Metaalpoeders voor halfgeleiders

Inhoudsopgave

In de steeds veranderende wereld van halfgeleiders is de rol van metaalpoeders cruciaal. Van de creatie van microprocessors tot de ontwikkeling van geavanceerde geheugenopslag, metaalpoeders zijn de onbezongen helden die deze technologische wonderen mogelijk maken. Dit artikel duikt in de complexiteit van metaalpoeders voor halfgeleiders, hun types, samenstellingen, toepassingen, specificaties en meer. Laten we een gedetailleerde verkenning van dit fascinerende onderwerp beginnen.

Overzicht van metaalpoeder voor halfgeleiders

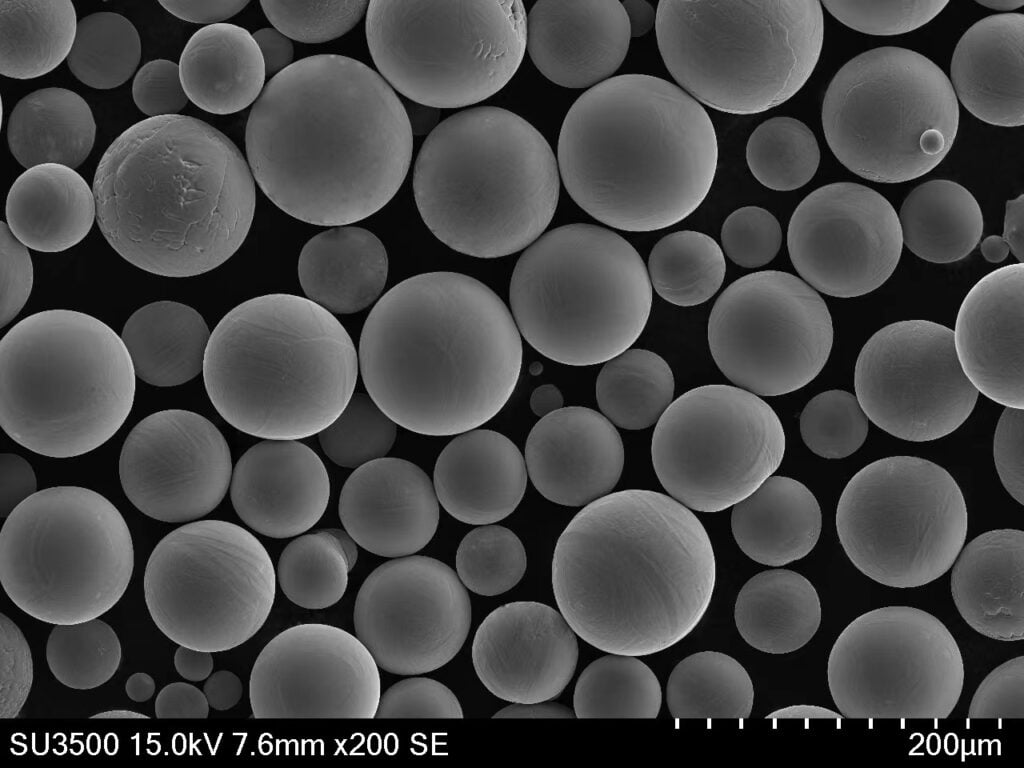

Metaalpoeders zijn fijn verdeelde deeltjes van metalen die worden gebruikt in verschillende toepassingen, waaronder de halfgeleiderindustrie. Hun belang ligt in hun unieke eigenschappen, zoals hoge zuiverheid, gecontroleerde deeltjesgrootte en specifiek oppervlak, waardoor ze ideaal zijn voor gebruik bij de productie van halfgeleiderapparaten.

Belangrijke punten:

- Metaalpoeders zijn essentieel in het halfgeleiderproductieproces.

- Ze bieden een hoge zuiverheid en gecontroleerde deeltjesgroottes.

- Wordt gebruikt bij de ontwikkeling van microprocessoren, geheugenopslag en andere halfgeleiderapparaten.

