VIGA-apparatuur voor één oven

Inhoudsopgave

Welkom bij de ultieme gids over VIGA-apparatuur (Vacuum Induction Gas Atomization) met één oven. Als u zich verdiept in de wereld van geavanceerde metallurgie en metaalpoederproductie, bent u hier aan het juiste adres. We gaan alles wat u moet weten over single-furnace VIGA-systemen uiteenzetten, waarbij we hun functionaliteit, voordelen, toepassingen en nog veel meer bespreken.

Overzicht van VIGA-apparatuur voor één oven

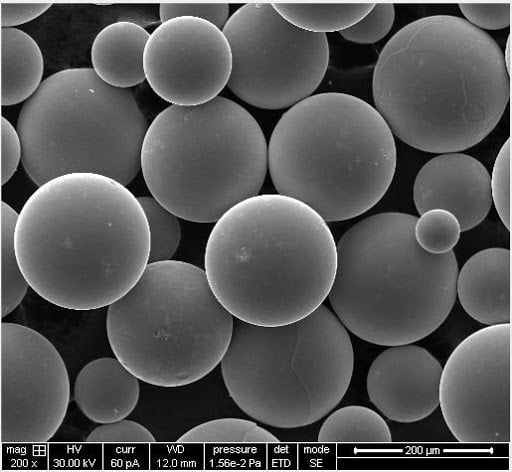

Single-furnace VIGA-apparatuur vertegenwoordigt een state-of-the-art methode voor het produceren van hoogwaardige metaalpoeders. Deze systemen maken gebruik van vacuüminductiesmelten gecombineerd met gasatomisatie om fijne, bolvormige poeders met superieure eigenschappen te creëren. Deze techniek is cruciaal voor industrieën die nauwkeurige materiaaleigenschappen vereisen, zoals de lucht- en ruimtevaart, automobiel- en biomedische sectoren.

Soorten metaalpoeders geproduceerd door VIGA met één oven

Laten we beginnen met een blik op een aantal specifieke metaalpoedermodellen die geproduceerd worden door single-furnace VIGA-apparatuur. Hier is een gedetailleerde lijst om u kennis te laten maken:

| Metaal Poeder Model | Samenstelling | Belangrijkste eigenschappen | Toepassingen |

|---|---|---|---|

| 316L roestvrij staal | Fe, Cr, Ni, Mo | Corrosiebestendigheid, hoge sterkte | Medische implantaten, scheepsuitrusting |

| 17-4 PH roestvrij staal | Fe, chroom, nikkel, koper, nikkel | Hoge sterkte, corrosieweerstand | Lucht- en ruimtevaartonderdelen, chemische verwerking |

| Ti-6Al-4V Titaniumlegering | Ti, Al, V | Hoge sterkte-gewichtsverhouding, biocompatibiliteit | Lucht- en ruimtevaartcomponenten, medische apparatuur |

| Inconel 718 | Ni, Cr, Fe, Nb, Mo | Hittebestendigheid, oxidatiebestendigheid | Onderdelen van straalmotoren, kernreactoren |

| Kobalt-chroom legering | Co, Cr, Mo, W | Slijtvastheid, hoge hardheid | Tandheelkundige implantaten, orthopedische hulpmiddelen |

| AlSi10Mg aluminiumlegering | Al, Si, Mg | Lichtgewicht, goede werpeigenschappen | Auto-onderdelen, lucht- en ruimtevaartstructuren |

| Maragingstaal | Fe, Ni, Co, Mo | Hoge sterkte, uitstekende taaiheid | Gereedschappen, lucht- en ruimtevaartstructuren |

| Haynes 282 | Ni, Cr, Co, Mo, Ti | Kruipsterkte, thermische stabiliteit | Gasturbines, warmtewisselaars |

| Koperlegering C18150 | Cu, Cr, Zr | Hoge elektrische geleidbaarheid, goede sterkte | Elektrische componenten, laselektroden |

| Nikkel Superlegering Nimonic 90 | Ni, Cr, Co, Ti, Al | Oxidatiebestendigheid, hoge temperatuursterkte | Turbinebladen, uitlaatkleppen |

