Полное руководство по процессу AM

Оглавление

Добро пожаловать в увлекательный мир Процесс AM, где границы традиционного производства постоянно расширяются. В этом руководстве мы глубоко погрузимся в тонкости AM, проливая свет на различные аспекты от моделей металлического порошка до их применения, преимуществ, недостатков и многого другого. Пристегните ремни для увлекательного и познавательного путешествия по современным чудесам производства!

Обзор аддитивного производства

Аддитивное производство, часто называемое 3D-печатью, представляет собой процесс создания трехмерных объектов путем добавления материала слой за слоем. В отличие от традиционных методов производства, которые часто подразумевают изъятие материала из более крупного блока, AM создает объекты с нуля, что позволяет создавать сложные конструкции и сокращать отходы.

Ключевые детали процесса AM

- Технология: Послойное добавление материала

- Используемые материалы: Металлы, полимеры, керамика и композиты

- Приложения: аэрокосмическая промышленность, автомобилестроение, здравоохранение, потребительские товары и многое другое

- Преимущества: Сложная геометрия, сокращение отходов, индивидуальная настройка и быстрое прототипирование

- Вызовы: Ограничения по материалу, качество поверхности и высокие первоначальные затраты

Типы металлических порошков, используемых в АМ

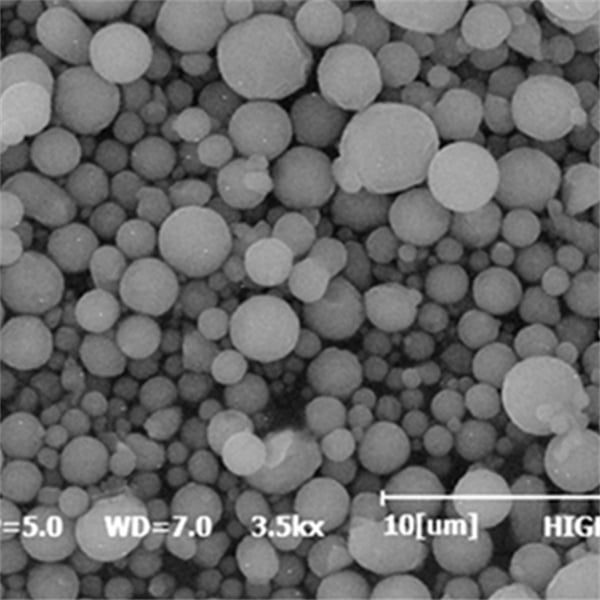

В сфере AM металлические порошки являются критически важным компонентом. Давайте рассмотрим некоторые из наиболее часто используемых металлических порошков, их составы и их уникальные свойства.

Распространенные металлические порошки для AM

| Металлический порошок | Состав | Свойства | Приложения |

|---|---|---|---|

| Титан (Ti-6Al-4V) | 90% Титан, 6% Алюминий, 4% Ванадий | Высокая прочность, легкий вес, устойчивость к коррозии | Аэрокосмическая промышленность, медицинские имплантаты |

| Нержавеющая сталь (316L) | 16-18% Хром, 10-14% Никель, 2-3% Молибден | Коррозионностойкий, прочный, хорошо сваривается | Медицинские инструменты, пищевая промышленность |

| Алюминий (AlSi10Mg) | 89-91% Алюминий, 9-11% Кремний, 0,2-0,4% Магний | Легкий, с хорошей теплопроводностью, прочный | Автомобильная промышленность, аэрокосмическая промышленность |

| Инконель (IN718) | 50-55% Никель, 17-21% Хром, 4,75-5,5% Ниобий | Термостойкость, высокая прочность при повышенных температурах | Турбины, аэрокосмические компоненты |

| Кобальт-хром (CoCr) | 55-65% Кобальт, 27-30% Хром, 5-7% Молибден | Износостойкий, биосовместимый, высокотвердый | Зубные имплантаты, ортопедические приспособления |

| Медь (Cu) | 99.9% Медь | Отличная тепло- и электропроводность | Электрические компоненты, теплообменники |

| Инструментальная сталь (H13) | 0,35-0,45% Углерод, 5-5,5% Хром, 1-1,2% Молибден | Высокая твердость, износостойкость, хорошая обрабатываемость | Пресс-формы, штампы, режущие инструменты |

| Никелевый сплав (Hastelloy X) | 47-52% Никель, 20,5-23% Хром, 17-20% Железо | Стойкость к окислению, высокая прочность при высоких температурах | Химическая переработка, аэрокосмическая промышленность |

| Магний (AZ91D) | 8,5-9,5% Алюминий, 0,6-1,4% Цинк, 0,15% Марганец | Легкий вес, хорошее соотношение прочности и веса | Автомобилестроение, электроника |

| Вольфрам (Вт) | 99.95% Вольфрам | Чрезвычайно высокая температура плавления, плотный, прочный | Аэрокосмическая и оборонная промышленность |

