå extrema förhållanden.

Typer och sammansättning av Material för ytbeläggning

Ytbeläggningsmaterial finns i olika former, var och en med sin unika sammansättning och egenskaper. Här är en detaljerad titt på några av de vanligaste typerna:

| Typ | Sammansättning | Fastigheter | Egenskaper |

|---|---|---|---|

| Pulverlackering | Termoplast eller värmehärdande polymerpulver | Slitstark, motståndskraftig mot flisning | Enhetlig finish, miljövänlig |

| Metalliska beläggningar | Aluminium-, zink- eller kopparpulver | Korrosionsbeständig, reflekterande | Hög ledningsförmåga, estetisk tilltalande |

| Keramiska beläggningar | Oxider, karbider, nitrider | Motståndskraft mot höga temperaturer | Hård, slitstark |

| Polymerbeläggningar | Epoxier, polyuretaner, silikoner | Flexibel, kemikaliebeständig | Mångsidig, enkel applicering |

| Nanobeläggningar | Nanopartiklar av olika material | Förbättrade mekaniska egenskaper | Ultratunn, överlägsen prestanda |

| Organiska beläggningar | Naturliga hartser, oljor och vaxer | Biologiskt nedbrytbart, förnybart | Säker för kontakt med mat, miljövänlig |

Applicering av ytbeläggningsmaterial

Ytbeläggningsmaterial används inom många industrier, var och en med specifika krav och tillämpningar. Så här är de anställda inom olika sektorer:

| Industri | Tillämpningar |

|---|---|

| Fordon | Bilkarosser, hjul, undervagnsskydd, interiördelar |

| Flyg- och rymdindustrin | Flygplans exteriörer, turbinmotorer, strukturella komponenter |

| Konstruktion | Byggnadsfasader, broar, rörledningar, golv |

| Elektronik | Kretskort, kontakter, höljen |

| Marin | Fartygsskrov, offshorekonstruktioner, undervattensutrustning |

| Medicinsk | Kirurgiska instrument, implantat, diagnostiska apparater |

| Bohag | Vitvaror, möbler, köksredskap |

Specifikationer, storlekar, kvaliteter och standarder

För att säkerställa kvalitet och prestanda följer ytbeläggningsmaterial olika specifikationer och standarder. Här är en omfattande tabell som visar några viktiga specifikationer:

| Materialtyp | Specifikation | Storlekar | Betyg | Standarder |

|---|---|---|---|---|

| Pulverlackering | ASTM D3451 | Fint pulver | Industriellt, kommersiellt | ISO 9001, ISO 14001 |

| Metalliska beläggningar | ASTM B633 | Micron tjocklek | Typ I, Typ II, Typ III | ASTM, ISO, MIL-STD |

| Keramiska beläggningar | ASTM C633 | Olika partikelstorlekar | Standard, högpresterande | ISO 20507, ASTM C704 |

| Polymerbeläggningar | ASTM D4060 | Vätska, pulver | Olika (baserat på applikation) | ISO 12944, ISO 14040 |

| Nanobeläggningar | Anpassade specifikationer | Nanotunna lager | Applikationsspecifik | ISO/TS 80004-2, ASTM E2456 |

| Organiska beläggningar | ASTM D2457 | Viskösa vätskor | Livsmedelskvalitet, industriell | FDA, EU-förordningar |

Leverantörer och prisuppgifter

Att välja rätt leverantör är avgörande för att säkerställa kvalitet och konsekvens. Här är en titt på några ledande leverantörer och deras prisinformation:

| Leverantör | Materialtyp | Prisintervall | Plats | Kontaktuppgifter |

|---|---|---|---|---|

| PPG Industrier | Pulverlackering | $5 – $10 per kg | USA | www.ppg.com |

| Sherwin-Williams | Metalliska beläggningar | $20 – $50 per kg | Globalt | www.sherwin-williams.com |

| AkzoNobel | Keramiska beläggningar | $30 - $70 per kg | Nederländerna | www.akzonobel.com |

| BASF | Polymerbeläggningar | $15 – $40 per liter | Tyskland | www.basf.com |

| RPM International | Nanobeläggningar | $100 – $300 per liter | USA | www.rpminc.com |

| Axalta Beläggningssystem | Organiska beläggningar | $10 – $25 per liter | Globalt | www.axalta.com |

Fördelar med Material för ytbeläggning

Ytbeläggningsmaterial erbjuder en mängd fördelar som gör dem oumbärliga i olika branscher. Låt oss utforska några av de viktigaste fördelarna:

Skydd mot korrosion

En av ytbeläggningsmaterialens primära funktioner är att skydda substrat från korrosion. Metaller som stål och aluminium är benägna att rosta när de utsätts för fukt och syre. Beläggningar fungerar som en barriär som förhindrar att dessa element kommer i kontakt med metallytan, vilket förlänger produktens livslängd.

