積層造形(AM)技術による摩耗した部品の修復:産業修理のための費用対効果の高いソリューション

目次

1. Introduction: The Growing Demand for Component Restoration in Industrial Sectors

In today’s industrial landscape, equipment reliability and operational uptime are more critical than ever. Across sectors like aerospace, automotive, energy, and manufacturing, the failure of a single component can lead to costly downtime, production delays, and even safety risks. Traditional methods of component repair or full replacement are often time-intensive, expensive, and limited by supply chain constraints.

This is where アディティブ・マニュファクチャリング(AM)—commonly referred to as メタル 3Dプリンティング—is reshaping the way worn-out components are restored. Rather than scrapping valuable parts, industries can now repair, rebuild, and reinforce コンポーネント precision-engineered metal layers, restoring them to like-new condition or even enhancing their original properties.

The Traditional Repair Challenge

| Repair Method | 制限事項 |

|---|---|

| Welding/Brazing | Inconsistent quality, heat distortion, limited to surface repair |

| 機械加工 | Material waste, not suitable for complex geometries |

| Part Replacement | Long lead times, high costs, especially for custom or legacy components |

アディティブ・マニュファクチャリングがゲームチェンジャーとなる理由

- Restores parts to original specifications or better

- Minimizes downtime with faster turnaround times

- Reduces cost compared to procuring new components

- 環境に優しい by extending the lifecycle of parts

As industrial maintenance evolves, component restoration via AM になりつつある strategic tool for cost control, sustainability, and operational efficiency.

2. Market Trends: How Additive Manufacturing is Transforming Equipment Maintenance

の採用 金属積層造形 is surging, not only for prototyping and production but also for repairing high-value, mission-critical components. According to industry reports, the global market for 3D printing in maintenance and repair is growing at over 20% 年平均成長率, with increasing applications in aerospace, automotive, oil & gas, and power generation.

主要統計

| メートル | 価値 |

|---|---|

| Global AM Repair Market Size (2023) | $1.2 Billion+ |

| Expected Market Size by 2028 | $3.5 Billion |

| Average Cost Savings per Repaired Component | 30%–70% |

| Reduction in Lead Time Compared to New Parts | 90%まで |

Industries Leading Adoption

- 航空宇宙 Repairing turbine blades, combustion chambers, and brackets

- 自動車: Restoring molds, dies, and engine components

- 石油・ガス Refurbishing impellers, pump housings, and valves

- Industrial Manufacturing: Rebuilding worn jigs, fixtures, and tools

Emerging Trends in AM Repair

- Digital Twin Integration: Scanning worn parts to create digital models enables precise restoration.

- On-Demand Spare Parts: Companies are building digital warehouses of printable parts.

- Sustainable Repair Models: Using AM reduces scrap and contributes to circular manufacturing.

🌐 Want to learn more about how additive manufacturing supports industrial transformation? Visit Metal3DPの金属3Dプリントソリューション.

3. Key Benefits of Using Additive Manufacturing for Repair Applications

Additive manufacturing offers a paradigm shift from reactive maintenance to proactive, precision-based restoration. For B2B buyers and industrial stakeholders, the advantages go far beyond basic repair.

✅ Major Benefits of AM-Based Component Restoration

- Lower Downtime & Maintenance Costs

- Avoid long procurement cycles for replacement parts

- Quick turnaround with local or in-house AM repair capacity

- Restoration of Obsolete or Discontinued Parts

- Rebuild components no longer available from OEMs

- Extend the usable life of expensive equipment

- 優れた機械的特性

- Metallurgical bonding ensures high strength and durability

- Multi-material capabilities allow for enhanced wear resistance

- 精度と複雑さ

- Rebuild parts with complex geometries and tight tolerances

- Ideal for aerospace and medical components

- Sustainability & Material Efficiency

- Minimal material waste compared to subtractive methods

- Supports circular manufacturing models

🛠 Real-World Examples of AM Repair Benefits

| 申し込み | Traditional Method | AM-Based Restoration | コスト削減 | Lead Time Reduction |

|---|---|---|---|---|

| Turbine Blade | 交換 | レーザー金属蒸着 | 60% | 80% |

| Pump Impeller | 機械加工 | 直接エネルギー蒸着 | 45% | 75% |

| Injection Mold | 溶接 | パウダーベッド・フュージョン | 35% | 60% |

🏭 Looking for a reliable AM partner? Learn more about Metal3DP’s full capabilities in metal 3D printing equipment and powder technology.

4. Top Industries Leveraging AM for Component Restoration

Additive Manufacturing (AM) is not limited to prototyping or small-batch custom parts. Today, it’s a mainstream industrial solution for restoring worn or damaged components across a range of critical sectors. Below is an industry-specific look at how AM is transforming maintenance, repair, and overhaul (MRO) workflows.

