Aditivní výroba SLM

Obsah

Přehled o Aditivní výroba SLM

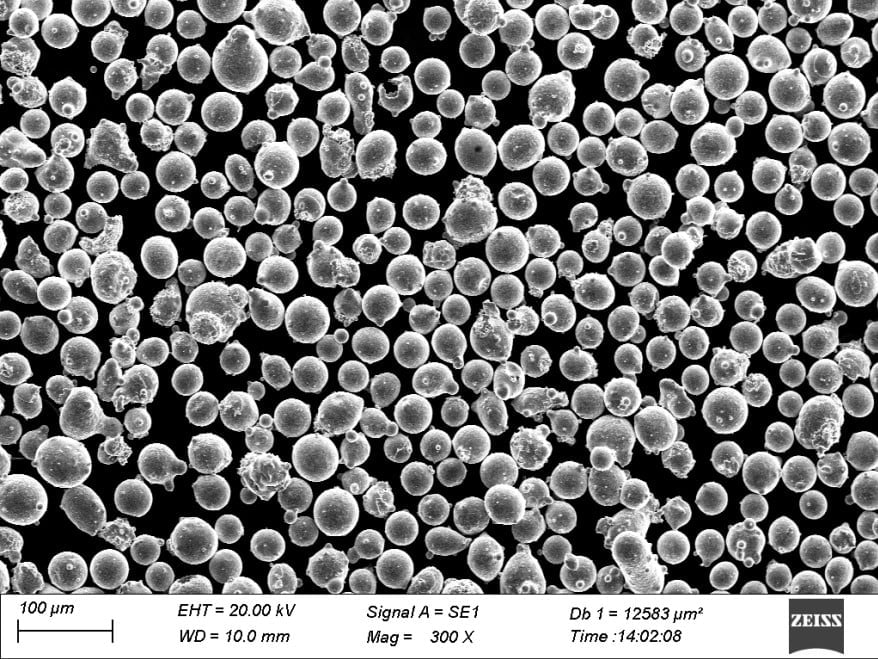

Selektivní laserové tavení (SLM) je aditivní výrobní technologie, která využívá laser k selektivnímu tavení a spojování kovového práškového materiálu vrstvu po vrstvě a vytváří tak 3D objekty. SLM je vhodná pro zpracování reaktivních kovů, jako je titan, hliník a nerezová ocel, do plně hustých a funkčních dílů se složitou geometrií.

SLM nabízí několik výhod ve srovnání s tradiční výrobou:

Výhody aditivní výroby SLM

| Benefit | Popis |

|---|---|

| Svoboda designu | SLM dokáže vyrobit složité geometrie, jako jsou mřížky, vnitřní kanály a organické tvary, které nelze vyrobit obráběním. |

| Přizpůsobení | Díly lze snadno přizpůsobit a optimalizovat spíše z hlediska funkčnosti než z hlediska omezení vyrobitelnosti. |

| Odlehčení | Organické tvary a mřížky umožňují, aby díly byly lehké a zároveň si zachovaly pevnost. |

| Úspora materiálu | SLM používá pouze potřebné množství materiálu oproti obrábění z masivních bloků. |

| Rychlá tvorba prototypů | Díly lze tisknout přímo z CADu oproti výrobě nástrojů pro prototypování. |

| Výroba Just-in-time | Tisk na vyžádání podle potřeby snižuje náklady na zásoby |

| Odolnost dodavatelského řetězce | Distribuovaná výroba snižuje rizika dodavatelského řetězce |

SLM má však také určitá omezení:

Omezení aditivní výroby SLM

| Omezení | Popis |

|---|---|

| Náklady na stroj | Průmyslové stroje SLM mají vysoké počáteční kapitálové náklady $100K-$1M+. |

| Možnosti materiálu | V současné době se omezuje na reaktivní kovy, jako je titan, hliník, nástrojové oceli a superslitiny. |

| Přesnost | Typická přesnost 0,1-0,2 mm je nižší než tolerance obrábění. |

| Povrchová úprava | Povrch po vytištění je drsný a vyžaduje následné zpracování. |

| Velikost stavby | Maximální velikost dílu je omezena velikostí komory tiskárny. |

| Nízká sériová výroba | Nejvýhodnější pro malé série a zakázkové díly oproti sériové výrobě. |

| Následné zpracování | Další kroky, jako je odstranění podpěr, tepelné zpracování |

Jak funguje 3D tisk SLM

SLM je technologie tavení v práškovém loži, která využívá fokusovaný laserový paprsek k selektivnímu tavení a spojování kovového práškového materiálu vrstvu po vrstvě.