Förbättrad estetik

Oavsett om det är en livfull färg på en bil eller en elegant finish på en elektronisk pryl, förbättrar beläggningar avsevärt produkternas visuella attraktionskraft. Denna estetiska förbättring handlar inte bara om utseende; det spelar också en roll för konsumentnöjdhet och varumärkesuppfattning.

Förbättrad hållbarhet

Beläggningar ger produkterna ett extra lager av hållbarhet. Till exempel skyddar keramiska beläggningar på turbinbladen i jetmotorer mot extrema temperaturer och slitage, vilket säkerställer att motorerna fungerar effektivt under längre perioder.

Funktionsförbättringar

Utöver skydd och estetik kan beläggningar också ge funktionella fördelar. Till exempel förbättrar antireflekterande beläggningar på glas sikten och minskar bländning, medan non-stick beläggningar på kokkärl gör rengöringen enklare.

Nackdelar med ytbeläggningsmaterial

Även om ytbeläggningar erbjuder många fördelar, har de också vissa nackdelar. Att förstå dessa begränsningar är avgörande för att fatta välgrundade beslut.

Kostnad

Högkvalitativa beläggningar, särskilt avancerade typer som nanobeläggningar och keramiska beläggningar, kan vara dyra. Denna kostnadsfaktor kan vara en viktig faktor för storskaliga applikationer.

Miljöpåverkan

Framställning och applicering av vissa beläggningar involverar kemikalier som kan vara skadliga för miljön. Även om många företag går över till miljövänliga alternativ, är miljöavtrycket fortfarande ett problem.

Komplexa ansökningsprocesser

Vissa beläggningar kräver specialiserad utrustning och expertis för applicering. Till exempel innebär applicering av pulverlackering elektrostatisk sprayavsättning, vilket kräver specifika maskiner och utbildad personal.

Jämföra ytbeläggningsmaterial

När du väljer ett ytbeläggningsmaterial är det viktigt att väga för- och nackdelar med varje typ. Här är en jämförande tabell som hjälper dig att göra ett välgrundat val:

| Materialtyp | Fördelar | Nackdelar |

|---|---|---|

| Pulverlackering | Miljövänlig, hållbar, enhetlig finish | Kräver specialutrustning |

| Metalliska beläggningar | Hög ledningsförmåga, korrosionsbeständig | Kan bli dyrt |

| Keramiska beläggningar | Hög temperaturbeständighet, hård | Hög kostnad, komplex applikation |

| Polymerbeläggningar | Mångsidig, flexibel, kemikaliebeständig | Miljöhänsyn |

| Nanobeläggningar | Överlägsen prestanda, ultratunn | Mycket hög kostnad, specialiserad applikation |

| Organiska beläggningar | Biologiskt nedbrytbart, förnybart | Begränsad hållbarhet, prestanda |

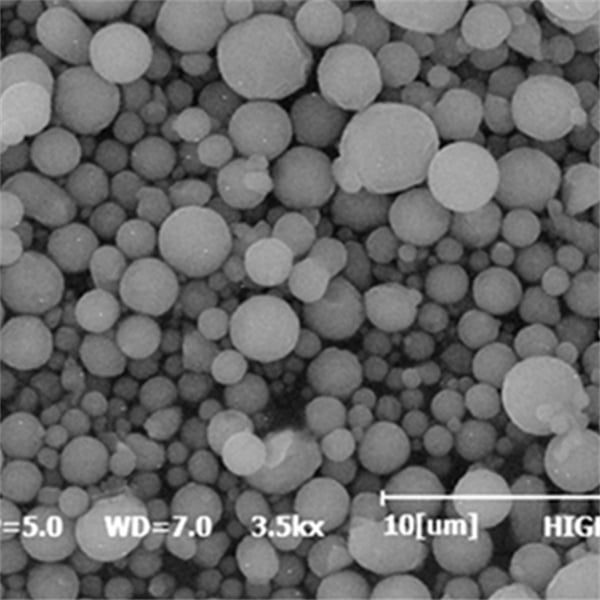

Toppmodeller av metallpulver för ytbeläggningar

Metallpulver är en integrerad del av många beläggningsprocesser och ger specifika egenskaper som ledningsförmåga, korrosionsbeständighet och estetisk tilltalande. Här är tio anmärkningsvärda metallpulvermodeller som används i ytbeläggningar:

- Aluminium 6061 pulver

- Beskrivning: Ett mångsidigt aluminiumlegeringspulver känt för sin utmärkta korrosionsbeständighet och höga hållfasthet.

