Smältning genom induktion i vakuum

Innehållsförteckning

Översikt över Smältning genom induktion i vakuum

Vakuuminduktionssmältning (VIM) är en sofistikerad och viktig process inom metallurgiindustrin, som främst används för att producera högkvalitativa metallegeringar. Genom att smälta metaller under vakuum minimerar denna metod risken för kontaminering från gaser och föroreningar, vilket resulterar i överlägsna materialegenskaper. Den används ofta i branscher där hög renhet och specifika legeringssammansättningar är kritiska, t.ex. flyg- och rymdindustrin, medicintekniska produkter och högpresterande tekniska komponenter.

Förståelse för smältning genom vakuuminduktion

Vakuuminduktionssmältning fungerar genom att elektromagnetisk induktion används för att värma och smälta metaller i en vakuumförsluten miljö. Vakuumförhållandena minskar närvaron av syre, kväve och väte, som kan orsaka defekter i slutprodukten. Denna process säkerställer att de metaller som produceras har utmärkta mekaniska egenskaper, hög renhet och kontrollerade sammansättningar.

Nyckelkomponenter och process

- Induktionsugn: Kärnan i VIM-processen, där växelström används för att skapa ett elektromagnetiskt fält som inducerar värme i metallen.

- Vakuumkammare: Omsluter induktionsugnen och säkerställer att smältningen sker i vakuum eller i en inert atmosfär.

- Strömförsörjning: Tillhandahåller den nödvändiga elektriska kraften för induktionsvärme.

- Kylningssystem: Håller rätt temperatur och förhindrar överhettning.

Fördelar med smältning genom induktion i vakuum

- Hög renhet: Eliminerar föroreningar och producerar exceptionellt rena metaller.

- Exakt kontroll: Ger möjlighet till exakt kontroll över legeringssammansättningen.

- Överlägsna mekaniska egenskaper: Förbättrar materialets styrka, duktilitet och övergripande prestanda.

- Mångsidighet: Lämplig för ett brett spektrum av metaller och legeringar.

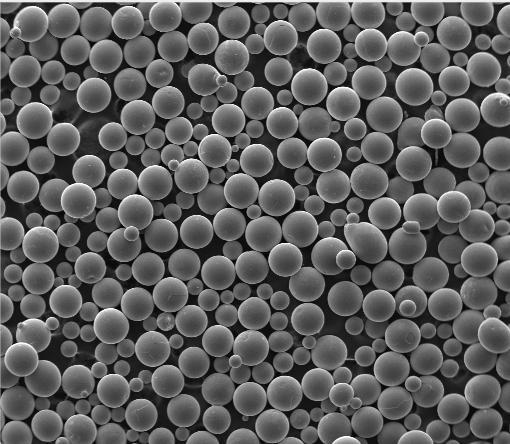

Typer av metallpulver som framställs med hjälp av Smältning genom induktion i vakuum

Vanliga metallpulver och deras användningsområden

| Metallpulver | Sammansättning | Fastigheter | Tillämpningar |

|---|---|---|---|

| Nickellegering 625 | Ni, Cr, Mo, Nb | Hög hållfasthet, korrosionsbeständig | Flyg- och rymdindustrin, marinindustrin, kemisk bearbetning |

| Titanlegering Ti-6Al-4V | Ti, Al, V | Högt förhållande mellan styrka och vikt, biokompatibilitet | Medicinska implantat, flyg- och rymdindustrin |

| Kobolt-kromlegering | Co, Cr, Mo | Slitstark, biokompatibel | Tand- och ortopediska implantat |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | Beständighet mot höga temperaturer, hållfasthet | Gasturbiner, kärnreaktorer |

| Rostfritt stål 316L | Fe, Cr, Ni, Mo | Korrosionsbeständig, god svetsbarhet | Medicintekniska produkter, livsmedelsbearbetning |

| Aluminiumlegering 7075 | Al, Zn, Mg, Cu | Hög hållfasthet, låg vikt | Flyg- och rymdindustrin, sportartiklar |

| Verktygsstål H13 | Fe, Cr, Mo, V | Hög seghet, slitstyrka | Verktyg för pressgjutning, extrudering |

| Kopparlegering C18200 | Cu, Cr | Hög ledningsförmåga, korrosionsbeständighet | Elektriska komponenter, svetselektroder |

| Magnesiumlegering AZ91D | Mg, Al, Zn | Lättvikt, god gjutbarhet | Fordon, elektronik |

| Tantalum | Ren Ta | Hög smältpunkt, korrosionsbeständig | Kemisk bearbetning, elektronik |

Tillämpningar av smältning genom induktion i vakuum

Vakuuminduktionssmältning används inom olika branscher för att tillverka komponenter som kräver hög integritet och specifika materialegenskaper. Här är några viktiga tillämpningar:

| Industri | Tillverkade komponenter |

|---|---|

| Flyg- och rymdindustrin | Turbinblad, motorkomponenter |

| Medicinsk | Implantat, kirurgiska instrument |

| Fordon | Motordelar med hög prestanda |

| Elektronik | Konduktiva material, halvledarkomponenter |

| Energi | Turbinkomponenter, delar till kärnreaktorer |

Specifikationer, storlekar, kvaliteter och standarder

När man hanterar metallpulver och komponenter som tillverkas via induktionssmältning i vakuum är det viktigt att följa specifika standarder och specifikationer för att säkerställa kvalitet och prestanda. Nedan följer en översikt över vanliga specifikationer:

| Material | Specifikationer | Storlekar | Betyg | Standarder |

|---|---|---|---|---|

| Nickellegering 625 | ASTM B446, AMS 5666 | Olika storlekar | UNS N06625 | ISO 9001, AS9100 |

| Titanlegering Ti-6Al-4V | ASTM F136, AMS 4911 | Olika storlekar | Betyg 5 | ISO 5832-3, ASTM F136 |

| Rostfritt stål 316L | ASTM A240, A276 | Olika storlekar | UNS S31603 | ISO 9001, ASTM A276 |

| Inconel 718 | ASTM B637, AMS 5663 | Olika storlekar | UNS N07718 | ISO 9001, AS9100 |

| Verktygsstål H13 | ASTM A681, AISI H13 | Olika storlekar | Klass H13 | ISO 9001, ASTM A681 |