Klíčové kroky v procesu SLM jsou:

Proces 3D tisku SLM

| Krok | Popis |

|---|---|

| 3D model | 3D model CAD je digitálně rozřezán na vrstvy. |

| Prášek na roztírání | Nůž pro nanášení prášku rozprostře tenkou vrstvu prášku na stavební plošinu. |

| Tavení laserem | Laserový paprsek sleduje každou vrstvu tavícího se prášku a spojuje ji na základě nakrájených dat CAD. |

| Dolní plošina | Stavební plošina se spustí a na ni se nanese další vrstva prášku. |

| Opakování kroků | Proces tavení vrstev se opakuje, dokud není vytvořen celý díl. |

| Odebrat část | Hotový 3D vytištěný díl se vyjme z práškového lože. |

| Následné zpracování | Díl je vyčištěn a tepelně zpracován, aby se uvolnilo pnutí. |

Materiály SLM

SLM dokáže zpracovat celou řadu reaktivních kovů do plně hustých dílů, včetně:

Materiály SLM

| Materiál | Klíčové vlastnosti | Aplikace |

|---|---|---|

| Titanové slitiny | Vysoký poměr pevnosti a hmotnosti, biokompatibilita | Letectví a kosmonautika, lékařské implantáty |

| Hliníkové slitiny | Lehké, vysoce pevné | Automobilový a letecký průmysl |

| Nerezové oceli | Odolnost proti korozi, vysoká pevnost | Průmyslové nářadí, lodní nářadí |

| Nástrojové oceli | Vysoká tvrdost, tepelná odolnost | Vstřikovací formy, zápustky |

| Niklové superslitiny | Odolnost proti teplu a korozi | Lopatky turbín, trysky raket |

| Kobalt Chrome | Odolnost proti opotřebení, biokompatibilita | Zubní implantáty, ortopedie |

Nejběžnějšími materiály pro SLM jsou slitiny titanu a hliníku, nástrojové oceli a nerezové oceli. Technologií SLM lze zpracovávat i exotičtější superslitiny a kovové kompozity.

Pokyny pro navrhování SLM

Pro úspěšný návrh dílů pro 3D tisk pomocí SLM by se konstruktéři měli řídit těmito pokyny:

Pokyny pro navrhování SLM

| Pokyn | Popis |

|---|---|

| Vyhněte se převisům | Minimalizace převisů vyžadujících podpěry, které je nutné odstranit. |

| Konstrukční kotvy | Včetně malých kotev nebo výstupků pro upevnění dílu ke stavební desce. |

| Orientujte se na sílu | Vyrovnejte díl tak, abyste maximalizovali pevnost ve funkčním směru. |

| Minimalizace výšky dílu | Orientujte se tak, abyste minimalizovali výšku Z, aby nedošlo ke zhroucení choulostivých prvků. |

| Umožňují dodatečné obrábění | V případě potřeby přísných tolerancí přidejte přídavek 0,1-0,3 mm na následné zpracování. |

| Optimalizace návrhů mříží | Vyladění velikosti buněk a vzpěr podle zatížení dílů a omezení SLM |

| Včetně větracích otvorů | Přidejte malé otvory, abyste zabránili vzniku defektů způsobených zachyceným práškem. |

| Konformní chladicí kanály | Navrhování složitých vnitřních chladicích kanálů, které není možné vrtáním/obráběním. |

| Kombinace dílů | Konsolidace sestav do jednotlivých dílů pro snížení požadavků na montáž |

Dodržování těchto pokynů pomáhá vyhnout se běžným vadám tisku SLM, jako je špatná povrchová úprava, deformace, praskání nebo zachycený prášek.

Výrobci tiskáren SLM

Mezi hlavní výrobce systémů SLM patří:

Výrobci 3D tiskáren SLM

| Společnost | Tiskárny | Klíčové vlastnosti |

|---|---|---|

| EOS | EOS M290, EOS M300 x4 | Průkopník kovového 3D tisku, vynikající vlastnosti dílů |

| Řešení SLM | SLM 280, SLM 500, SLM 800 | Velmi vysoký výkon laseru pro produktivitu a velké objemy stavebních prací |

| 3D Systems | DMP Factory 500 | Škálovatelné systémy pro velkosériovou výrobu |

| Přísady GE | Concept Laser M2, X Line 2000R | Nyní součást GE, spolehliví pracovní koně pro zvýšení produktivity |

| Renishaw | RenAM 500Q | Vynikající přesnost, integrovaný systém řízení kvality |

Při výběru systému SLM jsou klíčovými faktory objem výroby, výkon laseru, možnosti materiálů, přesnost a softwarový pracovní postup. Přední výrobci nabízejí zavedené systémy, ale objevuje se i mnoho nových výrobců z Číny a Indie.

