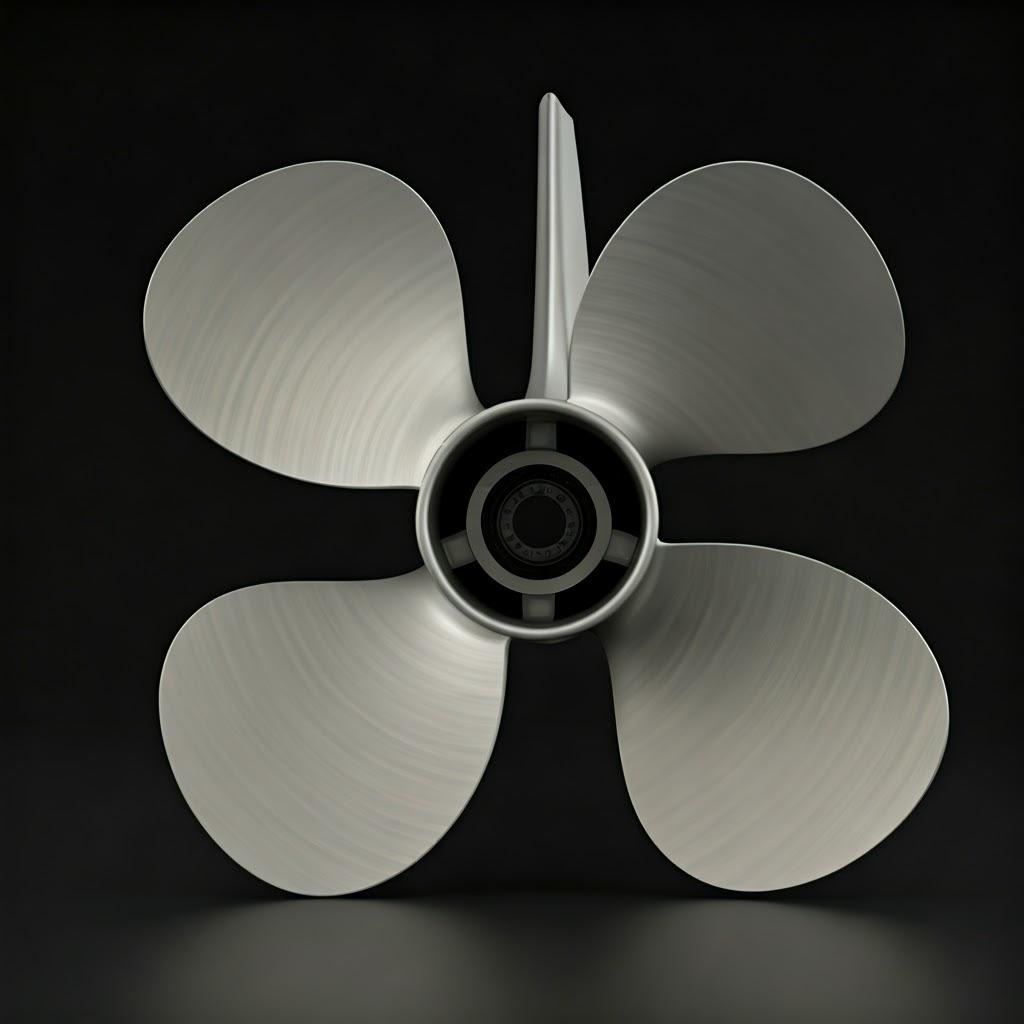

Corrosion-Resistant Boat Propeller Blades: The Future of Marine Propulsion

Inhoudsopgave

The relentless assault of saltwater and demanding operational conditions make boat propeller blades prime candidates for advanced material solutions. Traditional manufacturing methods often fall short in delivering the optimal combination of strength, weight reduction, and, crucially, corrosion resistance required for long-lasting performance. Metal 3d printen, also known as metal additive manufacturing, is emerging as a game-changer in the marine industry, offering the design freedom and material versatility to create next-generation propeller blades. This blog explores the advantages of using metal 3D printing to produce highly durable and efficient corrosion-resistant boat propeller blades, particularly highlighting the capabilities offered by industry leaders like Metaal3DP.

What Are Corrosion-Resistant Boat Propeller Blades Used For?