🛫 Aerospace Industry

The aerospace sector was one of the earliest adopters of AM for restoration due to its need for tight tolerances, lightweight parts, and high performance under extreme conditions.

- Common Restored Components:

- タービンブレード

- Engine combustion liners

- 燃料ノズル

- Brackets and mounts

- メリット:

- Maintain airworthiness of critical parts

- Reduce aircraft downtime

- Eliminate the need to scrap expensive components

🚗 Automotive Industry

OEMs and Tier 1 suppliers are using AM to rebuild tooling, molds, and engine parts, especially in motorsport and high-performance applications.

- Common Restored Components:

- Die-casting molds

- Engine blocks and cylinder heads

- Tooling inserts and jigs

- メリット:

- Extend tool life

- Improve thermal performance through conformal cooling

- Quick turnaround during production cycles

⚙️ Industrial Manufacturing

From robotics to heavy equipment, AM supports just-in-time maintenance by enabling the restoration of worn-out factory components.

- Common Restored Components:

- Gearboxes

- シャフト

- Rollers

- Bearings housings

- メリット:

- Reduce spare part inventory

- Restore obsolete parts

- Improve mechanical properties with custom alloys

⚡ Energy Sector (Oil & Gas, Power Generation)

In harsh environments where wear and corrosion are common, AM helps rebuild high-value parts と corrosion-resistant alloys, increasing uptime and safety.

- Common Restored Components:

- Impellers, valves, diffusers

- Turbine casings

- ポンプハウジング

- メリット:

- Reduce replacement costs

- Enhance wear and corrosion resistance

- Reduce lead times for large, complex components

5. Why Additive Manufacturing Outperforms Traditional Repair Methods

Traditional component repair methods like welding, machining, and brazing have served engineers for decades—but they have limitations when it comes to precision, repeatability, and material integrity. In contrast, AM-based repair techniques offer a data-driven, digitally controlled process that delivers consistent, high-quality results.

⚖️ Side-by-Side Comparison: AM vs. Traditional Repair

| ファクター | Traditional Repair Methods | Additive Manufacturing Repair |

|---|---|---|

| Precision and Tolerance | 限定 | Ultra-precise (micron-scale) |

| Heat-Affected Zone | Large, risk of warping | Minimal, localized heating |

| 材質の適合性 | 限定 | 幅広い合金 |

| 表面仕上げ | May require extensive machining | Near-net-shape possible |

| デザインの柔軟性 | 低い | High (complex geometries) |

| Data Traceability | Manual Documentation | Digital Workflow & QA Logs |

🔧 Metallurgical Bonding Advantages

Unlike cladding or welding, AM processes often achieve metallurgical bonding between the deposition and the substrate. This leads to:

- Higher fatigue life

- Better mechanical integrity

- Seamless material integration

🧪 Enhanced Properties Through Alloy Selection

AM allows engineers to tailor the material composition during the repair process. For example:

- Use of Ti6Al4V for aerospace parts with high strength-to-weight ratio

- CoCrMo合金 for wear-resistant energy components

- ニッケル基超合金 for high-temperature turbine repairs

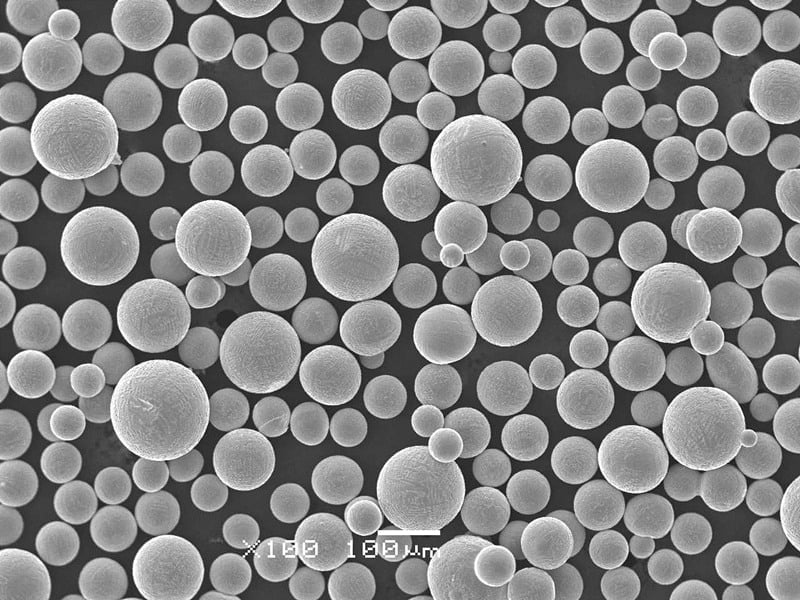

Met3DP offers a full catalog of 高性能金属粉末 optimized for various repair applications. These include:

