Металлические порошки для полупроводников

Оглавление

В постоянно развивающемся мире полупроводников роль металлических порошков является ключевой. От создания микропроцессоров до разработки усовершенствованной памяти металлические порошки являются невоспетыми героями, которые позволяют создавать эти технологические чудеса. В этой статье мы погружаемся в тонкости металлические порошки для полупроводников, их типы, составы, области применения, характеристики и многое другое. Давайте приступим к подробному исследованию этой увлекательной темы.

Обзор металлического порошка для полупроводников

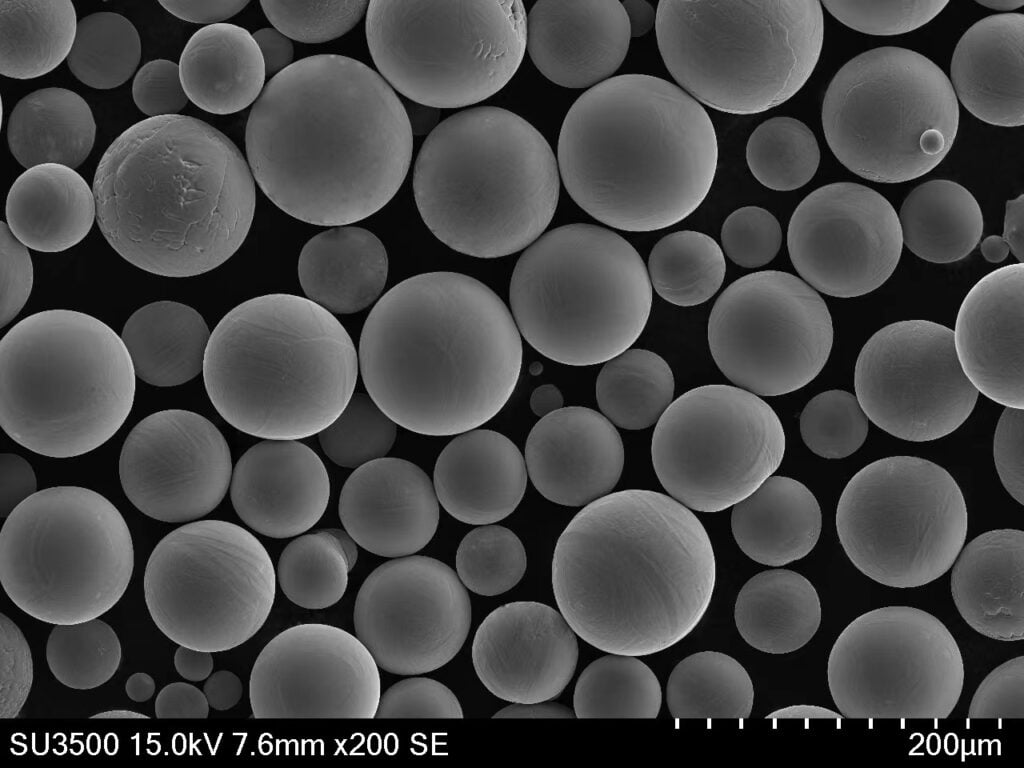

Металлические порошки — это тонкодисперсные частицы металлов, которые используются в различных областях, включая полупроводниковую промышленность. Их важность заключается в их уникальных свойствах, таких как высокая чистота, контролируемый размер частиц и удельная площадь поверхности, что делает их идеальными для использования в производстве полупроводниковых приборов.

Ключевые моменты:

- Металлические порошки играют решающую роль в процессе производства полупроводников.

- Они обеспечивают высокую чистоту и контролируемые размеры частиц.

- Используется при создании микропроцессоров, запоминающих устройств и других полупроводниковых приборов.

