ガスアトマイズ金属粉

目次

概要 ガスアトマイズ金属粉

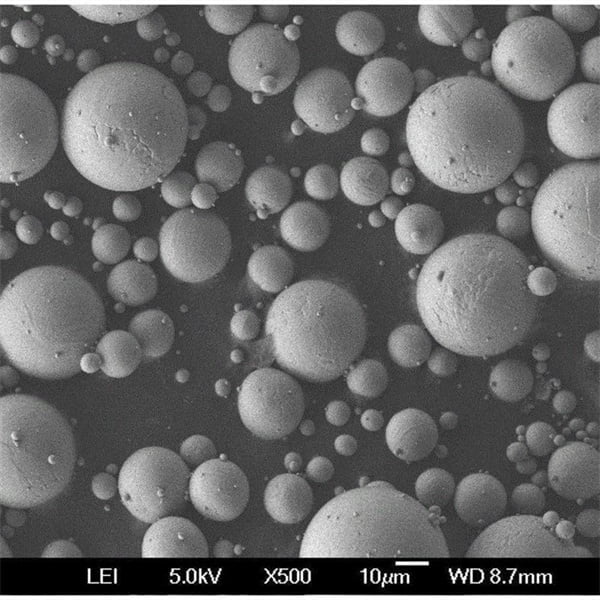

ガスアトマイズ金属粉末とは、溶融合金原料を高速不活性ガスジェットで噴霧化することにより製造される金属微粒子材料のことである。これにより、積層造形や金属射出成形などの用途に理想的な球状の形態が得られます。

ガス噴霧の特徴:

- 粒子形状、粒度分布の優れた制御

- チタン、アルミニウムを含む反応性合金に適用可能

- 先端プロセス用の高純度出発原料を提供

- 熱間静水圧プレス、熱処理用に調整された粉末

- 精密で再現性のある粉体特性をサポート

ガスアトマイズ粉末の組成オプション、粒子品質、使用用途、仕様については、引き続きお読みください。

合金 ガスアトマイズ金属粉末の種類

様々な合金は、微細な球状粉末にガスアトマイズ可能である:

| 合金カテゴリー | 材料 | 作曲 |

|---|---|---|

| ステンレス鋼 | 304、316、17-4ph、303、410 | Fe/Cr/Ni + 微量元素 |

| 工具鋼 | H13、M2、M4 | Fe + V, Mo, W炭化物 |

| コバルト合金 | CoCr、CoCrW、CoCrMo | Co/Cr+タングステン/モリブデン |

| ニッケル合金 | インコネル 625 & 718 | ニッケル/クロム/鉄/モリブデン |

| チタン合金 | Ti-6Al-4V、Ti-6242 | Ti/Al/V/Sn/Zr/Mo |

表1: ガスアトマイズ粉末で市販されている合金系の概要

航空宇宙/バイオメディカル用の特殊積層造形および業界固有の合金には、最低注文数量またはリードタイムが設定されている場合があります。

粉体の特徴

不活性ガスアトマイズにより達成される典型的な粒子特性:

| 特徴 | 詳細 | 意義 |

|---|---|---|

| 粒子形状 | 球形度が高い | 粉体の流動性と充填密度を向上 |

| サイズ範囲 | 10 μm~150 μm | 最終用途に最適化された管理された流通 |

| 構成 | 合金は±0.5wt%以内に維持 | 機械的特性を保持 |

| 純度 | 99.9%まで達成可能 | 汚染物質と介在物の低減 |

| 表面酸化物 | <50 nm厚のパッシベーション層 | 優れた粉体リサイクル性を維持 |

表2: ガスアトマイズ金属粉末の粒子品質の概要

航空宇宙、医療、自動車、工業の各分野における認証ニーズを満たすため、精密な特性を繰り返し生産。

製造工程

- 不活性ガス噴霧化の典型的なステップ:

- 誘導溶解またはアーク溶解は、保護カバーガスの下で合金溶融物を形成する。

- 高純度不活性ガス(ArまたはN2)を専用ノズルから噴射

- 溶融した流れが微細な液滴に分解され、急速に冷却されて粉末になる。

- 粉体は下の回収ホッパーに沈む

- ふるい分けにより分布を正規化

- 保護された雰囲気の中で梱包され、顧客に出荷される

- 重要なプロセスパラメータ:

- ノズル設計 - 粒度分布を支配する

- ガス圧 - 粒子速度と冷却速度に影響する

- 溶融注湯速度 - 粒度分布形状に影響

- 環境(真空か管理雰囲気か)は反応性に依存する。

の応用 ガスアトマイズ金属粉

| 申し込み | メリット | 例 |

|---|---|---|

| 積層造形 | 優れたパウダーフローとパッキングによる高密度部品 | 航空宇宙部品、医療用インプラント |

| 金属射出成形 | 小さな複雑な形状の成形性に優れる | タービンブレード、ノズル部品 |

| 溶射コーティング | 変形可能な粒子の衝突による緻密なコーティング | 耐摩耗性表面 |

| ブレージングペースト | 複雑な形状の接合 | 熱交換器、電気接点 |

| 熱間静水圧プレス | 球状粒子による閉鎖の問題を最小限に抑える | 鋳造タービンブレードの統合 |

| 熱処理前駆体 | オーダーメイドの粒構造 | 析出硬化合金 |

表3: ガスアトマイズ金属粉末の特性を活かしたアプリケーションの概要

ガスアトマイゼーションが提供する一貫性と純度は、再現性が重要な最先端の金属粉末プロセスに適しています。

仕様 ガスアトマイズ金属粉

ガスアトマイズされたパウダーは、様々な標準仕様に対して検証されます:

| スタンダード | 説明 |

|---|---|

| ASTM B214 | 光学顕微鏡による均一性とサテライトの欠如の検証 |

| AMS 7008 | 不活性ガスアトマイズ法を含む航空宇宙材料仕様 |

| ASTM F3049 | AM用金属粉末の特性評価のための標準ガイド |

| ASTM F3056 | 積層造形用ニッケル合金粉末の仕様 |

| ISO 21818 | DMLS/SLM製造グレードステンレス鋼の仕様 |

表4: 不活性ガス噴霧粉体に一般的に適用される業界標準

信頼できる生産者は、各粉末ロットの完全な認証書類と試験結果を提供し、適合性を検証する。

サプライヤーと価格

| サプライヤー | 材料 | 参考価格 |

|---|---|---|

| サンドビック・オスプレイ | Ti合金、Ni合金、工具鋼 | $100+/kg |

| カーペンター添加剤 | ステンレス鋼、コバルト合金、銅 | $50〜$150/kg |

| プラクセア | Ti合金、Al合金、シリコン粉末 | $100+/kg |

| LPWテクノロジー | 工具鋼、ステンレス鋼、インコネル | $50〜$500/kg |

| SLMソリューション | カスタム合金の開発 | $250+/kg |

表5: ガスアトマイズされた金属粉末を供給する企業の選択とおおよその価格

ほとんどのサプライヤーは、2~4週間のリードタイムで少量の標準合金を提供しています。また、ガスアトマイズベンダーとの直接取引により、カスタム処方や独自の粒子最適化も可能です。

賛否両論と代替案

| パラメータ | ガス噴霧 | 水の霧化 | プラズマ霧化 |

|---|---|---|---|

| 粒子形態 | 球形度が高い | より不規則なスフェロイド | ほとんどが球形 |

| 粒度分布 | タイトな配分、テーラブル | より広い分布 | タイトな分配 |

| 適合合金 | ほとんどの市販合金 | 限定合金 | 反応性金属を含む幅広いレンジ |

| kgあたりのコスト | 中程度 $50-150/kg | 1kgあたり$20-100を下回る | より高い $150-500/kg |

| 生産性 | 最大10,000 kg/日 | 非常に高い >50,000 kg/日 | <1,000kg/日 |

表6: ガスアトマイズと代替粉体製造法の比較

ガスアトマイズは、商業生産に適した量の粉末を供給しながら、能力と経済性の最適なバランスを実現します。

制限事項

- 最小バッチサイズでは、100kg以上の材料を使用する必要があり、機械のセットアップを正当化する。

- タングステンのような高融点合金を経済的にアトマイズする能力に限界がある。

- プラズマアトマイズのような球状ではなく、サテライトを含む。

- 酸化膜の厚さは、真空プラズマの代替品よりわずかに厚い。

- ターンキーシステムの初期資本コストは約$1~500万円

- バージン材料と比較して、粉体の取り扱い/保管の改善が必要

よくあるご質問

Q: 部品製造において、ガスアトマイズ粉末はバージン材料と比較してどのような利点がありますか?

A: ガスアトマイズ粉末は優れた一貫性と再現性を提供します。粉末の形態と粒構造を最初からエンジニアリングすることで、航空宇宙や医療分野で業界の最高要件を満たす認定部品を製造する成熟したプロセスを可能にします。

Q: ガスアトマイズされた粉体を取り扱う際には、どのような注意が必要ですか?

A: 酸化しやすい微細な金属材料であるため、不活性な保管および取り扱い手順を推奨する。爆発、吸入、汚染のリスクを最小限に抑えるため、湿度管理されたアルゴン充填グローブボックスや、個人用保護具を着用した作業員が含まれる。水や有機化合物とは絶対に接触させないこと。特別な施設建設は必ずしも必要ではないが、地域の規制が適用される場合がある。

Q: ガスアトマイズ粉体では、ロット間でどの程度の再現性が期待できますか?

A: 信頼できるメーカーは、バッチ間の粉末分布が±10%以内であることを保証しています。許容成分公差が厳しい場合は、同じ粉末サプライヤーであっても、標準的な慣行として再最適化が必要です。分析証明書は一貫性を証明します。

Q: 未使用のガスアトマイズ粉末は、どれくらいの期間保管できますか?

A: ベストプラクティスは、極端な温度を避け、密閉された容器に保護アルゴンでパウダーを保管することです。温度30℃以下、相対湿度50%以下に保ち、酸素と湿気を最小限に抑えれば、パウダーはグローブボックス内で流動性と再利用性を維持するためのリフレッシュサイクルが必要になるまで、何ヶ月ももちます。

Q: 粉体ベンダーは、部品の認定や認証に関してどのような技術サポートを提供していますか?

A: 評判の良いベンダーは、材料科学者やバリデーション担当者を抱えており、粉末の証明書を発行するための試験プロセスを通じて、アプリケーションのガイダンスを行い、部品購入者とのインターフェースを提供しています。彼らは、より要求の厳しい用途での材料の使用を拡大するために、規制基準を満たす再現性を実証することを求めています。実績のあるサプライヤーであれば、詳細な書類とプロトコルを期待してください。

シェアする

MET3DP Technology Co., LTDは、中国青島に本社を置く積層造形ソリューションのリーディングプロバイダーです。弊社は3Dプリンティング装置と工業用途の高性能金属粉末を専門としています。

関連記事

Met3DPについて

最新情報

製品

3Dプリンティングと積層造形用金属粉末