- Ti, TiAl, TiNbZr, and TiTa alloys

- CoCrMo, stainless steels, and 超合金

- Custom alloy development for industry-specific needs

🔗 Explore Met3DP’s product portfolio of high-quality metal powders 産業用。

6. Why Choose Metal3DP for Additive Component Restoration

With decades of expertise and a full-stack AM ecosystem, メタル3DP stands out as a trusted partner for industrial component restoration. Whether you’re a maintenance engineer, procurement managerあるいは OEM distributor, Metal3DP offers the technology, materials, and support to make AM-based repair practical and profitable.

🏭 What Sets Metal3DP Apart

| 特徴 | Metal3DPの利点 |

|---|---|

| 🇨🇳 Headquartered in Qingdao, China | Global reach with local expertise |

| 🖨️ Large-Format SEBM Printers | High precision, high volume, and high repeatability |

| ⚗️ Advanced Powder Production | PREP + Gas Atomization = Spherical powders with excellent flowability |

| 🧪 Custom Alloy Development | Tailored solutions for aerospace, medical, and energy sectors |

| 🔍 Application Consulting | End-to-end support from scanning to post-processing |

💡 Metal3DP Capabilities Snapshot

- 付加製造装置: SEBM and PBF systems built for industrial scale

- 金属粉: Titanium alloys, superalloys, stainless steels, and custom blends

- Repair Services: Engineering support for reverse engineering and component restoration

- 品質保証: Fully traceable production with ISO-grade standards

🧠 Learn more about Metal3DP’s industry-leading equipment and powder solutions on the 印刷方法ページ.

📈 Partnering for Growth

Metal3DP collaborates with:

- Aerospace OEMs on turbine blade restoration

- Automotive suppliers for tool and mold life extension

- Energy companies on high-wear component rebuilds

Whether you’re looking to build in-house AM capability or outsource restoration, Metal3DP is your strategic partner.

7. How to Implement AM-Based Repairs in Your Supply Chain

For many B2B companies—especially in aerospace, automotive, and industrial sectors—the shift to AM-based component restoration isn’t just a technical upgrade; it’s a strategic move to reduce downtime, control costs, and improve sustainability.

Metal3DP makes it easy for OEMs, MROs, and industrial maintenance teams to integrate AM into their repair workflows. Whether you’re outsourcing to a service provider or investing in in-house capabilities, here’s how the process works.

🛠 Step-by-Step AM Repair Workflow

| ステップ | 説明 | Tools & Tech |

|---|---|---|

| 1. Damage Inspection | Identify wear or failure zones using NDT or CT scanning | X-ray CT, 3D scanning |

| 2. Digital Modeling | Create or modify CAD models using reverse engineering | CAD software, digital twin |

| 3. Material Selection | Choose optimal alloy based on application & performance | Ti6Al4V, CoCrMo, Ni alloys |

| 4. Additive Repair Printing | Rebuild worn areas layer by layer using SEBM/PBF | Metal3DP printers |

| 5.後処理 | Heat treatment, CNC machining, surface finishing | HIP, EDM, polishing |

| 6. QA & Certification | Inspect and validate to ISO, ASTM or OEM standards | CMMs, metallurgical testing |

🧩 Choosing the Right Repair Modality

Different AM technologies offer unique benefits for repairs. Metal3DP supports the following methods:

| 方法 | Best Use Cases | メリット |

|---|---|---|

| SEBM(選択的電子ビーム溶解) | 航空宇宙、医療用インプラント | High-density, fast build, minimal residual stress |

| PBF (Powder Bed Fusion) | Automotive, molds, dental | Fine detail, high accuracy |

| DED (Directed Energy Deposition) | Large components, energy sector | Ideal for adding material to existing parts |

🔍 Want to learn which AM method is best for your components? Visit our overview of AM printing methods to compare capabilities.

📦 How to Get Started with Metal3DP

- Contact our engineering team for a free consultation

- Send your worn components or 3D scans for evaluation

- Choose from our catalog of industrial-grade printers and powders

- Start restoring high-value parts with confidence

8. Success Stories: Real-World Use Cases of AM in Component Repair

Additive manufacturing for repair isn’t just theoretical—it’s actively transforming maintenance programs in some of the world’s most demanding industries. Here are real-world examples of how companies have leveraged Metal3DP’s technology for high-impact results.

