Etsen van roestvrij staal en titanium in Daejeon: een uitgebreide gids voor B2B-kopers

Inhoudsopgave

1. Inleiding: Belang van het etsen van roestvast staal en titanium in industriële toepassingen

Etsen is een cruciaal productieproces dat wordt gebruikt om metalen precisiecomponenten te maken voor industrieën zoals lucht- en ruimtevaart, medische apparatuur, elektronica en de auto-industrie. Roestvrij staal en titanium zijn twee van de meest geëtste metalen vanwege hun hoge sterkte, corrosiebestendigheid en duurzaamheid.

Waarom etsen essentieel is voor industriële productie

- Precisie Micropatroonvorming - Ets maakt ingewikkelde ontwerpen mogelijk zonder de integriteit van het materiaal aan te tasten.

- Hoge duurzaamheid - Roestvrij staal en titanium behouden hun structurele integriteit, zelfs na het etsen.

- Corrosieweerstand - Deze metalen zijn ideaal voor medische, luchtvaart- en ruwe milieutoepassingen.

- Lichtgewicht en sterk - Vooral titanium heeft een uitstekende verhouding tussen sterkte en gewicht, waardoor het ideaal is voor ruimtevaart en medische implantaten.

Veel fabrikanten in Daejeon, Zuid-Koreawenden zich nu tot geavanceerde etstechnieken om roestvrijstalen en titanium onderdelen van hoge kwaliteit te produceren. Deze verschuiving wordt gedreven door de groeiende vraag naar aangepaste metalen onderdelen in hightechindustrieën.

2. Markttrends en groeipotentieel voor geëtste metalen in Zuid-Korea

Zuid-Korea, met name de stad Daejeonis een centrum voor geavanceerde materialen en precisietechniek. De markt voor geëtst roestvast staal en titanium groeit snel door de volgende factoren:

Belangrijkste markttrends

| Trend | Impact op de industrie |

|---|---|

| Stijgende vraag naar medische implantaten | Titanium etsen is essentieel voor zeer nauwkeurige medische implantaten. |

| Groei van de halfgeleiderindustrie | Roestvrij staal etsen wordt veel gebruikt bij de productie van halfgeleideronderdelen. |

| Groeiende lucht- en ruimtevaartsector | Lichtgewicht titanium onderdelen vereisen precisie-etsen voor vliegtuigen en ruimtevaartuigen. |

| Toenemend gebruik van 3D printen bij metaalproductie | Hybride technieken die 3d printen en etsen komen steeds vaker voor. |

Waarom Zuid-Korea een belangrijke speler is in etstechnologie

- Sterke R&D-investeringen - Overheids- en privéfinanciering stimuleren innovatie in metaalverwerking.

- Infrastructuur voor geavanceerde productie - Faciliteiten in Daejeon zijn gespecialiseerd in etsen met hoge precisie.

- Strategische locatie - Nabijheid van grote fabrikanten van elektronica, auto's en medische apparatuur.

Voor bedrijven die op zoek zijn naar bron geëtst roestvrij staal en titanium onderdelen, Zuid-Korea biedt hoogwaardige, kosteneffectieve oplossingen in vergelijking met westerse leveranciers.

3. Belangrijke factoren bij het kiezen van een leverancier van etsen in Daejeon

Het kiezen van de juiste etsleverancier is van cruciaal belang om ervoor te zorgen dat hoogwaardige precisiecomponentenDit zijn de belangrijkste factoren om te overwegen:

1. Materiële expertise

Zorg ervoor dat de leverancier ervaring heeft met roestvrij staal en titanium. Deze materialen vereisen speciale etstechnieken.

2. Gebruikte etstechnieken

De twee belangrijkste etsmethoden zijn:

- Chemisch etsen - Gebruikt zure of chemische oplossingen om selectief materiaal te verwijderen.

- Lasermarkeren - Gebruikt krachtige lasers voor nauwkeurig markeren en snijden.

3. Industriecertificeringen

Zoek naar leveranciers met ISO 9001-, AS9100- (lucht- en ruimtevaart) of ISO 13485- (medisch) certificeringen. Dit zorgt voor naleving van de industrienormen.

4. Productiecapaciteit en doorlooptijd

Kies een leverancier die kan omgaan met bulkbestellingen met behoud van snelle doorlooptijden.

5. Aanpassingsmogelijkheden

Als u aangepaste ontwerpenZorg ervoor dat de leverancier het volgende biedt CNC precisiebewerking, CAD-ondersteuning en prototyping-diensten.

6. Kosten en prijsstructuur

Vergelijk de prijzen voor bulktoetsdiensten. Sommige leveranciers bieden groothandelskortingen voor grote orders.

