Binder Jet 3D-utskrift

Innehållsförteckning

Välkommen till den fascinerande världen av binder jet 3D-utskrift! Om du är nyfiken på den här banbrytande tekniken har du kommit rätt. I den här guiden kommer vi att dyka djupt in i varje aspekt av binder jet 3D-utskrift, från grunderna till de intrikata detaljerna, komplett med tabeller, jämförelser och vanliga frågor. Redo att utforska? Låt oss komma igång!

Översikt över Binder Jet 3D-utskrift

Binder jet 3D-utskrift är en revolutionerande additiv tillverkningsprocess. Till skillnad från traditionella metoder använder den ett bindemedel för att fästa ihop pulverpartiklar, lager för lager, för att skapa komplexa och exakta delar. Denna teknik vinner popularitet i olika branscher på grund av dess mångsidighet och effektivitet.

Viktiga höjdpunkter:

- Process: Använder ett bindemedel för att smälta samman pulvermaterial.

- Material: Kompatibel med metaller, keramik och kompositer.

- Tillämpningar: Fordon, flyg, medicin och mer.

- Fördelar: Kostnadseffektiv, skalbar och kapabel att producera intrikata mönster.

Olika typer av metallpulver för Binder Jet 3D-utskrift

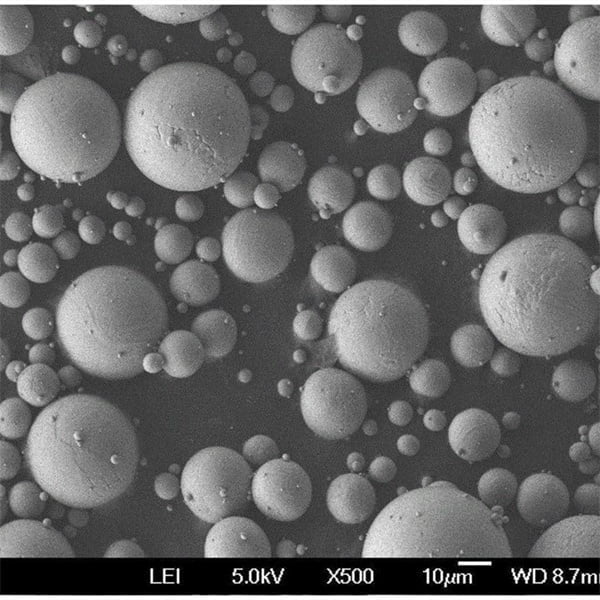

Att välja rätt metallpulver är avgörande för att uppnå optimala resultat vid binder jet 3D-utskrift. Här kommer vi att diskutera några specifika modeller och deras unika egenskaper.

| Metallpulvermodell | Beskrivning |

|---|---|

| 316L rostfritt stål | Känd för sin utmärkta korrosionsbeständighet och mekaniska egenskaper. Idealisk för medicinsk utrustning. |

| Inconel 625 | En nickelbaserad superlegering med hög hållfasthet och motståndskraft mot extrema miljöer. |

| Koppar | Erbjuder utmärkt termisk och elektrisk ledningsförmåga, vilket gör den lämplig för elektronik. |

| Aluminium AlSi10Mg | Lättvikt med goda mekaniska egenskaper, vanligen använd inom flyg- och bilindustrin. |

| Titan Ti6Al4V | Högt förhållande mellan styrka och vikt och biokompatibilitet, perfekt för rymd- och medicinska implantat. |

| Verktygsstål H13 | Ger hög hårdhet och motståndskraft mot slitage och värme, idealisk för verktygstillämpningar. |

| Nickellegering 718 | Hög hållfasthet och oxidationsbeständighet, används i högtemperaturapplikationer. |

| Kobolt-Krom | Utmärkt slitage- och korrosionsbeständighet, används ofta i dentala och ortopediska implantat. |

| 316 Rostfritt stål | Erbjuder en balans mellan styrka, korrosionsbeständighet och kostnadseffektivitet. |

| Brons | Känd för sin hållbarhet och värmeledningsförmåga, används i dekorativa och industriella delar. |

Sammansättning och egenskaper hos metallpulver

Att förstå sammansättningen och egenskaperna hos dessa metallpulver är avgörande för att välja rätt material för din specifika tillämpning. Låt oss bryta ner nyckelegenskaperna.

