Metallpulver för halvledare

Innehållsförteckning

I den ständigt föränderliga världen av halvledare är metallpulvrets roll central. Från skapandet av mikroprocessorer till utvecklingen av avancerad minneslagring är metallpulver de obesjungna hjältarna som möjliggör dessa tekniska underverk. Den här artikeln dyker ner i de invecklade metallpulver för halvledare, deras typer, sammansättningar, tillämpningar, specifikationer och mycket mer. Låt oss ge oss i kast med en detaljerad undersökning av detta fascinerande ämne.

Översikt över metallpulver för halvledare

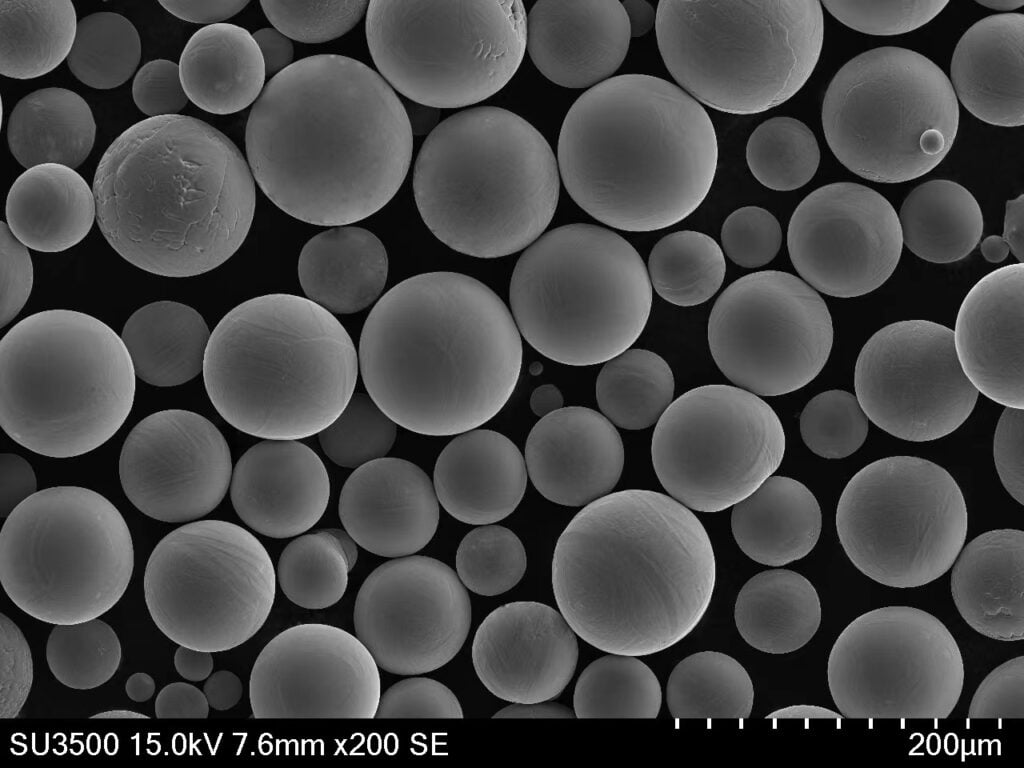

Metallpulver är finfördelade partiklar av metaller som används i olika applikationer, bland annat inom halvledarindustrin. Deras betydelse ligger i deras unika egenskaper, såsom hög renhet, kontrollerad partikelstorlek och specifik ytarea, vilket gör dem idealiska för användning vid tillverkning av halvledarkomponenter.

Viktiga punkter:

- Metallpulver är kritiska i tillverkningsprocessen för halvledare.

- De erbjuder hög renhet och kontrollerade partikelstorlekar.

- Används för att skapa mikroprocessorer, minneslagring och andra halvledarkomponenter.

