VIGA Makineleri

İçindekiler

Hakkında konuştuğumuz zaman VIGA makineleriçeşitli sektörlerde devrim yaratan gelişmiş metal tozu üretim teknolojisi dünyasına dalıyoruz. Bu makalede, genel bir bakıştan ayrıntılı teknik özelliklere, uygulamalara ve hatta bir SSS bölümüne kadar VIGA makineleri hakkında bilmeniz gereken her şeyi keşfedeceğiz. Öyleyse başlayalım!

VIGA Makinelerine Genel Bakış

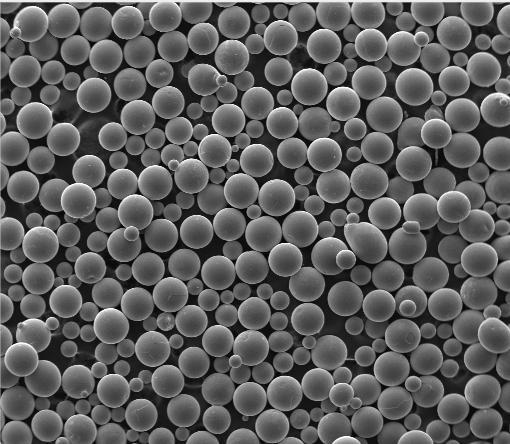

VIGA (Vakum İnert Gaz Atomizasyon) makineleri, yüksek kaliteli metal tozları üretmek için kullanılan son teknoloji ekipmanlardır. Bu tozlar havacılık, otomotiv, biyomedikal ve eklemeli imalat endüstrilerindeki uygulamalar için kritik öneme sahiptir. VIGA teknolojisi, mükemmel akışkanlığa, küresel şekle ve kontrollü partikül boyutu dağılımına sahip tozlar üretme kabiliyeti nedeniyle öne çıkmaktadır.

VIGA Makinelerinin Temel Özellikleri

- Yüksek Saflıkta Metal Tozları: VIGA makineleri vakum veya inert gaz ortamında çalışarak kontaminasyonu en aza indirir.

- Küresel Parçacıklar: Mükemmel akışkanlık ve paketleme yoğunluğu sağlar.

- Kontrollü Parçacık Boyutu: Özel toz özellikleri için ayarlanabilir atomizasyon parametreleri.

- Geniş Malzeme Yelpazesi: Titanyum, paslanmaz çelik ve süper alaşımlar dahil olmak üzere çeşitli metaller ve alaşımlar için uygundur.

Üretilen Metal Tozlarının Çeşitleri ve Modelleri VIGA Makineleri

İşte VIGA makineleri tarafından üretilen belirli metal tozu modelleri ve açıklamaları:

| Metal Tozu Modeli | Kompozisyon | Özellikler | Uygulamalar |

|---|---|---|---|

| Ti-6Al-4V | Titanyum Alaşım | Yüksek mukavemetli, korozyona dayanıklı, biyouyumlu | Havacılık ve uzay, tıbbi implantlar |

| 316L Paslanmaz Çelik | Fe-Cr-Ni-Mo Alaşımı | Mükemmel korozyon direnci, iyi mekanik özellikler | Biyomedikal cihazlar, denizcilik uygulamaları |

| IN718 | Nikel bazlı süper alaşım | Yüksek sıcaklık dayanımı, oksidasyona dayanıklı | Türbin kanatları, havacılık bileşenleri |

| AlSi10Mg | Alüminyum Alaşım | Hafif, iyi termal özellikler | Otomotiv, havacılık ve uzay |

| CoCrMo | Kobalt-Krom-Molibden Alaşımı | Yüksek aşınma direnci, biyouyumlu | Tıbbi implantlar, diş protezleri |

| CuCrZr | Bakır-Krom-Zirkonyum Alaşımı | Yüksek elektrik iletkenliği, iyi mekanik dayanım | Elektrikli bileşenler, kaynak elektrotları |

| Maraging Çelik (18Ni300) | Fe-Ni-Co-Mo-Ti Alaşım | Ultra yüksek mukavemet, iyi tokluk | Takımlar, yüksek performanslı dişliler |

| FeNiCo | Demir-Nikel-Kobalt Alaşımı | Manyetik özellikler, iyi mekanik dayanım | Manyetik bileşenler, havacılık ve uzay |

| NiTi (Nitinol) | Nikel-Titanyum Alaşımı | Şekil hafızası, süper esneklik | Tıbbi cihazlar, aktüatörler |

| Hastelloy X | Nikel-Krom-Molibden Alaşımı | Yüksek sıcaklık dayanımı, korozyona dayanıklı | Gaz türbini bileşenleri, kimyasal işleme |

VIGA Makinelerinin Uygulamaları

VIGA makineleri, yüksek kaliteli metal tozları üretme kabiliyetleri nedeniyle çeşitli sektörlerde kullanılmaktadır. İşte uygulamalarına ayrıntılı bir bakış:

| Endüstri | Uygulamalar |

|---|---|

| Havacılık ve Uzay | Türbin kanatları, yapısal bileşenler, bağlantı elemanları |

| Otomotiv | Hafif bileşenler, motor parçaları |

| Biyomedikal | İmplantlar, protezler, cerrahi aletler |

| Katmanlı Üretim | 3D baskı tozları, prototipleme, karmaşık geometriler |

| Enerji | Türbin bileşenleri, nükleer reaktör parçaları |

| Elektronik | İletken macunlar, manyetik bileşenler |

VIGA Makinelerinin Avantajları

- Yüksek Saflık ve Temizlik: Vakum veya inert gaz ortamında çalışmak kontaminasyonu azaltarak yüksek saflıkta metal tozları elde edilmesini sağlar.