Corrosion-resistant boat propeller blades are critical components in a wide array of marine vessels, from small recreational boats to large commercial ships and even underwater vehicles. Their primary function is to efficiently convert the rotational power from the engine into thrust, propelling the vessel through the water. The environments in which these blades operate are inherently harsh, exposing them to:

- Saltwater Corrosion: The high salinity of seawater is extremely corrosive to many metals, leading to pitting, weakening, and eventual failure of propeller blades.

- Cavitation: The rapid formation and collapse of vapor bubbles near the blade surface can cause significant material erosion and reduce efficiency.

- Mechanical Stress: Propeller blades endure substantial hydrodynamic forces, impacts with debris, and vibrations, requiring robust material properties.

- Fouling: The accumulation of marine organisms on the blade surface increases drag and reduces performance. While material choice isn’t the primary defense against fouling, smoother, more corrosion-resistant surfaces can sometimes make cleaning easier.

These demanding conditions necessitate the use of materials and manufacturing processes that can ensure longevity, reliability, and optimal performance. Metal 3D printing offers a pathway to achieve these critical attributes, allowing for the creation of complex geometries tailored to specific vessel types and operational requirements. Industries benefiting from advanced, corrosion-resistant propeller blades include:

- Marine Transportation: Cargo ships, tankers, and container vessels require durable and efficient propellers for global trade.

- Naval and Coast Guard: Military and patrol vessels demand high reliability and performance in challenging maritime environments.

- Fishing and Aquaculture: Commercial fishing boats and aquaculture operations rely on robust propellers for their livelihoods.

- Recreational Boating: Yachts, sailboats, and powerboats benefit from quieter, more efficient, and longer-lasting propellers.

- Subsea Exploration and Operations: Remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) require propellers that can withstand deep-sea conditions.

Why Use Metal 3D Printing for Corrosion-Resistant Boat Propeller Blades?

Opting for metal 3D printing over traditional manufacturing methods like casting or machining offers several compelling advantages for producing corrosion-resistant boat propeller blades:

- Enhanced Design Freedom: Additive manufacturing allows for the creation of complex and optimized blade geometries that are difficult or impossible to achieve with conventional techniques. This includes:

- Customized Pitch and Rake Angles: Tailoring the blade design to specific engine and hull characteristics for improved efficiency and reduced vibration.

- Lightweighting with Lattice Structures: Incorporating internal lattice structures to reduce weight without compromising strength, leading to improved fuel efficiency.

- Hydrodynamic Optimization: Designing blade profiles that minimize drag and cavitation, enhancing performance and reducing noise.

- Materiaaloptimalisatie: Metal 3D printing enables the use of advanced, high-performance alloys specifically chosen for their corrosion resistance and mechanical properties. Metal3DP’s extensive portfolio includes powders like 316L stainless steel and Ti-6Al-4V titanium alloy, both renowned for their excellent resistance to saltwater corrosion.

- Minder afval: Additive manufacturing processes are generally more material-efficient than subtractive methods, as material is only added where needed, minimizing waste and reducing material costs, especially when using expensive alloys.

- Snelle prototyping en iteratie: 3D printing allows for the quick production of prototypes, enabling faster design iterations and testing, ultimately leading to optimized blade designs in a shorter timeframe. This is particularly valuable for developing specialized propellers for niche applications.

- On-Demand Manufacturing and Customization: Metal 3D printing facilitates the production of customized propeller blades in smaller quantities, catering to specific vessel requirements or replacement needs without the high tooling costs associated with traditional manufacturing. This agility can be a significant advantage for boat builders and repair services.

- Integration of Features: Complex internal cooling channels or vibration dampening structures can be integrated directly into the blade design during the 3D printing process, enhancing performance and functionality.

Recommended Materials and Why They Matter

The selection of the right metal powder is paramount for achieving the desired corrosion resistance and mechanical properties in 3D-printed boat propeller blades. Metaal3DP offers a range of high-quality metal powders suitable for this application, with 316L stainless steel and Ti-6Al-4V titanium alloy being particularly noteworthy:

316L roestvrij staal:

- Uitstekende corrosiebestendigheid: 316L is an austenitic stainless steel alloyed with molybdenum, which significantly enhances its resistance to pitting and crevice corrosion, especially in chloride-rich environments like saltwater.

- Good Mechanical Properties: It offers a good balance of strength, ductility, and toughness, making it suitable for demanding marine applications.

- Weldability and Machinability: 316L is readily weldable and machinable, facilitating post-processing if required.