Soorten metaalpoeder voor halfgeleiders

Verschillende metalen worden gebruikt in de vorm van poeders voor verschillende halfgeleidertoepassingen. Elk metaalpoeder heeft verschillende eigenschappen die het geschikt maken voor specifieke toepassingen.

| Metaalpoeder | Samenstelling | Eigenschappen | Kenmerken |

|---|---|---|---|

| Koper (Cu) | Zuiver Koper | Hoge geleidbaarheid | Corrosiebestendigheid, vervormbaarheid |

| Aluminium (Al) | Zuiver aluminium | Lichtgewicht, hoge geleidbaarheid | Reflectiviteit, kneedbaarheid |

| Zilver (Ag) | Zuiver zilver | Hoogste elektrische geleidbaarheid | Aanslagbestendig, antimicrobieel |

| Goud (Au) | Puur goud | Uitstekend geleidingsvermogen | Niet-reactief, ductiliteit |

| Nikkel (Ni) | Puur nikkel | Corrosieweerstand | Magnetisme, hoog smeltpunt |

| Titaan (Ti) | Puur titanium | Kracht, lichtgewicht | Corrosiebestendigheid, biocompatibiliteit |

| Wolfraam (W) | Zuiver wolfraam | Hoog smeltpunt | Dichtheid, hardheid |

| Molybdeen (Mo) | Zuiver molybdeen | Grote sterkte | Hoge thermische geleidbaarheid, lage thermische uitzetting |

| Palladium (Pd) | Zuiver palladium | Corrosieweerstand | Goede geleidbaarheid, katalytische eigenschappen |

| Kobalt (Co) | Zuiver kobalt | Magnetische eigenschappen | Hoog smeltpunt, sterkte |

Toepassingen van metaalpoeder voor halfgeleiders

Metaalpoeders worden gebruikt in verschillende toepassingen binnen de halfgeleiderindustrie. Hier is een overzicht van waar en hoe deze poeders worden gebruikt.

| Sollicitatie | Gebruikte metaalpoeders | Beschrijving |

|---|---|---|

| Microprocessoren | Koper, goud, zilver | Geleidende paden en verbindingen |

| Geheugenopslag | Aluminium, nikkel | Gegevensopslaglagen en magnetische registratie |

| Sensoren | Palladium, Kobalt | Gevoelige elementen in sensoren |

| Transistors | Wolfraam, Molybdeen | Poort- en verbindingsmaterialen |

| Condensatoren | Titanium, Nikkel | Diëlektrische en elektrodematerialen |

| LED's | Aluminium, Goud | Geleidende paden en koellichamen |

| Stroomapparaten | Koper, Zilver | Componenten met hoge stroomsterkte |

| Zonnecellen | Zilver, Aluminium | Geleidende roosters en contacten |

Specificaties, maten, kwaliteiten en normen

Kennis van de specificaties, afmetingen, kwaliteiten en normen van metaalpoeders is essentieel voor een effectieve toepassing in halfgeleiders.

| Metaalpoeder | Afmetingen (µm) | Cijfers | Normen |

|---|---|---|---|

| Koper (Cu) | 0.1 – 10 | Hoge zuiverheid (99.99%) | ASTM B170-99 |

| Aluminium (Al) | 0.5 – 15 | Elektronische rang | ISO 8000 |

| Zilver (Ag) | 0.2 – 5 | 99.999% Zuiver | ASTM B779-99 |

| Goud (Au) | 0.1 – 3 | Halfgeleiderkwaliteit | ISO 9208 |

| Nikkel (Ni) | 1 – 20 | 99.98% Zuiver | ASTM B330-03 |

| Titaan (Ti) | 2 – 30 | Hoge zuiverheid (99.6%) | ASTM B348-19 |

| Wolfraam (W) | 0.3 – 15 | Hoge zuiverheid | ISO 2768-1 |

| Molybdeen (Mo) | 0.5 – 10 | 99.95% Zuiver | ASTM B386-03 |

| Palladium (Pd) | 0.1 – 5 | 99.9% Zuiver | ISO 6284 |

| Kobalt (Co) | 1 – 25 | 99.8% Zuiver | ASTM B330-03 |

Leveranciers en prijsinformatie

Weten waar u metaalpoeders kunt kopen en inzicht hebben in de prijzen ervan, is van essentieel belang voor de planning en budgettering in de halfgeleiderproductie.

| Leverancier | Beschikbare metaalpoeders | Prijs (per kg) |

|---|---|---|

| Amerikaanse elementen | Koper, goud, nikkel, zilver | $300 – $10,000 |

| NanoAmor | Aluminium, Wolfraam, Titanium | $200 – $8,000 |

| SkySpring Nanomaterialen | Palladium, Kobalt, Molybdeen | $500 – $12,000 |

| Tekna | Aluminium, Koper, Nikkel | $250 – $9,000 |

| Goodfellow | Goud, zilver, titanium | $400 – $15,000 |

De voor- en nadelen van metaalpoeders vergelijken

Elk metaalpoeder heeft zijn voordelen en beperkingen. Hier is een vergelijkende analyse om te begrijpen welke het meest geschikt is voor specifieke toepassingen.