Типы металлических порошков для полупроводников

Различные металлы используются в виде порошков для различных полупроводниковых применений. Каждый металлический порошок имеет различные свойства, которые делают его пригодным для определенных целей.

| Металлический порошок | Состав | Свойства | Характеристики |

|---|---|---|---|

| Медь (Cu) | Чистая медь | Высокая проводимость | Коррозионная стойкость, пластичность |

| Алюминий (Al) | Чистый алюминий | Легкий вес, высокая проводимость | Отражательная способность, пластичность |

| Серебро (Ag) | Чистое серебро | Высочайшая электропроводность | Устойчивость к потускнению, антимикробный |

| Золото (Au) | Чистое золото | Отличная электропроводность | Нереактивный, пластичный |

| Никель (Ni) | Чистый никель | Коррозионная стойкость | Магнетизм, высокая температура плавления |

| Титан (Ti) | Чистый титан | Прочность, легкость | Коррозионная стойкость, биосовместимость |

| Вольфрам (Вт) | Чистый вольфрам | Высокая температура плавления | Плотность, твердость |

| Молибден (Mo) | Чистый молибден | Высокая прочность | Высокая теплопроводность, низкое тепловое расширение |

| Палладий (Pd) | Чистый палладий | Коррозионная стойкость | Хорошая проводимость, каталитические свойства |

| Кобальт (Co) | Чистый кобальт | Магнитные свойства | Высокая температура плавления, прочность |

Применение металлического порошка для полупроводников

Металлические порошки используются в различных приложениях в полупроводниковой промышленности. Вот разбивка того, где и как используются эти порошки.

| Приложение | Используемые металлические порошки | Описание |

|---|---|---|

| Микропроцессоры | Медь, золото, серебро | Проводящие пути и соединения |

| Память для хранения данных | Алюминий, Никель | Уровни хранения данных и магнитная запись |

| Датчики | Палладий, Кобальт | Чувствительные элементы в датчиках |

| Транзисторы | Вольфрам, молибден | Материалы для затворов и соединений |

| Конденсаторы | Титан, никель | Диэлектрические и электродные материалы |

| светодиоды | Алюминий, Золото | Токопроводящие дорожки и радиаторы |

| Устройства питания | Медь, Серебро | Компоненты, проводящие большой ток |

| Солнечные батареи | Серебро, Алюминий | Проводящие сетки и контакты |

Технические характеристики, размеры, марки и стандарты

Понимание спецификаций, размеров, марок и стандартов металлических порошков имеет решающее значение для их эффективного применения в полупроводниках.

| Металлический порошок | Размеры (мкм) | Классы | Стандарты |

|---|---|---|---|

| Медь (Cu) | 0.1 – 10 | Высокая чистота (99,99%) | ASTM B170-99 |

| Алюминий (Al) | 0.5 – 15 | Электронная оценка | ИСО 8000 |

| Серебро (Ag) | 0.2 – 5 | 99.999% Чистый | ASTM B779-99 |

| Золото (Au) | 0.1 – 3 | Полупроводниковый класс | ИСО 9208 |

| Никель (Ni) | 1 – 20 | 99.98% Чистый | ASTM B330-03 |

| Титан (Ti) | 2 – 30 | Высокая чистота (99,6%) | ASTM B348-19 |

| Вольфрам (Вт) | 0.3 – 15 | Высокая чистота | ИСО 2768-1 |

| Молибден (Mo) | 0.5 – 10 | 99.95% Чистый | ASTM B386-03 |

| Палладий (Pd) | 0.1 – 5 | 99.9% Чистый | ISO 6284 |

| Кобальт (Co) | 1 – 25 | 99.8% Чистый | ASTM B330-03 |

Поставщики и ценовая политика

Знание того, где закупать металлические порошки, и понимание их ценообразования имеют решающее значение для планирования и составления бюджета в производстве полупроводников.

| Поставщик | Металлические порошки в наличии | Цена (за кг) |

|---|---|---|

| Американские элементы | Медь, золото, никель, серебро | $300 – $10,000 |

| NanoAmor | Алюминий, Вольфрам, Титан | $200 – $8,000 |

| SkySpring Nanomaterials | Палладий, кобальт, молибден | $500 – $12,000 |

| Tekna | Алюминий, медь, никель | $250 – $9,000 |

| Гудфеллоу | Золото, Серебро, Титан | $400 – $15,000 |

Сравнение плюсов и минусов металлических порошков

Каждый металлический порошок имеет свои преимущества и ограничения. Вот сравнительный анализ, который поможет понять, какой из них лучше подходит для конкретных применений.

