Prášky z kovových slitin

Obsah

Prášky z kovových slitin umožňují výrobu vysoce výkonných dílů pomocí metod lisování a slinování práškové metalurgie nebo aditivní výroby v dopravě, průmyslu, zdravotnictví a energetice. Tento průvodce se zabývá různými možnostmi slitin, procesy výroby práškových materiálů, klíčovými specifikacemi, případy použití, úvahami o kvalitě a poradenstvím při získávání zdrojů.

Typy prášků z kovových slitin

Společné kategorie:

| Typ | Příklady | Klíčové vlastnosti |

|---|---|---|

| Slitiny niklu | Inconel, Monel, Hastelloy | Odolnost proti korozi, tepelná odolnost |

| Kobaltové slitiny | MP35N, Haynes 25, Stellite | Odolnost proti opotřebení, biokompatibilita |

| Titanové slitiny | Třída CP, Ti-6Al-4V, Ti-6Al-7Nb | Vysoká pevnost, nízká hmotnost |

| Nerezové oceli | 316, 17-4PH, 15-5PH | Odolnost proti korozi, pevnost |

| Nástrojové oceli | H13, M2, M4, P20 | Odolnost proti opotřebení, houževnatost |

| Slitiny mědi | Chrom měď, mosaz, bronz | Elektrická a tepelná vodivost |

Srovnejte vlastnosti slitinového materiálu s kritickými požadavky na výkonnost dílů, jako je tepelná tolerance, tvrdost, únavová životnost atd., a zvolte třídu prášku.

Způsoby výroby kovového prášku

Klíčové výrobní procesy v komerčním měřítku:

- Atomizace plynu - Vysokotlaký inertní plyn rozbíjí proud roztaveného kovu na jemné kapičky. Dosahuje sférických prášků s dobrými tokovými a balicími vlastnostmi. Různé trysky vytvářejí požadované rozsahy velikostí.

- Plazmová atomizace - Vysokoenergetický plazmový oblouk taví suroviny. Výkonné indukční cívky vytvářejí kapky, které tuhnou do sférických prášků s těsným rozložením částic.

- Rotační elektroda - Odstředivé síly působící na roztavenou slitinu vystavenou proudům inertního plynu způsobují rozpad na jemné kapičky, jejichž výsledkem je sférický prášek.

- Elektrolýza - Ionty kovů z roztoku se vylučují na katodách jako jemné práškové částice. Používá se pro reaktivní materiály, jako je hliník, hořčík, titan.

Řízení procesních parametrů, jako je teplota, atmosféra a rychlost chlazení, vede ke kvalitním práškovým surovinám pro výrobu dílů pomocí aditivní výroby nebo zhutňování práškové metalurgie.

Typické specifikace

| Parametr | Popis | Zkušební metoda |

|---|---|---|

| Čistota | >99%, minimalizace nečistot | Analýza ICP |

| Tvar částic | Sférické >80% | Mikroskopie |

| Distribuce velikosti částic | Úzké rozsahy podle potřeby | Difrakce laseru |

| Hustota poklepání | Závislost na materiálu | Hallův průtokoměr |

| Zdánlivá hustota | Závislost na materiálu | Pyknometrie |

| Průtoky | Standardizováno pro každou jmenovitou velikost | Hallův průtokoměr |

| Povrchové oxidy | <3000 ppm; tloušťka oxidu | Fúze inertního plynu; XRD |

Zkontrolujte statistické údaje o šaržích od výrobce na základě těchto ukazatelů specifických pro cílovou třídu, které potvrzují kvalitu a konzistenci ve vztahu ke standardům.

Aplikace

Práškové aplikace kovových slitin zahrnují:

Aerospace - Součásti motorů, jako jsou lopatky, trysky; kování draku, části podvozku; palubní systémy.

Průmyslový - Čerpadla na zemní plyn/ropu, ventily, vrtáky; nástrojové destičky; jaderné reaktory; výměníky tepla

Automobilový průmysl - Součásti motoru, rotory turbodmychadla, převodovky; podvozek, díly hnacího ústrojí

Lékařský - Kolenní, kyčelní a zubní implantáty; chirurgické nástroje; zobrazovací přístroje

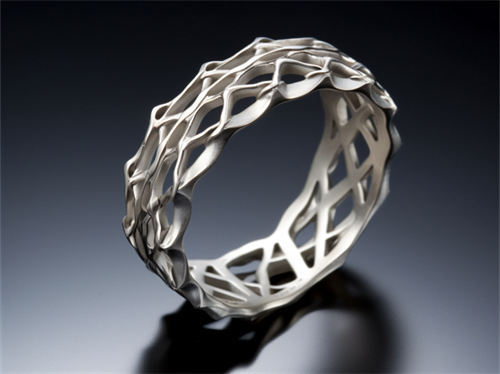

Spotřebitel - špičkové hodinky, sportovní vybavení, jako jsou jízdní kola, golfové hole atd., které vyžadují pevnost, estetiku.

Energie - Kontakty solárních článků, elektrody; generátory; součásti baterií; větrné turbíny

Využití výhod omezených vlastností materiálů s konstrukční svobodou a přesností.