Toepassingen van VIGA-apparatuur voor één oven

De veelzijdigheid van single-furnace VIGA-apparatuur blijkt uit het brede scala aan toepassingen. Hier zijn enkele specifieke toepassingen:

| Industrie | Sollicitatie | Voordelen |

|---|---|---|

| Lucht- en ruimtevaart | Turbinebladen, structurele onderdelen | Hoge sterkte-gewichtsverhouding, bestand tegen hoge temperaturen |

| Automobiel | Motoronderdelen, lichtgewicht constructies | Verbeterde brandstofefficiëntie, duurzaamheid |

| Biomedisch | Implantaten, chirurgische instrumenten | Biocompatibiliteit, precisie |

| Energie | Kernreactorcomponenten, warmtewisselaars | Corrosie- en hogetemperatuurbestendigheid |

| Gereedschap | Mallen, matrijzen | Slijtvastheid, levensduur |

| Elektronica | Geleidende componenten | Hoge elektrische geleidbaarheid, betrouwbaarheid |

Gedetailleerde specificaties, maten en normen

Het begrijpen van de specificaties en normen van metaalpoeders geproduceerd door VIGA-apparatuur is cruciaal voor het selecteren van het juiste materiaal voor uw behoeften. Hier is een overzicht:

| Metaal Poeder Model | Deeltjesgroottebereik | Normen | typische applicaties |

|---|---|---|---|

| 316L roestvrij staal | 15-45 µm | ASTM F138, ISO 5832-1 | Medisch, maritiem |

| 17-4 PH roestvrij staal | 20-63 µm | AMS 5643, ASTM A693 | Ruimtevaart, chemisch |

| Ti-6Al-4V Titaniumlegering | 15-45 µm | ASTM F1472, ISO 5832-3 | Lucht- en ruimtevaart, medisch |

| Inconel 718 | 20-53 µm | AMS 5662, ASTM B637 | Straalmotoren, kernenergie |

| Kobalt-chroom legering | 10-50 µm | ASTM F1537, ISO 5832-12 | Tandheelkundig, orthopedisch |

| AlSi10Mg aluminiumlegering | 20-60 µm | ISO 3522, ASTM B85 | Automobiel, ruimtevaart |

| Maragingstaal | 10-45 µm | AMS 6514, ASTM A538 | Gereedschap, lucht- en ruimtevaart |

| Haynes 282 | 20-53 µm | AMS 5918, ASTM B637 | Gasturbines, warmtewisselaars |

| Koperlegering C18150 | 15-45 µm | ASTM B820, AMS 4596 | Elektrisch, lassen |

| Nikkel Superlegering Nimonic 90 | 20-53 µm | AMS 5829, ASTM B637 | Turbinebladen, uitlaatkleppen |

Leveranciers en prijsinformatie

Als het gaat om de aankoop van metaalpoeders die via VIGA-apparatuur met één oven, het kennen van uw leveranciers en prijzen is essentieel. Hier is een lijst van enkele prominente leveranciers en hun geschatte prijzen:

| Leverancier | Metaal Poeder Modellen | Prijs (per kg) | Aanvullende diensten |

|---|---|---|---|

| Hogenäs | 316L, Ti-6Al-4V, Inconel 718 | $50-$200 | Aangepaste maatvoering, technische ondersteuning |

| Timmerman technologie | 17-4 PH, Maragingstaal | $60-$250 | Metallurgisch advies, legeringen op maat |

| Sandvik | Kobalt-chroom, Haynes 282 | $80-$300 | Kwaliteitstesten, R&D-ondersteuning |

| LPW-technologie | AlSi10Mg, koperlegering C18150 | $40-$150 | Poederlevenscyclusbeheer, traceerbaarheid |

| AP&C (GE additief) | 316L, Ti-6Al-4V, Inconel 718 | $55-$220 | Geavanceerde karakterisering, recyclingdiensten |

| Praxair Oppervlaktetechnologieën | Inconel 718, Nimonic 90 | $70-$280 | Toepassingstechniek, coatingoplossingen |