| Металлический порошок | Преимущества | Недостатки |

|---|---|---|

| Медь (Cu) | Высокая проводимость, экономичность | Восприимчивость к окислению |

| Алюминий (Al) | Легкий вес, хорошая проводимость | Низкая температура плавления |

| Серебро (Ag) | Самая высокая проводимость, устойчивость к потускнению | Дорогой |

| Золото (Au) | Нереактивный, отличная проводимость | Очень дорого |

| Никель (Ni) | Коррозионностойкий, магнитный | Умеренная проводимость |

| Титан (Ti) | Прочный, легкий, биосовместимый | Дорогой, реактивный |

| Вольфрам (Вт) | Высокая температура плавления, твердый | Очень плотный, трудно поддается обработке |

| Молибден (Mo) | Высокая прочность, теплопроводность | Хрупкие, дорогие |

| Палладий (Pd) | Хорошая проводимость, устойчивость к коррозии | Очень дорого |

| Кобальт (Co) | Магнитные свойства, высокая температура плавления | Дорогой, может быть токсичным |

Состав металлического порошка для полупроводников

Состав металлических порошков играет решающую роль в их эффективности и применении в полупроводниковых приборах. Ниже представлен более подробный анализ составов и их влияния.

Медный порошок (Cu):

- Состав: Чистая медь (99.99%)

- Влияние: Обеспечивает отличную электропроводность, необходимую для межсоединений и токопроводящих дорожек в микропроцессорах и устройствах памяти.

Алюминиевый порошок (Al):

- Состав: Чистый алюминий (99.98%)

- Влияние: Легкий и светоотражающий, идеально подходит для токопроводящих сеток в солнечных элементах и светодиодных радиаторах.

Серебряный (Ag) порошок:

- Состав: Чистое серебро (99.999%)

- Влияние: Самая высокая электропроводность, используется в высокочастотных и мощных устройствах для минимального сопротивления.

Золотой (Au) порошок:

- Состав: Чистое золото (99.99%)

- Влияние: Нереактивный и превосходный проводник, используемый в критических приложениях, где надежность и долговечность имеют первостепенное значение.

Никелевый (Ni) порошок:

- Состав: Чистый никель (99.98%)

- Влияние: Коррозионностойкий и магнитный, подходит для хранения данных и датчиков.

Титановый (Ti) порошок:

- Состав: Чистый титан (99.6%)

- Влияние: Прочный и легкий, используется в конденсаторах и современных силовых устройствах.

Вольфрамовый (W) порошок:

- Состав: Чистый вольфрам (99.95%)

- Влияние: Высокая температура плавления и плотность, идеально подходят для транзисторов и высокотемпературных применений.

Порошок молибдена (Mo):

- Состав: Чистый молибден (99,95%)

- Влияние: Высокая прочность и теплопроводность, используется в силовых устройствах и системах терморегулирования.

Порошок палладия (Pd):

- Состав: Чистый палладий (99,9%)

- Влияние: Отличная проводимость и коррозионная стойкость, используется в высокопроизводительных датчиках и каталитических системах.

Порошок кобальта (Co):

- Состав: Чистый кобальт (99.8%)

- Влияние: Магнитные свойства и высокая температура плавления, используемые в магнитных накопителях и современных сенсорных приложениях.

Характеристики металлического порошка для полупроводников

Уникальные характеристики каждого металлического порошка делают их пригодными для различных полупроводниковых применений. Вот разбивка этих характеристик.

