Custom Tungsten Components for the Defense Industry in Texas: A Comprehensive Guide for B2B Buyers

Innehållsförteckning

1. Introduction to Custom Tungsten Components in the Defense Industry

Tungsten is a critical material in modern defense applications due to its exceptional density, strength, and resistance to extreme conditions. Custom tungsten components are widely used in armor-piercing ammunition, radiation shielding, kinetic energy penetrators, and aerospace components.

For defense manufacturers in Texas, sourcing high-quality tungsten components is essential to ensure performance and reliability. Companies like Metall3DP specialize in producing custom tungsten parts using advanced metal additive manufacturing techniques, offering unparalleled precision and material integrity.

2. Market Trends & Demand for Tungsten in Defense Applications

The demand for tungsten components in the defense sector is increasing due to several key factors:

Growing Investment in Defense and Aerospace

- The U.S. Department of Defense (DoD) continues to invest in advanced materials for military applications.

- Texas is home to multiple defense contractors and aerospace manufacturers, driving demand for tungsten-based products.

Framsteg inom additiv tillverkning

- 3D printing technology enables the production of complex tungsten components with high precision.

- Företag gillar Metall3DP utilize Selective Electron Beam Melting (SEBM) and Powder Bed Fusion (PBF) techniques to manufacture tungsten parts with superior mechanical properties.

Increased Use of Tungsten in Ammunition and Armor

- Tungsten’s high density (19.25 g/cm³) makes it ideal for armor-piercing projectiles and kinetic energy penetrators.

- Military-grade tungsten alloys provide enhanced durability and impact resistance.

| Marknadstrend | Impact on Defense Industry |

|---|---|

| Increased defense spending | Higher demand for advanced materials like tungsten |

| Adoption of 3D printing | Faster prototyping and production of custom tungsten parts |

| Aerospace growth in Texas | More suppliers and manufacturers investing in tungsten components |

3. Key Factors to Consider When Choosing a Tungsten Supplier

Selecting the right tungsten supplier is crucial for defense manufacturers. Here are the key factors to consider:

Materialkvalitet och renhet

- Ensure the supplier offers high-purity tungsten alloys optimized for defense applications.

- Look for certifications that validate the material’s composition and performance.

Tillverkningsmöjligheter

- Advanced manufacturing processes like Selektiv smältning med elektronstråle (SEBM) och Fusion av pulverbäddar (PBF) are essential for producing high-precision tungsten parts.

- A reliable supplier should offer custom machining, sintering, and additive manufacturing for tungsten components.

Defense Industry Compliance

- The supplier must comply with defense industry standards, such as ITAR (International Traffic in Arms Regulations) och MIL-SPEC (Military Specifications).

- Certifications like ISO 9001 och AS9100 are critical for quality assurance.

Production Lead Times & Scalability

- Defense projects often require quick turnaround times for prototyping and full-scale production.

- En leverantör med in-house powder production and advanced 3D printing capabilities can reduce lead times.

| Faktor | Varför det är viktigt |

|---|---|

| Materialets renhet | Ensures high-performance tungsten components |

| Tillverkningsprocess | Affects precision, durability, and scalability |

| Efterlevnad | Necessary for military and aerospace contracts |

| Ledande tidningar | Impacts project timelines and delivery schedules |

Genom att samarbeta med Metall3DP, defense companies can access high-quality tungsten components manufactured with cutting-edge additive manufacturing technology.

4. Top Manufacturers of Tungsten Components in Texas

Texas is home to several leading manufacturers that specialize in tungsten components for the defense industry. These companies provide high-quality tungsten alloys, machining capabilities, and additive manufacturing solutions tailored for aerospace and military applications.

Top Tungsten Suppliers in Texas

| Företagsnamn | Specialisering | Viktiga styrkor |

|---|---|---|

| Metall3DP | Additive manufacturing & high-performance tungsten alloys | Advanced 3D printing technology, custom tungsten components, in-house powder production |

| Texas Tungsten | Tungsten raw materials & machining | High-purity tungsten alloys, precision machining |

| Global volfram & pulver | Powder production & sintering | Extensive tungsten powder portfolio, defense-grade materials |

| ATI Metals | Specialty metal components | Military-grade tungsten alloys, aerospace applications |

Bland dessa, Metall3DP sticker ut på grund av sin advanced additive manufacturing capabilities, allowing for the production of complex tungsten components with unmatched precision and mechanical integrity.