Ceny tiskáren SLM

Průmyslové systémy SLM mají vysoké počáteční kapitálové náklady, které se pohybují od $100 000 u základních strojů až po $1 000 000+ u špičkových výrobních systémů:

Ceny tiskáren SLM

| Výrobce | Model tiskárny | Objem sestavení | Cenové rozpětí |

|---|---|---|---|

| EOS | EOS M100 | 95 x 95 x 95 mm | $100k - $150k |

| Řešení SLM | SLM 125 | 125 x 125 x 125 mm | $175k - $250k |

| 3D Systems | DMP Factory 500 | 500 x 500 x 500 mm | $500k - $800k |

| Přísady GE | Concept Laser M2 Series 5 | 250 x 250 x 280 mm | $700k - $900k |

| Renishaw | RenAM 500M | 250 x 250 x 350 mm | $950k - $1.2M |

Větší objemy, vyšší výkon laseru a produktivní funkce zvyšují náklady na systém. Klíčový je však rozumný výběr na základě potřeb aplikace a výrobních požadavků.

Úvahy o zařízení SLM

Pro úspěšné provozování zařízení SLM by podniky měly zvážit:

Faktory zařízení SLM

| Faktor | Popis |

|---|---|

| Náklady na zařízení | Zohlednění nákladů na tiskárnu, materiál a vybudování zařízení. |

| Manipulace s materiálem | Instalace zařízení pro manipulaci s práškem a poskytnutí osobních ochranných pomůcek pro pracovníky |

| Následné zpracování | Čistící zařízení, tepelné zpracování, HIP, povrchová úprava atd. |

| Software | Software pro plánování pracovních postupů, vnořování a sledování procesů |

| Školení | Školení konstruktérů v oblasti designu a techniků v oblasti obsluhy tiskáren. |

| Bezpečnost | Dodržujte postupy pro manipulaci s práškem a mějte protipožární systémy. |

| Údržba | Plánujte pravidelnou údržbu a kalibraci systému |

| Kontrola kvality | Měření rozměrů a vlastností materiálu, testování opakovatelnosti |

| Certifikace | Certifikace ISO 9001, AS9100 pro regulovaná odvětví |

Výběr zkušeného poskytovatele služeb vám pomůže s nastavením zařízení, provozem a certifikací pro regulované aplikace, jako je letecký průmysl nebo zdravotnické přístroje.

Výhody aditivní výroby SLM

Mezi hlavní výhody 3D tisku SLM patří:

Výhody aditivní výroby SLM

| Výhoda | Popis |

|---|---|

| Složité geometrie | SLM dokáže vyrobit velmi složité organické tvary a složité vnitřní mřížky a kanály |

| Díly na míru | Snadné vytváření dílů na míru podle potřeb zákazníka v porovnání s omezením nástrojů. |

| Snížení hmotnosti | Mřížkové struktury a optimalizace topologie umožňují lehké a pevné konstrukce |

| Konsolidované sestavy | Kombinovat více komponentů do jednotlivých složitých dílů |

| Rychlé dodací lhůty | Tisk dílů na vyžádání přímo z dat CAD oproti měsícům na obrábění |

| Snížení množství odpadu | Použití pouze potřebného množství materiálu oproti obrábění z předvalku |

| Výroba na vyžádání | Umožňuje distribuovanou výrobu just-in-time v blízkosti zákazníků |

| Snížení zásob | Tisknout díly podle potřeby, což snižuje náklady na nástroje, skladování a zásoby. |

| Vysoce výkonné materiály | Zpracování pokročilých kovů, jako je titan a superslitiny, na díly pro konečné použití. |

Díky volnosti návrhu, přizpůsobení dílů a možnostem distribuované výroby je SLM ideální pro nízko až středně velkou výrobu pro aplikace v letectví, zdravotnictví, průmyslu a automobilovém průmyslu.

