Ni4Ti3 Dünyasını Keşfetmek

İçindekiler

Genel Bakış

Modern teknolojileri daha dayanıklı, esnek ve verimli kılan şeyin ne olduğunu hiç merak ettiniz mi? Bir temel bileşen, aşağıdaki gibi gelişmiş malzemelerdir: Ni4Ti3, Nikel Titanyum alaşımlarının daha geniş ailesindeki bir intermetalik bileşik (genellikle Nitinol olarak adlandırılır). Bu bileşiğin çeşitli yüksek teknoloji uygulamalarında vazgeçilmez kılan benzersiz özellikleri vardır. Bu yazıda, büyüleyici Nikel Titanyum alaşımları dünyasına derinlemesine dalacağız. Ni4Ti3, türlerini, bileşimini, özelliklerini, uygulamalarını ve daha fazlasını keşfedin. Bu olağanüstü malzemenin karmaşık ayrıntılarında ilgi çekici bir yolculuğa hazır olun.

Ni4Ti3 Nedir?

Ni4Ti3 Nikel Titanyumun (Nitinol) özel bir intermetalik fazıdır ve olağanüstü mekanik özellikleri ve benzersiz faz dönüşümleriyle bilinir. Peki onu öne çıkaran nedir? Ona benzersiz özellikler kazandıran şey, hassas bileşimi ve atomların düzenlenme şeklidir. Bu faz, Nitinol alaşımlarında şekil hafızası etkisini ve süperelastisiteyi kontrol etmede kritik öneme sahiptir.

Ni4Ti3 Neden Önemlidir?

Gelişmiş malzemeler dünyasında, malzeme özellikleri üzerinde kontrol sahibi olmak bir süper güce sahip olmak gibidir. Ni4Ti3 mühendislerin ve bilim insanlarının Nitinol alaşımlarının özelliklerini ince ayarlayarak bunları tıbbi cihazlardan havacılık bileşenlerine kadar geniş bir uygulama yelpazesi için uygun hale getirmelerine olanak tanır. Malzeme özelliklerini değiştirme ve geliştirme yeteneği Ni4Ti3 Teknolojik yeniliklerin merkezinde.

Ni4Ti3'ün Bileşimi ve Özellikleri

Bileşiminin ve özelliklerinin anlaşılması Ni4Ti3 süper bir sporcunun DNA'sını tanımak gibidir. Bu yönleri ayrıntılı olarak inceleyelim.

Kompozisyon

Birincil bileşenleri Ni4Ti3 nikel (Ni) ve titanyumdur (Ti). Ancak, sihir belirli atom oranında ve ortaya çıkan kristal yapıdadır. İşte bileşimi özetleyen ayrıntılı bir tablo:

| Element | Sembol | Atomik Yüzde |

|---|---|---|

| Nikel | Ni | 57.14% |

| Titanyum | Ti | 42.86% |

Özellikler

Ne ayarlar Ni4Ti3 diğer malzemelerden farklı olarak dikkat çekici özellikleri vardır. Bunlar şunları içerir:

- Şekil Hafızası Etkisi:Isıtıldığında önceden belirlenmiş bir şekle geri dönebilme yeteneği.

- Süper Esneklik: Büyük zorlanmalara dayanabilme ve boşaltım sırasında orijinal şeklini geri kazanabilme kapasitesi.

- Yüksek Korozyon Direnci: Korozyona karşı mükemmel direnci sayesinde tıbbi ve denizcilik uygulamaları için uygundur.

- Biyouyumluluk:İnsan dokusu ile uyumu nedeniyle tıbbi implantlarda kullanımı güvenlidir.

Özellikler

Kapsamlı bir anlayış elde etmek için, ayrıntılı özelliklerine bakalım Ni4Ti3:

| Karakteristik | Açıklama |

|---|---|

| Kristal Yapı | Belirli bir Ni:Ti oranına sahip düzenli intermetalik faz. |

| Faz Dönüşümü | Şekil hafızası ve süperelastisite açısından kritik olan martensitik dönüşümleri sergiler. |

| Termal Kararlılık | Çeşitli sıcaklık aralıklarında kararlıdır, çeşitli uygulamalarda güvenilirlik sağlar. |

| Mekanik Dayanım | Yüksek gerilme mukavemeti ve yorulma direnci. |

| Elektriksel İletkenlik | Orta düzeyde elektriksel iletkenliğe sahiptir, bazı elektronik uygulamalarda kullanılır. |

Uygulamaları Ni4Ti3

Çok yönlülüğü Ni4Ti3 çeşitli alanlarda tercih edilen bir malzeme haline getirir. İşte nerede kullanıldığına daha yakından bir bakış:

Tıbbi Cihazlar

En önemli uygulamalardan biri Ni4Ti3 tıbbi alandadır. Biyouyumluluğu ve benzersiz mekanik özellikleri onu tıbbi implantlar ve cihazlar için ideal hale getirir.