5. Why Texas Is a Strategic Hub for Defense Manufacturing

Texas has emerged as a key location for defense manufacturing, especially for advanced materials like tungsten. Several factors contribute to its strategic importance:

Strong Military & Aerospace Presence

- Texas is home to major defense contractors, including Lockheed Martin, Raytheon, and Bell Helicopter.

- Military bases such as Fort Hood, Joint Base San Antonio, and NAS Corpus Christi drive demand for advanced materials.

Pro-Business Policies & Manufacturing Incentives

- Texas offers tax incentives and grants for defense-related manufacturing.

- The state’s low corporate tax rates make it an attractive destination for suppliers.

Access to Skilled Workforce & Innovation

- Texas universities and research institutions support advanced manufacturing and material science innovations.

- Företag gillar Metall3DP benefit from Texas’s strong engineering talent pool for R&D in additive manufacturing.

| Faktor | Why It Benefits Tungsten Manufacturing |

|---|---|

| Military & Aerospace Presence | High demand for tungsten-based defense components |

| Pro-Business Policies | Uppmuntrar investeringar i avancerad tillverkning |

| Kvalificerad arbetskraft | Supports innovation in 3D printing & material science |

6. Why Choose Metal3DP for Custom Tungsten Components?

När det gäller inköp custom tungsten components for defense applications, Metall3DP is a leading choice. Here’s why:

1. Industry-Leading Additive Manufacturing Technology

- Metall3DP specialiserar sig på Selektiv smältning med elektronstråle (SEBM) och Fusion av pulverbäddar (PBF) to produce tungsten components.

- These processes enable high-precision, high-density, and defect-free tungsten parts for defense and aerospace applications.

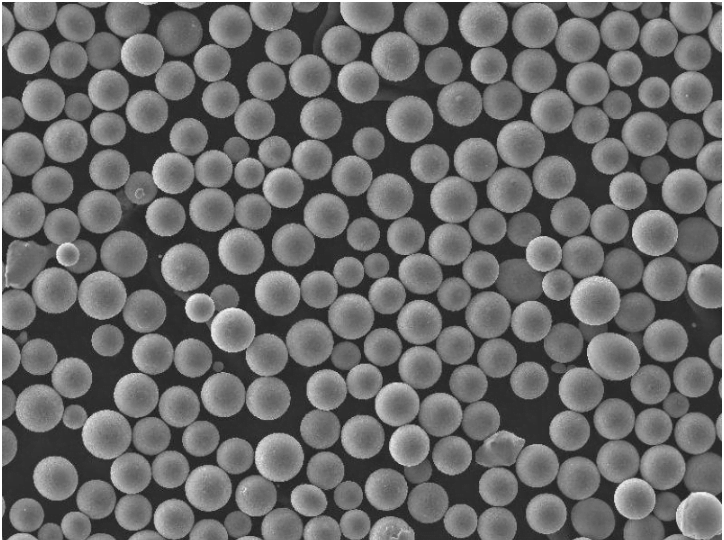

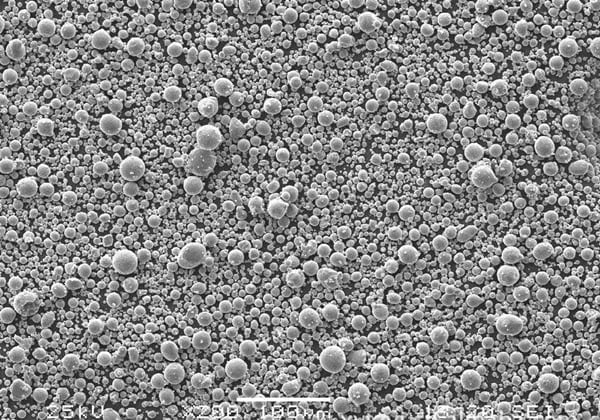

2. High-Quality Tungsten Powders

- Metall3DP produces its own tungsten powders using gasatomisering och PREP-teknik to ensure superior material properties.

- Our tungsten powders offer high sphericity, excellent flowability, and optimal particle size distribution for 3D printing applications.

3. Anpassning & Rapid Prototyping

- Vi tillhandahåller tailored tungsten parts, från armor-piercing projectiles to radiation shielding.

- Vår rapid prototyping capabilities allow for quick iteration and testing of defense components.

4. Compliance with Defense Standards

- Metall3DP adheres to military-grade material standards, ensuring all tungsten components meet ITAR and MIL-SPEC krav.