Olika typer av metallpulver för halvledare

Olika metaller används i form av pulver för olika halvledarapplikationer. Varje metallpulver har distinkta egenskaper som gör det lämpligt för specifika användningsområden.

| Metallpulver | Sammansättning | Fastigheter | Egenskaper |

|---|---|---|---|

| Koppar (Cu) | Ren koppar | Hög ledningsförmåga | Korrosionsbeständighet, duktilitet |

| Aluminium (Al) | Ren aluminium | Lättvikt, hög ledningsförmåga | Reflektivitet, formbarhet |

| Silver (Ag) | Rent silver | Högsta elektriska ledningsförmåga | Tarnish-resistens, antimikrobiell |

| Guld (Au) | Rent guld | Utmärkt ledningsförmåga | Icke-reaktiv, duktilitet |

| Nickel (Ni) | Ren nickel | Korrosionsbeständighet | Magnetism, hög smältpunkt |

| Titan (Ti) | Ren titan | Styrka, låg vikt | Korrosionsbeständighet, biokompatibilitet |

| Volfram (W) | Ren volfram | Hög smältpunkt | Densitet, hårdhet |

| Molybden (Mo) | Ren molybden | Hög hållfasthet | Hög värmeledningsförmåga, låg värmeutvidgning |

| Palladium (Pd) | Rent palladium | Korrosionsbeständighet | God ledningsförmåga, katalytiska egenskaper |

| Kobolt (Co) | Ren kobolt | Magnetiska egenskaper | Hög smältpunkt, styrka |

Tillämpningar av metallpulver för halvledare

Metallpulver används i en mängd olika applikationer inom halvledarindustrin. Här är en uppdelning av var och hur dessa pulver används.

| Tillämpning | Använda metallpulver | Beskrivning |

|---|---|---|

| Mikroprocessorer | Koppar, guld, silver | Ledningsbanor och sammankopplingar |

| Minneslagring | Aluminium, nickel | Datalagringslager och magnetisk inspelning |

| Sensorer | Palladium, kobolt | Känsliga element i sensorer |

| Transistorer | Volfram, molybden | Gate- och sammankopplingsmaterial |

| Kondensatorer | Titan, nickel | Dielektriska material och elektrodmaterial |

| Lysdioder | Aluminium, guld | Ledningsbanor och kylflänsar |

| Strömförsörjningsenheter | Koppar, Silver | Högströmsförande komponenter |

| Solceller | Silver, aluminium | Ledande gitter och kontakter |

Specifikationer, storlekar, kvaliteter och standarder

Att förstå specifikationerna, storlekarna, kvaliteterna och standarderna för metallpulver är avgörande för att de ska kunna användas effektivt i halvledare.

| Metallpulver | Storlekar (µm) | Betyg | Standarder |

|---|---|---|---|

| Koppar (Cu) | 0.1 – 10 | Hög renhet (99,99%) | ASTM B170-99 |

| Aluminium (Al) | 0.5 – 15 | Elektronisk klass | ISO 8000 |

| Silver (Ag) | 0.2 – 5 | 99,999% Ren | ASTM B779-99 |

| Guld (Au) | 0.1 – 3 | Halvledarkvalitet | ISO 9208 |

| Nickel (Ni) | 1 – 20 | 99.98% Ren | ASTM B330-03 |

| Titan (Ti) | 2 – 30 | Hög renhet (99,6%) | ASTM B348-19 |

| Volfram (W) | 0.3 – 15 | Hög renhet | ISO 2768-1 |

| Molybden (Mo) | 0.5 – 10 | 99.95% Ren | ASTM B386-03 |

| Palladium (Pd) | 0.1 – 5 | 99,9% Ren | ISO 6284 |

| Kobolt (Co) | 1 – 25 | 99,8% Ren | ASTM B330-03 |

Leverantörer och prisuppgifter

Att veta var man kan köpa metallpulver och förstå deras priser är avgörande för planering och budgetering inom halvledartillverkningen.

