VIGA Maskiner

Innehållsförteckning

När vi pratar om VIGA maskiner, dyker vi in i en värld av avancerad teknik för tillverkning av metallpulver som har revolutionerat olika industrier. I den här artikeln kommer vi att utforska allt du behöver veta om VIGA-maskiner, från en översikt till detaljerade specifikationer, applikationer och till och med en FAQ-sektion. Så, låt oss komma igång!

Översikt över VIGA-maskiner

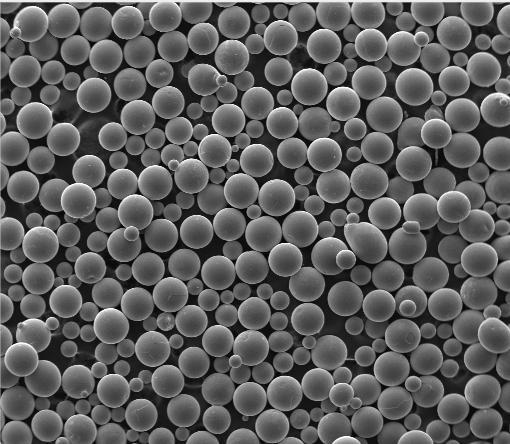

VIGA-maskiner (Vacuum Inert Gas Atomization) är spjutspetsutrustning som används för att producera metallpulver av hög kvalitet. Dessa pulver är avgörande för applikationer inom flyg-, bil-, biomedicinska och additiv tillverkningsindustri. VIGA-teknologin utmärker sig genom sin förmåga att producera pulver med utmärkt flytbarhet, sfärisk form och kontrollerad partikelstorleksfördelning.

Viktiga egenskaper hos VIGA-maskiner

- Metallpulver med hög renhet: VIGA-maskiner arbetar i en vakuum- eller inertgasmiljö, vilket minimerar kontaminering.

- Sfäriska partiklar: Säkerställer utmärkt flytbarhet och packningsdensitet.

- Kontrollerad partikelstorlek: Justerbara finfördelningsparametrar för skräddarsydda pulveregenskaper.

- Brett utbud av material: Lämplig för olika metaller och legeringar inklusive titan, rostfritt stål och superlegeringar.

Typer och modeller av metallpulver producerade av VIGA Maskiner

Här är specifika metallpulvermodeller tillverkade av VIGA-maskiner, tillsammans med deras beskrivningar:

| Metallpulvermodell | Sammansättning | Fastigheter | Tillämpningar |

|---|---|---|---|

| Ti-6Al-4V | Titanlegering | Hög hållfasthet, korrosionsbeständig, biokompatibel | Flyg- och rymdindustrin, medicinska implantat |

| 316L rostfritt stål | Fe-Cr-Ni-Mo-legering | Utmärkt korrosionsbeständighet, goda mekaniska egenskaper | Biomedicinsk utrustning, marina applikationer |

| IN718 | Nickelbaserad superlegering | Hög temperaturhållfasthet, oxidationsbeständig | Turbinblad, komponenter för flyg- och rymdindustrin |

| AlSi10Mg | Aluminiumlegering | Lättvikt, goda termiska egenskaper | Fordon, flyg- och rymdindustrin |

| CoCrMo | Kobolt-krom-molybdenlegering | Hög slitstyrka, biokompatibel | Medicinska implantat, tandproteser |

| CuCrZr | Koppar-krom-zirkoniumlegering | Hög elektrisk ledningsförmåga, god mekanisk hållfasthet | Elektriska komponenter, svetselektroder |

| Maråldrat stål (18Ni300) | Fe-Ni-Co-Mo-Ti legering | Ultrahög hållfasthet, god seghet | Verktyg, högpresterande kugghjul |

| FeNiCo | Järn-nickel-koboltlegering | Magnetiska egenskaper, god mekanisk hållfasthet | Magnetiska komponenter, flyg |

| NiTi (nitinol) | Nickel-Titanlegering | Formminne, superelasticitet | Medicinsk utrustning, ställdon |

| Hastelloy X | Nickel-krom-molybdenlegering | Hög temperaturhållfasthet, korrosionsbeständig | Gasturbinkomponenter, kemisk bearbetning |

Tillämpningar av VIGA-maskiner

VIGA-maskiner används inom en rad industrier på grund av deras förmåga att producera metallpulver av hög kvalitet. Här är en detaljerad titt på deras applikationer:

| Industri | Tillämpningar |

|---|---|

| Flyg- och rymdindustrin | Turbinblad, strukturella komponenter, fästelement |

| Fordon | Lättviktskomponenter, motordelar |

| Biomedicinsk | Implantat, proteser, kirurgiska instrument |

| Additiv tillverkning | 3D-utskriftspulver, prototyper, komplexa geometrier |

| Energi | Turbinkomponenter, delar till kärnreaktorer |

| Elektronik | Ledande pastor, magnetiska komponenter |

Fördelar med VIGA-maskiner

- Hög renhet och renhet: Att arbeta i en vakuum- eller inertgasmiljö minskar kontamineringen, vilket leder till metallpulver med hög renhet.

