半導体用金属粉末

目次

In the ever-evolving world of semiconductors, the role of metal powders is pivotal. From the creation of microprocessors to the development of advanced memory storage, metal powders are the unsung heroes enabling these technological marvels. This article dives into the intricacies of metal powders for semiconductors, their types, compositions, applications, specifications, and more. Let’s embark on a detailed exploration of this fascinating topic.

Overview of Metal Powder for Semiconductor

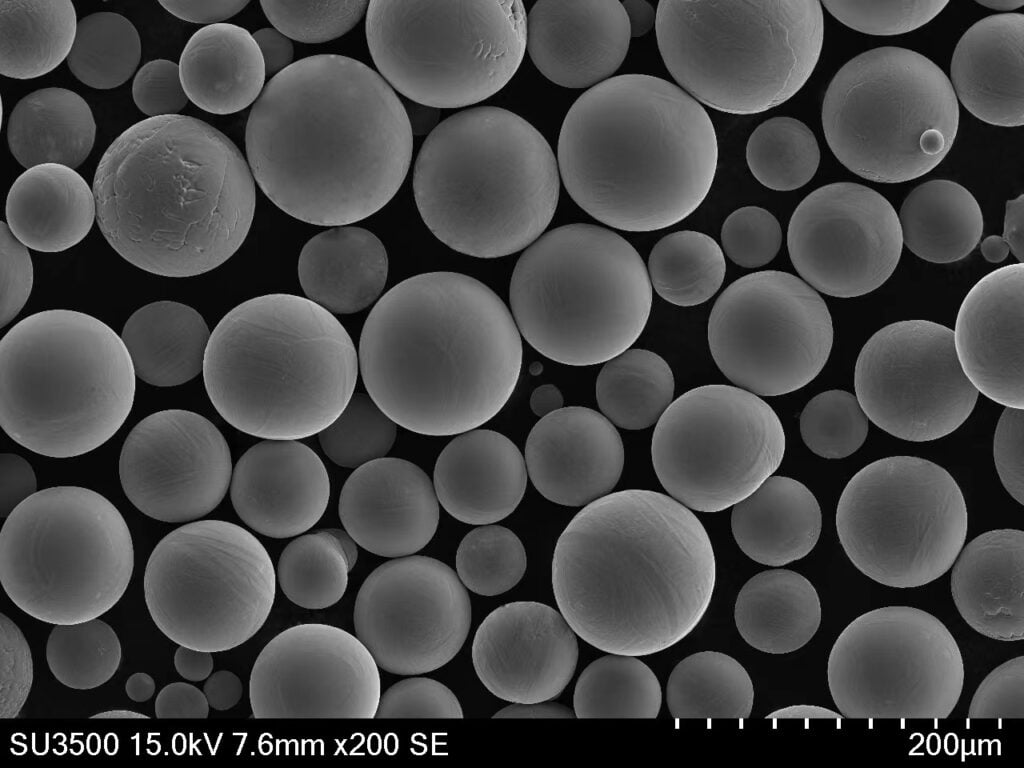

Metal powders are finely divided particles of metals that are used in various applications, including the semiconductor industry. Their importance lies in their unique properties, such as high purity, controlled particle size, and specific surface area, which make them ideal for use in manufacturing semiconductor devices.

重要なポイント

- Metal powders are critical in the semiconductor manufacturing process.

- They offer high purity and controlled particle sizes.

- Used in the creation of microprocessors, memory storage, and other semiconductor devices.

Types of Metal Powder for Semiconductor

Different metals are used in the form of powders for various semiconductor applications. Each metal powder has distinct properties that make it suitable for specific uses.

| 金属粉末 | 構成 | プロパティ | 特徴 |

|---|---|---|---|

| 銅(Cu) | 純銅 | 高い導電性 | 耐食性、延性 |

| アルミニウム(Al) | 純アルミニウム | 軽量、高導電性 | Reflectivity, malleability |

| 銀(Ag) | 純銀 | 最高の導電性 | Tarnish resistance, antimicrobial |

| 金(Au) | 純金 | 優れた導電性 | Non-reactive, ductility |

| ニッケル(Ni) | 純ニッケル | 耐食性 | Magnetism, high melting point |

| チタン(Ti) | 純チタン | 強度、軽量 | 耐食性、生体適合性 |

| タングステン(W) | 純タングステン | 高融点 | Density, hardness |

| モリブデン (Mo) | 純モリブデン | 高強度 | 高熱伝導性、低熱膨張 |

| パラジウム | 純パラジウム | 耐食性 | Good conductivity, catalytic properties |

| コバルト | ピュア・コバルト | 磁気特性 | High melting point, strength |

Applications of Metal Powder for Semiconductor

Metal powders are used in a variety of applications within the semiconductor industry. Here’s a breakdown of where and how these powders are utilized.