✈️ Aerospace: Turbine Blade Repair

チャレンジ:

A Tier 1 aerospace supplier faced high costs and long lead times for turbine blade replacements (Ti6Al4V alloy).

解決策

Using Metal3DP’s SEBM technology and high-purity Ti6Al4V powder, the worn edges of the blade were rebuilt layer by layer, achieving metallurgical bonding and OEM-spec geometry.

結果:

- 70% cost savings

- 85% reduction in downtime

- 100% pass rate in quality inspection

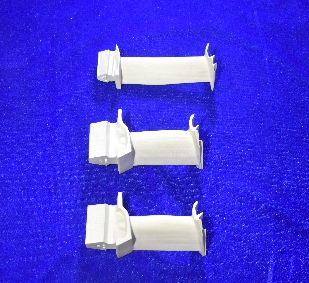

⚙️ Automotive: Mold Core Refurbishment

チャレンジ:

An automotive OEM needed to extend the life of injection mold cores that suffered thermal cracking and wear.

解決策

Metal3DP provided CoCrMo spherical powder, and the customer used PBF printing to restore the damaged regions. Post-processing included polishing and CNC finishing.

結果:

- Increased mold life by 40%

- Reduced retooling costs

- Improved thermal performance

⚡ Oil & Gas: Pump Impeller Restoration

チャレンジ:

A refinery required urgent repair of a custom impeller. OEM replacement would take 12 weeks and cost over $40,000.

解決策

Metal3DP reverse-engineered the impeller, printed the damaged region using Ni-based superalloy, and delivered it within 10 days.

結果:

- Saved over $25,000

- Avoided shutdown penalties

- 耐食性の向上

📘 Ready to explore more case studies or discuss your project? Visit our main website to get in touch with our application team.

9. FAQs: Common Questions About Using AM for Industrial Component Repair

Below are frequently asked questions from industrial buyers, engineers, and procurement teams considering additive manufacturing for component restoration.

❓ What types of damage can be repaired using AM?

- Surface wear and erosion

- Cracks and pitting

- Dimensional degradation

- Missing material due to impact or corrosion

❓ Which materials are compatible with AM repair?

Metal3DP offers powders for:

- Titanium alloys (Ti6Al4V, TiAl, TiNbZr, TiTa)

- ステンレス鋼(316L、17-4PH)

- ニッケル基超合金

- コバルトクロム(CoCrMo)

- アルミニウム合金(AlSi10Mg)

❓ What part sizes can be restored?

Our SEBM printers support large-format builds and complex geometries, making them suitable for:

- Small precision tools (medical, dental)

- Mid-size automotive molds and dies

- Large aerospace and energy components

❓ How long does the repair process take?

Typical turnaround times range from:

- 48–72 hours for small parts

- 1~2週間 for complex or custom components

- Same-day service available for emergency cases (contact us)

❓ How does AM repair affect part strength?

AM repairs often restore or exceed original mechanical properties when using proper post-processing and heat treatment. Metal3DP ensures ISO and ASTM compliance across all projects.

🏭 Curious about Metal3DP’s full-scale powder production capabilities? Read how our 高度な粉末製造システム ensure flowability, purity, and consistent particle morphology.

🏁 Conclusion & Call to Action

As industries face rising maintenance costs, supply chain disruptions, and sustainability demands, Additive Manufacturing for component restoration is no longer optional—it’s a competitive necessity.

Metal3DP empowers OEMs, MROs, and industrial buyers to:

✅ Restore high-value parts with precision

✅ Reduce downtime and operational risk

✅ Extend tool and equipment life cycles

✅ Use optimized powders and world-class AM equipment

✅ Build a smarter, more sustainable supply chain

📞 Ready to Transform Your Repair Strategy?

訪問 メタル3DP.com or contact our team to:

- Schedule a component evaluation

- Request a quote for your next repair project

- Consult with our materials and AM experts

🔗 Internal Links Summary:

| アンカーテキスト | Target URL |

|---|---|

| Metal3DPの金属3Dプリントソリューション | https://met3dp.com/metal-3d-printing/ |

| Learn more about Metal3DP’s full capabilities | https://met3dp.com/about-us/ |

| 高品質の金属粉末 | https://met3dp.com/product/ |

| Overview of AM printing methods | https://met3dp.com/printing-methods/ |

| Main website | https://met3dp.com/ |

シェアする

MET3DP Technology Co., LTDは、中国青島に本社を置く積層造形ソリューションのリーディングプロバイダーです。弊社は3Dプリンティング装置と工業用途の高性能金属粉末を専門としています。

関連記事

Met3DPについて

最新情報

製品

3Dプリンティングと積層造形用金属粉末