- Kontrollerad partikelstorleksfördelning: Tillåter anpassning för specifika applikationer, vilket förbättrar prestandan.

- Sfäriska partiklar: Förbättrar flytbarhet och packningstäthet, avgörande för additiv tillverkning.

- Mångsidigt materialsortiment: Kan bearbeta en mängd olika metaller och legeringar, vilket gör dem lämpliga för olika industrier.

Nackdelar med VIGA Maskiner

- Hög initial kostnad: VIGA-maskiner är dyra att skaffa och sätta upp.

- Komplex operation: Kräver skickliga operatörer och regelbundet underhåll.

- Energikrävande: Processen kräver betydande energi, vilket ökar driftskostnaderna.

Detaljerade specifikationer för VIGA-maskiner

| Specifikation | Detaljer |

|---|---|

| Materialkapacitet | Titan, rostfritt stål, nickellegeringar, aluminiumlegeringar, kobolt-kromlegeringar, etc. |

| Atomiseringsgas | Argon, kväve, helium |

| Arbetstryck | Upp till 150 bar |

| Partikelstorleksintervall | 10 – 200 mikron |

| Produktionstakt | Upp till 500 kg/timme |

| Vakuumnivå | Upp till 10^-5 mbar |

| Strömförbrukning | 100 – 500 kW |

| Kylningssystem | Vattenkyld |

Jämförelse av för- och nackdelar med VIGA Maskiner

| Fördelar | Nackdelar |

|---|---|

| Metallpulver med hög renhet | Hög initial kostnad |

| Sfäriska partiklar | Komplex operation |

| Kontrollerad partikelstorlek | Energikrävande |

| Mångsidigt materialsortiment | Kräver kvalificerade operatörer |

| Utmärkt flytbarhet | Regelbundet underhåll behövs |

VANLIGA FRÅGOR

| Fråga | Svar |

|---|---|

| Vad används VIGA-maskiner till? | Producerar högkvalitativa metallpulver för olika industrier inklusive flyg-, bil- och biomedicin. |

| Hur fungerar VIGA-maskiner? | De använder vakuum eller inert gas för att finfördela smält metall till fina pulver med sfäriska partiklar. |

| Vilka metaller kan VIGA-maskiner bearbeta? | Titan, rostfritt stål, nickellegeringar, aluminiumlegeringar och mer. |

| Vad är partikelstorleksintervallet för pulver som produceras? | Typiskt mellan 10 till 200 mikron. |

| Är VIGA-maskiner dyra? | Ja, de har en hög initial kostnad, från $900 000 till över $2 500 000. |

| Vilka är fördelarna med att använda VIGA-maskiner? | Hög renhet, kontrollerad partikelstorlek, utmärkt flytbarhet och mångsidighet vid materialbearbetning. |

| Vilka industrier drar nytta av VIGA-pulver? | Flyg, bil, biomedicin, additiv tillverkning, energi och elektronik. |

| Kan VIGA-maskiner producera pulver för 3D-utskrift? | Ja, de är idealiska för att producera högkvalitativa pulver för additiv tillverkning. |

| Kräver VIGA-maskiner speciellt underhåll? | Ja, de kräver regelbundet underhåll och skickliga operatörer för att säkerställa optimal prestanda. |

| Vilka är de vanligaste atomiseringsgaserna som används? | Argon, kväve och helium används vanligtvis för finfördelning. |

Slutsats

VIGA-maskiner representerar en höjdpunkt inom metallpulverproduktionsteknik, och tillhandahåller pulver av hög kvalitet som är avgörande för modern industri. Deras förmåga att producera sfäriska, högrena och exakt kontrollerade pulver gör dem ovärderliga för applikationer som sträcker sig från rymd till biomedicinsk utrustning. Trots deras höga initiala kostnad och komplexitet är fördelarna de erbjuder när det gäller materialegenskaper och prestanda oöverträffade. Om du funderar på att fördjupa dig i högkvalitativ metallpulverproduktion kan förståelse och användning av VIGA-maskiner vara en spelomvandlare.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731