| Leverantör | Metallpulver tillgängliga | Prissättning (per kg) |

|---|---|---|

| Amerikanska element | Koppar, Guld, Nickel, Silver | $300 – $10,000 |

| NanoAmor | Aluminium, volfram, titan | $200 – $8,000 |

| SkySpring Nanomaterial | Palladium, kobolt, molybden | $500 – $12,000 |

| Tekna | Aluminium, koppar, nickel | $250 – $9,000 |

| Goodfellow | Guld, silver, titan | $400 – $15,000 |

Jämförelse av för- och nackdelar med metallpulver

Varje metallpulver har sina fördelar och begränsningar. Här är en jämförande analys som hjälper dig att förstå vilket som kan vara bäst lämpat för specifika applikationer.

| Metallpulver | Fördelar | Nackdelar |

|---|---|---|

| Koppar (Cu) | Hög ledningsförmåga, kostnadseffektivt | Känslig för oxidation |

| Aluminium (Al) | Låg vikt, god ledningsförmåga | Lägre smältpunkt |

| Silver (Ag) | Högsta ledningsförmåga, fläckbeständig | Dyrt |

| Guld (Au) | Icke-reaktiv, utmärkt ledningsförmåga | Mycket dyrt |

| Nickel (Ni) | Korrosionsbeständig, magnetisk | Måttlig ledningsförmåga |

| Titan (Ti) | Stark, lättviktig och biokompatibel | Dyrt, reaktivt |

| Volfram (W) | Hög smältpunkt, hård | Mycket tät, svår att bearbeta |

| Molybden (Mo) | Hög hållfasthet, värmeledningsförmåga | Skör, dyr |

| Palladium (Pd) | God ledningsförmåga, korrosionsbeständig | Mycket dyrt |

| Kobolt (Co) | Magnetiska egenskaper, hög smältpunkt | Dyrt, kan vara giftigt |

Sammansättning av metallpulver för halvledare

Sammansättningen av metallpulver spelar en avgörande roll för deras effektivitet och tillämpning i halvledaranordningar. Här är en djupare titt på sammansättningarna och deras inverkan.

Koppar (Cu) pulver:

- Sammansättning: Ren koppar (99,99%)

- Påverkan: Ger utmärkt elektrisk ledningsförmåga, vilket är avgörande för sammankopplingar och ledande banor i mikroprocessorer och minnesenheter.

Pulver av aluminium (Al):

- Sammansättning: Ren aluminium (99,98%)

- Påverkan: Lätt och reflekterande, idealisk för ledande galler i solceller och LED-kylflänsar.

Silver (Ag) pulver:

- Sammansättning: Rent silver (99,999%)

- Påverkan: Högsta elektriska ledningsförmåga, används i högfrekvens- och högeffektsapparater för minimalt motstånd.

Guld (Au) pulver:

- Sammansättning: Rent guld (99,99%)

- Påverkan: Icke-reaktiv och utmärkt ledare, används i kritiska applikationer där tillförlitlighet och hållbarhet är av största vikt.

Nickel (Ni) pulver:

- Sammansättning: Ren nickel (99,98%)

- Påverkan: Korrosionsbeständiga och magnetiska, lämpliga för datalagring och sensorer.

Titan (Ti) pulver:

- Sammansättning: Ren titan (99,6%)

- Påverkan: Stark och lätt, används i kondensatorer och avancerade kraftaggregat.

Volfram (W) pulver:

- Sammansättning: Ren volfram (99,95%)

- Påverkan: Hög smältpunkt och densitet, perfekt för transistorer och högtemperaturtillämpningar.

Molybden (Mo)-pulver:

- Sammansättning: Ren molybden (99,95%)

- Påverkan: Hög hållfasthet och värmeledningsförmåga, används i kraftaggregat och för termisk hantering.

Palladium (Pd) pulver:

- Sammansättning: Rent palladium (99,9%)

- Påverkan: Utmärkt ledningsförmåga och korrosionsbeständighet, används i högpresterande sensorer och katalytiska applikationer.

Kobolt (Co) pulver:

- Sammansättning: Ren kobolt (99,8%)

- Påverkan: Magnetiska egenskaper och hög smältpunkt, används i magnetisk lagring och avancerade sensortillämpningar.