| 申し込み | 使用金属粉 | 説明 |

|---|---|---|

| Microprocessors | Copper, Gold, Silver | Conductive paths and interconnects |

| Memory Storage | Aluminum, Nickel | Data storage layers and magnetic recording |

| センサー | Palladium, Cobalt | Sensitive elements in sensors |

| トランジスタ | タングステン、モリブデン | Gate and interconnect materials |

| コンデンサー | チタン、ニッケル | Dielectric and electrode materials |

| LEDs | Aluminum, Gold | Conductive paths and heat sinks |

| Power Devices | Copper, Silver | High current carrying components |

| Solar Cells | Silver, Aluminum | Conductive grids and contacts |

仕様、サイズ、等級、規格

Understanding the specifications, sizes, grades, and standards of metal powders is crucial for their effective application in semiconductors.

| 金属粉末 | サイズ (µm) | グレード | 規格 |

|---|---|---|---|

| 銅(Cu) | 0.1 – 10 | High Purity (99.99%) | ASTM B170-99 |

| アルミニウム(Al) | 0.5 – 15 | 電子グレード | ISO 8000 |

| 銀(Ag) | 0.2 – 5 | 99.999% Pure | ASTM B779-99 |

| 金(Au) | 0.1 – 3 | Semiconductor Grade | ISO 9208 |

| ニッケル(Ni) | 1 – 20 | 99.98% Pure | ASTM B330-03 |

| チタン(Ti) | 2 – 30 | High Purity (99.6%) | ASTM B348-19 |

| タングステン(W) | 0.3 – 15 | 高純度 | ISO 2768-1 |

| モリブデン (Mo) | 0.5 – 10 | 99.95% Pure | ASTM B386-03 |

| パラジウム | 0.1 – 5 | 99.9% Pure | ISO 6284 |

| コバルト | 1 – 25 | 99.8% Pure | ASTM B330-03 |

サプライヤーと価格詳細

Knowing where to source metal powders and understanding their pricing is vital for planning and budgeting in semiconductor manufacturing.

| サプライヤー | 金属パウダー | 価格(1kgあたり) |

|---|---|---|

| アメリカの要素 | Copper, Gold, Nickel, Silver | $300 – $10,000 |

| ナノアモール | Aluminum, Tungsten, Titanium | $200 – $8,000 |

| スカイスプリング ナノマテリアル | Palladium, Cobalt, Molybdenum | $500 – $12,000 |

| テクナ | アルミニウム、銅、ニッケル | $250 – $9,000 |

| グッドフェロー | Gold, Silver, Titanium | $400 – $15,000 |

金属粉末の長所と短所を比較する

Every metal powder has its advantages and limitations. Here’s a comparative analysis to help understand which might be better suited for specific applications.

| 金属粉末 | メリット | デメリット |

|---|---|---|

| 銅(Cu) | High conductivity, cost-effective | 酸化に弱い |

| アルミニウム(Al) | 軽量、良好な導電性 | 低融点 |

| 銀(Ag) | Highest conductivity, tarnish-resistant | 高い |

| 金(Au) | Non-reactive, excellent conductivity | 非常に高価 |

| ニッケル(Ni) | Corrosion-resistant, magnetic | 中程度の導電性 |

| チタン(Ti) | 強力、軽量、生体適合性 | Expensive, reactive |

| タングステン(W) | High melting point, hard | Very dense, difficult to process |

| モリブデン (Mo) | High strength, thermal conductivity | 脆い、高価 |

| パラジウム | Good conductivity, corrosion-resistant | 非常に高価 |

| コバルト | Magnetic properties, high melting point | 高価、毒性がある |

Composition of Metal Powder for Semiconductor

The composition of metal powders plays a crucial role in their effectiveness and application in semiconductor devices. Here’s a deeper look into the compositions and their impacts.