Подробные модели из металлического порошка

- Титан (Ti-6Al-4V): Известный своим исключительным соотношением прочности к весу и биосовместимостью, этот сплав является основным в аэрокосмической и медицинской промышленности. Он обеспечивает впечатляющую устойчивость к усталости и коррозии, что делает его идеальным для критических компонентов.

- Нержавеющая сталь (316L): Универсальный сплав, нержавеющая сталь 316L ценится за свою прочность и устойчивость к коррозии. Она широко используется в средах, где гигиена и долговечность имеют первостепенное значение, например, в медицинских приборах и оборудовании для обработки пищевых продуктов.

- Алюминий (AlSi10Mg): Этот сплав известен своей легкостью и превосходной теплопроводностью. Это популярный выбор в автомобильной и аэрокосмической промышленности, где снижение веса имеет решающее значение без ущерба для прочности.

- Инконель (IN718): Известный своей способностью выдерживать экстремальные температуры и механические нагрузки, Inconel 718 широко используется в аэрокосмической промышленности для турбинных двигателей и других высокотемпературных применений.

- Кобальт-хром (CoCr): Этот биосовместимый сплав идеально подходит для медицинских имплантатов благодаря своей высокой твердости и износостойкости. Он обеспечивает долговечность и надежность в ортопедических и стоматологических применениях.

- Медь (Cu): Благодаря непревзойденной тепло- и электропроводности медь незаменима в электротехнике и теплообменниках, где эффективная передача тепла имеет решающее значение.

- Инструментальная сталь (H13): Инструментальная сталь H13 идеально подходит для изготовления форм и режущих инструментов, обладает высокой твердостью и износостойкостью, гарантируя долговечность и точность производственных процессов.

- Никелевый сплав (Hastelloy X): Этот сплав отлично работает в условиях высоких температур, устойчив к окислению и сохраняет прочность. Он используется в химической обработке и аэрокосмической промышленности, где надежность в экстремальных условиях имеет решающее значение.

- Магний (AZ91D): Будучи одним из самых легких конструкционных металлов, магний AZ91D используется там, где критически важна экономия веса, например, в автомобильной и электронной промышленности, обеспечивая хороший баланс прочности и легкости.

- Вольфрам (Вт): Известный своей невероятно высокой температурой плавления и плотностью, вольфрам незаменим в аэрокосмической и оборонной промышленности, особенно там, где ожидается воздействие экстремальных условий.

Применение процесса AM

Универсальность AM отражается в широком спектре ее применения. Здесь мы углубимся в различные отрасли, использующие AM для расширения границ инноваций.

Отрасли, использующие AM

| Промышленность | Приложения | Преимущества |

|---|---|---|

| Аэрокосмическая промышленность | Компоненты двигателя, конструктивные детали, инструменты | Легкие детали, сокращенные сроки выполнения, сложная геометрия |

| Автомобильная промышленность | Прототипы, индивидуальные детали, легкие компоненты | Гибкость конструкции, быстрое прототипирование, уменьшенный вес |

| Здравоохранение | Имплантаты, протезы, хирургические инструменты | Индивидуализация, биосовместимость, точная геометрия |

| Потребительские товары | Индивидуальные продукты, носимые технологии, бытовая техника | Персонализация, производство по требованию, сокращение запасов |

| Архитектура | Масштабные модели, индивидуальные компоненты, строительные инструменты | Индивидуальный дизайн, быстрое производство, сокращение отходов материала |

| Образование | Учебные пособия, разработка прототипов, исследования | Практическое обучение, инновационные проекты, экономически эффективное прототипирование |

| Оборона | Легкая броня, компоненты оружия, инструменты для полевого ремонта | Долговечность, кастомизация, быстрое изготовление |

| Энергия | Детали турбин, теплообменники, трубопроводы | Высокая производительность, эффективность материалов, сложные конструкции |

Преимущества процесса AM

- Гибкость конструкции: АП позволяет создавать сложные и замысловатые конструкции, которые было бы невозможно или дорого реализовать с помощью традиционных методов.