| Металлический порошок | Характеристика | Описание |

|---|---|---|

| Медь (Cu) | Проводимость | Высокая электропроводность, необходимая для микропроцессоров. |

| Алюминий (Al) | Легкий | Уменьшает общий вес устройства, что полезно для портативной электроники. |

| Серебро (Ag) | Проводимость | Самая высокая электропроводность, оптимальная для высокочастотных устройств. |

| Золото (Au) | Нереактивный | Не тускнеет и не подвержен коррозии, идеально подходит для ответственных соединений. |

| Никель (Ni) | Магнетизм | Магнитные свойства, полезные для хранения данных. |

| Титан (Ti) | Прочность | Высокое отношение прочности к весу, используется в долговечных компонентах. |

| Вольфрам (Вт) | Высокая температура плавления | Подходит для высокотемпературных применений, например, для транзисторов. |

| Молибден (Mo) | Теплопроводность | Отлично подходит для терморегулирования в силовых устройствах. |

| Палладий (Pd) | Коррозионная стойкость | Устойчив к коррозии, используется в датчиках и высокопроизводительных устройствах. |

| Кобальт (Co) | Магнитные свойства | Высокая температура плавления и магнетизм, полезны для хранения данных. |

Марки металлических порошков для полупроводников

Сорта металлических порошков указывают на их чистоту и пригодность для различных применений. Ниже приведен подробный обзор сортов, доступных для различных металлических порошков.

| Металлический порошок | Класс | Чистота | Приложение |

|---|---|---|---|

| Медь (Cu) | Высокая чистота | 99.99% | Межсоединения, токопроводящие дорожки |

| Алюминий (Al) | Электронная оценка | 99.98% | Солнечные элементы, светодиоды |

| Серебро (Ag) | 99.999% Чистый | 99.999% | Высокочастотные устройства |

| Золото (Au) | Полупроводниковый класс | 99.99% | Критические соединения |

| Никель (Ni) | 99.98% Чистый | 99.98% | Хранение данных, датчики |

| Титан (Ti) | Высокая чистота | 99.6% | Конденсаторы, силовые устройства |

| Вольфрам (Вт) | Высокая чистота | 99.95% | Транзисторы, высокотемпературные применения |

| Молибден (Mo) | 99.95% Чистый | 99.95% | Терморегулирование |

| Палладий (Pd) | 99.9% Чистый | 99.9% | Высокопроизводительные датчики |

| Кобальт (Co) | 99.8% Чистый | 99.8% | Магнитное хранилище, датчики |

Поставщики и цены на металлический порошок для полупроводников

Понимание того, где закупать металлические порошки и каковы их цены, имеет решающее значение для производства полупроводников.

| Поставщик | Металлические порошки в наличии | Цена (за кг) |

|---|---|---|

| Американские элементы | Медь, золото, никель, серебро | $300 – $10,000 |

| NanoAmor | Алюминий, Вольфрам, Титан | $200 – $8,000 |

| SkySpring Nanomaterials | Палладий, кобальт, молибден | $500 – $12,000 |

| Tekna | Алюминий, медь, никель | $250 – $9,000 |

| Гудфеллоу | Золото, Серебро, Титан | $400 – $15,000 |

Сравнение Металлические порошки для полупроводников: Преимущества и ограничения

Каждый металлический порошок имеет свой собственный набор преимуществ и ограничений. Вот сравнительный анализ, который поможет вам решить, какой металлический порошок лучше всего подходит для ваших нужд.

| Металлический порошок | Преимущества | Недостатки |

|---|---|---|

| Медь (Cu) | Высокая проводимость, экономичность | Восприимчивость к окислению |

| Алюминий (Al) | Легкий вес, хорошая проводимость | Низкая температура плавления |

| Серебро (Ag) | Самая высокая проводимость, устойчивость к потускнению | Дорогой |

| Золото (Au) | Нереактивный, отличная проводимость | Очень дорого |

| Никель (Ni) | Коррозионностойкий, магнитный | Умеренная проводимость |

| Титан (Ti) | Прочный, легкий, биосовместимый | Дорогой, реактивный |

| Вольфрам (Вт) | Высокая температура плавления, твердый | Очень плотный, трудно поддается обработке |

| Молибден (Mo) | Высокая прочность, теплопроводность | Хрупкие, дорогие |

| Палладий (Pd) | Хорошая проводимость, устойчивость к коррозии | Очень дорого |

| Кобальт (Co) | Магнитные свойства, высокая температура плавления | Дорогой, может быть токсичным |

Вопросы и ответы

В1: Какие металлические порошки чаще всего используются в производстве полупроводников?