- Kosteneffectief: Compared to some other corrosion-resistant alloys like titanium, 316L is generally more cost-effective.

Ti-6Al-4V Titanium Alloy:

- Superieure corrosieweerstand: Titanium alloys, particularly Ti-6Al-4V, exhibit exceptional resistance to saltwater corrosion, surpassing that of most stainless steels. They form a stable oxide layer that provides excellent protection against degradation.

- Hoge verhouding sterkte/gewicht: Ti-6Al-4V offers significantly higher strength-to-weight ratio compared to steel alloys. This allows for the production of lighter propeller blades, reducing inertia, improving acceleration, and potentially enhancing fuel efficiency.

- Excellent Fatigue Resistance: Titanium alloys possess high fatigue strength, crucial for components subjected to cyclic loading in marine environments.

- Biocompatibiliteit: While less relevant for standard propeller blades, the biocompatibility of titanium alloys is significant for specialized marine applications, such as components for underwater research equipment.

The choice between 316L and Ti-6Al-4V depends on the specific requirements of the application, including the level of corrosion resistance needed, weight considerations, performance targets, and budget constraints. Consulting with material experts at companies like Metaal3DP can help engineers and procurement managers make informed decisions about the most suitable powder for their specific needs. Their advanced powder making system ensures the production of high-quality, spherical powders essential for optimal 3D printing outcomes.

Design Considerations for Additive Manufacturing of Propeller Blades

Designing for metal additive manufacturing requires a different mindset compared to traditional methods. To fully leverage the capabilities of 3D printing and achieve optimal performance and durability in corrosion-resistant boat propeller blades, several key design considerations must be taken into account:

- Topologieoptimalisatie: This computational approach can identify and remove material from low-stress areas of the blade while maintaining structural integrity. This results in lightweight designs with optimized material distribution, potentially improving efficiency and reducing material usage. Metal 3D printing’s geometric freedom allows for the realization of these complex, organic-like structures.

- Roosterstructuren: Incorporating internal lattice structures within the blade can significantly reduce weight without sacrificing stiffness or strength. These intricate networks are only achievable through additive manufacturing and can be tailored to specific load requirements.

- Hydrodynamic Efficiency: Computational Fluid Dynamics (CFD) simulations should be used iteratively with design modifications to optimize the blade’s hydrodynamic profile. Metal 3D printing enables the creation of complex curved surfaces and leading/trailing edge geometries that minimize drag, reduce cavitation, and improve thrust efficiency.

- Wall Thickness and Ribbing: Careful consideration of wall thickness is crucial to balance weight and structural integrity. Incorporating internal ribs or stiffening features can enhance the blade’s resistance to bending and torsional loads without excessive weight gain.

- Ondersteunende structuren: While necessary for certain overhangs and complex geometries during the printing process, support structures should be minimized to reduce material waste and post-processing effort. Design features like self-supporting angles and strategic part orientation on the build platform can help achieve this.

- Surface Finish Considerations: The as-printed surface finish can impact hydrodynamic performance and corrosion resistance. Designing the blade with consideration for necessary post-processing steps, such as polishing or coating, is important. Smoother surfaces generally reduce drag and can be less prone to fouling.

- Feature Integration: Metal 3D printing allows for the integration of features like cooling channels (for specialized applications) or mounting interfaces directly into the blade design, reducing the need for assembly and improving overall functionality.

By embracing these design principles, engineers can unlock the full potential of metal 3D printing to create high-performance, corrosion-resistant boat propeller blades that surpass the capabilities of conventionally manufactured parts.

Tolerance, Surface Finish, and Dimensional Accuracy in 3D-Printed Propeller Blades

Achieving the required tolerance, surface finish, and dimensional accuracy is critical for the performance and longevity of 3D-printed boat propeller blades. Understanding the capabilities and limitations of metal 3D printing processes is essential for setting realistic expectations and designing accordingly.

- Tolerance: Metal Powder Bed Fusion (PBF) technologies, such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM), offered by companies like Metaal3DP, can achieve relatively tight tolerances, typically in the range of ±0.05 to ±0.2 mm, depending on the part size, geometry, and printing parameters. Critical dimensions that affect balance and hydrodynamic performance will require careful consideration and potentially post-machining for tighter tolerances.

