Tek Fırınlı VIGA Ekipmanı

İçindekiler

Nihai rehbere hoş geldiniz Tek Fırınlı VIGA (Vakum İndüksiyonlu Gaz Atomizasyonu) Ekipmanı. Gelişmiş metalurji ve metal tozu üretimi dünyasına giriyorsanız doğru yerdesiniz. Tek fırınlı VIGA sistemleri hakkında bilmeniz gereken her şeyi, işlevlerini, avantajlarını, uygulamalarını ve çok daha fazlasını kapsayacak şekilde açıklayacağız.

Genel Bakış Tek Fırınlı VIGA Ekipmanı

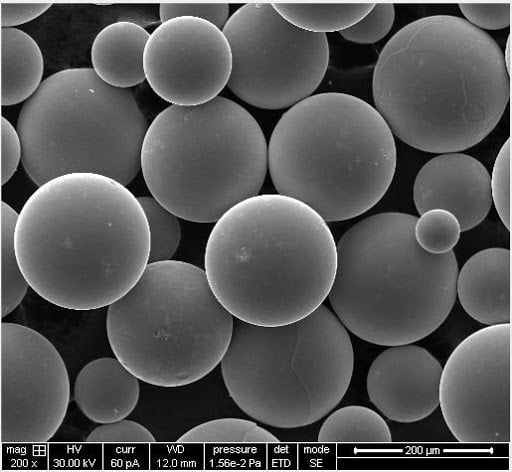

Tek fırınlı VIGA ekipmanı, yüksek kaliteli metal tozları üretmek için son teknoloji ürünü bir yöntemi temsil eder. Bu sistemler, üstün özelliklere sahip ince, küresel tozlar oluşturmak için gaz atomizasyonu ile birlikte vakum indüksiyonlu ergitme kullanır. Bu teknik, havacılık, otomotiv ve biyomedikal sektörleri gibi hassas malzeme özellikleri gerektiren endüstriler için kritik öneme sahiptir.

Tek Fırınlı VIGA ile Üretilen Metal Tozu Türleri

Tek fırınlı VIGA ekipmanı tarafından üretilen bazı özel metal tozu modellerine bir göz atarak başlayalım. İşte sizi tanıştırmak için ayrıntılı bir liste:

| Metal Tozu Modeli | Kompozisyon | Anahtar Özellikler | Uygulamalar |

|---|---|---|---|

| 316L Paslanmaz Çelik | Fe, Cr, Ni, Mo | Korozyon direnci, yüksek mukavemet | Tıbbi implantlar, denizcilik ekipmanları |

| 17-4 PH Paslanmaz Çelik | Fe, Cr, Ni, Cu, Nb | Yüksek mukavemet, korozyon direnci | Havacılık ve uzay parçaları, kimyasal işleme |

| Ti-6Al-4V Titanyum Alaşımı | Ti, Al, V | Yüksek mukavemet/ağırlık oranı, biyouyumluluk | Havacılık ve uzay bileşenleri, tıbbi cihazlar |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | Isı direnci, oksidasyon direnci | Jet motoru parçaları, nükleer reaktörler |

| Kobalt-Krom Alaşımı | Co, Cr, Mo, W | Aşınma direnci, yüksek sertlik | Diş implantları, ortopedik cihazlar |

| AlSi10Mg Alüminyum Alaşım | Al, Si, Mg | Hafif, iyi döküm özellikleri | Otomotiv parçaları, havacılık ve uzay yapıları |

| Maraging Çelik | Fe, Ni, Co, Mo | Yüksek mukavemet, mükemmel tokluk | Kalıplama, havacılık ve uzay yapıları |

| Haynes 282 | Ni, Cr, Co, Mo, Ti | Sürünme mukavemeti, termal stabilite | Gaz türbinleri, ısı eşanjörleri |

| Bakır Alaşımı C18150 | Cu, Cr, Zr | Yüksek elektrik iletkenliği, iyi mukavemet | Elektrikli bileşenler, kaynak elektrotları |

| Nikel Süperalaşım Nimonic 90 | Ni, Cr, Co, Ti, Al | Oksidasyon direnci, yüksek sıcaklık dayanımı | Türbin kanatları, egzoz valfleri |