Egenskaper hos metallpulver för halvledare

De unika egenskaperna hos varje metallpulver gör dem lämpliga för olika halvledarapplikationer. Här är en uppdelning av dessa egenskaper.

| Metallpulver | Karaktäristisk | Beskrivning |

|---|---|---|

| Koppar (Cu) | Konduktivitet | Hög elektrisk ledningsförmåga, nödvändig för mikroprocessorer. |

| Aluminium (Al) | Lättvikt | Minskar enhetens totala vikt, vilket är fördelaktigt för bärbar elektronik. |

| Silver (Ag) | Konduktivitet | Högsta elektriska ledningsförmåga, optimal för högfrekventa enheter. |

| Guld (Au) | Icke-reaktiv | Missfärgas eller korroderar inte, perfekt för kritiska anslutningar. |

| Nickel (Ni) | Magnetism | Magnetiska egenskaper, användbara för datalagring. |

| Titan (Ti) | Styrka | Högt förhållande mellan styrka och vikt, används i hållbara komponenter. |

| Volfram (W) | Hög smältpunkt | Lämplig för applikationer med höga temperaturer, t.ex. transistorer. |

| Molybden (Mo) | Termisk konduktivitet | Utmärkt för termisk hantering i kraftaggregat. |

| Palladium (Pd) | Motståndskraft mot korrosion | Motståndskraftig mot korrosion, används i sensorer och högpresterande enheter. |

| Kobolt (Co) | Magnetiska egenskaper | Hög smältpunkt och magnetism, användbar för lagringsapplikationer. |

Sorter av metallpulver för halvledare

Metallpulvrets kvalitet anger dess renhet och lämplighet för olika tillämpningar. Här följer en detaljerad genomgång av de kvaliteter som finns för olika metallpulver.

| Metallpulver | Betyg | Renhet | Tillämpning |

|---|---|---|---|

| Koppar (Cu) | Hög renhet | 99.99% | Sammankopplingar, ledande banor |

| Aluminium (Al) | Elektronisk klass | 99.98% | Solceller, lysdioder |

| Silver (Ag) | 99,999% Ren | 99.999% | Högfrekventa enheter |

| Guld (Au) | Halvledarkvalitet | 99.99% | Kritiska kopplingar |

| Nickel (Ni) | 99.98% Ren | 99.98% | Datalagring, sensorer |

| Titan (Ti) | Hög renhet | 99.6% | Kondensatorer, kraftaggregat |

| Volfram (W) | Hög renhet | 99.95% | Transistorer, applikationer för höga temperaturer |

| Molybden (Mo) | 99.95% Ren | 99.95% | Termisk hantering |

| Palladium (Pd) | 99,9% Ren | 99.9% | Högpresterande sensorer |

| Kobolt (Co) | 99,8% Ren | 99.8% | Magnetisk lagring, sensorer |

Leverantörer och priser för metallpulver för halvledare

Att förstå var man kan köpa metallpulver och deras priser är avgörande för halvledartillverkningen.

| Leverantör | Metallpulver tillgängliga | Prissättning (per kg) |

|---|---|---|

| Amerikanska element | Koppar, Guld, Nickel, Silver | $300 – $10,000 |

| NanoAmor | Aluminium, volfram, titan | $200 – $8,000 |

| SkySpring Nanomaterial | Palladium, kobolt, molybden | $500 – $12,000 |

| Tekna | Aluminium, koppar, nickel | $250 – $9,000 |

| Goodfellow | Guld, silver, titan | $400 – $15,000 |

Jämförelse Metallpulver för halvledare: Fördelar och begränsningar

Varje metallpulver har sin egen uppsättning fördelar och begränsningar. Här är en jämförande analys som hjälper dig att bestämma vilket metallpulver som passar dina behov bäst.