- Applikationer: Används i stor utsträckning inom fordons- och rymdbeläggningar.

- Zinkpulver

- Beskrivning: Ett vanligt metallpulver som används för sina överlägsna korrosionsskyddsegenskaper.

- Applikationer: Galvaniserat stål, skyddande beläggningar för marina miljöer.

- Kopparpulver

- Beskrivning: Erbjuder utmärkt elektrisk ledningsförmåga och används ofta i elektroniska beläggningar.

- Applikationer: Kretskort, elektriska kontakter.

- Rostfritt stål 316 pulver

- Beskrivning: Känd för sin korrosionsbeständighet och styrka, idealisk för tuffa miljöer.

- Applikationer: Medicinsk utrustning, marina applikationer.

- Nickelpulver

- Beskrivning: Ger högtemperaturbeständighet och korrosionsskydd.

- Applikationer: Flyg-, industrimaskiner.

- Titanpulver

- Beskrivning: Lätt, stark och korrosionsbeständig, används i avancerade applikationer.

- Applikationer: Flyg-, biomedicinska implantat.

- Järnpulver

- Beskrivning: Ekonomisk och mångsidig, används ofta i magnetiska beläggningar.

- Applikationer: Bildelar, elektronik.

- Kobolt-krom pulver

- Beskrivning: Ger utmärkt slitstyrka och hållfasthet, lämplig för applikationer med hög belastning.

- Applikationer: Medicinska implantat, turbinmotorer.

- Pulver av volframkarbid

- Beskrivning: Extremt hårt och slitstarkt, används i nötande miljöer.

- Applikationer: Skärverktyg, slitstarka beläggningar.

- Silverpulver

- Beskrivning: Känd för sin överlägsna elektriska ledningsförmåga och antimikrobiella egenskaper.

- Applikationer: Elektronik, medicinsk utrustning.

Tillämpningar och användningar av specifika metallpulvermodeller

Varje metallpulvermodell har specifika applikationer som utnyttjar dess unika egenskaper. Så här används några av dessa pulver i olika industrier:

| Metallpulvermodell | Primära användningsområden |

|---|---|

| Aluminium 6061 pulver | Bildelar, komponenter till flyg- och rymdindustrin |

| Zinkpulver | Galvaniserat stål, marina skyddsbeläggningar |

| Kopparpulver | Kretskort, elektriska kontakter |

| Rostfritt stål 316 | Medicinsk utrustning, marina applikationer |

| Nickelpulver | Turbinblad, industrimaskiner |

| Titanpulver | Flyg- och rymdindustrin, biomedicinska implantat |

| Järnpulver | Magnetiska beläggningar, bildelar |

| Kobolt-krom pulver | Medicinska implantat, högspänningskomponenter |

| Volframkarbid | Skärande verktyg, slitstarka beläggningar |

| Silverpulver | Elektronik, medicinsk utrustning |

Fördelar och begränsningar med specifika metallpulvermodeller

Att förstå styrkorna och svagheterna hos varje metallpulvermodell kan hjälpa dig att välja rätt för din applikation. Här är en jämförelse:

| Metallpulvermodell | Fördelar | Begränsningar |

|---|---|---|

| Aluminium 6061 | Korrosionsbeständig, hög hållfasthet | Kan bli dyrt |

| Zink | Överlägset korrosionsskydd | Relativt låg styrka |

| Koppar | Utmärkt ledningsförmåga | Känslig för oxidation |

| Rostfritt stål 316 | Hög korrosionsbeständighet, hållbar | Hög kostnad |

| Nickel | Beständighet mot höga temperaturer | Dyrt, kan orsaka allergiska reaktioner |

| Titan | Lätt och stark | Mycket hög kostnad |

| Järn | Ekonomisk, mångsidig | Benägen att rosta om den inte beläggs ordentligt |

| Kobolt-Krom | Utmärkt slitstyrka | Hög kostnad |

| Volframkarbid | Extremt hård, slitstark | Skör, hög kostnad |

| Silver | Överlägsen ledningsförmåga, antimikrobiell | Mycket dyrt |

Tekniska specifikationer och standarder för metallpulver

Att säkerställa metallpulvers kvalitet och prestanda innebär att man följer specifika tekniska specifikationer och standarder:

