Stroje VIGA

Obsah

Když mluvíme o Stroje VIGA, ponoříme se do světa pokročilé technologie výroby kovového prášku, která způsobila revoluci v různých průmyslových odvětvích. V tomto článku prozkoumáme vše, co potřebujete vědět o strojích VIGA, od přehledu po podrobné specifikace, aplikace a dokonce i sekci FAQ. Takže, pojďme začít!

Přehled strojů VIGA

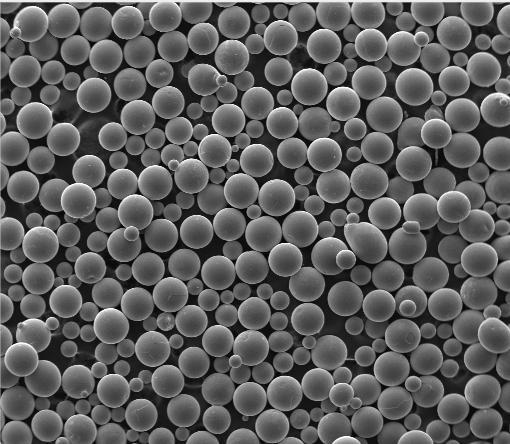

Stroje VIGA (Vacuum Inert Gas Atomization) jsou špičková zařízení používaná pro výrobu vysoce kvalitních kovových prášků. Tyto prášky jsou kritické pro aplikace v leteckém, automobilovém, biomedicínském a aditivním průmyslu. Technologie VIGA vyniká svou schopností produkovat prášky s vynikající tekutostí, kulovitým tvarem a řízenou distribucí velikosti částic.

Klíčové vlastnosti strojů VIGA

- Kovové prášky vysoké čistoty: Stroje VIGA pracují ve vakuu nebo v prostředí inertního plynu, čímž se minimalizuje kontaminace.

- Sférické částice: Zajišťuje vynikající tekutost a hustotu balení.

- Řízená velikost částic: Nastavitelné parametry atomizace pro přizpůsobené charakteristiky prášku.

- Široká škála materiálů: Vhodné pro různé kovy a slitiny včetně titanu, nerezové oceli a superslitin.

Typy a modely kovových prášků Produkce Stroje VIGA

Zde jsou konkrétní modely kovového prášku vyráběné stroji VIGA spolu s jejich popisy:

| Model kovového prášku | Složení | Vlastnosti | Aplikace |

|---|---|---|---|

| Ti-6Al-4V | Slitina titanu | Vysoká pevnost, odolnost proti korozi, biokompatibilita | Letectví a kosmonautika, lékařské implantáty |

| Nerezová ocel 316L | Slitina Fe-Cr-Ni-Mo | Vynikající odolnost proti korozi, dobré mechanické vlastnosti | Biomedicínská zařízení, námořní aplikace |

| IN718 | Superslitina na bázi niklu | Pevnost při vysokých teplotách, odolná proti oxidaci | Turbínových lopatek, leteckých komponentů |

| AlSi 10Mg | Hliníková slitina | Lehké, dobré tepelné vlastnosti | Automobilový a letecký průmysl |

| CoCrMo | Slitina kobaltu, chromu a molybdenu | Vysoká odolnost proti opotřebení, biokompatibilní | Lékařské implantáty, zubní protetika |

| CuCrZr | Slitina měď-chrom-zirkon | Vysoká elektrická vodivost, dobrá mechanická pevnost | Elektrické komponenty, svařovací elektrody |

| Maraging Steel (18Ni300) | Slitina Fe-Ni-Co-Mo-Ti | Velmi vysoká pevnost, dobrá houževnatost | Nástroje, vysoce výkonná ozubená kola |

| FeNiCo | Slitina železa-nikl-kobalt | Magnetické vlastnosti, dobrá mechanická pevnost | Magnetické součástky, letectví a kosmonautika |

| NiTi (Nitinol) | Slitina niklu a titanu | Tvarová paměť, superelasticita | Lékařská zařízení, aktuátory |

| Hastelloy X | Slitina nikl-chrom-molybden | Pevnost při vysokých teplotách, odolná proti korozi | Součásti plynových turbín, chemické zpracování |

Aplikace strojů VIGA

Stroje VIGA se používají v celé řadě průmyslových odvětví díky své schopnosti vyrábět vysoce kvalitní kovové prášky. Zde je podrobný pohled na jejich aplikace:

| Průmysl | Aplikace |

|---|---|

| Aerospace | Lopatky turbíny, konstrukční součásti, spojovací materiál |

| Automobilový průmysl | Lehké součásti, díly motoru |

| Biomedicína | Implantáty, protézy, chirurgické nástroje |

| Aditivní výroba | 3D tiskové prášky, prototypování, složité geometrie |

| Energie | Součásti turbín, díly jaderných reaktorů |

| Elektronika | Vodivé pasty, magnetické součástky |

Výhody strojů VIGA

- Vysoká čistota a čistota: Provoz ve vakuu nebo prostředí inertního plynu snižuje kontaminaci, což vede k vysoce čistým kovovým práškům.

