Detaljerad analys av EBM:s processflöde

Innehållsförteckning

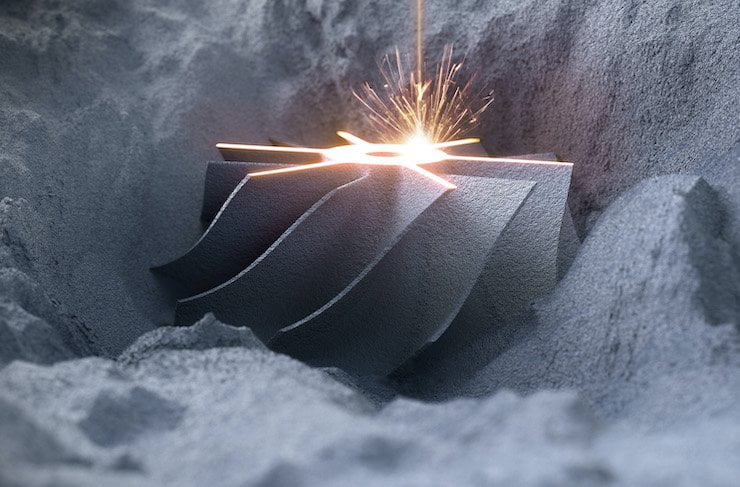

Smältning med elektronstråle (EBM) is a revolutionary 3D printing technology that’s rapidly transforming the manufacturing landscape. Imagine building complex metal parts layer by layer using a focused electron beam – that’s the essence of EBM! But have you ever wondered what goes on behind the scenes of this high-tech process? Buckle up, because we’re about to embark on a detailed analysis of the EBM process flow, dissecting each stage to unveil its magic.

Preparation Work for EBM Process Flow

Before the electron beam starts its dance, some crucial groundwork needs to be laid. Here’s what sets the stage:

- CAD-design: Everything starts with a digital blueprint. Your 3D model, meticulously crafted using CAD software, acts as the blueprint for the EBM machine to follow.

- Val av metallpulver: The heart of EBM lies in the metal powder used. These fine, metallic particles (typically ranging from 20 to 100 microns) come in various flavors, each with unique properties. We’ll delve deeper into the fascinating world of metal powders in a moment.

- Machine Setup and Calibration: The EBM machine itself is a marvel of engineering. It houses a high-powered electron gun, a vacuum chamber to maintain a pristine environment, and a build platform that meticulously lowers with each layer. Calibration ensures the electron beam strikes the powder bed with pinpoint accuracy, a crucial step for achieving dimensional precision.

Metal Powder Selection: A Powder Powerhouse

As mentioned earlier, metal powder is the lifeblood of EBM. Here’s a closer look at some of the most popular options, along with their key characteristics:

| Metallpulver | Sammansättning | Fastigheter | Tillämpningar |

|---|---|---|---|

| Ti-6Al-4V (titanlegering) | 6% Aluminum, 4% Vanadium, Titanium Balance | Högt förhållande mellan styrka och vikt, utmärkt biokompatibilitet | Aerospace components, biomedical implants, prosthetics |

| Rostfritt stål 316L | Chromium, Nickel, Molybdenum, Iron Balance | Korrosionsbeständighet, goda mekaniska egenskaper | Medical devices, chemical processing equipment, marine components |

| Inconel 625 (Superalloy) | Nickel, Chromium, Molybdenum, Columbium, Iron Balance | Hållfasthet vid höga temperaturer, oxidationsbeständighet | Komponenter till gasturbiner, delar till raketmotorer, värmeväxlare |

| CoCrMo (Cobalt-Chromium Molybdenum Alloy) | Kobolt, krom, molybden | Biokompatibel, slitstark | Ledproteser, tandimplantat |

| Aluminum Alloys (AlSi10Mg, etc.) | Aluminum with Silicon, Magnesium | Lätt vikt, god hållfasthet | Automotive components, aerospace structures, heat sinks |

| Koppar | Ren koppar | Hög värmeledningsförmåga, bra elektrisk ledningsförmåga | Värmeväxlare, elektriska komponenter, vågledare |

| Volfram | Ren volfram | Hög smältpunkt, hög densitet | Moulding tools, electrodes, ballistic applications |

| Maråldrat stål | Nickel, Molybdenum, Titanium, Iron Balance | Hög hållfasthet, bra duktilitet | Aerospace components, firearms parts, tooling |

| Nickel Superalloys (Inconel 718, etc.) | Complex compositions with Nickel, Chromium, Molybdenum | Exceptional high-temperature performance | Turbine blades, rocket engine parts, heat exchangers |

| Titanium Alloys (CP Ti, etc.) | Kommersiellt ren titan | Excellent biocompatibility, good corrosion resistance | Medical implants, dental applications, chemical processing equipment |

This list is just a glimpse into the vast array of metal powders available for EBM. The choice of powder depends on the desired properties of the final part, such as strength, weight, corrosion resistance, biocompatibility, and thermal conductivity.

Electron Beam Scanning of EBM Process Flow

Now comes the magic! The electron gun within the EBM machine hums to life, generating a highly focused beam of electrons. This beam acts like a virtual paintbrush, selectively melting the metal powder according to the pre-programmed CAD design. Here’s a breakdown of the scanning process:

- Deflection System: The electron beam isn’t a rigid line. A sophisticated deflection system controls its movement, directing it across the powder bed to precisely define the desired pattern for each layer.

- Scan Strategies: There are various scan strategies employed in EBM, each with its advantages. Common approaches include raster scanning, vector scanning, and island scanning. The choice of strategy depends on factors like part geometry, surface finish requirements, and thermal management.

