Блог

все коллекции

3D Printed Air Scoops for Performance Vehicles

Introduction: Optimizing Performance with 3D Printed Metal Air Intake Scoops In the relentless pursuit of performance, engineers in the automotive, motorsports, and performance aftermarket sectors are constantly seeking innovative ways to enhance vehicle efficiency, power, and responsiveness. One critical component influencing engine performance is the air intake system. Custom air

Precision Frames for Space Telescopes via Metal AM

Introduction: The Critical Role of Precision Frames in Modern Space Telescopes Space telescopes represent the pinnacle of observational astronomy, providing humanity with unprecedented views of the cosmos, unhindered by Earth’s atmospheric distortion. From the iconic Hubble Space Telescope to the revolutionary James Webb Space Telescope (JWST), these complex instruments rely

Mounting Brackets for EV Powertrain Systems: Leveraging Metal 3D Printing for Automotive Innovation

The electric vehicle (EV) revolution is transforming the automotive landscape, demanding innovative approaches to design, manufacturing, and supply chain management. Central to this transformation are the powertrain systems – the heart of any EV – encompassing batteries, electric motors, power electronics, and gearboxes. Securely mounting these critical components while optimizing

3D Printed Thermocouple Housings for Jet Engines

The aerospace industry operates at the cutting edge of engineering, demanding components that meet extreme performance, reliability, and safety standards. Jet engines, the heart of modern aircraft, are marvels of complex machinery operating under intense heat, pressure, and vibration. Within this demanding environment, even seemingly small components play critical roles.

Lightweight GPS Antenna Mounts for Drones

Introduction: The Critical Role of Optimized GPS Antenna Mounts in UAV Performance Unmanned Aerial Vehicles (UAVs), commonly known as drones, have revolutionized industries ranging from aerial surveying and infrastructure inspection to defense reconnaissance and package delivery. Central to their autonomous or remotely piloted operation is the Global Positioning System (GPS),

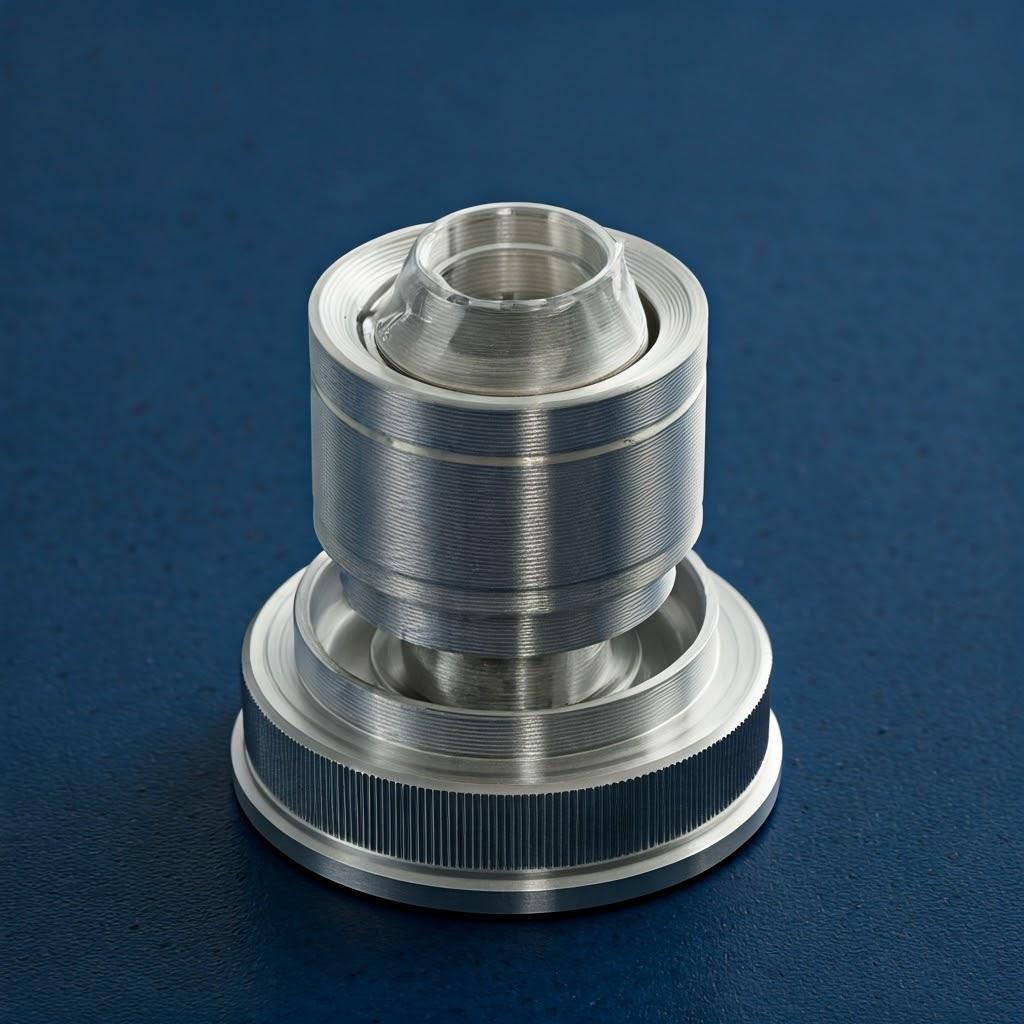

High-Strength Clamps via Metal 3D Printing

Introduction: The Critical Role of High-Strength Custom Clamps in Industry In the intricate dance of modern manufacturing, seemingly simple components often play pivotal roles. Among these unsung heroes are industrial clamps – devices designed to hold, secure, position, or fasten objects with precision and reliability. From delicate medical device assembly

3D Printed Air Scoops for Performance Vehicles

Introduction: Optimizing Performance with 3D Printed Metal Air Intake Scoops In the relentless pursuit of performance, engineers in the automotive, motorsports, and performance aftermarket sectors

Precision Frames for Space Telescopes via Metal AM

Introduction: The Critical Role of Precision Frames in Modern Space Telescopes Space telescopes represent the pinnacle of observational astronomy, providing humanity with unprecedented views of

Mounting Brackets for EV Powertrain Systems: Leveraging Metal 3D Printing for Automotive Innovation

The electric vehicle (EV) revolution is transforming the automotive landscape, demanding innovative approaches to design, manufacturing, and supply chain management. Central to this transformation are

3D Printed Thermocouple Housings for Jet Engines

The aerospace industry operates at the cutting edge of engineering, demanding components that meet extreme performance, reliability, and safety standards. Jet engines, the heart of

Lightweight GPS Antenna Mounts for Drones

Introduction: The Critical Role of Optimized GPS Antenna Mounts in UAV Performance Unmanned Aerial Vehicles (UAVs), commonly known as drones, have revolutionized industries ranging from

High-Strength Clamps via Metal 3D Printing

Introduction: The Critical Role of High-Strength Custom Clamps in Industry In the intricate dance of modern manufacturing, seemingly simple components often play pivotal roles. Among

Наш продукт

ПРОДУКТ ГОРЯЧЕЙ ПРОДАЖИ

CONTACT US

Есть вопросы? Отправьте нам сообщение прямо сейчас! После получения Вашего сообщения мы всей командой выполним Ваш запрос.

Металлические порошки для 3D-печати и аддитивного производства

КОМПАНИЯ

ПРОДУКТ

ИНФОРМАЦИЯ О КОНТАКТЕ

- Город Циндао, Шаньдун, Китай

- [email protected]

- [email protected]

- +86 19116340731