Průmyslové normy

Klíčové specifikace platné pro práškové slitiny kovů:

| Standard | Popis |

|---|---|

| ASTM B213 | Standardní klasifikační systém pro kovové prášky |

| ISO 4490 | Chemická analýza, postupy odběru vzorků |

| ASTM B822 | Měření zdánlivé hustoty a průtoku |

| MPIF 04 | Statistické metody pro analýzu kovových prášků |

Přezkoumání statisticky ověřených certifikátů prokazujících shodu s limity složení třídy a konzistenci kvality výroby ve vztahu k platným normám.

Běžné třídy kovového prášku

| Slitina | Obchodní názvy | Specifikace | |

|---|---|---|---|

| Slitiny niklu | Inconel 718, 625; Hastelloy X; Monel K500 | AMS 5662, 5663 atd. | |

| Kobaltové slitiny | MP35N, Haynes 25, Stellite 21 | ASTM F90, F1537 atd. | |

| Titanové slitiny | Ti-6Al-4V třída 5; Ti-6Al-7Nb ; CP Ti třída 2 | AMS 4911, ASTM B348 atd. | |

| Nerezové oceli | SS 316L; 17-4PH; 15-5 PH; | ASTM A240, B945 atd. | |

| Nástrojové oceli | H13; M2; M4; P20+Ni | Typy AISI | ASTM A681 |

| Slitiny mědi | C18150, C19500, C95810 | Číslo UNS, ASTM B194 atd. |

Přizpůsobte cílovou třídu příslušným specifikacím slitiny, které odpovídají potřebám funkčnosti hotového dílu v parametrech pevnosti, vodivosti a odolnosti proti korozi.

Úvahy o kvalitě

| Metrický | Účel | Zkušební metoda |

|---|---|---|

| Složení | Ověření čistoty třídy | Analýza ICP |

| Distribuce velikosti částic | Kompatibilita s AM, odezva na spékání | Difrakce laseru |

| Hallův průtok | Hustota balení prášku, rovnoměrnost vrstvy | Hallův průtokoměr |

| Hustota poklepání | Označuje konečnou hustotu dílu | Vážení naměřeného objemu |

| Zdánlivá hustota | Hustota práškového systému | Plynová pyknometrie |

| Tvar částic | Sféricita optimalizuje vlastnosti | Mikroskopie |

| Povrchové oxidy | Dopady opětovného použití prášku | Analyzátor fúze inertních plynů |

Konzistentní kvalita v těchto ukazatelích přímo souvisí s konzistentním výkonem finálního dílu, který splňuje specifikace.

Úvahy o získávání zdrojů

| Parametr | Důležitost |

|---|---|

| Datové listy šarží | Vysoký |

| Podpora vzorkování | Vysoký |

| Doba realizace | Střední |

| Přizpůsobení | Nízký |

| Cenové faktory | Nízký |

Před velkým nákupem si nejprve vyzkoušejte vzorky prášku, abyste si ověřili reakce na tisk nebo kompresi vzhledem k potřebám aplikace.

Nejčastější dotazy

Otázka: Jaký je rozdíl mezi předlegovanými a směsnými elementárními prášky?

Odpověď: Předlegované prášky mají rovnoměrné složení v každé kulovité částici. Směsné prvkové směsi mohou mít mezi částicemi mírné rozdíly ve složení, které mohou způsobit nehomogenity v konečných dílech.

Otázka: Měly by se kovové prášky skladovat za zvláštních podmínek?

Odpověď: Uchovávejte je uzavřené s desikantem mimo dosah vlhkosti a kyslíku, které způsobují znehodnocení. Omezte kolísání teploty na 10-30 °C. Vyhoďte, pokud dojde k výrazné změně barvy, tvorbě krupičky nebo výrazné ztrátě průtoku. Skladovatelnost je při správném skladování obvykle delší než jeden rok.

Otázka: Jaké jsou běžné směsi kovových prášků?

Odpověď: Práškové směsi kobaltu a chromu, nerezové oceli 17-4PH a niklové slitiny s nerezovou ocelí nabízejí způsoby, jak přizpůsobit vlastnosti materiálu finálního dílu, jako je pevnost, odolnost proti opotřebení nebo odolnost proti korozi, a to s nižšími náklady než u vysoce čistých tříd.

Otázka: Jaká bezpečnostní opatření jsou nutná při manipulaci s kovovými prášky?

Odpověď: Při manipulaci s práškem používejte vhodné osobní ochranné prostředky a zabraňte kontaktu s kůží nebo vdechnutí. Pasivované prášky představují menší zdravotní rizika ve srovnání s rozprašovanými prášky, které mohou být reaktivnější. Prostudujte si bezpečnostní listy o hořlavosti, reaktivitě a protokoly o expozici.

Sdílet na

MET3DP Technology Co., LTD je předním poskytovatelem řešení aditivní výroby se sídlem v Qingdao v Číně. Naše společnost se specializuje na zařízení pro 3D tisk a vysoce výkonné kovové prášky pro průmyslové aplikace.

Dotaz k získání nejlepší ceny a přizpůsobeného řešení pro vaše podnikání!

Související články

Vysoce výkonné segmenty lopatek trysek: Revoluce v účinnosti turbín díky 3D tisku z kovu

Přečtěte si více "O Met3DP

Nedávná aktualizace

Náš produkt

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731