- Řízená distribuce velikosti částic: Umožňuje přizpůsobení pro konkrétní aplikace a zvyšuje výkon.

- Sférické částice: Zlepšuje tekutost a hustotu balení, což je klíčové pro aditivní výrobu.

- Všestranný sortiment materiálů: Dokáže zpracovávat různé kovy a slitiny, takže jsou vhodné pro různá průmyslová odvětví.

Nevýhody Stroje VIGA

- Vysoké počáteční náklady: Pořízení a nastavení strojů VIGA je nákladné.

- Složitý provoz: Vyžaduje kvalifikovanou obsluhu a pravidelnou údržbu.

- Energeticky náročné: Proces vyžaduje značné množství energie a zvyšuje provozní náklady.

Podrobné specifikace strojů VIGA

| Specifikace | Podrobnosti |

|---|---|

| Materiálová způsobilost | Titan, nerezová ocel, slitiny niklu, slitiny hliníku, slitiny kobaltu a chrómu atd. |

| Atomizační plyn | Argon, dusík, helium |

| Provozní tlak | Až 150 barů |

| Rozsah velikosti částic | 10 – 200 mikronů |

| Rychlost výroby | Až 500 kg/hod |

| Úroveň vakua | Až 10^-5 mbar |

| Spotřeba energie | 100 – 500 kW |

| Chladicí systém | Vodou chlazené |

Porovnání výhod a nevýhod Stroje VIGA

| Výhody | Nevýhody |

|---|---|

| Kovové prášky vysoké čistoty | Vysoké počáteční náklady |

| Sférické částice | Složitý provoz |

| Řízená velikost částic | Energeticky náročné |

| Všestranný sortiment materiálů | Vyžaduje kvalifikovanou obsluhu |

| Vynikající tekutost | Nutná pravidelná údržba |

FAQ

| Otázka | Odpovědět |

|---|---|

| K čemu se stroje VIGA používají? | Produkce vysoce kvalitních kovových prášků pro různá průmyslová odvětví včetně letectví, automobilového průmyslu a biomedicíny. |

| Jak stroje VIGA fungují? | Používají vakuum nebo inertní plyn k atomizaci roztaveného kovu na jemné prášky s kulovitými částicemi. |

| Jaké kovy mohou stroje VIGA zpracovávat? | Titan, nerezová ocel, slitiny niklu, slitiny hliníku a další. |

| Jaký je rozsah velikosti částic vyráběných prášků? | Typicky mezi 10 až 200 mikrony. |

| Jsou stroje VIGA drahé? | Ano, mají vysoké počáteční náklady v rozmezí od $900 000 do více než $2 500 000. |

| Jaké jsou výhody používání strojů VIGA? | Vysoká čistota, kontrolovaná velikost částic, vynikající tekutost a všestrannost při zpracování materiálu. |

| Jaká průmyslová odvětví těží z prášků VIGA? | Letecký a kosmický průmysl, automobilový průmysl, biomedicína, aditivní výroba, energetika a elektronika. |

| Mohou stroje VIGA vyrábět prášky pro 3D tisk? | Ano, jsou ideální pro výrobu vysoce kvalitních prášků pro aditivní výrobu. |

| Vyžadují stroje VIGA speciální údržbu? | Ano, pro zajištění optimálního výkonu vyžadují pravidelnou údržbu a kvalifikovanou obsluhu. |

| Jaké se běžně používají atomizační plyny? | Pro atomizaci se běžně používá argon, dusík a helium. |

Závěr

Stroje VIGA představují vrchol v technologii výroby kovových prášků a poskytují vysoce kvalitní prášky nezbytné pro moderní průmyslová odvětví. Jejich schopnost produkovat sférické, vysoce čisté a přesně kontrolované prášky je činí neocenitelnými pro aplikace od letectví až po biomedicínská zařízení. Navzdory vysokým počátečním nákladům a složitosti jsou výhody, které nabízejí, pokud jde o materiálové vlastnosti a výkon, bezkonkurenční. Pokud se chcete ponořit do výroby vysoce kvalitního kovového prášku, pochopení a využití strojů VIGA může změnit hru.

Sdílet na

MET3DP Technology Co., LTD je předním poskytovatelem řešení aditivní výroby se sídlem v Qingdao v Číně. Naše společnost se specializuje na zařízení pro 3D tisk a vysoce výkonné kovové prášky pro průmyslové aplikace.

Dotaz k získání nejlepší ceny a přizpůsobeného řešení pro vaše podnikání!

Související články

Vysoce výkonné segmenty lopatek trysek: Revoluce v účinnosti turbín díky 3D tisku z kovu

Přečtěte si více "O Met3DP

Nedávná aktualizace

Náš produkt

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731