Copper (Cu) Powder:

- 構成: Pure Copper (99.99%)

- Impact: Provides excellent electrical conductivity, crucial for interconnects and conductive paths in microprocessors and memory devices.

Aluminum (Al) Powder:

- 構成: Pure Aluminum (99.98%)

- Impact: Lightweight and reflective, ideal for conductive grids in solar cells and LED heat sinks.

Silver (Ag) Powder:

- 構成: Pure Silver (99.999%)

- Impact: Highest electrical conductivity, used in high-frequency and high-power devices for minimal resistance.

Gold (Au) Powder:

- 構成: Pure Gold (99.99%)

- Impact: Non-reactive and excellent conductor, used in critical applications where reliability and durability are paramount.

Nickel (Ni) Powder:

- 構成: Pure Nickel (99.98%)

- Impact: Corrosion-resistant and magnetic, suitable for data storage and sensors.

Titanium (Ti) Powder:

- 構成: Pure Titanium (99.6%)

- Impact: Strong and lightweight, used in capacitors and advanced power devices.

Tungsten (W) Powder:

- 構成: Pure Tungsten (99.95%)

- Impact: High melting point and density, ideal for transistors and high-temperature applications.

Molybdenum (Mo) Powder:

- 構成: Pure Molybdenum (99.95%)

- Impact: High strength and thermal conductivity, used in power devices and thermal management.

Palladium (Pd) Powder:

- 構成: Pure Palladium (99.9%)

- Impact: Excellent conductivity and corrosion resistance, used in high-performance sensors and catalytic applications.

Cobalt (Co) Powder:

- 構成: Pure Cobalt (99.8%)

- Impact: Magnetic properties and high melting point, used in magnetic storage and advanced sensor applications.

Characteristics of Metal Powder for Semiconductor

The unique characteristics of each metal powder make them suitable for different semiconductor applications. Here’s a breakdown of these characteristics.

| 金属粉末 | 特徴 | 説明 |

|---|---|---|

| 銅(Cu) | 導電率 | High electrical conductivity,essential for microprocessors. |

| アルミニウム(Al) | 軽量 | Reduces overall device weight, beneficial for portable electronics. |

| 銀(Ag) | 導電率 | Highest electrical conductivity, optimal for high-frequency devices. |

| 金(Au) | Non-reactive | Does not tarnish or corrode, ideal for critical connections. |

| ニッケル(Ni) | 磁気 | Magnetic properties, useful for data storage. |

| チタン(Ti) | 強さ | High strength-to-weight ratio, used in durable components. |

| タングステン(W) | 高融点 | Suitable for high-temperature applications like transistors. |

| モリブデン (Mo) | 熱伝導率 | Excellent for thermal management in power devices. |

| パラジウム | 耐食性 | Resistant to corrosion, used in sensors and high-performance devices. |

| コバルト | 磁気特性 | High melting point and magnetism, useful for storage applications. |

Grades of Metal Powder for Semiconductor

Grades of metal powders indicate their purity and suitability for various applications. Here’s a detailed look at the grades available for different metal powders.

| 金属粉末 | グレード | 純度 | 申し込み |

|---|---|---|---|

| 銅(Cu) | 高純度 | 99.99% | Interconnects, conductive paths |

| アルミニウム(Al) | 電子グレード | 99.98% | Solar cells, LEDs |

| 銀(Ag) | 99.999% Pure | 99.999% | High-frequency devices |

| 金(Au) | Semiconductor Grade | 99.99% | Critical connections |

| ニッケル(Ni) | 99.98% Pure | 99.98% | Data storage, sensors |

| チタン(Ti) | 高純度 | 99.6% | Capacitors, power devices |

| タングステン(W) | 高純度 | 99.95% | Transistors, high-temperature applications |

| モリブデン (Mo) | 99.95% Pure | 99.95% | 熱管理 |

| パラジウム | 99.9% Pure | 99.9% | High-performance sensors |

| コバルト | 99.8% Pure | 99.8% | Magnetic storage, sensors |

Suppliers and Pricing for Metal Powder for Semiconductor

Understanding where to source metal powders and their pricing is crucial for semiconductor manufacturing.