- Vår ISO 9001 och AS9100 certifieringar guarantee quality and consistency.

| Varför välja Metal3DP? | Benefits for Defense Industry |

|---|---|

| Avancerad 3D-utskrift | Enables complex tungsten part production |

| High-Purity Tungsten Powders | Ensures superior mechanical properties |

| Anpassad tillverkning | Supports unique defense applications |

| Compliance with Defense Standards | Meets ITAR, MIL-SPEC, and aerospace regulations |

Att lära sig mer om Metal3DP’s advanced tungsten 3D printing solutions, besök vår 3D-utskrift av metall sida.

7. How to Order Custom Tungsten Parts for Defense Applications

Ordering custom tungsten components for defense applications requires a streamlined approach to ensure precision, compliance, and timely delivery. At Metall3DP, we make the process seamless for our B2B customers.

Steg-för-steg beställningsprocess

| Steg | Beskrivning |

|---|---|

| Step 1: Consultation & Requirement Analysis | Contact our team to discuss your project requirements, including material specifications, part geometries, and performance needs. |

| Step 2: Design & Prototyping | Our engineers assist in designing the tungsten components using state-of-the-art additive manufacturing technologies. We offer rapid prototyping for design validation. |

| Step 3: Material Selection | Choose from our högrent volframpulver optimerad för Selektiv smältning med elektronstråle (SEBM) och Fusion av pulverbäddar (PBF). |

| Step 4: Manufacturing & Quality Assurance | We manufacture the components using precision 3D-utskrifter and conduct strict quality control checks to meet ITAR and MIL-SPEC standarder. |

| Steg 5: Leverans & Logistik | We ensure safe packaging and on-time delivery to your facility in Texas or anywhere in the U.S. |

Why Choose Metal3DP for Your Tungsten Orders?

- Quick Turnaround: Faster production with in-house powder manufacturing och avancerad 3D-utskrift.

- Anpassade lösningar: We tailor tungsten components to specific defense applications.

- Strict Compliance: Adherence to military and aerospace standards säkerställer tillförlitlighet.

To place an order or request a quote, visit our Produktsida.

8. FAQs: Common Questions About Tungsten Components for Defense

Q1: Why is tungsten preferred over other metals for defense applications?

Tungsten is chosen for its high density, strength, and resistance to extreme temperaturesvilket gör den idealisk för armor-piercing ammunition, kinetic energy penetrators, and radiation shielding.

Q2: What tungsten alloys are commonly used in military applications?

Common tungsten alloys include:

- Tung legering av volfram (WHA) – Used for kinetic energy penetrators and counterweights.

- Tungsten-Nickel-Iron (W-Ni-Fe) – Offers high density with good machinability.

- Tungsten-Copper (W-Cu) – Used in electrical contacts and heat-resistant applications.

Q3: Can Metal3DP provide custom tungsten components in small-batch production?

Ja! Vår additive manufacturing technology allows for both small-batch prototyping and large-scale production, ensuring flexibility for defense manufacturers.

Q4: What certifications does Metal3DP hold for tungsten manufacturing?

We comply with ISO 9001, AS9100, and ITAR regulations, ensuring all parts meet military and aerospace standards.

Q5: How does 3D printing improve tungsten component manufacturing?

By using Selektiv elektronstrålesmältning (SEBM) och pulverbäddsfusion (PBF), we achieve:

- Higher precision in complex geometries.

- Minskat materialspill jämfört med traditionell bearbetning.

- Snabbare prototypframställning och produktionscykler.

For more details on our manufacturing processes, visit our Tryckmetoder sida.

9. Slutsats och nästa steg

The defense industry requires high-performance materials like tungsten for mission-critical applications. Texas, with its strong military presence and advanced manufacturing ecosystem, is an ideal location for sourcing and producing custom tungsten components.

På Metall3DP, we provide:

✅ High-quality tungsten powders & 3D-printed components

✅ Military-grade compliance (ITAR, MIL-SPEC, AS9100)

✅ Custom manufacturing for defense and aerospace applications

✅ Fast, reliable, and scalable production solutions

Next Steps: Get in Touch with Metal3DP

Om du letar efter en trusted tungsten supplier for defense projects, Metall3DP is here to help. Contact us today to discuss your requirements or request a quote.

Learn more about us: Om Metal3DP

Explore our metal 3D printing capabilities: 3D-utskrift av metall

Partner with Metal3DP for cutting-edge tungsten components in defense manufacturing!

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731