- Персонализация: Изделия можно адаптировать к индивидуальным потребностям, что делает их идеальными для медицинских имплантатов и деталей, изготавливаемых по индивидуальному заказу.

- Сокращение отходов: Материал добавляется слой за слоем, что сводит к минимуму отходы по сравнению с субтрактивными производственными процессами.

- Быстрое прототипирование: АП обеспечивает быструю итерацию и тестирование проектов, ускоряя цикл разработки.

- Легкие конструкции: AM позволяет производить легкие компоненты, имеющие решающее значение в аэрокосмической и автомобильной промышленности.

Недостатки процесса AM

- Материальные ограничения: Не все материалы подходят для АМ, что ограничивает спектр возможных применений.

- Отделка поверхности: Детали, изготовленные методом AM, часто требуют последующей обработки для достижения желаемого качества поверхности.

- Первоначальные затраты: Первоначальные инвестиции в технологию и материалы AM могут быть высокими, что делает ее менее доступной для мелкосерийных предприятий.

- Скорость производства: Хотя АМ отличается сложностью и возможностью настройки, он может быть медленнее традиционных методов массового производства больших партий.

Сравнение металлических порошков AM

Давайте подробнее рассмотрим, как эти металлические порошки соотносятся друг с другом по различным параметрам.

| Металлический порошок | Прочность | Вес | Коррозионная стойкость | Термостойкость | Стоимость |

|---|---|---|---|---|---|

| Титан (Ti-6Al-4V) | Высокая | Свет | Отличный | Хороший | Высокая |

| Нержавеющая сталь (316L) | Умеренный | Heavy | Отличный | Умеренный | Умеренный |

| Алюминий (AlSi10Mg) | Умеренный | Очень легкий | Хороший | Умеренный | Низкий |

| Инконель (IN718) | Очень высокий | Heavy | Хороший | Отличный | Очень высокий |

| Кобальт-хром (CoCr) | Высокая | Heavy | Отличный | Хороший | Высокая |

| Медь (Cu) | Низкий | Heavy | Бедный | Бедный | Низкий |

| Инструментальная сталь (H13) | Высокая | Heavy | Умеренный | Умеренный | Умеренный |

| Никелевый сплав (Hastelloy X) | Высокая | Heavy | Хороший | Отличный | Очень высокий |

| Магний (AZ91D) | Низкий | Очень легкий | Бедный | Бедный | Низкий |

| Вольфрам (Вт) | Очень высокий | Очень тяжелый | Отличный | Отличный | Очень высокий |

Поставщики и ценовая политика

Когда дело доходит до поиска металлических порошков для AM, важно знать ведущих поставщиков и их цены. Вот разбивка:

| Поставщик | Металлический порошок | Цена (за кг) | Контактная информация |

|---|---|---|---|

| Höganäs AB | Титан (Ti-6Al-4V) | $300 | www.hoganas.com |

| Sandvik | Нержавеющая сталь (316L) | $150 | www.materials.sandvik |

| EOS GmbH | Алюминий (AlSi10Mg) | $100 | www.eos.info |

| Технология столярных работ | Инконель (IN718) | $400 | www.carpentertechnology.com |

| Arcam AB | Кобальт-хром (CoCr) | $350 | www.arcam.com |

| GKN Hoeganaes | Медь (Cu) | $50 | www.gknpm.com |

| Бёлер Уддехольм | Инструментальная сталь (H13) | $120 | www.bohler-uddeholm.com |

| Haynes International | Никелевый сплав (Hastelloy X) | $450 | www.haynesintl.com |

| Передовые порошки и покрытия (AP&C) | Магний (AZ91D) | $80 | www.advancedpowders.com |

| Buffalo Tungsten Inc. | Вольфрам (Вт) | $500 | www.buffalotungsten.com |

Плюсы и минусы процесса AM

Каждая технология имеет свои сильные и слабые стороны. Вот подробное сравнение плюсов и минусов процесса AM:

| Аспект | Преимущества | Ограничения |

|---|---|---|

| Дизайн | Позволяет создавать сложные геометрии, настраивать | Ограничено свойствами материала |

| Использование материалов | Сокращение отходов, эффективное использование | Ограниченный ассортимент используемых материалов |

| Производство | Быстрое прототипирование, производство по требованию | Медленнее для больших объемов |

| Стоимость | Снижение затрат на оснастку, уменьшение отходов материала | Высокие первоначальные инвестиции |

| Гибкость | Простые изменения дизайна, Универсальные приложения | Часто требуется постобработка |