Uygulamaları Tek Fırınlı VIGA Ekipmanı

Tek fırınlı VIGA ekipmanının çok yönlülüğü, geniş uygulama yelpazesinden anlaşılmaktadır. İşte bazı özel kullanımlar:

| Endüstri | Uygulama | Avantajlar |

|---|---|---|

| Havacılık ve Uzay | Türbin kanatları, yapısal bileşenler | Yüksek mukavemet/ağırlık oranı, yüksek sıcaklıklara karşı direnç |

| Otomotiv | Motor parçaları, hafif yapılar | Geliştirilmiş yakıt verimliliği, dayanıklılık |

| Biyomedikal | İmplantlar, cerrahi aletler | Biyouyumluluk, hassasiyet |

| Enerji | Nükleer reaktör bileşenleri, ısı eşanjörleri | Korozyona ve yüksek sıcaklıklara karşı direnç |

| Aletler | Kalıplar, kalıplar | Aşınma direnci, uzun ömürlülük |

| Elektronik | İletken bileşenler | Yüksek elektrik iletkenliği, güvenilirlik |

Ayrıntılı Özellikler, Boyutlar ve Standartlar

VIGA ekipmanı tarafından üretilen metal tozlarının özelliklerini ve standartlarını anlamak, ihtiyaçlarınız için doğru malzemeyi seçmek açısından çok önemlidir. İşte bir döküm:

| Metal Tozu Modeli | Partikül Boyut Aralığı | Standartlar | Tipik Uygulamalar |

|---|---|---|---|

| 316L Paslanmaz Çelik | 15-45 µm | ASTM F138, ISO 5832-1 | Tıbbi, denizcilik |

| 17-4 PH Paslanmaz Çelik | 20-63 µm | AMS 5643, ASTM A693 | Havacılık ve uzay, kimya |

| Ti-6Al-4V Titanyum Alaşımı | 15-45 µm | ASTM F1472, ISO 5832-3 | Havacılık ve uzay, medikal |

| Inconel 718 | 20-53 µm | AMS 5662, ASTM B637 | Jet motorları, nükleer |

| Kobalt-Krom Alaşımı | 10-50 µm | ASTM F1537, ISO 5832-12 | Diş, ortopedi |

| AlSi10Mg Alüminyum Alaşım | 20-60 µm | ISO 3522, ASTM B85 | Otomotiv, havacılık ve uzay |

| Maraging Çelik | 10-45 µm | AMS 6514, ASTM A538 | Kalıp, havacılık ve uzay |

| Haynes 282 | 20-53 µm | AMS 5918, ASTM B637 | Gaz türbinleri, ısı eşanjörleri |

| Bakır Alaşımı C18150 | 15-45 µm | ASTM B820, AMS 4596 | Elektrik, kaynak |

| Nikel Süperalaşım Nimonic 90 | 20-53 µm | AMS 5829, ASTM B637 | Türbin kanatları, egzoz valfleri |

Tedarikçiler ve Fiyatlandırma Detayları

yoluyla üretilen metal tozlarının satın alınması söz konusu olduğunda tek fırınlı VIGA ekipmanıTedarikçilerinizi ve fiyatlarını bilmek çok önemlidir. İşte bazı önde gelen tedarikçilerin listesi ve yaklaşık fiyatları:

| Tedarikçi | Metal Tozu Modelleri | Fiyatlandırma (kg başına) | Ek Hizmetler |

|---|---|---|---|

| Höganäs | 316L, Ti-6Al-4V, Inconel 718 | $50-$200 | Özel boyutlandırma, teknik destek |

| Marangoz Teknolojisi | 17-4 PH, Maraging Çelik | $60-$250 | Metalurjik danışmanlık, özel alaşımlar |

| Sandvik | Kobalt-Krom, Haynes 282 | $80-$300 | Kalite testi, Ar-Ge desteği |

| LPW Teknoloji | AlSi10Mg, Bakır Alaşımı C18150 | $40-$150 | Toz yaşam döngüsü yönetimi, izlenebilirlik |

| AP&C (GE Katkı Maddesi) | 316L, Ti-6Al-4V, Inconel 718 | $55-$220 | Gelişmiş karakterizasyon, geri dönüşüm hizmetleri |

| Praxair Yüzey Teknolojileri | Inconel 718, Nimonic 90 | $70-$280 | Uygulama mühendisliği, kaplama çözümleri |