| Metallpulvermodell | Specifikation | Standarder |

|---|---|---|

| Aluminium 6061 | ASTM B928 | ISO 209-1 |

| Zink | ASTM B6 | ISO 752 |

| Koppar | ASTM B170 | ISO 13307 |

| Rostfritt stål 316 | ASTM A240 | ISO 5832-1 |

| Nickel | ASTM B330 | ISO 4287 |

| Titan | ASTM B348 | ISO 5832-2 |

| Järn | ASTM A955 | ISO 10807 |

| Kobolt-Krom | ASTM F75 | ISO 5832-4 |

| Volframkarbid | ASTM B777 | ISO 6158 |

| Silver | ASTM B832 | ISO 920 |

Leverantörer och prisuppgifter för metallpulver

Att välja rätt leverantör för metallpulver är avgörande för kvalitetssäkringen. Här är en titt på några ledande leverantörer och deras prisinformation:

| Leverantör | Metallpulvermodell | Prisintervall | Plats | Kontaktuppgifter |

|---|---|---|---|---|

| Höganäs AB | Aluminium 6061 | $15 – $30 per kg | Sverige | www.hoganas.com |

| Amerikanska element | Zink | $20 – $40 per kg | USA | www.americanelements.com |

| Tillverkning av metallpulver | Koppar | $50 - $100 per kg | STORBRITANNIEN | www.makin-metals.com |

| GKN Hoeganaes | Rostfritt stål 316 | $60 – $120 per kg | USA | www.gknpm.com |

| Kennametal | Nickel | $80 – $150 per kg | Globalt | www.kennametal.com |

| Läsa legeringar | Titan | $150 – $300 per kg | USA | www.readingalloys.com |

| Rio Tinto Metallpulver | Järn | $5 – $10 per kg | Kanada | www.riotinto.com |

| Snickeriteknik | Kobolt-Krom | $100 – $250 per kg | USA | www.carpentertechnology.com |

| Global volfram & pulver | Volframkarbid | $200 – $400 per kg | USA | www.globaltungsten.com |

| Amerikanska element | Silver | $300 – $600 per kg | USA | www.americanelements.com |

Vanliga frågor

Ytbeläggningsmaterial kan vara komplexa och du kan ha flera frågor. Här är ett avsnitt med vanliga frågor om några vanliga frågor:

| Fråga | Svar |

|---|---|

| Vad är ytbeläggningsmaterial? | Ytbeläggningsmaterial är ämnen som appliceras på ytor för att skydda, förbättra utseendet eller lägga till funktionalitet. |

| Vilka typer av ytbeläggningar finns det? | Typer inkluderar pulverbeläggningar, metallbeläggningar, keramiska beläggningar, polymerbeläggningar, nanobeläggningar och organiska beläggningar. |

| Varför är beläggningar viktiga? | Beläggningar skyddar mot korrosion, förbättrar estetiken, förbättrar hållbarheten och ger funktionella fördelar. |

| Vilka är några vanliga applikationer? | Tillämpningar sträcker sig från fordon och flyg till elektronik, marin, medicinsk utrustning och hushållsartiklar. |

| Hur appliceras beläggningar? | Metoder inkluderar bland annat sprutning, doppning, elektrostatisk avsättning och termisk sprutning. |

| Vilka är fördelarna med nanobeläggningar? | Nanobeläggningar erbjuder överlägsen prestanda, ultratunn applicering och förbättrade mekaniska egenskaper. |

| Vilka faktorer påverkar valet av beläggning? | Faktorer inkluderar substratmaterialet, miljöförhållanden, önskade egenskaper och kostnad. |

| Kan beläggningar vara miljövänliga? | Ja, många moderna beläggningar är designade för att vara miljövänliga, använda mindre skadliga kemikalier och erbjuda hållbarhetsfördelar. |

Slutsats

Ytbeläggningsmaterial är en integrerad del av ett brett spektrum av industrier, ger viktigt skydd, förbättrar estetiken och levererar ytterligare funktionalitet. Från den glänsande finishen på din bil till den hållbara beläggningen på en skyskrapa, dessa material spelar en avgörande roll i vårt dagliga liv. Genom att förstå de olika typerna, tillämpningarna, fördelarna och begränsningarna för ytbeläggningar kan du fatta välgrundade beslut för dina projekt och produkter.

Oavsett om du är en tillverkare som vill förbättra produktens hållbarhet eller en konsument som letar efter kvalitetsfinish, erbjuder ytbeläggningsmaterial lösningar som möter olika behov. Med framsteg inom tekniken lovar framtiden för ytbeläggningar ännu större innovationer och fördelar.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731