- Stentler: Kalp damar tedavilerinde atardamarların açık tutulması amacıyla kullanılır.

- Ortodontik Ark Telleri: Süper elastik özelliklerinden dolayı desteklerde kullanılırlar.

- Kemik Plakaları ve Vidaları:Ortopedik cerrahide kemik fiksasyonu amacıyla kullanılır.

Havacılık ve Uzay Bileşenleri

Havacılık ve uzay sektöründe aşırı koşullara dayanıklı malzemeler hayati önem taşıyor. Ni4Ti3 tam istediğim gibi.

- Aktüatörler: Şekil hafızası özelliğinden dolayı adaptif kontrol sistemlerinde kullanılır.

- Bağlantı Elemanları ve Bağlantı Elemanları: Yüksek stres koşullarında güvenilir performans sağlar.

- Contalar ve Contalar: Hava geçirmez ve esnek sızdırmazlık çözümleri sağlayın.

Tüketici Elektroniği

Günlük elektronik cihazlarda bile, Ni4Ti3 dayanıklılığı ve eşsiz özellikleri nedeniyle kendine yer buluyor.

- Esnek Ekranlar: Kırılmadan bükülebilen ve esneyebilen ekranlarda kullanılır.

- Akıllı Giyilebilirler: Esneklik ve dayanıklılık gerektiren cihazlarda kullanılır.

- Konnektör Pinleri: Çeşitli cihazlarda güvenilir elektrik bağlantıları sağlayın.

Endüstriyel Uygulamalar

Yüksek teknoloji ve tıbbi alanların ötesinde, Ni4Ti3 birçok endüstriyel uygulamada da değerlidir.

- Robotik: Esneklik ve dayanıklılıklarından dolayı robotik eklemlerde ve aktüatörlerde kullanılırlar.

- Otomotiv: Performans ve dayanıklılığı artırmak için çeşitli bileşenlerde kullanılır.

- Enerji Sektörü: Yüksek yorulma dayanımı ve güvenilirlik gerektiren sistemlerde uygulanır.

Tablo: Ni4Ti3'ün Ayrıntılı Uygulamaları

| Endüstri | Uygulama | Ni4Ti3'ün Faydaları |

|---|---|---|

| Tıbbi Cihazlar | Stentler | Biyouyumluluk, esneklik |

| Ortodontik Ark Telleri | Süper Esneklik | |

| Kemik Plakaları ve Vidaları | Yüksek mukavemet, korozyon direnci | |

| Havacılık ve Uzay Bileşenleri | Aktüatörler | Şekil hafızası özellikleri, güvenilirlik |

| Bağlantı Elemanları ve Bağlantı Elemanları | Yüksek stres altında performans | |