Avantajları ve Dezavantajları Tek Fırınlı VIGA Ekipmanı

Metal tozu üretimi için tek fırınlı VIGA sistemlerini kullanmanın artılarını ve eksilerini inceleyelim:

| Avantajlar | Dezavantajlar |

|---|---|

| Yüksek Saflık: Vakum ortamı kontaminasyonu en aza indirir. | Maliyet: Yüksek ilk yatırım ve işletme maliyetleri. |

| Düzgün Parçacık Boyutu: Tutarlı toz kalitesi. | Karmaşıklık: Yetenekli operatörler ve bakım gerektirir. |

| Çok Yönlülük: Çok çeşitli metal alaşımları için uygundur. | Enerji Tüketimi: Önemli güç kullanımı. |

| Geliştirilmiş Malzeme Özellikleri: Tozların geliştirilmiş mekanik özellikleri. | Sınırlı Kapasite: Tek fırın, çok fırınlı kurulumlara kıyasla üretim hacmini sınırlar. |

SSS

| Soru | Cevap |

|---|---|

| Tek fırınlı VIGA ekipmanı ne için kullanılır? | Havacılık, otomotiv ve biyomedikal gibi çeşitli endüstriler için yüksek kaliteli metal tozları üretmek için kullanılır. |

| Tek fırınlı VIGA ekipmanı nasıl çalışır? | İnce, küresel metal tozları üretmek için gaz atomizasyonu ile birlikte vakum indüksiyon ergitme kullanır. |

| Metal tozu üretimi için VIGA kullanmanın faydaları nelerdir? | Faydaları arasında yüksek saflık, tek tip partikül boyutu ve gelişmiş malzeme özellikleri yer alır. |

| VIGA ekipmanı kullanılarak hangi metaller işlenebilir? | Paslanmaz çelikler, titanyum alaşımları, nikel süper alaşımları ve daha fazlasını içeren geniş bir ürün yelpazesi. |

| Tek fırınlı VIGA ekipmanı kullanmanın herhangi bir sınırlaması var mı? | Evet, yüksek maliyet, karmaşıklık ve sınırlı üretim kapasitesi de dahil olmak üzere. |

| VIGA tarafından üretilen tozlardan en çok hangi sektörler faydalanıyor? | Havacılık, otomotiv, biyomedikal, enerji, takım ve elektronik endüstrileri. |

| VIGA tarafından üretilen tozlar için tipik partikül boyutları nelerdir? | Partikül boyutları, alaşıma ve özel gereksinimlere bağlı olarak tipik olarak 10 ila 63 mikron arasında değişir. |

| VIGA diğer toz üretim yöntemlerine kıyasla nasıldır? | VIGA daha yüksek saflık ve partikül boyutu üzerinde daha iyi kontrol sağlar ancak su atomizasyonu gibi diğer yöntemlere göre daha pahalı ve karmaşık olabilir. |

Sonuç

Tek fırınlı VIGA ekipmanı, benzersiz saflık, tutarlılık ve çok yönlülük sunarak metal tozu üretimi alanında oyunun kurallarını değiştirir. İster havacılık, ister otomotiv veya biyomedikal endüstrilerinde çalışıyor olun, VIGA teknolojisinin inceliklerini anlamak bilinçli kararlar vermenize ve yüksek kaliteli metal tozlarının avantajlarından yararlanmanıza yardımcı olabilir.

Başka sorularınız varsa veya özel bilgiye ihtiyacınız varsa, çekinmeden bize ulaşın. Tek fırınlı VIGA ekipmanıyla gelişmiş metalurji dünyasına dalın ve malzeme yeteneklerinizi yeni zirvelere taşıyın!

Paylaş

MET3DP Technology Co, LTD, merkezi Qingdao, Çin'de bulunan lider bir katmanlı üretim çözümleri sağlayıcısıdır. Şirketimiz, endüstriyel uygulamalar için 3D baskı ekipmanları ve yüksek performanslı metal tozları konusunda uzmanlaşmıştır.

İşletmeniz için en iyi fiyatı ve özelleştirilmiş Çözümü almak için sorgulayın!

İlgili Makaleler

Yüksek Performanslı Nozul Kanat Segmentleri: Metal 3D Baskı ile Türbin Verimliliğinde Devrim

Daha Fazla Oku "Met3DP Hakkında

Son Güncelleme

Bizim Ürünümüz

BİZE ULAŞIN

Herhangi bir sorunuz var mı? Bize şimdi mesaj gönderin! Mesajınızı aldıktan sonra tüm ekibimizle talebinize hizmet edeceğiz.

3D Baskı ve Katmanlı Üretim için Metal Tozları

ÜRÜN

cONTACT BİLGİLERİ

- Qingdao Şehri, Shandong, Çin

- [email protected]

- [email protected]

- +86 19116340731