Jämförelse av för- och nackdelar med Smältning genom induktion i vakuum

| Fördelar | Nackdelar |

|---|---|

| Hög renhet: Producerar metaller med färre orenheter och defekter. | Kostnad: Höga initiala installations- och driftskostnader. |

| Kontrollerad atmosfär: Minimerar kontaminering från gaser och andra element. | Komplexitet: Kräver skickliga operatörer och exakta kontrollsystem. |

| Mångsidighet: Kan användas för ett brett spektrum av metaller och legeringar. | Skala: Begränsade batchstorlekar jämfört med andra metoder. |

| Förbättrade egenskaper: Förbättrar metallers mekaniska egenskaper och prestanda. | Underhåll: Kräver regelbundet underhåll av vakuumsystemet och induktionsugnen. |

Större leverantörer och prisuppgifter

När du köper metallpulver och komponenter som tillverkas genom induktionssmältning i vakuum är det viktigt att ta hänsyn till leverantörernas rykte, kvalitetsstandarder och prissättning. Här är en sammanfattning av några anmärkningsvärda leverantörer:

| Leverantör | Plats | Produkter | Prissättning (ungefärlig) |

|---|---|---|---|

| ATI Metals | USA | Nickellegeringar, titanlegeringar | $50 - $200/kg |

| Snickeriteknik | USA | Speciallegeringar, rostfritt stål | $40 - $180/kg |

| Sandvik Materialteknik | Sverige | Rostfritt stål, högpresterande legeringar | $30 - $150/kg |

| VSMPO-AVISMA | Ryssland | Titanlegeringar | $60 - $220/kg |

| H.C. Starck Lösningar | Tyskland | Svårsmälta metaller, avancerade legeringar | $70 - $250/kg |

Fördelar och begränsningar med smältning genom induktion i vakuum

Fördelar

- Renhet och kvalitet: En av de viktigaste fördelarna med VIM är möjligheten att producera extremt rena metaller, vilket är avgörande för högpresterande applikationer.

- Exakt legeringssammansättning: Processen möjliggör en exakt kontroll över legeringselementen, vilket säkerställer att slutprodukten uppfyller exakta specifikationer.

- Förbättrade mekaniska egenskaper: Metaller som produceras genom VIM uppvisar ofta överlägsna mekaniska egenskaper, t.ex. ökad hållfasthet, seghet och motståndskraft mot utmattning och korrosion.

Begränsningar

- Höga kostnader: Både installations- och driftskostnaderna för induktionssmältning i vakuum är höga, vilket kan vara ett hinder för mindre företag eller lågvolymsproduktion.

- Komplex drift: Processen kräver mycket skickliga operatörer och sofistikerade styrsystem för att upprätthålla de nödvändiga villkoren för kvalitetsproduktion.

- Batchstorlek: Storleken på de satser som kan produceras är ofta mindre jämfört med andra smältprocesser, vilket kan begränsa produktionskapaciteten.

Jämförelse Smältning genom induktion i vakuum med andra smältprocesser

| Parameter | Smältning genom induktion i vakuum | Smältning med elektrisk ljusbåge | Smältning genom luftinduktion |

|---|---|---|---|

| Renhet | Hög | Måttlig | Låg |

| Kostnad | Hög | Måttlig | Låg |

| Kontroll över sammansättning | Utmärkt | Bra | Rättvist |

| Batchstorlek | Liten till medelstor | Medium till stor | Stor |

| Mekaniska egenskaper | Överlägsen | Bra | Rättvist |

Vanliga frågor

| Fråga | Svar |

|---|---|

| Vad är vakuuminduktionssmältning? | Vakuuminduktionssmältning är en process som använder elektromagnetisk induktion för att smälta metaller i en vakuumförseglad miljö för att producera legeringar med hög renhet. |

| Varför används vakuum i den här processen? | Vakuumet minskar förekomsten av gaser som syre, kväve och väte, vilka kan orsaka föroreningar och defekter i metallen. |

| Vilka typer av metaller kan smältas med hjälp av VIM? | Olika metaller som nickel, titan, kobolt, rostfritt stål med mera kan smältas med VIM. |

| Vilka branscher använder vanligtvis VIM? | Inom flyg-, medicin-, fordons-, elektronik- och energiindustrin används VIM ofta för att tillverka högpresterande komponenter. |

| Vilka är fördelarna med att använda VIM jämfört med andra smältprocesser? | VIM ger högre renhet, bättre kontroll över legeringssammansättningen och överlägsna mekaniska egenskaper jämfört med andra smältprocesser. |

| Finns det några begränsningar i användningen av VIM? | Ja, VIM kan vara kostsamt och komplext och kräver skickliga operatörer och exakta styrsystem. Det hanterar också vanligtvis mindre batchstorlekar. |

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731