4. Top 5 leveranciers van roestvrij staal en titaniumetsen in Daejeon

Daejeon is de thuisbasis van verschillende hoogwaardige leveranciers van metaaletsen gespecialiseerd in roestvrij staal en titanium. Hieronder staat de top vijf van bedrijven die bekend staan om hun precisie-etsdiensten en B2B groothandel.

Top etsleveranciers in Daejeon

| Naam leverancier | Sterke punten | Industrieën bediend | Methoden voor etsen |

|---|---|---|---|

| Daejeon precisiemetalen | Zeer nauwkeurig etsen van roestvrij staal | Medisch, Ruimtevaart, Elektronica | Chemisch etsen en lasermarkeren |

| Korea Metal Engraving Co. | Titaniumetsen voor toepassingen met hoge sterkte | Auto-industrie, Ruimtevaart | Chemisch etsen |

| Daejeon etsoplossingen | Grootschalige etsdiensten in bulk met snelle doorlooptijden | Halfgeleider, Industriële machines | Lasermarkeren |

| Hitech Metaalbewerking | Metalen etsen op maat met CAD-ontwerpondersteuning | Medische apparaten, Elektronica | Chemisch etsen en lasermarkeren |

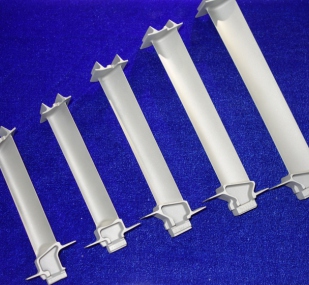

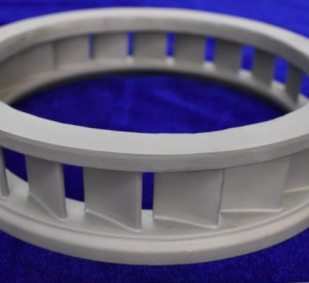

| Metaal3DP | Geavanceerd 3D printen & etsen voor industriële toepassingen | Ruimtevaart, Medisch, Automobiel | Hybride 3D printen & etsen |

Elk van deze leveranciers biedt unieke voordelen afhankelijk van de vereisten in uw sector. Als je echter een totaaloplossing voor metaalproductie, Metaal3DP biedt zowel additieve productie (3D printen) als precisie-etsenwaardoor het een ideale keuze is.

👉 Meer informatie over De geavanceerde metaalverwerkingsmogelijkheden van Metal3DP: Metaal 3D-printen

5. Waarom meer fabrikanten kiezen voor lokale etsdiensten in plaats van import

Veel bedrijven vertrouwden voorheen op geïmporteerde geëtste onderdelen uit China, Japan of de VS. Recente trends wijzen echter op een verschuiving naar lokale Zuid-Koreaanse leveranciers.

Belangrijkste redenen om lokale leveranciers van etsen te kiezen

1. Snellere doorlooptijden

- Lokaal Leveranciers uit Daejeon snellere doorlooptijden bieden in vergelijking met import uit het buitenland.

- Geen vertragingen door internationale verzending en inklaring.

2. Kostenbesparingen op logistiek

- Elimineert de hoge kosten van internationale vracht- en invoerbelastingen.

- Bulkbestellingen kunnen sneller en goedkoper geleverd binnen Zuid-Korea.

3. Hogere kwaliteitscontrole

- Zuid-Koreaanse leveranciers houden zich aan strenge productienormen (ISO 9001, AS9100, enz.).

- Gemakkelijker uit te voeren inspecties en kwaliteitscontroles ter plaatse.

4. Aanpassing en flexibiliteit

- Lokale leveranciers bieden aangepaste etsoplossingen aangepast aan de specificaties van de klant.

- Makkelijker samenwerking bij ontwerpwijzigingen zonder taalbarrières.

5. Geavanceerde technologie en innovatie

- Korea is een wereldleider in hightech productieen garandeert state-of-the-art etsoplossingen.

- Leveranciers zoals Metaal3DP integreren 3D printen met etsen voor de volgende generatie industriële toepassingen.

Door te sourcen van lokale etsleveranciers in Daejeonkunnen bedrijven het volgende bereiken hogere efficiëntie, lagere kosten en betere kwaliteitscontrole.

6. Waarom kiezen voor Metal3DP voor het Hoogwaardig Etsen van Roestvast Staal en Titanium?

Als je op zoek bent naar een betrouwbare leverancier die geavanceerde metaalbewerking, Metaal3DP is de ideale keuze.