- Afwerking oppervlak: The as-printed surface finish in metal PBF processes is typically rougher compared to machined surfaces, with Ra (average roughness) values ranging from 5 to 20 µm. This surface roughness can increase drag and potentially affect corrosion resistance by providing more surface area for corrosive attack. Post-processing techniques like polishing, sanding, or abrasive flow machining can significantly improve the surface finish to the required levels.

- Maatnauwkeurigheid: Achieving high dimensional accuracy requires careful optimization of printing parameters, including laser power, scan speed, powder layer thickness, and build orientation. Thermal stresses during the printing process can lead to distortion, and support structures can influence the final part dimensions. Accurate simulation and experienced build preparation are crucial to minimize these effects. Metal3DP’s industry-leading accuracy highlights their commitment to producing dimensionally accurate parts.

| Parameter | Typical Range for Metal PBF | Impact on Propeller Blades | Matigingsstrategieën |

|---|---|---|---|

| Tolerantie | ±0,05 tot ±0,2 mm | Affects balance, fitment to the propeller shaft, and hydrodynamic performance. | Optimized printing parameters, experienced build preparation, post-machining for critical dimensions. |

| Oppervlakteruwheid (Ra) | 5 to 20 µm | Increases drag, potential for increased corrosion, and fouling. | Post-processing techniques like polishing, abrasive flow machining, and coating. |

| Dimensionale nauwkeurigheid | Varies with size & geometry | Impacts hydrodynamic performance, balance, and overall functionality of the propeller. | Optimized printing parameters, accurate simulation, strategic support placement, stress relief heat treatment. |

Exporteren naar Sheets

Post-Processing Requirements for 3D-Printed Metal Propeller Blades

While metal 3D printing offers significant advantages in creating complex geometries, post-processing is often necessary to achieve the final desired properties, surface finish, and dimensional accuracy for boat propeller blades. Common post-processing steps include:

- Ondersteuning verwijderen: Support structures, essential for printing overhangs and complex features, must be carefully removed. This can involve manual breaking, cutting, or using specialized tools and machines. The design should aim to minimize the need for extensive support to simplify this process.

- Hittebehandeling: Stress relief annealing is often performed to reduce residual stresses that build up during the printing process, preventing warping and improving the overall mechanical properties of the blade. Specific heat treatment cycles are determined by the material and application requirements.

- Afwerking oppervlak: To improve hydrodynamic performance and corrosion resistance, surface finishing techniques are commonly employed. These can include:

- Polijsten: Mechanical or chemical polishing to achieve a smoother surface finish, reducing drag and the potential for fouling.

- Abrasive Flow Machining (AFM): Using abrasive media forced through internal channels or over external surfaces to smooth and refine complex geometries.

- Media Blasting: Using abrasive particles to remove surface oxides and achieve a more uniform surface texture.

- CNC-bewerking: For critical features requiring very tight tolerances, such as the bore for the propeller shaft or specific mounting surfaces, precision CNC machining may be necessary as a secondary operation.

- Coating: Applying protective coatings can further enhance corrosion resistance and prevent fouling. These may include:

- Elektrolytisch polijsten: To create a passive, corrosion-resistant layer on stainless steel.

- Anodiseren: For titanium alloys to improve corrosion resistance and wear properties.

- Anti-fouling coatings: Specialized coatings to prevent the growth of marine organisms on the blade surface.

- Inspection and Quality Control: Non-destructive testing methods, such as dye penetrant inspection or ultrasonic testing, are used to ensure the structural integrity and absence of defects in the finished propeller blades. Dimensional accuracy is verified using coordinate measuring machines (CMMs).

The specific post-processing requirements will depend on the material, the intended application, and the desired performance characteristics of the 3D-printed boat propeller blade. Collaborating with experienced metal 3D printing service providers like Metaal3DP, who offer comprehensive post-processing services, is crucial for achieving the highest quality and performance.

Common Challenges and How to Avoid Them in 3D Printing Propeller Blades

While metal 3D printing offers numerous advantages, several challenges can arise during the production of boat propeller blades. Understanding these potential issues and implementing preventative measures is crucial for successful outcomes:

- Vervorming en vervorming: Thermal stresses during the printing process can lead to warping or distortion of the blade geometry, especially for large or complex parts.

- Mitigation: Optimize part orientation on the build platform, use appropriate support structures to anchor the part, employ stress relief heat treatment, and consider design modifications to reduce stress concentrations.

- Support Removal Difficulties: Intricate support structures can be challenging to remove without damaging the delicate blade features.