- Beam Power Control: The power of the electron beam plays a crucial role. Higher power results in deeper melting and potentially faster build times. However, meticulous control is essential to prevent overheating and distortion of the part. Imagine balancing a searing hot paintbrush on a bed of metal powder – that’s the delicate dance of EBM!

-

Ti45Nb-pulver för additiv tillverkning

Ti45Nb-pulver för additiv tillverkning -

Pulver av TiNb-legering

Pulver av TiNb-legering -

Pulver av TiNbZrSn-legering

Pulver av TiNbZrSn-legering -

Ti6Al4V Pulver Titanbaserat metallpulver för additiv tillverkning

Ti6Al4V Pulver Titanbaserat metallpulver för additiv tillverkning -

CPTi Pulver

CPTi Pulver -

TC18 Pulver : Frigör kraften hos titankarbid

TC18 Pulver : Frigör kraften hos titankarbid -

TC11 Pulver : En omfattande guide

TC11 Pulver : En omfattande guide -

TC4 ELI Pulver

TC4 ELI Pulver -

Bästa Ti-6Al-4V-pulver (TC4-pulver) för additiv tillverkning

Bästa Ti-6Al-4V-pulver (TC4-pulver) för additiv tillverkning

Layer by Layer Manufacturing of EBM Process Flow

EBM builds parts in a truly additive fashion, one layer at a time. Here’s how this layer-by-layer magic unfolds:

- Recoat Blade: After each layer is scanned by the electron beam, a recoat blade meticulously spreads a fresh layer of metal powder across the build platform. This ensures a continuous supply of material for the next layer to be melted.

- Termisk hantering: EBM involves localized melting, but heat doesn’t stay confined. The machine employs various techniques, like preheating the build platform and using support structures, to manage thermal gradients and prevent warping or cracking in the part.

- Skiktets tjocklek: The thickness of each layer in EBM can vary depending on the desired resolution and build time. Typical layer thicknesses range from 30 to 100 microns, offering a balance between detail and efficiency.

Imagine building a complex structure brick by brick, but instead of bricks, you’re using layers of melted metal – that’s the essence of EBM’s layer-by-layer manufacturing process. This approach allows for the creation of intricate geometries and internal features that would be impossible with traditional subtractive techniques like machining.

Post Processing of EBM Process Flow

The journey doesn’t end after the final layer is melted. Here’s what follows:

- Stressavlastning: EBM parts can experience residual stress due to the thermal cycles involved in the process. Stress relief annealing helps to alleviate these stresses, improving the part’s dimensional stability and mechanical properties.

- Borttagning av stödstruktur: Similar to removing scaffolding from a building, support structures used during the EBM process need to be removed. This can be done through various methods, such as wire EDM or mechanical cutting.

- Ytbehandling: As-built EBM surfaces can be slightly rough due to the nature of the process. Post-processing techniques like machining, polishing, or blasting can be used to achieve the desired surface finish.

Think of post-processing as the final touches on your masterpiece. These steps ensure the EBM part meets the required dimensional accuracy, mechanical properties, and surface aesthetics.

Advantages and Limitations of EBM

EBM boasts several compelling advantages:

- Designfrihet: EBM excels at creating complex geometries, including internal features and lattice structures, that are difficult or impossible with traditional methods.

- High-Performance Materials: The process is compatible with a wide range of high-performance metal powders, enabling the creation of parts with exceptional strength, heat resistance, and biocompatibility.

- Tillverkning i nära-nätform: EBM minimizes material waste compared to subtractive techniques, offering a more sustainable and cost-effective approach for certain applications.

However, EBM also has limitations to consider:

- Byggtid: EBM can be a slower process compared to some other 3D printing methods, especially for larger parts.

- Ytjämnhet: As-built EBM surfaces can be slightly rough, requiring additional post-processing for some applications.

- Kostnad: EBM machines and metal powders can be expensive, making the process more suitable for high-value parts or applications where its unique capabilities are essential.

EBM is a powerful tool, but like any tool, it’s best suited for specific jobs. Understanding its strengths and weaknesses allows you to make informed decisions about its suitability for your project.

VANLIGA FRÅGOR

Here are some frequently asked questions about the EBM process flow, answered in a clear and concise format:

| Fråga | Svar |

|---|---|

| What are the benefits of EBM over other 3D printing methods? | EBM offers superior design freedom, enables the use of high-performance metal powders, and minimizes material waste compared to some subtractive techniques. |

| What are some limitations of EBM? | EBM can be slower than other methods, may require post-processing for surface finish, and can be more expensive due to machine and material costs. |

| What types of metal powders can be used in EBM? | A wide range of metal powders can be used, including titanium alloys, stainless steel, superalloys, cobalt-chrome, aluminum alloys, and more. |

| What are some applications of EBM? | EBM is used in various industries, including aerospace, biomedical, automotive, and energy, for creating high-performance metal parts. |

| How does the electron beam scan the powder bed? | A sophisticated deflection system controls the electron beam, directing it across the powder bed to define the desired pattern for each layer. |

Slutsats

Electron Beam Melting (EBM) is more than just a 3D printing technology; it’s a gateway to a world of possibilities. By meticulously melting metal powder layer by layer, EBM unlocks the creation of complex, high-performance parts that were once thought impossible. From intricate aerospace components to life-saving biomedical implants, EBM is pushing the boundaries of design and manufacturing.

As with any complex technology, understanding the EBM process flow is crucial. We’ve delved into each stage, from the meticulous preparation work to the layer-by-layer magic and the finishing touches of post-processing. This knowledge empowers you to make informed decisions about whether EBM is the right tool for your project.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731