Prášek TC4: Technický přehled

Obsah

Prášek TC4, známý také jako karbid titanu, je extrémně tvrdý keramický materiál složený z titanu a uhlíku. Vyznačuje se vysokou tvrdostí, vynikající odolností proti opotřebení, dobrou tepelnou vodivostí a vysokou odolností proti chemickému působení. Prášek TC4 má řadu aplikací v různých průmyslových odvětvích, včetně leteckého a automobilového průmyslu, vojenství, nástrojů pro řezání a tváření kovů a dalších.

Složení prášku TC4

TC4 powder contains both titanium and carbon in varying proportions based on the grade. The titanium carbide chemical formula is TiC, but commercial TC4 powder can have carbon content ranging from 6.25% to 11.7% by weight.

| Živel | Hmotnost % |

|---|---|

| titan (Ti) | 88.3 – 93.75 |

| uhlík (C) | 6.25 – 11.7 |

By controlling the ratio of titanium to carbon, manufacturers can tailor the properties like hardness, toughness, and thermal conductivity. Higher carbon TC4 grades have higher hardness whereas lower carbon variants have greater toughness.

Properties and Characteristics of TC4 Powder

TC4 powder stands out due to its exceptional hardness and wear properties combined with good corrosion resistance. Here are the key technical characteristics and capabilities:

| Vlastnictví | Podrobnosti |

|---|---|

| Tvrdost | 2800-3100 HV, up to 3500 HV for high carbon variants |

| Hustota | 4.9 – 5.2 g/cm3 |

| Bod tání | 3160°C |

| Tepelná vodivost | ~35 W/m-K |

| Koeficient tepelné roztažnosti | 7.4 x 10-6/K |

| Youngův modul | 450 GPa |

| Pevnost v tlaku | 1.7 – 3.5 GPa |

| Chemická odolnost | Resistant to acids, bases, salts, oxidizing environments up to 800°C |

The unparalleled hardness makes TC4 ideal for wear protection and cutting applications. It retains strength and corrosion resistance at high temperatures. The high thermal conductivity improves heat dissipation in tools and inserts.

Specifications and Grades of TC4 Powder

TC4 powder is available in a range of particle sizes, carbon content, and purity levels to meet application requirements:

| Specifikace | Podrobnosti |

|---|---|

| Velikost částic | 0.5 – 45 microns |

| Obsah uhlíku | Low (6.25%), Medium (8%), High (10-11.7%) |

| Čistota | Up to 99% |

| Krystalová struktura | Cubic |

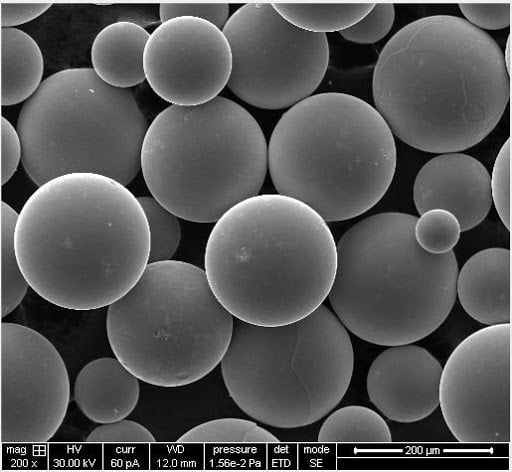

| Morfologie prášku | Angular, granular, spherical |

| Známky | R, P, S, M |

| Normy | ISO, RoHS |

Common TC4 powder grades include:

- Grade R – For sintered products with medium carbon 8%

- Grade P – High purity for special applications

- Grade S – For spraying and welding products

- Grade M – For molding and pressing

Higher purity, controlled particle size distribution, and consistent morphology results in higher quality sintered parts.

Applications and Uses of TC4 Powder

The unique properties of TC4 powder make it suitable for the following applications:

| Průmysl | Aplikace |

|---|---|

| Řezání kovů | Indexable inserts, end mills, drills, reamers |

| Tváření kovů | Extrusion dies, swaging dies, wire drawing dies |

| Těžba | Rock drill bits, well drilling inserts |

| Automobilový průmysl | Camshafts, valves, seals |

| Aerospace | Air seals, engine components |

| Elektronika | Thermal conductors, contacts |

| Textil | Textile machinery parts |

| Čerpadla | Seals, bearings |

| Lékařský | Chirurgické nástroje, implantáty |

The automotive sector uses TC4 powder for cams, valves and other engine components needing heat and wear resistance. The aerospace industry relies on it for air seals needing stability at high temperatures. TC4 powder also makes excellent cutting inserts with increased tool life.

