Al 7075 pulver

Al 7075-pulver är en höghållfast aluminiumlegering som huvudsakligen består av aluminium, zink, koppar och små mängder magnesium och krom. Den är känd för sina imponerande mekaniska egenskaper, vilket gör den till ett idealiskt val för applikationer som kräver styrka, hållbarhet och lättviktsegenskaper. Al 7075-pulver produceras vanligtvis genom en process som kallas atomisering, där smält aluminium sprutas och stelnar till fina pulverpartiklar.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över Al 7075 Powder

Al 7075 är en av de högsta hållfastheten i 7000-seriens aluminiumlegeringar, och erbjuder hållfasthet överlägsen många stål. Zink är den huvudsakliga legeringstillsatsen medan magnesium ger styrka genom utfällningshärdning.

Viktiga egenskaper hos Al 7075-pulver inkluderar:

- Exceptionellt hög drag- och sträckgräns

- Hög hårdhet och god utmattningshållfasthet

- Bra seghet och måttlig duktilitet

- Utmärkta efterbehandlingsegenskaper

- Hög korrosionsbeständighet

- Finns i en rad olika pulverstorlekar och former

Al 7075-pulver är idealiskt för högpresterande flyg- och försvarskomponenter som behöver den optimala kombinationen av styrka, hårdhet, utmattningsbeständighet och måttlig svetsbarhet.

Kemisk sammansättning av Al 7075-pulver

Den typiska kemiska sammansättningen av Al 7075-pulver är:

| Element | Vikt % |

|---|---|

| Aluminium (Al) | 87.1-91.4% |

| Zink (Zn) | 5.1-6.1% |

| Magnesium (Mg) | 2.1-2.9% |

| Koppar (Cu) | 1.2-2.0% |

| Järn (Fe) | 0-0.5% |

| Kisel (Si) | 0-0.4% |

| Mangan (Mn) | 0-0.3% |

| Krom (Cr) | 0.18-0.28% |

| Titan (Ti) | 0-0.2% |

Zink är det primära legeringselementet medan magnesium och koppar ökar styrkan genom utfällningshärdning. Spårämnen som järn, mangan, krom har mindre effekter.

Egenskaper för Al 7075 Powder

Viktiga egenskaper hos Al 7075-pulver inkluderar:

| Fastighet | Värde |

|---|---|

| Täthet | 2,81 g/cm3 |

| Smältpunkt | 477–635°C |

| Termisk konduktivitet | 130–210 W/mK |

| Elektrisk konduktivitet | 22-30% IACS |

| Young's modul | 71–72 GPa |

| Poissonförhållande | 0.33 |

| Draghållfasthet | 570–635 MPa |

| Utbyteshållfasthet | 505–570 MPa |

| Töjning | 7–10% |

| Hårdhet | 150–190 Brinell |

Zinktillsatserna resulterar i extremt hög hållfasthet och hårdhet samtidigt som rimlig duktilitet och seghet bibehålls. Legeringen har utmärkta ytbehandlingsegenskaper.

Produktionsmetod för Al 7075 pulver

Kommersiella produktionsmetoder för Al 7075-pulver inkluderar:

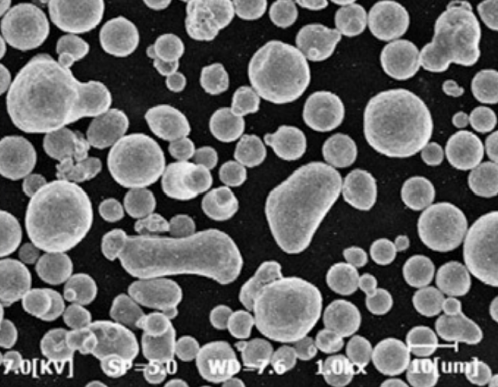

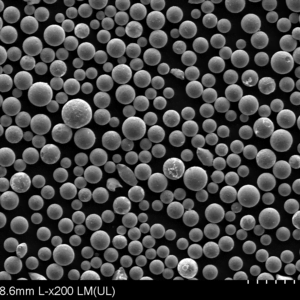

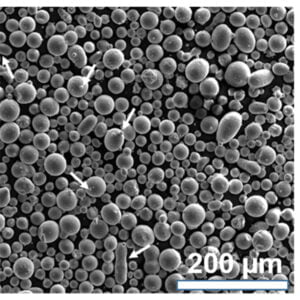

- Atomisering av gas – Smält legeringsström sönderdelas av inerta gasstrålar till fina sfäriska pulverpartiklar med kontrollerad storleksfördelning.

- Atomisering av vatten – Högtrycksvattenstråle som används för att producera fina Al 7075-pulver med oregelbunden form. Lägre kostnad men högre syreupptagning.

- Mekanisk legering – Kulfräsning en blandning av pulver av aluminium och legeringselement följt av kallkomprimering och sintring.

Gasatomisering ger överlägsen kontroll över pulveregenskaper som partikelstorlek, form och mikrostruktur.

Tillämpningar av Al 7075 Powder

Vanliga tillämpningar av Al 7075-pulver inkluderar:

- Additiv tillverkning – Används vid selektiv lasersmältning, direkt metalllasersintring för att producera komplexa, lätta flyg- och försvarsdelar.

- Formsprutning av metall – Att tillverka små komplicerade komponenter med hög hållfasthet och måttlig korrosionsbeständighet.

- Pulvermetallurgi – Press- och sintringsprocess för att skapa högpresterande bildelar och maskinkomponenter.

- Termisk sprutning – Trådbågssprutning för att avsätta mycket hårda och slitstarka Al 7075-beläggningar.