| Metaalpoeder | Voordelen | Nadelen |

|---|---|---|

| Koper (Cu) | Hoge geleidbaarheid, kosteneffectief | Gevoelig voor oxidatie |

| Aluminium (Al) | Lichtgewicht, goede geleiding | Lager smeltpunt |

| Zilver (Ag) | Hoogste geleidbaarheid, bestand tegen aanslag | Dure |

| Goud (Au) | Niet-reactief, uitstekende geleiding | Zeer duur |

| Nikkel (Ni) | Corrosiebestendig, magnetisch | Matige geleidbaarheid |

| Titaan (Ti) | Sterk, lichtgewicht, biocompatibel | Duur, reactief |

| Wolfraam (W) | Hoog smeltpunt, hard | Zeer dicht, moeilijk te verwerken |

| Molybdeen (Mo) | Hoge sterkte, thermische geleidbaarheid | Broos, duur |

| Palladium (Pd) | Goede geleidbaarheid, corrosiebestendig | Zeer duur |

| Kobalt (Co) | Magnetische eigenschappen, hoog smeltpunt | Duur, kan giftig zijn |

Samenstelling van metaalpoeder voor halfgeleiders

De samenstelling van metaalpoeders speelt een cruciale rol in hun effectiviteit en toepassing in halfgeleiderapparaten. Hier is een diepere blik op de samenstellingen en hun impact.

Koper (Cu) poeder:

- Samenstelling: Zuiver koper (99.99%)

- Invloed: Zorgt voor uitstekende elektrische geleiding, cruciaal voor onderlinge verbindingen en geleidende paden in microprocessoren en geheugenapparaten.

Aluminium (Al) poeder:

- Samenstelling: Zuiver aluminium (99.98%)

- Invloed: Lichtgewicht en reflecterend, ideaal voor geleidende roosters in zonnecellen en LED-koellichamen.

Zilver (Ag) Poeder:

- Samenstelling: Puur zilver (99.999%)

- Invloed: Hoogste elektrische geleidbaarheid, gebruikt in hoogfrequente en hoogvermogenapparaten voor minimale weerstand.

Goud (Au) poeder:

- Samenstelling: Puur goud (99.99%)

- Invloed: Niet-reactieve en uitstekende geleider, gebruikt in kritische toepassingen waar betrouwbaarheid en duurzaamheid van het grootste belang zijn.

Nikkel (Ni) poeder:

- Samenstelling: Zuiver nikkel (99.98%)

- Invloed: Corrosiebestendig en magnetisch, geschikt voor gegevensopslag en sensoren.

Titanium (Ti) poeder:

- Samenstelling: Zuiver titanium (99.6%)

- Invloed: Sterk en lichtgewicht, gebruikt in condensatoren en geavanceerde vermogensapparaten.

Wolfraam (W) poeder:

- Samenstelling: Zuiver wolfraam (99.95%)

- Invloed: Hoog smeltpunt en dichtheid, ideaal voor transistoren en toepassingen met hoge temperaturen.

Molybdeen (Mo) poeder:

- Samenstelling: Zuiver molybdeen (99.95%)

- Invloed: Hoge sterkte en thermische geleidbaarheid, gebruikt in energie-apparaten en thermisch beheer.

Palladium (Pd) poeder:

- Samenstelling: Zuiver palladium (99.9%)

- Invloed: Uitstekende geleidbaarheid en corrosiebestendigheid, gebruikt in hoogwaardige sensoren en katalytische toepassingen.

Kobalt (Co) poeder:

- Samenstelling: Zuiver kobalt (99.8%)

- Invloed: Magnetische eigenschappen en een hoog smeltpunt, gebruikt in magnetische opslag en geavanceerde sensortoepassingen.