| Metallpulvermodell | Sammansättning | Fastigheter |

|---|---|---|

| 316L rostfritt stål | Fe, Cr, Ni, Mo | Hög korrosionsbeständighet, goda mekaniska egenskaper, icke-magnetisk. |

| Inconel 625 | Ni, Cr, Mo, Nb | Hög hållfasthet, utmärkt oxidations- och korrosionsbeständighet, bra svetsbarhet. |

| Koppar | Cu | Utmärkt termisk och elektrisk ledningsförmåga, duktil, korrosionsbeständig. |

| Aluminium AlSi10Mg | Al, Si, Mg | Lättvikt, hög hållfasthet i förhållande till vikt, goda gjutegenskaper. |

| Titan Ti6Al4V | Ti, Al, V | Hög hållfasthet, låg densitet, utmärkt biokompatibilitet, korrosionsbeständig. |

| Verktygsstål H13 | Fe, Cr, Mo, V, Si | Hög hårdhet, värmebeständighet, slitstyrka, god seghet. |

| Nickellegering 718 | Ni, Cr, Fe, Mo, Nb | Hög hållfasthet, utmärkt oxidations- och korrosionsbeständighet, bra utmattningsbeständighet. |

| Kobolt-Krom | Co, Cr, Mo | Hög slitstyrka, utmärkt korrosionsbeständighet, biokompatibel. |

| 316 Rostfritt stål | Fe, Cr, Ni | Balans mellan styrka och korrosionsbeständighet, kostnadseffektiv. |

| Brons | Cu, Sn | Hållbar, bra värmeledningsförmåga, korrosionsbeständig, estetiskt tilltalande. |

Tillämpningar av Binder Jet 3D-utskrift

Binder jet 3D-utskrift skapar vågor i olika branscher. Här är några anmärkningsvärda applikationer där denna teknik lyser.

| Industri | Tillämpning | Metallpulvermodell |

|---|---|---|

| Fordon | Lättviktsstrukturkomponenter, motordelar | Aluminium AlSi10Mg, Inconel 625 |

| Flyg- och rymdindustrin | Turbinblad, strukturella komponenter, satellitdelar | Titan Ti6Al4V, Nickellegering 718 |

| Medicinsk | Tandimplantat, ortopediska implantat, kirurgiska instrument | Kobolt-krom, 316L rostfritt stål |

| Elektronik | Kylflänsar, elkontakter, kretskort | Koppar, aluminium AlSi10Mg |

| Verktyg | Gjutformar, matriser, skärverktyg | Verktygsstål H13, Inconel 625 |

| Energi | Turbinkomponenter, värmeväxlare | Nickellegering 718, Inconel 625 |

| Konsumentvaror | Smycken, prydnadsföremål, kundanpassade produkter | Brons, koppar |

| Försvar | Lättviktspansar, vapenkomponenter | Titan Ti6Al4V, Inconel 625 |

| Konstruktion | Arkitektoniska modeller, anpassade metalldelar | Brons, 316L rostfritt stål |

| Forskning | Prototyper, materialtestning, anpassade experimentuppställningar | Olika utifrån forskningsbehov |

Specifikationer, storlekar, kvaliteter och standarder

När det gäller binder jet 3D-utskrift är det viktigt att följa specifika standarder och välja rätt storlekar och kvaliteter. Här är en uppdelning av dessa specifikationer för olika metallpulver.

| Metallpulvermodell | Specifikationer | Storlekar | Betyg | Standarder |

|---|---|---|---|---|

| 316L rostfritt stål | ASTM A276, ASTM A240 | 15-45 µm | 316L | ISO 5832-1, UNS S31603 |

| Inconel 625 | ASTM B443, AMS 5599 | 15-53 µm | 625 | AMS 5666, UNS N06625 |

| Koppar | ASTM B152, ASTM B187 | 20-45 µm | ETP, OFHC | UNS C11000, UNS C10100 |

| Aluminium AlSi10Mg | ISO 3522, ASTM B918 | 20-63 µm | AlSi10Mg | DIN EN 1706, UNS A03600 |

| Titan Ti6Al4V | ASTM B348, ASTM F1472 | 15-45 µm | Ti6Al4V | AMS 4911, UNS R56400 |

| Verktygsstål H13 | ASTM A681, SAE J438 | 15-53 µm | H13 | UNS T20813, ISO 4957 |

| Nickellegering 718 | ASTM B637, AMS 5662 | 15-53 µm | 718 | UNS N07718, ISO 15156-3 |

| Kobolt-Krom | ASTM F1537, ASTM F75 | 15-45 µm | CoCrMo | ISO 5832-12, UNS R31538 |

| 316 Rostfritt stål | ASTM A276, ASTM A240 | 15-45 µm | 316 | ISO 5832-1, UNS S31600 |

| Brons | ASTM B427, ASTM B505 | 20-45 µm | Olika | UNS C90700, UNS C90500 |

Leverantörer och prisuppgifter

Att välja rätt leverantör och förstå prisdetaljer är avgörande för budgetering och planering. Här är några välrenommerade leverantörer tillsammans med uppskattade priser.

