Kovový prášek atomizovaný plynem

Obsah

Přehled o kovový prášek rozprašovaný plynem

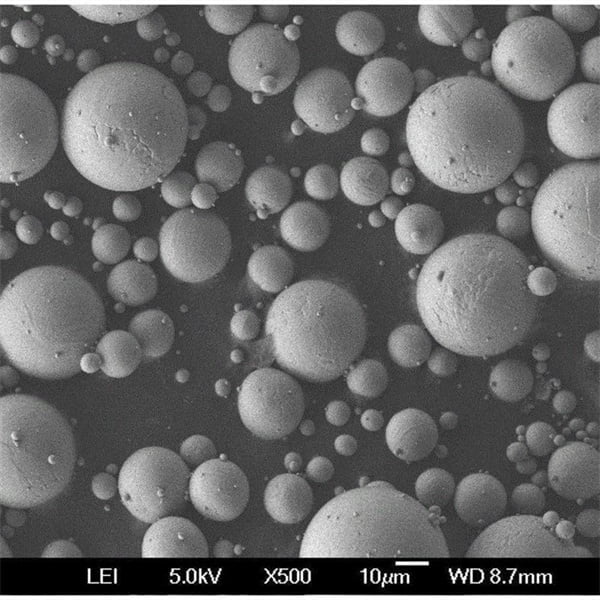

Plynem atomizovaný kovový prášek označuje kovové částice vyráběné atomizací roztavených slitinových surovin vysokorychlostními proudy inertního plynu. Tím se získá sférická morfologie ideální pro aditivní výrobu, vstřikování kovů a další aplikace.

Funkce rozprašování plynu:

- Vynikající kontrola tvaru částic, distribuce velikosti

- Použitelné pro reaktivní slitiny včetně titanu, hliníku a jiných slitin.

- Poskytuje vysoce čistý výchozí materiál pro pokročilé procesy

- Prášky přizpůsobené pro izostatické lisování za tepla, tepelné zpracování

- Podporuje přesné opakovatelné charakteristiky prášku

Pokračujte ve čtení, abyste se dozvěděli o možnostech složení, kvalitě částic, aplikacích a specifikacích prášků rozprašovaných plynem.

Typy slitin kovového prášku rozprašovaného plynem

Různé slitiny lze rozprašovat v plynu na jemné sférické prášky:

| Kategorie slitin | Materiály | Složení |

|---|---|---|

| Nerezové oceli | 304, 316, 17-4PH, 303, 410 | Fe/Cr/Ni + stopové prvky |

| Nástrojové oceli | H13, M2, M4 | Fe + V, Mo, W karbidy |

| Kobaltové slitiny | CoCr, CoCrW, CoCrMo | Co/Cr + wolfram/molybden |

| Slitiny niklu | Inconel 625 a 718 | Ni/Cr/Fe/Mo |

| Slitiny titanu | Ti-6Al-4V, Ti-6242 | Ti/Al/V/Sn/Zr/Mo |

Tabulka 1: Přehled komerčně dostupných systémů slitin v prášku rozprašovaném plynem

Speciální aditivní výroba a specifické průmyslové slitiny pro letecké/biomedicínské použití mohou mít minimální objednací množství nebo dodací lhůty.

Vlastnosti prášku

Typické vlastnosti částic dosažené pomocí atomizace inertním plynem:

| Charakteristický | Podrobnosti | Význam |

|---|---|---|

| Tvar částic | Vysoce sférický | Zlepšuje tok prášku a hustotu balení |

| Rozsah velikostí | 10 μm až 150 μm | Řízená distribuce optimalizovaná pro koncové použití |

| Složení | Slitina udržovaná v rozmezí ± 0,5 wt% | Zachovává mechanické vlastnosti |

| Čistota | Dosažitelnost až 99,9% | Snižuje obsah nečistot a inkluzí |

| Povrchové oxidy | <50 nm silná pasivační vrstva | Zachovává vynikající recyklovatelnost prášku |

Tabulka 2: Přehled vlastností částic kovových prášků rozprašovaných plynem

Přesné vlastnosti opakovaně vyráběné pro potřeby certifikace v letectví, zdravotnictví, automobilovém průmyslu a průmyslových kategoriích.

Výrobní proces

- Typické kroky při atomizaci inertním plynem:

- Indukční nebo obloukové tavení vytváří taveninu slitiny pod ochranným krycím plynem.