- Mitigation: Design for minimal support, utilize breakaway support materials, and carefully plan support placement for easy access.

- Porosity and Defects: Internal voids or defects can compromise the mechanical strength and corrosion resistance of the blade.

- Mitigation: Optimize printing parameters (laser power, scan speed, powder flow), ensure high-quality metal powders with good flowability (as provided by Metal3DP’s advanced powder making system), and employ inert build atmospheres.

- Surface Roughness Issues: Achieving a smooth surface finish directly from the printer can be difficult, leading to increased drag and potential corrosion initiation sites.

- Mitigation: Plan for appropriate post-processing techniques like polishing or abrasive flow machining during the design phase.

- Dimensional Inaccuracies: Deviations from the intended dimensions can affect the balance and hydrodynamic performance of the propeller.

- Mitigation: Calibrate the 3D printer regularly, optimize printing parameters for the specific material and geometry, and consider post-machining for critical dimensions.

- Material Selection Errors: Choosing an inappropriate metal powder with inadequate corrosion resistance or mechanical properties will lead to premature failure.

- Mitigation: Carefully evaluate the application requirements and consult with material experts (like those at Metaal3DP) to select the optimal powder (e.g., 316L or Ti-6Al-4V).

- Cost Management: Metal 3D printing can be expensive, especially for large parts or complex geometries requiring significant post-processing.

- Mitigation: Optimize the design for efficient printing, minimize material usage through topology optimization and lattice structures, and carefully evaluate the cost-effectiveness of different materials and post-processing options.

By proactively addressing these potential challenges through careful design, material selection, process optimization, and collaboration with experienced metal 3D printing service providers, manufacturers can successfully produce high-quality, corrosion-resistant boat propeller blades that offer superior performance and longevity.

How to Choose the Right Metal 3D Printing Service Provider for Propeller Blades

Selecting the right metal 3D printing service provider is crucial for obtaining high-quality, corrosion-resistant boat propeller blades that meet your specific requirements. Consider the following factors when evaluating potential suppliers:

- Material Capabilities: Ensure the provider has experience working with the recommended corrosion-resistant metal powders, such as 316L stainless steel and Ti-6Al-4V titanium alloy. Verify their expertise in processing these materials to achieve optimal mechanical properties and corrosion resistance. Metal3DP’s wide range of high-quality metal powders makes them a strong contender in this aspect.

- Printing Technology and Equipment: Inquire about the types of metal 3D printing technologies they employ (e.g., SLM, DMLS, EBM). Understand the capabilities of their equipment in terms of build volume, accuracy, and surface finish. Providers with toonaangevend printvolume, nauwkeurigheid en betrouwbaarheid are well-positioned to handle demanding projects.

- Design Optimization Support: A good service provider should offer support in optimizing your propeller blade design for additive manufacturing. This includes guidance on topology optimization, lattice structures, support minimization, and design for manufacturability.

- Post-Processing Services: Determine if the provider offers the necessary post-processing services to meet your requirements, such as support removal, heat treatment, surface finishing (polishing, coating), and CNC machining for critical tolerances. A comprehensive suite of services can streamline the production process.

- Quality Assurance and Certifications: Check if the provider has robust quality control procedures and relevant certifications (e.g., ISO 9001, AS9100 for aerospace). This ensures that the manufactured parts meet stringent quality standards.

- Experience and Expertise: Look for a provider with a proven track record in metal 3D printing, ideally with experience in marine or similarly demanding applications. Their expertise can help anticipate and mitigate potential challenges.

- Lead Times and Production Capacity: Understand the provider’s lead times for manufacturing and post-processing, as well as their production capacity to meet your volume requirements.

- Cost Structure and Transparency: Obtain a clear breakdown of the costs involved, including printing, materials, post-processing, and any additional services. A transparent pricing structure is essential for budget planning.

- Communication and Customer Support: Evaluate the provider’s responsiveness, communication effectiveness, and willingness to collaborate throughout the project. Strong communication is key to a successful partnership.

By carefully evaluating these factors, you can select a metal 3D printing service provider that can reliably produce high-performance, corrosion-resistant boat propeller blades tailored to your specific needs.

Cost Factors and Lead Time for 3D-Printed Metal Propeller Blades

The cost and lead time for producing boat propeller blades using metal 3D printing are influenced by several factors:

Kostenfactoren:

- Materiaalkosten: The type and quantity of metal powder used significantly impact the overall cost. Alloys like titanium (Ti-6Al-4V) are generally more expensive than stainless steel (316L). The complexity of the blade design, which affects material usage, also plays a role.