| Contalar ve Contalar | Hava geçirmez ve esnek sızdırmazlık çözümleri | |

| Tüketici Elektroniği | Esnek Ekranlar | Dayanıklılık, esneklik |

| Akıllı Giyilebilirler | Esneklik, dayanıklılık | |

| Konnektör Pinleri | Güvenilir elektrik bağlantıları | |

| Endüstriyel Uygulamalar | Robotik | Esneklik, güç |

| Otomotiv | Gelişmiş performans, dayanıklılık | |

| Enerji Sektörü | Yüksek yorulma direnci, güvenilirlik |

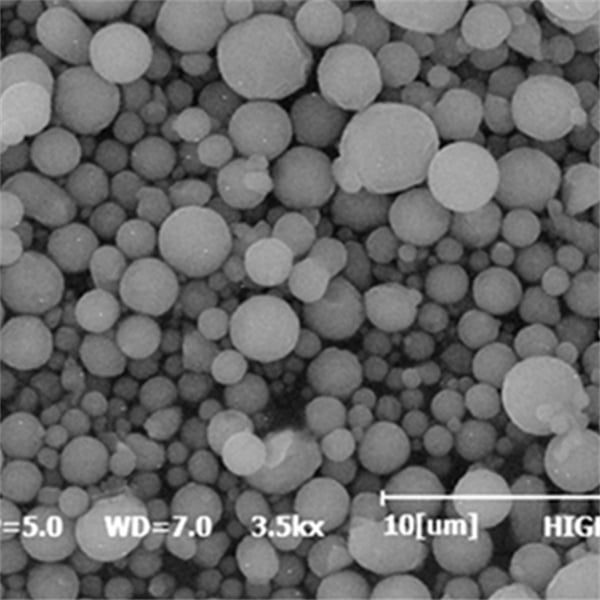

Türleri Ni4Ti3 Metal Tozu Modelleri

Çalışmaya gelince Ni4Ti3, her biri belirli uygulamalar ve gereksinimler için tasarlanmış farklı metal tozu modelleri mevcuttur. İşte açıklamalarıyla birlikte bazı önemli modellerin bir listesi:

1. Ni4Ti3-100

Ni4Ti3-100 İnce parçacık boyutu ve yüksek saflığıyla bilinen standart bir modeldir ve bu özelliği onu tıbbi alanda hassas uygulamalar için ideal hale getirir.

- Parçacık Boyutu: 10-50 mikron

- Saflık: 99.9%

- Uygulamalar: Tıbbi implantlar, hassas aletler

2. Ni4Ti3-200

Ni4Ti3-200 Dayanıklılık ve güvenilirliğin ön planda olduğu havacılık uygulamaları için tasarlanmıştır.

- Parçacık Boyutu: 20-60 mikron

- Saflık: 99.8%

- Uygulamalar: Havacılık bileşenleri, aktüatörler

3. Ni4Ti3-300

Bu model, yüksek gerilimli endüstriyel uygulamalara uygun, geliştirilmiş mekanik özellikler sunmaktadır.

- Parçacık Boyutu: 15-55 mikron

- Saflık: 99.7%

- Uygulamalar: Endüstriyel robotik, otomotiv bileşenleri

4. Ni4Ti3-400

Ni4Ti3-400 Tüketici elektroniğinde olağanüstü detay ve performans sağlayan ultra ince parçacıklara sahiptir.

- Parçacık Boyutu: 5-30 mikron

- Saflık: 99.9%

- Uygulamalar: Esnek ekranlar, akıllı giyilebilir cihazlar

5. Ni4Ti3-500

Bu model, üstün yorulma direnci sunarak yüksek performanslı enerji uygulamaları için tasarlanmıştır.

- Parçacık Boyutu: 10-40 mikron

- Saflık: 99.85%

- Uygulamalar: Enerji sektörü bileşenleri, yüksek yorulma uygulamaları

6. Ni4Ti3-600

Ni4Ti3-600 Katkılı imalat için optimize edilmiştir ve yüksek kaliteli 3D baskılı bileşenler sağlar.

- Parçacık Boyutu: 20-50 mikron

- Saflık: 99.9%

- Uygulamalar: 3D baskı, özel üretim

7. Ni4Ti3-700

Aşırı hassasiyet gerektiren uygulamalar için tasarlanmıştır, Ni4Ti3-700 Serideki en ince partikül boyutunu sunar.

- Parçacık Boyutu: 2-20 mikron

- Saflık: 99.95%

- Uygulamalar: Mikroelektronik, hassas aletler

8. Ni4Ti3-800

Bu model, mükemmel korozyon direnci sağlayarak denizcilik uygulamaları için mükemmeldir.

- Parçacık Boyutu: 10-60 mikron

- Saflık: 99.8%

- Uygulamalar: Deniz bileşenleri, su altı ekipmanları

9. Ni4Ti3-900

Ni4Ti3-900 Dayanıklılık ve esnekliğin dengeli bir kombinasyonunu sunarak çeşitli kullanımlara çok yönlülük kazandırır.

- Parçacık Boyutu: 15-45 mikron

- Saflık: 99.85%

- Uygulamalar: Genel endüstriyel kullanım, esnek bileşenler

10. Ni4Ti3-1000

En gelişmiş model, Ni4Ti3-1000, ileri düzey araştırma ve geliştirme projeleri için tasarlanmıştır.

- Parçacık Boyutu: 5-25 mikron

- Saflık: 99.95%

- Uygulamalar: Ar-Ge, deneysel uygulamalar

Ni4Ti3'ün Avantajları ve Dezavantajları

Herhangi bir malzeme gibi, Ni4Ti3'ün de kendine özgü avantajları ve dezavantajları vardır. Bunları anlamak, kullanımı hakkında bilinçli kararlar almaya yardımcı olabilir.