- Vysoce čistý inertní plyn (Ar nebo N2) protlačovaný přes specializované trysky.

- Roztavený proud se rozpadá na jemné kapičky, které se rychle ochlazují na prášek.

- Prášky se usazují ve sběrných zásobnících pod

- Třídění pomocí sít pro normalizaci rozdělení

- Balení a přeprava k zákazníkům v ochranné atmosféře

- Kritické parametry procesu:

- Konstrukce trysek - určuje distribuci velikosti částic

- Tlak plynu - ovlivňuje rychlost částic a rychlost chlazení.

- Rychlost lití taveniny - ovlivňuje tvar distribuce velikosti

- Prostředí (vakuum vs. řízená atmosféra) závisí na reaktivitě

Aplikace z kovový prášek rozprašovaný plynem

| aplikace | Výhody | Příklady |

|---|---|---|

| Aditivní výroba | Dílce s vysokou hustotou díky vynikajícímu toku a balení prášku | Letecké komponenty, lékařské implantáty |

| Vstřikování kovů | Dobrá tvarovatelnost pro malé složité tvary | Lopatky turbíny, součásti trysky |

| Tepelně stříkané povlaky | Husté povlaky z nárazů deformovatelných částic | Povrchy odolné proti opotřebení |

| Braze pasty | Spojování složitých geometrií | Výměníky tepla, elektrické kontakty |

| Izostatické lisování za tepla | Minimalizace problémů s uzavíráním sférických částic | Konsolidace litých lopatek turbín |

| Prekurzory tepelného zpracování | Přizpůsobitelná struktura zrna | Slitiny pro srážkové kalení |

Tabulka 3: Přehled aplikací využívajících vlastností kovových prášků rozprašovaných plynem

Konzistence a čistota, kterou nabízí plynová atomizace, je vhodná pro většinu pokročilých procesů s kovovým práškem, kde je opakovatelnost kritická.

Specifikace kovový prášek rozprašovaný plynem

Prášky rozprašované plynem jsou validovány podle různých standardních specifikací:

| Standard | Popis |

|---|---|

| ASTM B214 | Ověření pomocí optické mikroskopie na rovnoměrnost a absenci satelitů |

| AMS 7008 | Specifikace leteckého materiálu včetně metody atomizace inertním plynem |

| ASTM F3049 | Standardní příručka pro charakterizaci vlastností kovových prášků pro AM |

| ASTM F3056 | Specifikace pro prášky ze slitin niklu pro aditivní výrobu |

| ISO 21818 | Specifikace pro výrobní nerezové oceli DMLS/SLM |

Tabulka 4: Průmyslové normy běžně používané pro prášky rozprašované inertním plynem

Renomovaní výrobci poskytnou kompletní certifikační dokumentaci a výsledky testování pro každou šarži prášku, aby potvrdili shodu.

Dodavatelé a ceny

| Dodavatel | Materiály | Orientační ceny |

|---|---|---|

| Sandvik Osprey | Ti slitiny, Ni slitiny, nástrojové oceli | $100+ za kg |

| Přísada pro tesaře | Nerezové oceli, kobaltové slitiny, Cu | $50 - $150 za kg |

| Praxair | Ti slitiny, Al slitiny, křemíkové prášky | $100+ za kg |

| Technologie LPW | Nástrojové oceli, nerezové oceli, inkonely | $50 - $500 za kg |

| Řešení SLM | Vývoj slitin na zakázku | $250+ za kg |

Tabulka 5: Výběr společností dodávajících kovové prášky rozprašované plynem s přibližnými cenami

Většina dodavatelů nabízí standardní slitiny s dodací lhůtou 2-4 týdny v malých množstvích. Přímo s dodavateli plynových atomizátorů je také možné spolupracovat na zakázkových formulacích a optimalizaci jedinečných částic.

Výhody a nevýhody vs. alternativy

| Parametr | Atomizace plynu | Atomizace vody | Plazmová atomizace |

|---|---|---|---|

| Morfologie částic | Vysoce sférický | Další nepravidelné sféroidy | Převážně sférické |

| Distribuce velikosti částic | Těsné rozdělení, přizpůsobitelné | Širší distribuce | Těsné rozdělení |

| Kompatibilní slitiny | Většina komerčních slitin | Omezené slitiny | Široký sortiment včetně reaktivních kovů |

| Náklady na kg | Mírný $50-150 za kg | Nižší $20-100 za kg | Vyšší $150-500 za kg |

| Míra produktivity | Kapacita až 10 000 kg za den | Velmi vysoký >50 000 kg denně | <1 000 kg denně |

Tabulka 6: Srovnání plynové atomizace s alternativními metodami výroby prášku

Plynová atomizace zajišťuje optimální rovnováhu mezi schopnostmi a ekonomikou a zároveň poskytuje množství prášku vhodné pro komerční výrobu.