Kenmerken van metaalpoeder voor halfgeleiders

De unieke eigenschappen van elk metaalpoeder maken ze geschikt voor verschillende halfgeleidertoepassingen. Hier is een overzicht van deze eigenschappen.

| Metaalpoeder | Kenmerkend | Beschrijving |

|---|---|---|

| Koper (Cu) | Geleidbaarheid | Hoge elektrische geleidbaarheid, essentieel voor microprocessoren. |

| Aluminium (Al) | Lichtgewicht | Vermindert het totale gewicht van het apparaat, wat gunstig is voor draagbare elektronica. |

| Zilver (Ag) | Geleidbaarheid | Hoogste elektrische geleidbaarheid, optimaal voor hoogfrequente apparaten. |

| Goud (Au) | Niet-reactief | Wordt niet dof en corrodeert niet, ideaal voor kritische verbindingen. |

| Nikkel (Ni) | Magnetisme | Magnetische eigenschappen, handig voor gegevensopslag. |

| Titaan (Ti) | Kracht | Hoge sterkte-gewichtsverhouding, gebruikt in duurzame componenten. |

| Wolfraam (W) | Hoog smeltpunt | Geschikt voor toepassingen met hoge temperaturen, zoals transistoren. |

| Molybdeen (Mo) | Warmtegeleiding | Uitstekend geschikt voor thermisch beheer in elektrische apparaten. |

| Palladium (Pd) | Corrosieweerstand | Corrosiebestendig, gebruikt in sensoren en hoogwaardige apparaten. |

| Kobalt (Co) | Magnetische eigenschappen | Hoog smeltpunt en magnetisme, handig voor opslagtoepassingen. |

Soorten metaalpoeder voor halfgeleiders

De kwaliteiten van metaalpoeders geven hun zuiverheid en geschiktheid voor verschillende toepassingen aan. Hier is een gedetailleerde blik op de kwaliteiten die beschikbaar zijn voor verschillende metaalpoeders.

| Metaalpoeder | Cijfer | Puurheid | Sollicitatie |

|---|---|---|---|

| Koper (Cu) | Hoge zuiverheid | 99.99% | Interconnecties, geleidende paden |

| Aluminium (Al) | Elektronische rang | 99.98% | Zonnecellen, LED's |

| Zilver (Ag) | 99.999% Zuiver | 99.999% | Hoogfrequente apparaten |

| Goud (Au) | Halfgeleiderkwaliteit | 99.99% | Kritische verbindingen |

| Nikkel (Ni) | 99.98% Zuiver | 99.98% | Gegevensopslag, sensoren |

| Titaan (Ti) | Hoge zuiverheid | 99.6% | Condensatoren, vermogensapparaten |

| Wolfraam (W) | Hoge zuiverheid | 99.95% | Transistoren, hogetemperatuurtoepassingen |

| Molybdeen (Mo) | 99.95% Zuiver | 99.95% | Thermisch beheer |

| Palladium (Pd) | 99.9% Zuiver | 99.9% | Hoogwaardige sensoren |

| Kobalt (Co) | 99.8% Zuiver | 99.8% | Magnetische opslag, sensoren |

Leveranciers en prijzen voor metaalpoeder voor halfgeleiders

Voor de productie van halfgeleiders is het van cruciaal belang om te weten waar metaalpoeders vandaan komen en wat de prijzen ervan zijn.

| Leverancier | Beschikbare metaalpoeders | Prijs (per kg) |

|---|---|---|

| Amerikaanse elementen | Koper, goud, nikkel, zilver | $300 – $10,000 |

| NanoAmor | Aluminium, Wolfraam, Titanium | $200 – $8,000 |

| SkySpring Nanomaterialen | Palladium, Kobalt, Molybdeen | $500 – $12,000 |

| Tekna | Aluminium, Koper, Nikkel | $250 – $9,000 |

| Goodfellow | Goud, zilver, titanium | $400 – $15,000 |

vergelijken Metaalpoeders voor halfgeleiders: Voordelen en beperkingen

Elk metaalpoeder heeft zijn eigen voordelen en beperkingen. Hier is een vergelijkende analyse om u te helpen bepalen welk metaalpoeder het beste bij uw behoeften past.

| Metaalpoeder | Voordelen | Nadelen |

|---|---|---|

| Koper (Cu) | Hoge geleidbaarheid, kosteneffectief | Gevoelig voor oxidatie |

| Aluminium (Al) | Lichtgewicht, goede geleiding | Lager smeltpunt |

| Zilver (Ag) | Hoogste geleidbaarheid, bestand tegen aanslag | Dure |

| Goud (Au) | Niet-reactief, uitstekende geleiding | Zeer duur |

| Nikkel (Ni) | Corrosiebestendig, magnetisch | Matige geleidbaarheid |

| Titaan (Ti) | Sterk, lichtgewicht, biocompatibel | Duur, reactief |

| Wolfraam (W) | Hoog smeltpunt, hard | Zeer dicht, moeilijk te verwerken |

| Molybdeen (Mo) | Hoge sterkte, thermische geleidbaarheid | Broos, duur |

| Palladium (Pd) | Goede geleidbaarheid, corrosiebestendig | Zeer duur |

| Kobalt (Co) | Magnetische eigenschappen, hoog smeltpunt | Duur, kan giftig zijn |

Veelgestelde vragen

Vraag 1: Welke metaalpoeders worden het meest gebruikt bij de productie van halfgeleiders?