| サプライヤー | 金属パウダー | 価格(1kgあたり) |

|---|---|---|

| アメリカの要素 | Copper, Gold, Nickel, Silver | $300 – $10,000 |

| ナノアモール | Aluminum, Tungsten, Titanium | $200 – $8,000 |

| スカイスプリング ナノマテリアル | Palladium, Cobalt, Molybdenum | $500 – $12,000 |

| テクナ | アルミニウム、銅、ニッケル | $250 – $9,000 |

| グッドフェロー | Gold, Silver, Titanium | $400 – $15,000 |

比較 半導体用金属粉末:利点と限界

Each metal powder comes with its own set of advantages and limitations. Here’s a comparative analysis to help you decide which metal powder suits your needs best.

| 金属粉末 | メリット | デメリット |

|---|---|---|

| 銅(Cu) | High conductivity, cost-effective | 酸化に弱い |

| アルミニウム(Al) | 軽量、良好な導電性 | 低融点 |

| 銀(Ag) | Highest conductivity, tarnish-resistant | 高い |

| 金(Au) | Non-reactive, excellent conductivity | 非常に高価 |

| ニッケル(Ni) | Corrosion-resistant, magnetic | 中程度の導電性 |

| チタン(Ti) | 強力、軽量、生体適合性 | Expensive, reactive |

| タングステン(W) | High melting point, hard | Very dense, difficult to process |

| モリブデン (Mo) | High strength, thermal conductivity | 脆い、高価 |

| パラジウム | Good conductivity, corrosion-resistant | 非常に高価 |

| コバルト | Magnetic properties, high melting point | 高価、毒性がある |

よくあるご質問

Q1: What are the most commonly used metal powders in semiconductor manufacturing?

A1: The most commonly used metal powders in semiconductor manufacturing include Copper (Cu), Aluminum (Al), Silver (Ag), Gold (Au), Nickel (Ni), Titanium (Ti), Tungsten (W), Molybdenum (Mo), Palladium (Pd), and Cobalt (Co).

Q2: Why is purity important in metal powders for semiconductors?

A2: Purity is crucial because impurities can affect the electrical properties, performance, and reliability of semiconductor devices. High-purity metal powders ensure optimal conductivity and minimize defects.

Q3: How are metal powders used in microprocessors?

A3: Metal powders such as Copper and Gold are used to create conductive paths and interconnects within microprocessors, ensuring efficient electrical connections between different components.

Q4: What are the advantages of using Gold powder in semiconductors?

A4: Gold powder offers excellent conductivity, is non-reactive, and does not tarnish or corrode, making it ideal for critical connections where reliability and longevity are essential.

Q5: Can you explain the role of Tungsten powder in semiconductor devices?

A5: Tungsten powder is used in semiconductor devices due to its high melting point and density, making it suitable for high-temperature applications such as transistors and power devices.

Q6: What factors influence the choice of metal powder for a specific semiconductor application?

A6: Factors include the required electrical and thermal conductivity, melting point, strength, corrosion resistance, and specific application needs such as weight and magnetic properties.

Q7: Are there any environmental concerns with using metal powders in semiconductors?

A7: Yes, the production and disposal of metal powders can have environmental impacts. It is essential to follow sustainable practices and recycling measures to minimize these effects.

Q8: How does the particle size of metal powders affect their application in semiconductors?

A8: The particle size affects the surface area, packing density, and electrical properties of the metal powders, influencing their performance in semiconductor applications.

Q9: What are the challenges in processing metal powders for semiconductors?

A9: Challenges include achieving uniform particle size distribution, maintaining high purity, preventing oxidation, and ensuring consistent quality during production and processing.

Q10: Where can I buy high-quality metal powders for semiconductor applications?

A10: High-quality metal powders can be sourced from suppliers such as American Elements, NanoAmor, SkySpring Nanomaterials, Tekna, and Goodfellow.

シェアする

MET3DP Technology Co., LTDは、中国青島に本社を置く積層造形ソリューションのリーディングプロバイダーです。弊社は3Dプリンティング装置と工業用途の高性能金属粉末を専門としています。

関連記事

Met3DPについて

最新情報

製品

3Dプリンティングと積層造形用金属粉末