- Kontrollü Parçacık Boyutu Dağılımı: Belirli uygulamalar için özelleştirmeye izin vererek performansı artırır.

- Küresel Parçacıklar: Katmanlı üretim için çok önemli olan akışkanlığı ve paketleme yoğunluğunu geliştirir.

- Çok Yönlü Malzeme Aralığı: Çeşitli metalleri ve alaşımları işleyebilir, bu da onları farklı endüstriler için uygun hale getirir.

Dezavantajları VIGA Makineleri

- Yüksek Başlangıç Maliyeti: VIGA makinelerini edinmek ve kurmak pahalıdır.

- Karmaşık Operasyon: Yetenekli operatörler ve düzenli bakım gerektirir.

- Enerji Yoğun: Süreç önemli ölçüde enerji gerektirmekte ve işletme maliyetlerini artırmaktadır.

VIGA Makinelerinin Detaylı Özellikleri

| Şartname | Detaylar |

|---|---|

| Malzeme Kapasitesi | Titanyum, paslanmaz çelik, nikel alaşımları, alüminyum alaşımları, kobalt-krom alaşımları vb. |

| Atomizasyon Gazı | Argon, nitrojen, helyum |

| Çalışma Basıncı | 150 bara kadar |

| Partikül Boyut Aralığı | 10 - 200 mikron |

| Üretim Oranı | 500 kg/saat'e kadar |

| Vakum Seviyesi | 10^-5 mbar'a kadar |

| Güç Tüketimi | 100 - 500 kW |

| Soğutma Sistemi | Su soğutmalı |

Artıları ve Eksilerinin Karşılaştırılması VIGA Makineleri

| Avantajlar | Dezavantajlar |

|---|---|

| Yüksek saflıkta metal tozları | Yüksek başlangıç maliyeti |

| Küresel parçacıklar | Karmaşık operasyon |

| Kontrollü partikül boyutu | Enerji yoğun |

| Çok yönlü malzeme yelpazesi | Yetenekli operatörler gerektirir |

| Mükemmel akışkanlık | Düzenli bakım gerekli |

SSS

| Soru | Cevap |

|---|---|

| VIGA makineleri ne için kullanılır? | Havacılık, otomotiv ve biyomedikal dahil olmak üzere çeşitli endüstriler için yüksek kaliteli metal tozları üretmek. |

| VIGA makineleri nasıl çalışır? | Erimiş metali küresel parçacıklara sahip ince tozlar halinde atomize etmek için vakum veya inert gaz kullanırlar. |

| VIGA makineleri hangi metalleri işleyebilir? | Titanyum, paslanmaz çelik, nikel alaşımları, alüminyum alaşımları ve daha fazlası. |

| Üretilen tozların partikül boyutu aralığı nedir? | Tipik olarak 10 ila 200 mikron arasındadır. |

| VIGA makineleri pahalı mı? | Evet, $900,000 ile $2,500,000 arasında değişen yüksek bir başlangıç maliyetleri var. |

| VIGA makinelerini kullanmanın faydaları nelerdir? | Yüksek saflık, kontrollü partikül boyutu, mükemmel akışkanlık ve malzeme işlemede çok yönlülük. |

| Hangi sektörler VIGA tozlarından yararlanır? | Havacılık ve uzay, otomotiv, biyomedikal, katmanlı üretim, enerji ve elektronik. |

| VIGA makineleri 3D baskı için toz üretebilir mi? | Evet, eklemeli üretim için yüksek kaliteli tozlar üretmek için idealdirler. |

| VIGA makineleri özel bakım gerektirir mi? | Evet, optimum performansı sağlamak için düzenli bakım ve kalifiye operatörlere ihtiyaç duyarlar. |

| Yaygın olarak kullanılan atomizasyon gazları nelerdir? | Atomizasyon için yaygın olarak argon, nitrojen ve helyum kullanılır. |

Sonuç

VIGA makineleri metal tozu üretim teknolojisinde bir zirveyi temsil eder ve modern endüstriler için gerekli olan yüksek kaliteli tozları sağlar. Küresel, yüksek saflıkta ve hassas bir şekilde kontrol edilen tozlar üretme kabiliyetleri, onları havacılıktan biyomedikal cihazlara kadar çeşitli uygulamalar için paha biçilmez kılmaktadır. Yüksek başlangıç maliyetlerine ve karmaşıklıklarına rağmen, malzeme özellikleri ve performans açısından sundukları faydalar eşsizdir. Yüksek kaliteli metal tozu üretimine girmek istiyorsanız, VIGA makinelerini anlamak ve kullanmak oyunun kurallarını değiştirebilir.

Paylaş

MET3DP Technology Co, LTD, merkezi Qingdao, Çin'de bulunan lider bir katmanlı üretim çözümleri sağlayıcısıdır. Şirketimiz, endüstriyel uygulamalar için 3D baskı ekipmanları ve yüksek performanslı metal tozları konusunda uzmanlaşmıştır.

İşletmeniz için en iyi fiyatı ve özelleştirilmiş Çözümü almak için sorgulayın!

İlgili Makaleler

Yüksek Performanslı Nozul Kanat Segmentleri: Metal 3D Baskı ile Türbin Verimliliğinde Devrim

Daha Fazla Oku "Met3DP Hakkında

Son Güncelleme

Bizim Ürünümüz

BİZE ULAŞIN

Herhangi bir sorunuz var mı? Bize şimdi mesaj gönderin! Mesajınızı aldıktan sonra tüm ekibimizle talebinize hizmet edeceğiz.

3D Baskı ve Katmanlı Üretim için Metal Tozları

ÜRÜN

cONTACT BİLGİLERİ

- Qingdao Şehri, Shandong, Çin

- [email protected]

- [email protected]

- +86 19116340731