Wat maakt Metal3DP onderscheidend?

| Functie | Voordeel |

|---|---|

| Hybride 3D printen & etsen | Combineert additieve productie met precisie-etsen voor superieure resultaten. |

| Toonaangevende expertise | Tientallen jaren ervaring in additieve metaalproductie en materiaalverwerking. |

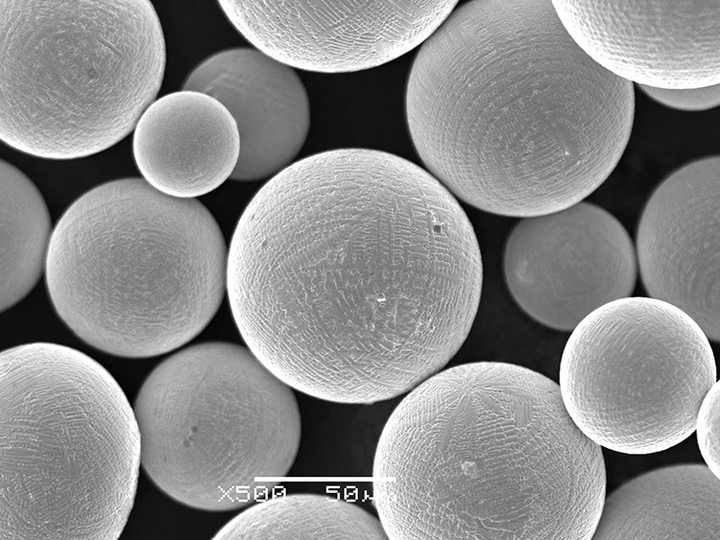

| Geavanceerde technologie voor het maken van poeder | Produceert hoge kwaliteit sferische metaalpoeders voor superieure etsprestaties. |

| Zuiver titanium en roestvrij staal | Zorgt voor duurzame, corrosiebestendige en zeer sterke geëtste onderdelen. |

| ISO- en luchtvaartcertificering | Voldoet aan strenge industrienormen voor medische, luchtvaart- en automobieltoepassingen. |

De belangrijkste mogelijkheden van Metal3DP op het gebied van etsen

1. Hoge precisie roestvrij staal etsen

- Ideaal voor halfgeleiders, medische apparatuur en industriële componenten.

2. Titaniumetsen voor ruimtevaart en medische toepassingen

- Produceert lichtgewicht, zeer sterk componenten met superieure corrosiebestendigheid.

3. Ondersteuning voor aangepaste ontwerpen en prototypes

- Volledig CAD-ontwerpserviceswaardoor aangepaste metalen onderdelen.

4. Groothandelsorders in bulk met concurrerende prijzen

- Speciaal B2B-prijzen voor het etsen van roestvrij staal en titanium in bulk.

👉 Meer informatie over Metal3DP's geavanceerde metalen materialen en 3D printoplossingen: Productpagina

7. Hoe bestel ik op maat gemaakte geëtste roestvrijstalen en titanium onderdelen?

Sourcing zeer nauwkeurig geëtste onderdelen van roestvrij staal en titanium vereist een goed gestructureerde aanpak om kwaliteit, kosteneffectiviteit en tijdige levering te garanderen. Hieronder volgt een stap-voor-stap handleiding voor het bestellen van geëtste metalen onderdelen bij Metaal3DP en andere topleveranciers in Daejeon.

Stap 1: Definieer uw vereisten

Zorg ervoor dat je de volgende gegevens hebt voordat je een bestelling plaatst:

- Materiaalkeuze - Roestvrij staal of titanium?

- Etsmethode - Chemisch etsen of lasermarkeren?

- Dikte en afmetingen - Exacte afmetingen voor je onderdelen.

- Ontwerpspecificaties - CAD-tekeningen of prototypen.

- Hoeveelheid - Bulkproductie of productie in kleine batches?

- Industriestandaarden - Eventueel vereiste certificeringen (ISO 9001, AS9100, enz.).

💡 Tip: Als je hulp nodig hebt bij het kiezen van materialen of bij het ontwerp, Metal3DP biedt deskundig advies voor industriële toepassingen.

Stap 2: Vraag een offerte aan

Meest B2B-leveranciers bieden prijzen gebaseerd op factoren zoals:

| Factor | Invloed op de prijsstelling |

|---|---|

| Type materiaal | Titanium is over het algemeen duurder dan roestvrij staal. |

| Complexiteit van etsen | Voor ingewikkelde ontwerpen kan meer verwerkingstijd nodig zijn. |

| Ordervolume | Voor bulkorders gelden meestal gereduceerde tarieven. |

| Vereisten voor oppervlakteafwerking | Extra polijsten of coaten kan de kosten verhogen. |

👉 Vraag een offerte op maat aan bij Metal3DP: Neem contact met ons op

Stap 3: Prototype en testen van monsters

Voordat we overgaan op volledige productie, bieden veel leveranciers:

- Ontwikkeling van prototypes - Een kleine partij voor goedkeuring.