- Bouwtijd: The duration of the printing process is a key cost driver. Larger or more complex blades that require longer build times will incur higher machine operating costs.

- Kosten voor nabewerking: The extent of post-processing required (support removal, heat treatment, surface finishing, machining, coating) will add to the overall cost. Complex geometries often necessitate more extensive and costly post-processing.

- Arbeidskosten: The labor involved in design optimization, build preparation, machine operation, post-processing, and quality control contributes to the final price.

- Machine and Overhead Costs: The service provider’s capital investment in 3D printing equipment and their operational overhead are factored into their pricing.

- Quantity and Complexity: While metal 3D printing can be cost-effective for low to medium volumes and complex designs, very high production volumes might be more economical with traditional manufacturing methods.

Lead Time Factors:

- Design and Engineering: The time required for design optimization and preparation for additive manufacturing.

- Afdrukken tijd: The actual duration of the 3D printing process, which depends on the size and complexity of the blade.

- Post-Processing Time: The time needed for support removal, heat treatment, surface finishing, and other secondary operations.

- Kwaliteitscontrole en inspectie: The time allocated for ensuring the dimensional accuracy and structural integrity of the printed parts.

- Shipping and Logistics: The time taken for the finished propeller blades to be delivered.

Lead times can vary significantly depending on the complexity of the blade, the chosen material, the required post-processing, and the service provider’s current workload. It’s essential to discuss lead time expectations clearly with potential providers early in the project.

Veelgestelde vragen (FAQ)

- Q: Are 3D-printed metal propeller blades as strong as traditionally manufactured ones?

- A: Yes, when manufactured correctly using high-quality metal powders and optimized printing parameters, 3D-printed metal propeller blades can achieve comparable or even superior strength and fatigue resistance to traditionally manufactured parts. The mechanical properties are highly dependent on the material and the printing process. Metal3DP’s metal spherical powders are designed to enable the creation of dense, high-quality metal parts with superior mechanical properties.

- Q: Can metal 3D printing produce large boat propeller blades?

- A: Yes, the build volume capabilities of metal 3D printers are continuously increasing. While extremely large propellers for massive ships might still be challenging for single-print production, advancements in technology and techniques like segmented printing and joining are expanding the size limitations. Metal3DP’s industry-leading print volume allows for the production of substantial parts.

- Q: How does the cost of 3D-printed metal propeller blades compare to traditional methods?

- A: The cost-effectiveness of metal 3D printing depends on factors like volume, complexity, and material. For low to medium volumes of complex, customized blades, it can be more cost-competitive than traditional methods that require expensive tooling. As production volumes increase, traditional methods might become more economical. However, the benefits of design freedom and material optimization offered by 3D printing can often justify a potentially higher per-part cost in specialized applications.

Conclusion: Embracing Additive Manufacturing for Superior Marine Propulsion

Metal 3D printing stands at the forefront of innovation in marine manufacturing, offering a transformative approach to producing high-performance, corrosion-resistant boat propeller blades. The ability to optimize designs for hydrodynamic efficiency, utilize advanced materials like 316L and Ti-6Al-4V for exceptional durability, and achieve complex geometries unattainable with traditional methods positions metal AM as a key technology for the future of marine propulsion.

Bedrijven zoals Metaal3DP, with their expertise in metal 3D printing equipment, high-quality metal powders, and comprehensive application development services, are empowering industries to leverage these advantages. By carefully considering design principles, material selection, post-processing requirements, and the choice of a knowledgeable service provider, engineers and procurement managers can unlock the full potential of metal 3D printing to create next-generation boat propeller blades that deliver enhanced performance, longevity, and reliability in the demanding marine environment. Contact Metaal3DP today to explore how their capabilities can power your organization’s additive manufacturing goals in the marine sector.

Delen op

MET3DP Technology Co, LTD is een toonaangevende leverancier van additieve productieoplossingen met hoofdkantoor in Qingdao, China. Ons bedrijf is gespecialiseerd in 3D printapparatuur en hoogwaardige metaalpoeders voor industriële toepassingen.

Onderzoek om de beste prijs en een op maat gemaakte oplossing voor uw bedrijf te krijgen!

gerelateerde artikelen

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Lees verder "Over Met3DP

Recente update

Ons product

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.