TC4 Powder vs. Alternatives

Here is how TC4 powder compares to other hard materials in terms of properties and performance:

| Vlastnictví | TC4 | Karbid wolframu | Karbid křemíku |

|---|---|---|---|

| Tvrdost | 2800 – 3500 HV | 1300 – 1900 HV | 2300 – 3000 HV |

| Houževnatost | Střední | Vyšší | Dolní |

| Tepelná vodivost | Vyšší | Dolní | Vyšší |

| Chemická odolnost | Vynikající | Špatný | Vynikající |

| Odolnost proti oxidaci | Dobrý | Vynikající | Dobrý |

| Náklady | Střední | Vyšší | Dolní |

Advantages of TC4 powder:

- Extremely hard with excellent wear resistance

- Better corrosion resistance than tungsten carbide

- More thermally conductive than tungsten carbide

- Lower cost than tungsten carbide

Limitations of TC4 powder:

- More brittle than tungsten carbide, prone to chipping

- Not as chemically inert as silicon carbide

- Lower temperature stability than silicon carbide

So TC4 provides the best combination of hardness, toughness, thermal properties and cost for most applications. It outperforms tungsten carbide for wear protection and silicon carbide for high temperature stability.

TC4 Powder Pricing

TC4 powder is more expensive than titanium powder but lower cost compared to tungsten carbide powder. Here are typical prices per kg:

| Třída | Čistota | Cena ($/kg) |

|---|---|---|

| R | 99% | 70 – 90 |

| P | 99.5% | 100 – 130 |

| S | 97% | 50 – 70 |

| M | 96% | 40 – 60 |

Ceny se liší podle:

- Purity and oxygen/nitrogen content

- Distribuce velikosti částic

- Powder morphology (angular, spherical)

- Nákupní množství

- Značka dodavatele

High purity TC4 powder with controlled particle sizes can cost up to $130/kg whereas lower purity grades for pressing or welding start around $40/kg.

Where to Buy TC4 Powder

Here are some of the leading global suppliers manufacturing and selling TC4 titanium carbide powder:

| Dodavatel | Umístění |

|---|---|

| Micron Metals | USA |

| Atlantik vybavení inženýrů | USA |

| Met3DP | Čína |

| I-Matec | Německo |

| Pokročilé materiály Inframat | USA |

| Beijing BoYu Tech | Čína |

When selecting a TC4 powder supplier, consider:

- Reputation and years in business

- Certifikace kvality

- Úrovně čistoty

- Particle size control

- Morfologie prášku

- Výrobní kapacita

- Stanovení cen

- Customer service and technical support

Established companies like Micron Metals, ZhuZhou GuangYuan and Inframat Advanced Materials are leading producers with strict quality control and competitive pricing.

TC4 Powder: FAQs

Q: What is the difference between TC4 and TC16 powder grades?

A: TC16 powder has lower carbon content around 6.25% while TC4 powder has medium carbon around 8%. So TC16 has higher toughness while TC4 is harder.

Q: Is TC4 powder toxic?

A: TC4 powder is considered relatively non-toxic. But it may cause irritation upon contact with skin or eyes. Proper PPE should be used when handling.

Q: What is the best way to make TC4 parts?

A: Most TC4 components are made by sintering TC4 powder. Cold pressing and hot isostatic pressing can also be used. CVD deposition of TC4 is also possible.

Q: What industries use TC4 powder the most?

A: Cutting tools, aerospace engine parts, automotive components, and mining tools account for the bulk of TC4 powder consumption. The combination of hardness, wear resistance and temperature capabilities make it ideal for these applications.

Q: Does TC4 powder rust?

A: No, TC4 powder does not rust or corrode easily. It offers excellent corrosion resistance due to the presence of stable titanium carbide. TC4 retains its properties in a wide range of chemicals.

Q: Is TC4 powder fine grain or coarse?

A: TC4 powder is available in both fine micrograin sizes and coarser grain sizes. Fine powder below 10 microns is preferred for sintering while coarser 20-45 micron powder is used for welding or thermal spraying.

Q: Can TC4 powder be 3D printed?

A: Yes, advanced binder jetting and laser powder bed fusion techniques allow 3D printing complex geometries using TC4 powder for added hardness, strength, and wear resistance.

Sdílet na

MET3DP Technology Co., LTD je předním poskytovatelem řešení aditivní výroby se sídlem v Qingdao v Číně. Naše společnost se specializuje na zařízení pro 3D tisk a vysoce výkonné kovové prášky pro průmyslové aplikace.

Dotaz k získání nejlepší ceny a přizpůsobeného řešení pro vaše podnikání!

Související články

Vysoce výkonné segmenty lopatek trysek: Revoluce v účinnosti turbín díky 3D tisku z kovu

Přečtěte si více "O Met3DP

Nedávná aktualizace

Náš produkt

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731