A1: De meest gebruikte metaalpoeders bij de productie van halfgeleiders zijn koper (Cu), aluminium (Al), zilver (Ag), goud (Au), nikkel (Ni), titanium (Ti), wolfraam (W), molybdeen (Mo), palladium (Pd) en kobalt (Co).

Vraag 2: Waarom is zuiverheid belangrijk in metaalpoeders voor halfgeleiders?

A2: Zuiverheid is cruciaal omdat onzuiverheden de elektrische eigenschappen, prestaties en betrouwbaarheid van halfgeleiderapparaten kunnen beïnvloeden. Metaalpoeders met een hoge zuiverheid zorgen voor optimale geleiding en minimaliseren defecten.

Vraag 3: Hoe worden metaalpoeders gebruikt in microprocessoren?

A3: Metaalpoeders zoals koper en goud worden gebruikt om geleidende paden en verbindingen binnen microprocessoren te creëren, waardoor efficiënte elektrische verbindingen tussen verschillende componenten worden gegarandeerd.

Vraag 4: Wat zijn de voordelen van het gebruik van goudpoeder in halfgeleiders?

A4: Goudpoeder geleidt uitstekend, is niet-reactief en verkleurt of corrodeert niet. Hierdoor is het ideaal voor kritieke verbindingen waarbij betrouwbaarheid en duurzaamheid essentieel zijn.

V5: Kunt u uitleggen welke rol wolfraampoeder speelt in halfgeleiderapparaten?

A5: Wolfraampoeder wordt gebruikt in halfgeleiderapparaten vanwege het hoge smeltpunt en de hoge dichtheid, waardoor het geschikt is voor toepassingen met hoge temperaturen, zoals transistoren en vermogensapparaten.

Vraag 6: Welke factoren beïnvloeden de keuze van metaalpoeder voor een specifieke halfgeleidertoepassing?

A6: Factoren die hierbij een rol spelen zijn onder meer de vereiste elektrische en thermische geleidbaarheid, het smeltpunt, de sterkte, de corrosiebestendigheid en specifieke toepassingsvereisten, zoals het gewicht en de magnetische eigenschappen.

V7: Zijn er milieurisico's verbonden aan het gebruik van metaalpoeders in halfgeleiders?

A7: Ja, de productie en verwijdering van metaalpoeders kunnen gevolgen hebben voor het milieu. Het is essentieel om duurzame praktijken en recyclingmaatregelen te volgen om deze effecten te minimaliseren.

V8: Welke invloed heeft de deeltjesgrootte van metaalpoeders op hun toepassing in halfgeleiders?

A8: De deeltjesgrootte heeft invloed op het oppervlak, de pakkingsdichtheid en de elektrische eigenschappen van de metaalpoeders, en beïnvloedt zo hun prestaties in halfgeleidertoepassingen.

V9: Wat zijn de uitdagingen bij de verwerking van metaalpoeders voor halfgeleiders?

A9: Uitdagingen zijn onder meer het bereiken van een uniforme deeltjesgrootteverdeling, het handhaven van een hoge zuiverheid, het voorkomen van oxidatie en het garanderen van een consistente kwaliteit tijdens de productie en verwerking.

V10: Waar kan ik hoogwaardige metaalpoeders voor halfgeleidertoepassingen kopen?

A10: Hoogwaardige metaalpoeders zijn verkrijgbaar bij leveranciers zoals American Elements, NanoAmor, SkySpring Nanomaterials, Tekna en Goodfellow.

Delen op

MET3DP Technology Co, LTD is een toonaangevende leverancier van additieve productieoplossingen met hoofdkantoor in Qingdao, China. Ons bedrijf is gespecialiseerd in 3D printapparatuur en hoogwaardige metaalpoeders voor industriële toepassingen.

Onderzoek om de beste prijs en een op maat gemaakte oplossing voor uw bedrijf te krijgen!

gerelateerde artikelen

Over Met3DP

Recente update

Ons product

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Metaalpoeders voor 3D printen en additieve productie

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731