- Materiaal testen - Ervoor zorgen dat de industrienormen worden nageleefd.

- Testen van de oppervlakteafwerking - Controle van corrosiebestendigheid, duurzaamheid en precisie.

Stap 4: Bulkproductie en kwaliteitsinspectie

Zodra het prototype is goedgekeurd:

- De grootschalige etsproductie begint.

- Er worden kwaliteitscontroles uitgevoerd (maatnauwkeurigheid, oppervlakteafwerking, mechanische eigenschappen).

- Producten worden verpakt en klaargemaakt voor verzending.

📦 Verzendopties:

- Binnenlandse levering binnen Zuid-Korea.

- Internationale verzending voor wereldwijde B2B-kopers.

💡 Tip: Metal3DP biedt kortingen voor bulkbestellingen en kwaliteitsgarantie voor roestvrijstalen en titanium onderdelen.

8. FAQ's: Veelgestelde vragen over het etsen van roestvast staal en titanium

Hieronder staan enkele veelgestelde vragen over etsen van roestvrij staal en titanium voor B2B-kopers.

V1: Wat is het verschil tussen chemisch etsen en lasermarkeren?

| Type ets | Beschrijving | Beste voor |

|---|---|---|

| Chemisch etsen | Gebruikt zure of chemische oplossingen om materiaal te verwijderen. | Hoge precisie, complexe ontwerpen, massaproductie. |

| Lasermarkeren | Gebruikt krachtige lasers om materiaal te verdampen. | Aangepaste markeringen, productie in kleine series, serienummers. |

V2: Is titanium moeilijker te etsen dan roestvrij staal?

Ja, titanium is meer uitdagend om te etsen vanwege zijn hoge sterkte en corrosiebestendigheid. Het vereist gespecialiseerde chemische oplossingen en gecontroleerde verwerkingsomstandigheden.

V3: Welke industrieën hebben het meeste baat bij geëtste onderdelen van roestvast staal en titanium?

- Lucht- en ruimtevaart - Lichtgewicht, zeer sterke titanium onderdelen.

- Medische apparaten – Biocompatibele implantaten en chirurgische instrumenten.

- Halfgeleider & Elektronica - Zeer nauwkeurige roestvrijstalen onderdelen.

- Automobiel - Duurzaamheid en corrosiebestendige metalen onderdelen.

V4: Hoe lang duurt het etsproces?

- Prototypen: 1-2 weken

- Bulkproductie: 3-6 weken, afhankelijk van de grootte en complexiteit van de bestelling.

V5: Kan ik 3D printen combineren met etsen voor mijn metalen onderdelen?

Ja! Metal3DP is gespecialiseerd in hybride productiecombineren 3D metaal printen en precisie-etsen voor geavanceerde industriële toepassingen.

👉 Meer informatie over De printmethodes van Metal3DP: Afdrukmethoden

9. Conclusie en volgende stappen voor B2B-kopers

Waarom Metal3DP kiezen voor uw roestvast staal en titanium etsen?

Als uw bedrijf zeer nauwkeurige geëtste metalen onderdelen, Metaal3DP is de beste keus voor:

✅ Geavanceerde hybride productie - 3D printen en etsen voor superieure kwaliteit.

✅ Hoogwaardige metaalpoeders - Geoptimaliseerd voor ruimtevaart, medische en industriële toepassingen.

✅ Oplossingen op maat & bulkbestellingen - Concurrerende prijzen voor B2B-kopers.

✅ Vertrouwde industrie-expertise - Jarenlange ervaring in additieve metaalproductie.

Wat is de volgende stap?

🔹 Neem contact op met Metal3DP voor een offerte voor etsen op maat: Een offerte aanvragen

🔹 Ontdek onze geavanceerde metalen materialen: Metaal 3D-printen

🔹 Meer informatie over onze geavanceerde producten: Productcatalogus

Werk samen met Metal3DP en til uw metaalproductie naar een hoger niveau!

Delen op

MET3DP Technology Co, LTD is een toonaangevende leverancier van additieve productieoplossingen met hoofdkantoor in Qingdao, China. Ons bedrijf is gespecialiseerd in 3D printapparatuur en hoogwaardige metaalpoeders voor industriële toepassingen.

Onderzoek om de beste prijs en een op maat gemaakte oplossing voor uw bedrijf te krijgen!

gerelateerde artikelen

Over Met3DP

Recente update

Ons product

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Metaalpoeders voor 3D printen en additieve productie

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731