| Leverantör | Metallpulvermodell | Prissättning (per kg) | Kontaktuppgifter |

|---|---|---|---|

| Höganäs | 316L rostfritt stål | $80 – $120 | www.hoganas.com |

| Snickeriteknik | Inconel 625 | $100 – $150 | www.cartech.com |

| GKN Additiv | Koppar | $50 – $70 | www.gknpm.com |

| Sandvik | Aluminium AlSi10Mg | $60 – $90 | www.materials.sandvik |

| Arcam AB | Titan Ti6Al4V | $200 – $300 | www.arcam.com |

| Aubert & Duval | Verktygsstål H13 | $70 – $110 | www.aubertduval.com |

| ATI Specialmaterial | Nickellegering 718 | $150 – $200 | www.atimetals.com |

| EOS GmbH | Kobolt-Krom | $200 – $250 | www.eos.info |

| LPW-teknik | 316 Rostfritt stål | $80 – $120 | www.lpwtechnology.com |

| Metal Powder Works | Brons | $40 – $60 | www.metalpowderworks.com |

För- och nackdelar med Binder Jet 3D-utskrift

Att förstå fördelarna och begränsningarna med binder jet 3D-utskrift kan hjälpa dig att fatta välgrundade beslut. Låt oss bryta ner det.

Fördelar med Binder Jet 3D-utskrift

| Fördel | Beskrivning |

|---|---|

| Kostnadseffektivt | Lägre material- och produktionskostnader jämfört med andra 3D-utskriftsmetoder. |

| Skalbarhet | Lämplig för både småskalig och storskalig produktionsserie. |

| Flexibilitet i designen | Kan producera komplexa geometrier och intrikata mönster. |

| Materialvariation | Kompatibel med ett brett utbud av material, inklusive metaller, keramik och kompositer. |

| Ingen termisk distorsion | Inga termiska spänningar eller förvrängningar, eftersom processen sker vid rumstemperatur. |

Nackdelar med Binder Jet 3D-utskrift

| Nackdel | Beskrivning |

|---|---|

| Efterbearbetning krävs | Kräver ytterligare steg som härdning, sintring eller infiltrering. |

| Lägre styrka | Delar kan ha lägre mekanisk styrka jämfört med andra 3D-utskriftsmetoder. |

| Pulverhantering | Hantering och återvinning av pulver kan vara utmanande och kräver rätt utrustning. |

| Ytfinish | Kan kräva ytterligare efterbehandling för att uppnå jämna ytor. |

| Porositet | Delar kan vara porösa, vilket påverkar deras strukturella integritet och prestanda. |

VANLIGA FRÅGOR

| Fråga | Svar |

|---|---|

| Vad är binder jet 3D-utskrift? | Binder jet 3D-utskrift är en additiv tillverkningsprocess som använder ett bindemedel för att smälta pulverpartiklar. |

| Vilka material kan användas i binder jet 3D-utskrift? | En mängd olika material inklusive metaller, keramik och kompositer kan användas. |

| Vilka är fördelarna med binder jet 3D-utskrift? | Kostnadseffektiv, skalbar, designflexibilitet, materialvariation och ingen termisk distorsion. |

| Vilka är nackdelarna med binder jet 3D-utskrift? | Kräver efterbearbetning, lägre hållfasthet, pulverhantering, ytfinish och problem med porositet. |

| Vilka branscher drar nytta av binder jet 3D-utskrift? | Fordon, flyg, medicin, elektronik, verktyg, energi, konsumentvaror, försvar, konstruktion och forskning. |

| Hur jämför binder jet 3D-utskrift med andra 3D-utskriftsmetoder? | Det är i allmänhet mer kostnadseffektivt och mångsidigt men kan kräva mer efterbearbetning och ha lägre delstyrka. |

| Kan binder jet 3D-utskrift producera komplexa mönster? | Ja, det utmärker sig i att producera komplexa geometrier och intrikata mönster. |

| Vad kostar metallpulver för 3D-utskrift med bindestråle? | Kostnaden varierar beroende på material, från $40 till $300 per kilogram. |

| Vilka efterbehandlingssteg krävs för binder jet 3D-utskrift? | Vanliga steg inkluderar härdning, sintring och infiltrering för att förbättra delens styrka och finish. |

| Är binder jet 3D-utskrift lämplig för massproduktion? | Ja, den är skalbar och kan användas för både småskaliga och storskaliga produktionskörningar. |

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731