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

Давайте рассмотрим некоторые распространенные вопросы о процессе АП, чтобы развеять все оставшиеся сомнения.

| Вопрос | Отвечать |

|---|---|

| Что такое аддитивное производство (АП)? | АМ, или 3D-печать, — это процесс создания объектов путем добавления материала слой за слоем, что позволяет создавать сложные конструкции и сокращать количество отходов. |

| Какие материалы можно использовать в АМ? | Могут использоваться различные материалы, включая металлы, полимеры, керамику и композиты. |

| Каковы основные преимущества АМ? | АП обеспечивает гибкость проектирования, возможность настройки, сокращение отходов, быстрое прототипирование и возможность создания легких конструкций. |

| Существуют ли какие-либо ограничения для АМ? | Да, к ограничениям относятся ограничения по материалам, проблемы с отделкой поверхности, высокие первоначальные затраты и более низкие скорости производства при больших объемах. |

| Какие отрасли промышленности получают наибольшую выгоду от AM? | АП значительно выигрывают от применения в аэрокосмической, автомобильной, медицинской, потребительской, архитектурной, образовательной, оборонной и энергетической отраслях. |

| Чем AM отличается от традиционного производства? | АП отлично подходит для создания сложных, индивидуальных деталей с меньшим количеством отходов, но изначально может быть более медленным и дорогим по сравнению с традиционными методами массового производства. |

| Какие металлические порошки чаще всего используются в АМ? | Распространенные металлические порошки включают титан (Ti-6Al-4V), нержавеющую сталь (316L), алюминий (AlSi10Mg), инконель (IN718), кобальт-хром (CoCr) и другие. |

| Можно ли использовать АМ для массового производства? | Хотя АМ идеально подходит для создания прототипов и изготовления индивидуальных деталей, для массового производства он, как правило, медленнее и менее экономически эффективен по сравнению с традиционными методами. |

| Какая постобработка требуется для деталей АМ? | Последующая обработка может включать в себя отделку поверхности, термическую обработку, механическую обработку и нанесение покрытия для достижения желаемого качества и свойств. |

| Какова стоимость материалов AM по сравнению со стоимостью традиционных материалов? | Материалы для АМ могут быть более дорогими из-за их специализированного характера, но экономия средств может быть достигнута за счет сокращения отходов и затрат на оснастку. |

Заключение

Аддитивное производство меняет подход к проектированию и производству, предлагая непревзойденную гибкость и эффективность. От аэрокосмической отрасли до здравоохранения — области применения АМ обширны и разнообразны. Несмотря на трудности, которые необходимо преодолеть, преимущества этой инновационной технологии очевидны. Поскольку эта область продолжает развиваться, мы можем ожидать еще более захватывающих разработок и более широкого внедрения в различных отраслях.

Поделиться

MET3DP Technology Co., LTD - ведущий поставщик решений для аддитивного производства со штаб-квартирой в Циндао, Китай. Наша компания специализируется на производстве оборудования для 3D-печати и высокопроизводительных металлических порошков для промышленного применения.

Сделайте запрос, чтобы получить лучшую цену и индивидуальное решение для вашего бизнеса!

Похожие статьи

Высокопроизводительные сегменты сопловых лопаток: Революция в эффективности турбин с помощью 3D-печати металла

Читать далее "

3D-печатные крепления для автомобильных радарных датчиков: Точность и производительность

Читать далее "О компании Met3DP

Последние обновления

Наш продукт

CONTACT US

Есть вопросы? Отправьте нам сообщение прямо сейчас! После получения Вашего сообщения мы всей командой выполним Ваш запрос.

Получите информацию о Metal3DP

Брошюра о продукции

Получить последние продукты и прайс-лист

Металлические порошки для 3D-печати и аддитивного производства

КОМПАНИЯ

ПРОДУКТ

ИНФОРМАЦИЯ О КОНТАКТЕ

- Город Циндао, Шаньдун, Китай

- [email protected]

- [email protected]

- +86 19116340731