Avantajlar

- Yüksek Mukavemet: Mükemmel mekanik mukavemeti sayesinde yüksek stresli uygulamalar için uygundur.

- Esneklik: Üstün süperelastikiyet ve şekil hafızası özellikleri.

- Korozyon Direnci: Korozyona karşı yüksek direnç, zorlu ortamlarda kullanım ömrünü uzatır.

- Biyouyumluluk: Tıbbi uygulamalarda kullanımı güvenlidir, istenmeyen reaksiyon riskini azaltır.

- Termal Kararlılık:Geniş bir sıcaklık aralığında kararlıdır, güvenilirliği garanti eder.

Dezavantajlar

- Maliyet:Karmaşık üretim süreçleri nedeniyle konvansiyonel malzemelere kıyasla daha yüksek maliyetlidir.

- İşlenebilirlik: İşlenmesi zordur, özel ekipman ve teknikler gerektirir.

- Kullanılabilirlik: Sınırlı bulunabilirlik, bazı uygulamalar için kaynak bulmayı zorlaştırıyor.

- Karmaşıklık: İstenilen özelliklerin elde edilmesi için imalat sırasında hassas kontrol gerektirir.

- Aşınma ve Yıpranma: Dayanıklı olmasına rağmen aşındırıcı ortamlarda yıpranabilir.

Tablo: Ni4Ti3'ün Avantajları ve Dezavantajları

| Aspect | Avantajlar | Dezavantajlar |

|---|---|---|

| Güç | Yüksek mekanik dayanım | Yüksek maliyet |

| Esneklik | Üstün süperelastikiyet ve şekil hafızası özellikleri | İşlenmesi zor |

| Korozyon Direnci | Korozyona karşı yüksek direnç | Sınırlı kullanılabilirlik |

| Biyouyumluluk | Tıbbi uygulamalar için güvenli | Hassas üretim kontrolü gerektirir |

| Termal Kararlılık | Geniş bir sıcaklık aralığında kararlıdır | Çok aşındırıcı ortamlarda aşınmaya maruz kalabilir |

Teknik Özellikler, Boyutlar, Sınıflar ve Standartlar Ni4Ti3

Doğru ürünü seçmek için özellikleri, boyutları, dereceleri ve standartları anlamak çok önemlidir. Ni4Ti3 İhtiyaçlarınıza uygun bir model. İşte bu yönleri özetleyen ayrıntılı bir tablo:

| Şartname | Detay |

|---|---|

| Partikül Boyut Aralığı | 2-60 mikron |

| Saflık Seviyeleri | 99.7%'den 99.95%'ye |

| Standart Sınıflar | ASTM F2063, ISO 5832-11 |

| Mevcut Formlar | Tozlar, teller, çubuklar, levhalar |

| Üretim Yöntemleri | Gaz atomizasyonu, Plazma atomizasyonu, Mekanik alaşımlama |

| Sertifikasyon | ISO 9001, ISO 13485 (tıbbi uygulamalar için) |

Tablo: Ni4Ti3'ün Özellikleri, Boyutları, Sınıfları ve Standartları

| Parametre | Açıklama |

|---|---|

| Partikül Boyut Aralığı | 2-60 mikron |

| Saflık Seviyeleri | 99.7%'den 99.95%'ye |

| Standart Sınıflar | ASTM F2063, ISO 5832-11 |

| Mevcut Formlar | Tozlar, teller, çubuklar, levhalar |

| Üretim Yöntemleri | Gaz atomizasyonu, Plazma atomizasyonu, Mekanik alaşımlama |

| Sertifikasyon | ISO 9001, ISO 13485 (tıbbi uygulamalar için) |

Ni4Ti3 Tedarikçileri ve Fiyatlandırma Ayrıntıları

Güvenilir tedarikçiler bulmak ve fiyatlandırma ayrıntılarını anlamak kaynak sağlamak için çok önemlidir Ni4Ti3İşte bazı önemli tedarikçilerin detaylı tablosu ve fiyatlandırma detayları:

| Tedarikçi | Konum | Ürün Yelpazesi | Fiyatlandırma (kg başına) | İletişim Bilgileri |

|---|---|---|---|---|

| Johnson Matthey | ABD | Ni4Ti3-100, Ni4Ti3-200 | $500 – $700 | www.matthey.com |

| ATI Özel Alaşımlar | ABD | Ni4Ti3-300, Ni4Ti3-400 | $600 – $800 | www.atimetals.com |

| Daido Çelik A.Ş. | Japonya | Ni4Ti3-500, Ni4Ti3-600 | $550 – $750 | www.daido.co.jp |

| Gelişmiş Tozlar ve Kaplamalar | Kanada | Ni4Ti3-700, Ni4Ti3-800 | $580 – $780 | www.advancedpowders.com |

| Marangoz Teknolojisi | ABD | Ni4Ti3-900, Ni4Ti3-1000 | $600 – $800 | www.cartech.com |

| Sandvik Malzeme Teknolojisi | İsveç | Çeşitli sınıflar | $550 – $770 | www.materials.sandvik |