A1: Наиболее часто используемые металлические порошки в производстве полупроводников включают медь (Cu), алюминий (Al), серебро (Ag), золото (Au), никель (Ni), титан (Ti), вольфрам (W), молибден (Mo), палладий (Pd) и кобальт (Co).

В2: Почему важна чистота в металлические порошки для полупроводников?

A2: Чистота имеет решающее значение, поскольку примеси могут влиять на электрические свойства, производительность и надежность полупроводниковых приборов. Высокочистые металлические порошки обеспечивают оптимальную проводимость и минимизируют дефекты.

В3: Как металлические порошки используются в микропроцессорах?

A3: Металлические порошки, такие как медь и золото, используются для создания токопроводящих дорожек и межсоединений в микропроцессорах, обеспечивая эффективные электрические соединения между различными компонентами.

В4: Каковы преимущества использования золотого порошка в полупроводниках?

A4: Золотой порошок обеспечивает превосходную проводимость, не вступает в реакцию, не тускнеет и не подвержен коррозии, что делает его идеальным для ответственных соединений, где надежность и долговечность имеют решающее значение.

В5: Можете ли вы объяснить роль вольфрамового порошка в полупроводниковых приборах?

A5: Вольфрамовый порошок используется в полупроводниковых приборах благодаря своей высокой температуре плавления и плотности, что делает его пригодным для высокотемпературных применений, таких как транзисторы и силовые приборы.

В6: Какие факторы влияют на выбор металлического порошка для конкретного применения полупроводников?

A6: К факторам относятся требуемая электро- и теплопроводность, температура плавления, прочность, коррозионная стойкость, а также особые требования к применению, такие как вес и магнитные свойства.

В7: Существуют ли какие-либо экологические проблемы при использовании металлических порошков в полупроводниках?

A7: Да, производство и утилизация металлических порошков может иметь воздействие на окружающую среду. Важно следовать устойчивым практикам и мерам по переработке, чтобы минимизировать это воздействие.

В8: Как размер частиц металлических порошков влияет на их применение в полупроводниках?

A8: Размер частиц влияет на площадь поверхности, плотность упаковки и электрические свойства металлических порошков, влияя на их эксплуатационные характеристики в полупроводниковых приборах.

В9: Какие проблемы возникают при обработке металлических порошков для полупроводников?

A9: К числу проблем относятся достижение равномерного распределения размеров частиц, поддержание высокой чистоты, предотвращение окисления и обеспечение постоянного качества в процессе производства и переработки.

В10: Где можно купить высококачественные металлические порошки для полупроводниковой промышленности?

A10: Высококачественные металлические порошки можно приобрести у таких поставщиков, как American Elements, NanoAmor, SkySpring Nanomaterials, Tekna и Goodfellow.

Поделиться

MET3DP Technology Co., LTD - ведущий поставщик решений для аддитивного производства со штаб-квартирой в Циндао, Китай. Наша компания специализируется на производстве оборудования для 3D-печати и высокопроизводительных металлических порошков для промышленного применения.

Сделайте запрос, чтобы получить лучшую цену и индивидуальное решение для вашего бизнеса!

Похожие статьи

Высокопроизводительные сегменты сопловых лопаток: Революция в эффективности турбин с помощью 3D-печати металла

Читать далее "

3D-печатные крепления для автомобильных радарных датчиков: Точность и производительность

Читать далее "О компании Met3DP

Последние обновления

Наш продукт

CONTACT US

Есть вопросы? Отправьте нам сообщение прямо сейчас! После получения Вашего сообщения мы всей командой выполним Ваш запрос.

Получите информацию о Metal3DP

Брошюра о продукции

Получить последние продукты и прайс-лист

Металлические порошки для 3D-печати и аддитивного производства

КОМПАНИЯ

ПРОДУКТ

ИНФОРМАЦИЯ О КОНТАКТЕ

- Город Циндао, Шаньдун, Китай

- [email protected]

- [email protected]

- +86 19116340731