- Pyroteknik – Tillsätts som bränslebeståndsdel i pyrotekniska kompositioner på grund av dess höga reaktivitet.

- Fyllmedel för svetsning – Används som tillsatstråd som ger svetsstyrka men begränsad svetsbarhet.

Specifikationer för Al 7075 Powder

Al 7075 pulver finns i olika storleksintervall, former, kvaliteter och renhetsnivåer:

- Partikelstorlek: Från 10-45 mikrometer för AM-metoder, upp till 120 mikrometer för termiska sprutprocesser.

- Morfologi: Sfäriska, oregelbundna och blandade partikelformer. Smidigt sfäriskt pulver har bättre flytbarhet.

- Renhet: Från kommersiella till högrenhetskvaliteter skräddarsydda för den specifika applikationen.

- Betyg: Överensstämmer med ASTM B951, AMS 4045, AMS 4282, EN 573-3 och andra likvärdiga standarder.

- Syrehalt: Varierar mellan 500-1500 ppm baserat på produktionsmetod. Lägre är bättre.

Globala leverantörer av Al 7075-pulver

Några av de största leverantörerna globalt är:

- Sandvik Osprey (Storbritannien)

- TLS Technik (Tyskland)

- Valimet Inc (USA)

- CNPC Pulver (Kina)

- Makin Metal Powders (Storbritannien)

- PyroGenesis Kanada

- Metal Powder Company (USA)

Dessa företag producerar Al 7075-pulver lämpligt för olika applikationer med olika tillverkningsprocesser.

Al 7075 Powder Prissättning

Prissättning av Al 7075-pulver beror på faktorer som:

- Renhetsnivåer

- Partikelns egenskaper

- Produktionsmetod för pulver

- Orderkvantitet

- Leverantör och geografisk placering

| Betyg | Prisintervall |

|---|---|

| Kommersiell | $10-20 per kg |

| Hög renhet | $20-40 per kg |

| Ultrafin | $40-80 per kg |

| Särskild klass | $80-150 per kg |

Gasfinfördelad, kontrollerad partikelstorlek, högrenhetspulver kräver mycket högre priser än enkelt kommersiellt Al 7075-pulver.

Förvaring och hantering av Al 7075-pulver

Al 7075 reaktivt legeringspulver måste hanteras med försiktighet för att förhindra:

- Oxidation och reaktion med fukt

- Risker för dammexplosion från fint pulver

- Hälsoproblem relaterade till inandning

- Säkerhetsrutiner som rekommenderas av leverantören ska följas

Inertgasfiltar, korrekt jordning, ventilation och PPE bör användas för säker hantering.

Test- och karakteriseringsmetoder

Viktiga testmetoder som används för Al 7075-pulver inkluderar:

- Analys av kemisk sammansättning med hjälp av OES eller XRF

- Partikelstorleksfördelning enligt ASTM B822-standarden

- Morfologisk analys genom SEM

- Pulverflödeshastighet med Hall flödesmätare

- Densitetsmätning med heliumpyknometri

- Test av föroreningar med ICP-MS

- Mikrostrukturundersökning med röntgendiffraktion

Dessa tester säkerställer att pulvret uppfyller de erforderliga kemiska, fysikaliska och mikrostrukturella egenskaperna för den specifika applikationen.

Jämförelse mellan Al 7075 och Al 6061 Powder

Al 7075 och Al 6061 är två aluminiumlegeringspulver som jämförs:

| Parameter | Al 7075 | Al 6061 |

|---|---|---|

| Legeringstyp | Värmebehandlingsbar | Värmebehandlingsbar |

| Zn-innehåll | 5.1-6.1% | 0% |

| Mg-innehåll | 2.1-2.9% | 0.8-1.2% |

| Styrka | Mycket högre | Måttlig |

| Bearbetbarhet | Dålig | Utmärkt |

| Svetsbarhet | Dålig | Mycket bra |

| Korrosionsbeständighet | Måttlig | Utmärkt |

| Kostnad | Högre | Lägre |

Al 7075 erbjuder mycket hög hållfasthet medan Al 6061 ger bättre korrosionsbeständighet, svetsbarhet och bearbetbarhet till lägre kostnad.

Al 7075 Powder Vanliga frågor

F: Hur produceras Al 7075-pulver?

S: Al 7075-pulver tillverkas kommersiellt med användning av gasatomisering, vattenförstoftning, mekanisk legering och elektrolysteknik. Gasatomisering ger den bästa kontrollen av partikelegenskaperna.

F: Vilka är de viktigaste tillämpningarna för Al 7075-pulver?

S: De viktigaste applikationerna för Al 7075 är additiv tillverkning, termisk spraybeläggning, tillverkning av pulvermetallurgiska delar, metallformsprutning och pyrotekniska kompositioner som kräver exceptionellt hög hållfasthet.

F: Vilken är den rekommenderade partikelstorleken för Al 7075-pulver i AM?

S: För de flesta metall-3D-utskriftsprocesser är det idealiska partikelstorleksintervallet för Al 7075 15-45 mikron med sfärisk morfologi och god pulverflytbarhet.

F: Kräver Al 7075-pulver några särskilda försiktighetsåtgärder?

S: Ja, det rekommenderas att hantera reaktiva aluminiumlegeringspulver försiktigt under inert atmosfär med korrekt jordning, ventilation och personlig skyddsutrustning.

F: Var kan jag köpa ultrafint Al 7075-pulver lämpligt för flyg- och rymdkomponenter?

S: Gasatomiserade ultrafina Al 7075-pulver med hög renhet som uppfyller flyg- och rymdkraven kan erhållas från ledande leverantörer som Sandvik Osprey, TLS Technik och Valimet Inc.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731