Voordelen en nadelen van VIGA-apparatuur voor één oven

Laten we eens kijken naar de voor- en nadelen van het gebruik van VIGA-systemen met één oven voor de productie van metaalpoeder:

| Voordelen | Nadelen |

|---|---|

| Hoge zuiverheid:De vacuümomgeving minimaliseert verontreiniging. | Kosten: Hoge initiële investering en operationele kosten. |

| Uniforme deeltjesgrootte: Consistente poederkwaliteit. | Complexiteit: Vereist vakkundige operators en onderhoud. |

| Veelzijdigheid: Geschikt voor een breed scala aan metaallegeringen. | Energieverbruik: Aanzienlijk stroomverbruik. |

| Verbeterde materiaaleigenschappen: Verbeterde mechanische eigenschappen van poeders. | Beperkte capaciteit: Eén oven beperkt het productievolume in vergelijking met opstellingen met meerdere ovens. |

Veelgestelde vragen

| Vraag | Antwoord |

|---|---|

| Waarvoor wordt VIGA-apparatuur met één oven gebruikt? | Het wordt gebruikt voor de productie van hoogwaardige metaalpoeders voor diverse industrieën, zoals de lucht- en ruimtevaart, de automobielindustrie en de biomedische sector. |

| Hoe werkt VIGA-apparatuur met één oven? | Hierbij wordt gebruikgemaakt van vacuüminductiesmelten in combinatie met gasatomisatie om fijne, bolvormige metaalpoeders te produceren. |

| Wat zijn de voordelen van het gebruik van VIGA voor de productie van metaalpoeder? | Voordelen zijn onder andere een hoge zuiverheid, een uniforme deeltjesgrootte en verbeterde materiaaleigenschappen. |

| Welke metalen kunnen met VIGA-apparatuur worden bewerkt? | Een breed assortiment, waaronder roestvrij staal, titaniumlegeringen, nikkel-superlegeringen en meer. |

| Zijn er beperkingen bij het gebruik van VIGA-apparatuur met één oven? | Ja, maar dit heeft hoge kosten, complexiteit en een beperkte productiecapaciteit. |

| Welke industrieën profiteren het meest van door VIGA geproduceerde poeders? | Lucht- en ruimtevaart-, automobiel-, biomedische, energie-, gereedschaps- en elektronica-industrie. |

| Wat zijn de typische deeltjesgroottes voor door VIGA geproduceerde poeders? | De deeltjesgrootte varieert doorgaans van 10 tot 63 micron, afhankelijk van de legering en de specifieke vereisten. |

| Hoe verhoudt VIGA zich tot andere poederproductiemethoden? | VIGA biedt een hogere zuiverheid en betere controle over de deeltjesgrootte, maar kan duurder en complexer zijn dan andere methoden, zoals waterverneveling. |

Conclusie

VIGA-apparatuur met één oven is een game-changer op het gebied van metaalpoederproductie en biedt ongeëvenaarde zuiverheid, consistentie en veelzijdigheid. Of u nu in de lucht- en ruimtevaart, automobiel- of biomedische industrie werkt, inzicht in de complexiteit van VIGA-technologie kan u helpen weloverwogen beslissingen te nemen en de voordelen van hoogwaardige metaalpoeders te benutten.

Als u nog vragen heeft of specifieke informatie nodig hebt, neem dan gerust contact met ons op. Duik in de wereld van geavanceerde metallurgie met single-furnace VIGA-apparatuur en til uw materiaalcapaciteiten naar nieuwe hoogten!

Delen op

MET3DP Technology Co, LTD is een toonaangevende leverancier van additieve productieoplossingen met hoofdkantoor in Qingdao, China. Ons bedrijf is gespecialiseerd in 3D printapparatuur en hoogwaardige metaalpoeders voor industriële toepassingen.

Onderzoek om de beste prijs en een op maat gemaakte oplossing voor uw bedrijf te krijgen!

gerelateerde artikelen

Over Met3DP

Recente update

Ons product

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Metaalpoeders voor 3D printen en additieve productie

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731