Tablo: Ni4Ti3 Tedarikçileri ve Fiyatlandırma Ayrıntıları

| Tedarikçi | Konum | Ürün Yelpazesi | Fiyatlandırma (kg başına) | İletişim Bilgileri |

|---|---|---|---|---|

| Johnson Matthey | ABD | Ni4Ti3-100, Ni4Ti3-200 | $500 – $700 | www.matthey.com |

| ATI Özel Alaşımlar | ABD | Ni4Ti3-300, Ni4Ti3-400 | $600 – $800 | www.atimetals.com |

| Daido Çelik A.Ş. | Japonya | Ni4Ti3-500, Ni4Ti3-600 | $550 – $750 | www.daido.co.jp |

| Gelişmiş Tozlar ve Kaplamalar | Kanada | Ni4Ti3-700, Ni4Ti3-800 | $580 – $780 | www.advancedpowders.com |

| Marangoz Teknolojisi | ABD | Ni4Ti3-900, Ni4Ti3-1000 | $600 – $800 | www.cartech.com |

| Sandvik Malzeme Teknolojisi | İsveç | Çeşitli sınıflar | $550 – $770 | www.materials.sandvik |

Karşılaştırma Ni4Ti3 Modeller: Artıları ve Eksileri

Doğru olanı seçmenize yardımcı olmak için Ni4Ti3 Uygulamanız için bir model arıyorsanız, farklı modellerin artılarını ve eksilerini vurgulayan karşılaştırmalı bir analizini burada bulabilirsiniz:

| Model | Artıları | Eksiler |

|---|---|---|

| Ni4Ti3-100 | Yüksek saflık, ince partikül boyutu | Daha yüksek maliyet |

| Ni4Ti3-200 | Havacılık ve uzay için ideal, iyi mekanik özellikler | Orta düzeyde kullanılabilirlik |

| Ni4Ti3-300 | Güçlendirilmiş dayanıklılık, endüstriyel kullanıma uygundur | İşlenmesi zor |

| Ni4Ti3-400 | Elektronik cihazlar için mükemmel, ultra ince parçacıklar | Belirli uygulamalarla sınırlı |

| Ni4Ti3-500 | Üstün yorulma direnci, enerji uygulamaları | Daha yüksek üretim karmaşıklığı |

| Ni4Ti3-600 | 3D baskı için optimize edilmiş, yüksek kaliteli çıktı | Gelişmiş ekipman gerektirir |

| Ni4Ti3-700 | Son derece hassas, en ince parçacık boyutu | Çok yüksek maliyet |

| Ni4Ti3-800 | Mükemmel korozyon direnci, deniz kullanımı | Mevcutluk sınırlı olabilir |

| Ni4Ti3-900 | Dengeli özellikler, çok yönlü kullanım | Hiçbir mülkte en iyisi değil |

| Ni4Ti3-1000 | Son teknoloji araştırma uygulamaları, en yüksek saflık | Son derece yüksek maliyet, Ar-Ge ile sınırlı |

SSS

1. Ni4Ti3 ne için kullanılır?

Ni4Ti3 tıbbi cihazlar, havacılık bileşenleri, tüketici elektroniği, endüstriyel robotik, otomotiv parçaları ve enerji sektörü bileşenleri dahil olmak üzere çeşitli uygulamalarda kullanılır. Şekil hafızası etkisi, süper elastikiyet ve biyouyumluluk gibi benzersiz özellikleri onu bu yüksek teknoloji uygulamaları için uygun hale getirir.

2. Ni4Ti3 nasıl üretilir?

Ni4Ti3 tipik olarak gaz atomizasyonu, plazma atomizasyonu ve mekanik alaşımlama gibi işlemlerle üretilir. Bu yöntemler, malzemenin istenen özelliklerini elde etmek için çok önemli olan yüksek saflık ve parçacık boyutu üzerinde hassas kontrol sağlar.