| Metallpulver | Fördelar | Nackdelar |

|---|---|---|

| Koppar (Cu) | Hög ledningsförmåga, kostnadseffektivt | Känslig för oxidation |

| Aluminium (Al) | Låg vikt, god ledningsförmåga | Lägre smältpunkt |

| Silver (Ag) | Högsta ledningsförmåga, fläckbeständig | Dyrt |

| Guld (Au) | Icke-reaktiv, utmärkt ledningsförmåga | Mycket dyrt |

| Nickel (Ni) | Korrosionsbeständig, magnetisk | Måttlig ledningsförmåga |

| Titan (Ti) | Stark, lättviktig och biokompatibel | Dyrt, reaktivt |

| Volfram (W) | Hög smältpunkt, hård | Mycket tät, svår att bearbeta |

| Molybden (Mo) | Hög hållfasthet, värmeledningsförmåga | Skör, dyr |

| Palladium (Pd) | God ledningsförmåga, korrosionsbeständig | Mycket dyrt |

| Kobolt (Co) | Magnetiska egenskaper, hög smältpunkt | Dyrt, kan vara giftigt |

Vanliga frågor

Q1: Vilka är de vanligaste metallpulvren inom halvledartillverkning?

A1: De vanligaste metallpulvren vid tillverkning av halvledare är koppar (Cu), aluminium (Al), silver (Ag), guld (Au), nickel (Ni), titan (Ti), volfram (W), molybden (Mo), palladium (Pd) och kobolt (Co).

F2: Varför är renhet viktigt i metallpulver för halvledare?

A2: Renheten är avgörande eftersom orenheter kan påverka de elektriska egenskaperna, prestandan och tillförlitligheten hos halvledarkomponenter. Metallpulver med hög renhet säkerställer optimal ledningsförmåga och minimerar defekter.

F3: Hur används metallpulver i mikroprocessorer?

A3: Metallpulver som koppar och guld används för att skapa ledande banor och sammankopplingar inom mikroprocessorer, vilket säkerställer effektiva elektriska anslutningar mellan olika komponenter.

Fråga 4: Vilka är fördelarna med att använda guldpulver i halvledare?

A4: Guldpulver har utmärkt ledningsförmåga, är icke-reaktivt och varken missfärgas eller korroderar, vilket gör det idealiskt för kritiska anslutningar där tillförlitlighet och lång livslängd är avgörande.

F5: Kan du förklara vilken roll volframpulver har i halvledaranordningar?

A5: Volframpulver används i halvledarkomponenter på grund av sin höga smältpunkt och densitet, vilket gör det lämpligt för högtemperaturapplikationer som transistorer och kraftkomponenter.

F6: Vilka faktorer påverkar valet av metallpulver för en specifik halvledarapplikation?

A6: Bland faktorerna finns krav på elektrisk och termisk ledningsförmåga, smältpunkt, hållfasthet, korrosionsbeständighet och specifika applikationsbehov som vikt och magnetiska egenskaper.

Fråga 7: Finns det några miljöproblem med att använda metallpulver i halvledare?

A7: Ja, produktion och avfallshantering av metallpulver kan ha miljöpåverkan. Det är viktigt att följa hållbara metoder och återvinningsåtgärder för att minimera dessa effekter.

Fråga 8: Hur påverkar partikelstorleken hos metallpulver deras användning i halvledare?

A8: Partikelstorleken påverkar metallpulvrets ytarea, packningstäthet och elektriska egenskaper, vilket påverkar deras prestanda i halvledarapplikationer.

F9: Vilka är utmaningarna med att bearbeta metallpulver för halvledare?

A9: Utmaningarna är bland annat att uppnå en jämn partikelstorleksfördelning, bibehålla hög renhet, förhindra oxidation och säkerställa en jämn kvalitet under produktion och bearbetning.

Q10: Var kan jag köpa metallpulver av hög kvalitet för halvledartillämpningar?

A10: Metallpulver av hög kvalitet kan köpas från leverantörer som American Elements, NanoAmor, SkySpring Nanomaterials, Tekna och Goodfellow.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731