Omezení aditivní výroby SLM

SLM má některá omezení, včetně:

Omezení aditivní výroby SLM

| Omezení | Popis |

|---|---|

| Náklady na stroj | Tiskárny SLM mají vysoké investiční náklady, které často přesahují $500 000. |

| Dostupnost materiálu | V současné době se omezuje na reaktivní konstrukční kovy a plasty. |

| Přesnost | Typická přesnost 0,1-0,2 mm je nižší než u CNC obrábění. |

| Povrchová úprava | Povrch po potisku je poměrně drsný a má schodovitý efekt. |

| Následné zpracování | Často je vyžadováno odstranění podpěr, obrábění, leštění |

| Rychlost tisku | Rychlost výroby obvykle 5-100 cc/hod omezuje rychlost oproti hromadné výrobě |

| Maximální velikost dílu | Omezeno objemem tiskárny, obvykle pod 500 x 500 x 500 mm |

| Monitorování procesů | Nedostatečné monitorování na místě může vést k neodhaleným závadám. |

| Odbornost operátora | Technici SLM potřebují významné školení o postupech |

| Náklady na materiál | Práškové kovy mohou být 2-5krát dražší než surové materiály. |

Pro potřeby velmi vysoké přesnosti, extrémně velkých dílů nebo hromadné výroby jsou subtraktivní metody, jako je CNC obrábění, vhodnější než aditivní metody SLM.

Úloha SLM ve výrobě

SLM je nejvhodnější pro:

Nejlepší role pro SLM ve výrobě

| Výrobní role | Příklady |

|---|---|

| Rychlé prototypování | Rychlé iterace návrhu a zkušební koncepční díly |

| Malosériová výroba | Letecké konzoly, oběžná kola, lékařské implantáty |

| Nástroje pro mosty | Výroba prvních kusů během výroby vstřikovacích forem |

| Konsolidace části | Kombinace více součástí do jednoho dílu |

| Hromadné přizpůsobení | Výrobky na míru pro konečné použití, jako jsou zubní rovnátka |

| Distribuovaná výroba | Místní výroba na vyžádání v blízkosti zákazníků |

Pro velmi vysoké objemy je konvenční vysokotlaké lití pod tlakem nebo vstřikování plastů obvykle nákladově efektivnější než 3D tisk pomocí SLM. Pro výrobu krátkých sérií však SLM vyniká.

Budoucnost aditivní výroby SLM

Očekává se, že SLM se v budoucnu rozšíří do širšího použití prostřednictvím:

Budoucnost SLM

| Trend | Popis |

|---|---|

| Větší tiskárny | Objemy staveb o délce a výšce nad 1 metr |

| Multilaserové systémy | Víceúčelové laserové stroje s vyšším výkonem nad 1 kW |

| Vyšší rychlosti | Rychlost tisku až 500 cc/hod. pomocí skenovaných galvo laserů |

| Nové materiály | Vysokoteplotní slitiny, MMC, nové kompozity |

| Hybridní výroba | Kombinace AM a subtraktivních procesů v jednom systému |

| Automatizované následné zpracování | Snížení ruční práce při odstraňování podpěr a povrchové úpravě |

| Monitorování během procesu | Monitorování vad taveniny, práškového lože a dílů in-situ |

| Simulace | Fyzikální simulace pro předvídání chování a optimalizaci sestav. |

| Strojové učení | Umělá inteligence pro návrh, optimalizaci procesů a zajištění kvality |

| Digitální dodavatelský řetězec | Bezproblémový digitální pracovní postup od návrhu po výrobu |

Výběr poskytovatele služeb SLM

Při výběru poskytovatele služeb SLM by kupující měli posoudit:

Výběr poskytovatele služeb SLM

| Faktor | Popis |

|---|---|

| Tisková zařízení | Hledejte renomované průmyslové tiskárny kovů s vysokým výkonem paprsku a velkým objemem tisku. |

| Materiály | Schopnost zpracovávat požadované slitiny, jako je titan, nástrojová ocel, nerezová ocel. |

| Následné zpracování | Nabídka kompletního zpracování po tisku, jako je HIP, obrábění, leštění. |

| Postupy kvality | Certifikát ISO 9001 nebo AS9100 s přísnými procesy zajištění kvality |

| Zkušenosti s aplikacemi | Odborné znalosti a případové studie v cílových aplikacích, jako je letectví, automobilový průmysl, zdravotnictví. |

| Podpora designu | Schopnost navrhovat a optimalizovat díly pro výrobu pomocí AM |

| Předběžné časy | Schopnost dodávat vzorky a výrobní díly v požadovaných termínech. |