3. Ni4Ti3'ün tıbbi cihazlarda kullanılmasının faydaları nelerdir?

Kullanmanın faydaları Ni4Ti3 Tıbbi cihazlardaki avantajları arasında yüksek biyouyumluluk, esneklik ve korozyon direnci bulunur. Bu özellikler onu, stentler ve ortodontik ark telleri gibi insan dokusuyla etkileşime giren implantlar ve cihazlar için ideal hale getirir.

4. Ni4Ti3 3D baskıda kullanılabilir mi?

Evet, belirli modeller Ni4Ti3Ni4Ti3-600 gibi, katkı üretimi veya 3D baskı için optimize edilmiştir. Bu modeller, özel üretim ve karmaşık bileşenler için uygun, yüksek kaliteli, hassas çıktı sağlar.

5. Ni4Ti3’ün sınırlamaları nelerdir?

Bir yandan Ni4Ti3 sayısız avantaj sunar, ancak daha yüksek maliyet, işleme zorluğu ve sınırlı bulunabilirlik gibi sınırlamaları da vardır. Ek olarak, istenen özellikleri elde etmek için üretim sırasında hassas kontrol gerektirir, bu da üretim karmaşıklığını ve maliyeti artırabilir.

6. Ni4Ti3 diğer Nikel Titanyum alaşımlarıyla karşılaştırıldığında nasıldır?

Diğer Nikel Titanyum alaşımlarına kıyasla, Ni4Ti3 Özel bileşimi ve faz yapısı sayesinde şekil hafızası ve süperelastik özellikler üzerinde üstün kontrol sağlar. Bu, onu tıbbi ve havacılık endüstrileri gibi hassas performans gerektiren uygulamalar için özellikle değerli kılar.

7. Ni4Ti3 kullanımında çevresel açıdan herhangi bir endişe var mıdır?

Ni4Ti3 tıbbi ve endüstriyel alanlar dahil olmak üzere çeşitli uygulamalarda kullanımı genellikle güvenli kabul edilir. Ancak, herhangi bir malzeme gibi, çevresel etkiyi en aza indirmek için uygun kullanım ve bertaraf uygulamaları izlenmelidir.

8. Ni4Ti3 tedarikinde en iyi uygulamalar nelerdir?

Kaynak için Ni4Ti3 Etkili bir şekilde, yüksek kaliteli malzeme sağlayan ve endüstri standartlarına uyan saygın tedarikçilerle çalışmak önemlidir. ISO 9001 ve ISO 13485 gibi sertifikaları kontrol etmek, malzemenin uygulamanız için gerekli özellikleri karşıladığından da emin olabilir.

Sonuç olarak, Ni4Ti3 Gelişmiş teknolojiler alanında benzersiz özellikler ve çok yönlülük sunan kritik bir malzeme olarak öne çıkıyor. Tıbbi cihazlardan havacılık bileşenlerine kadar, benzersiz özellikleri inovasyonu ve performansı yönlendiriyor. Bileşimini, özelliklerini ve uygulamalarını, avantajlarını ve dezavantajlarını anlamak, kullanımı hakkında bilinçli kararlar almanıza yardımcı olabilir. İster tıbbi, ister havacılık veya endüstriyel sektörde olun, Ni4Ti3 Daha verimli, dayanıklı ve güvenilir ürünler yaratmak için yeni olanaklar yaratıyor.

Paylaş

MET3DP Technology Co, LTD, merkezi Qingdao, Çin'de bulunan lider bir katmanlı üretim çözümleri sağlayıcısıdır. Şirketimiz, endüstriyel uygulamalar için 3D baskı ekipmanları ve yüksek performanslı metal tozları konusunda uzmanlaşmıştır.

İşletmeniz için en iyi fiyatı ve özelleştirilmiş Çözümü almak için sorgulayın!

İlgili Makaleler

Yüksek Performanslı Nozul Kanat Segmentleri: Metal 3D Baskı ile Türbin Verimliliğinde Devrim

Daha Fazla Oku "Met3DP Hakkında

Son Güncelleme

Bizim Ürünümüz

BİZE ULAŞIN

Herhangi bir sorunuz var mı? Bize şimdi mesaj gönderin! Mesajınızı aldıktan sonra tüm ekibimizle talebinize hizmet edeceğiz.

3D Baskı ve Katmanlı Üretim için Metal Tozları

ÜRÜN

cONTACT BİLGİLERİ

- Qingdao Şehri, Shandong, Çin

- [email protected]

- [email protected]

- +86 19116340731