Omezení

- Minimální velikosti dávek vyžadují použití více než 100 kg materiálu, aby bylo možné odůvodnit nastavení stroje.

- Omezená schopnost hospodárně atomizovat slitiny s vysokou teplotou tání, jako je wolfram.

- Prášky nejsou tak kulovité jako při plazmové atomizaci a obsahují některé satelity.

- Tloušťka oxidu je o něco vyšší než u alternativ vakuové plazmy

- Vysoké počáteční kapitálové náklady kolem $1-5 milionů za systém na klíč.

- Vyžaduje lepší manipulaci/skladování prášku ve srovnání s primárními materiály.

FAQ

Otázka: Jaká je výhoda prášku rozprašovaného plynem oproti původním materiálům pro výrobu dílů?

Odpověď: Plynem rozprašované prášky nabízejí vynikající konzistenci a opakovatelnost. Inženýrské řešení morfologie a struktury zrn prášku od samého počátku umožňuje vyspělé procesy výroby certifikovaných součástí splňujících nejvyšší průmyslové požadavky v leteckém a lékařském průmyslu.

Otázka: Jaká bezpečnostní opatření jsou nutná při manipulaci s prášky rozprašovanými plynem?

Odpověď: Vzhledem k tomu, že se jedná o jemné kovové materiály náchylné k oxidaci, doporučují se inertní protokoly o skladování a manipulaci. Patří k nim rukavicové boxy naplněné argonem s kontrolovanou vlhkostí a pracovníci používající osobní ochranné prostředky, aby se minimalizovalo riziko výbuchu, vdechnutí nebo kontaminace. Nikdy nedovolte kontakt s vodou nebo organickými sloučeninami. Speciální konstrukce zařízení není nezbytně nutná, ačkoli se na ni mohou vztahovat místní předpisy.

Otázka: Jakou úroveň opakovatelnosti lze očekávat u jednotlivých šarží prášků rozprašovaných plynem?

Odpověď: Renomovaní výrobci zaručují distribuci prášku v rozmezí ±10% mezi jednotlivými šaržemi. Drobné odchylky přesto vyžadují opětovnou optimalizaci jako standardní postup, a to i od stejného dodavatele prášku, pokud jsou přijatelné tolerance komponentů přísné. Certifikáty analýzy dokládají konzistenci.

Otázka: Jak dlouho mohou zůstat nepoužité prášky rozprašované plynem životaschopné při skladování?

Odpověď: Podle osvědčených postupů se prášek skladuje v ochranném argonu v uzavřených nádobách, aby se zabránilo extrémním teplotám. Pokud se uchovává při teplotě pod 30 °C a relativní vlhkosti 50% s minimem kyslíku a vlhkosti, vydrží prášek mnoho měsíců, než bude třeba provést obnovovací cykly v rukavicovém boxu, aby se zachoval tok a vlastnosti pro opakované použití.

Otázka: Jakou technickou podporu poskytují dodavatelé prášků pro kvalifikaci a certifikaci dílů?

Odpověď: Renomovaní dodavatelé mají vědce zabývající se materiály a pracovníky pro validaci, kteří poskytují pokyny pro použití a spolupracují s odběrateli dílů v procesu testování, aby mohli prášky certifikovat. Chtějí prokázat opakovatelnost splňující regulované normy, aby mohli rozšířit použití materiálů v náročnějších aplikacích. Od každého zavedeného dodavatele očekávejte podrobnou dokumentaci a protokoly.

Sdílet na

MET3DP Technology Co., LTD je předním poskytovatelem řešení aditivní výroby se sídlem v Qingdao v Číně. Naše společnost se specializuje na zařízení pro 3D tisk a vysoce výkonné kovové prášky pro průmyslové aplikace.

Dotaz k získání nejlepší ceny a přizpůsobeného řešení pro vaše podnikání!

Související články

Vysoce výkonné segmenty lopatek trysek: Revoluce v účinnosti turbín díky 3D tisku z kovu

Přečtěte si více "O Met3DP

Nedávná aktualizace

Náš produkt

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731