| Příprava souborů | Přijímání standardních formátů CAD a polygonových souborů s analýzou návrhu |

| Služby po dokončení stavby | Čištění, tepelné zpracování, povrchová úprava, povlakování |

| Další služby | Kontrola, rychlé prototypování, mostní nástroje, odlitky, lisování |

| Stanovení cen | Konkurenceschopné a škálovatelné ceny pro různé objemy výroby |

| Umístění | Blízkost pro logistiku dodavatelského řetězce a komunikaci |

Výběr poskytovatele služeb s komplexními schopnostmi od návrhu až po následné zpracování zajišťuje vysokou kvalitu výsledků. Prověření případových studií a návštěva zařízení pomáhá ověřit zkušenosti.

Nejčastější dotazy

Otázka: Jaké materiály lze tisknout pomocí technologie SLM?

Odpověď: SLM dokáže zpracovávat celou řadu reaktivních kovů, jako je nerezová ocel, nástrojová ocel, titanové slitiny, niklové superslitiny, hliníkové slitiny a kobalt-chrom. Nejoblíbenějšími materiály SLM jsou titan Ti6Al4V a hliník AlSi10Mg.

Otázka: Jak přesný je 3D tisk pomocí SLM?

Odpověď: SLM obvykle poskytuje přesnost kolem 0,1-0,2 mm. I když je tato tolerance nižší než u CNC obrábění, následné zpracování, jako je obrábění a leštění, může přesnost zlepšit. Velikost prvků pod 0,3 mm se nedoporučuje.

Otázka: V jakých odvětvích se používá aditivní výroba SLM?

Odpověď: Letecký, lékařský, zubní, automobilový a průmyslový průmysl jsou dnes hlavními uživateli technologie SLM díky výhodám, jako je odlehčení, konsolidace dílů, hromadné přizpůsobení a rychlá doba realizace.

Otázka: Jaké následné zpracování je nutné po tisku SLM?

Odpověď: Mezi běžné zpracování po tisku patří odstranění podpěr, tepelné zpracování pro uvolnění napětí, lisování za tepla (HIP), CNC obrábění, leštění a lakování. Požadavky závisí na aplikaci, materiálu a potřebách povrchové úpravy.

Otázka: Jak drahý je 3D tisk kovů pomocí SLM?

Odpověď: Průmyslové systémy SLM se pohybují od $100 000 do více než $1 milionu v závislosti na objemu výroby, výkonu laseru a funkcích. Materiálové náklady na kovový prášek mohou být 2 až 5krát vyšší než náklady na surový materiál. Celkové náklady se však snižují.

Otázka: Lze pomocí SLM tisknout převisy a složité tvary?

Odpověď: Ano, pomocí SLM lze tisknout geometrie, jako jsou převisy, mříže a tenké stěny, a to pomocí podpůrných struktur. Je třeba pečlivé orientace, aby se zabránilo deformaci a vyvážily se požadavky na podporu.

Otázka: Jaký software se používá pro tisk SLM?

Odpověď: Tiskárny SLM se dodávají s proprietárním softwarem pro tisk. Další software se používá pro návrh, opravu souborů, simulaci, přípravu sestavení, vkládání, správu sestavení a řízení kvality.

Otázka: Jak dlouho trvá 3D tisk dílu pomocí SLM?

Odpověď: Doba tisku se pohybuje od hodin do dnů v závislosti na velikosti dílu, složitosti geometrie a parametrech tisku. U kovových dílů pracují SLM tiskárny obvykle s rychlostí tisku od 5 do 100 cm3/hod. Větší díly se tisknou déle.

Otázka: Vyrábí SLM bezpečné a funkční kovové díly pro konečné použití?

Odpověď: Ano, při správném návrhu a zpracování lze pomocí SLM vyrábět plně hutné kovové díly, které splňují nebo převyšují materiálové vlastnosti tradičně vyráběných dílů pro funkční konečné použití v náročných aplikacích.

Sdílet na

MET3DP Technology Co., LTD je předním poskytovatelem řešení aditivní výroby se sídlem v Qingdao v Číně. Naše společnost se specializuje na zařízení pro 3D tisk a vysoce výkonné kovové prášky pro průmyslové aplikace.

Dotaz k získání nejlepší ceny a přizpůsobeného řešení pro vaše podnikání!

Související články

Vysoce výkonné segmenty lopatek trysek: Revoluce v účinnosti turbín díky 3D tisku z kovu

Přečtěte si více "O Met3DP

Nedávná aktualizace

Náš produkt

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731