GH4169 Pulver för additiv tillverkning

GH4169 pulver är ett utskiljningshärdande rostfritt stålpulver som är utformat för att ge hög hållfasthet, hårdhet och korrosionsbeständighet efter värmebehandling. Det innehåller 17% krom tillsammans med tillsatser av nickel, aluminium, titan och niob för förbättrade mekaniska egenskaper och korrosionsegenskaper.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

GH4169 pulver är ett utskiljningshärdande rostfritt stålpulver som är utformat för att ge hög hållfasthet, hårdhet och korrosionsbeständighet efter värmebehandling. Det innehåller 17% krom tillsammans med tillsatser av nickel, aluminium, titan och niob för förbättrade mekaniska egenskaper och korrosionsegenskaper.

| Storleksintervall | 15-45um/15-53um/20-63 um | 45-105um |

| Form | Sfärisk | Sfärisk |

| Flödesförmåga | ≤25s | |

| Skenbar densitet | ≥4,0 g/c㎡ | |

| Syrehalt | ≤200 ppm | |

| Kväveinnehåll | ≤150ppm | |

Viktiga egenskaper hos GH4169-pulver:

GH4169 Pulver Egenskaper

| Fastigheter | Detaljer |

|---|---|

| Sammansättning | Fe-17Cr-4Ni-1.5Ti-0.7Al-0.25Nb alloy |

| Täthet | 7,9 g/cc |

| Partikelns form | Oregelbunden, kantig |

| Storleksintervall | 10-150 mikrometer |

| Skenbar densitet | Upp till 50% av verklig densitet |

| Flytbarhet | Måttlig |

| Styrka | Mycket hög efter åldringsbehandling |

| Korrosionsbeständighet | Utmärkt, även i marina miljöer |

GH4169:s exceptionella styrka/vikt-förhållande i kombination med enastående korrosionsbeständighet gör den lämplig för kritiska konstruktionsdelar inom flyg-, marin- och kärnkraftsindustrin samt andra krävande applikationer.

GH4169 Pulversammansättning

Typisk sammansättning av GH4169 utskiljningshärdande rostfritt stål:

GH4169 Pulversammansättning

| Element | Vikt % |

|---|---|

| Järn (Fe) | Balans |

| Krom (Cr) | 16-18% |

| Nickel (Ni) | 3.5-5.5% |

| Titan (Ti) | 1.2-1.8% |

| Aluminium (Al) | 0.3-1.2% |

| Niob (Nb) | 0.15-0.45% |

| Kol (C) | 0,04% max |

| Kisel (Si), mangan (Mn) | 1% max varje |

- Järn ger den ferritiska matrisen

- Krom förbättrar korrosions- och oxidationsbeständigheten

- Nickel, aluminium, titan och niob underlättar utskiljningshärdning

- Kol och andra element som är begränsade till trampföroreningar

Sammansättningen är utformad för att maximera utskiljningshärdningsresponsen och korrosionsbeständigheten som krävs i strukturella applikationer.

GH4169 Pulver Fysikaliska egenskaper

GH4169 Pulver Fysikaliska egenskaper

| Fastighet | Värden |

|---|---|

| Täthet | 7,9 g/cc |

| Smältpunkt | 1400-1450°C |

| Elektrisk resistivitet | 0,80 μΩ-m |

| Termisk ledningsförmåga | 12 W/mK |

| Termisk expansion | 12 x 10^-6 /K |

| Maximal driftstemperatur | 650°C |

- Högt förhållande mellan styrka och vikt

- Bibehåller styrka och hårdhet upp till 650°C

- Relativt låg värmeledningsförmåga

- Resistiviteten ökar efter utskiljningshärdning

- Måttlig expansionskoefficient

Egenskaperna gör det möjligt att använda GH4169 i bärande konstruktionsapplikationer som kräver korrosionsbeständighet och hållfasthet vid höga temperaturer.

GH4169 Pulver Mekaniska egenskaper

GH4169 Pulver Mekaniska egenskaper

| Fastighet | Skick | Värden |

|---|---|---|

| Hårdhet | Lösningsglödgad | 90 HRB |

| Hårdhet | Högsta ålder | 40-45 HRC |

| Draghållfasthet | Glödgad | 550-750 MPa |

| Draghållfasthet | Högsta ålder | 1300-1600 MPa |

| Sträckgräns | Högsta ålder | 1100-1400 MPa |

| Töjning | Högsta ålder | 8-13% |

- Åldras till höga hållfasthetsnivåer som överstiger andra utskiljningshärdande rostfria stål

- Bibehåller god duktilitet i åldrat tillstånd

- Betydande ökning av hårdheten efter åldringsbehandling

- Styrkan kan skräddarsys genom mognadstid och temperatur

Dessa egenskaper gör GH4169 lämplig för lätta, höghållfasta konstruktionsdelar som kräver korrosionsbeständighet.

GH4169 Pulver Applikationer

Typiska användningsområden för GH4169 utskiljningshärdande pulver av rostfritt stål är bl.a:

GH4169 Pulver Applikationer

| Industri | Exempel på användningsområden |

|---|---|

| Flyg- och rymdindustrin | Flygplansskrov och motorkomponenter, fästelement |

| Marin | Axlar, fixturer, solenoider, ventiler |

| Kärnkraft | Beklädnad av bränsleelement, interna strukturer |

| Olja och gas | Strukturella delar till borrhuvuden, offshore-plattformar |

| Kemisk | Processutrustning som kärl och rör |

Några specifika användningsområden:

- Bultar, muttrar, skruvar och tappar som kräver hög hållfasthet

- Kritiska roterande axelkomponenter

- Ventil- och pumphus som används i korrosiva miljöer

- Blandningsutrustning som pumphjul och omrörare

- Inkapsling av kärnbränsleelement och inre delar av kärl

GH4169 ger en exceptionell kombination av styrka, hårdhet och korrosionsbeständighet som krävs i kritiska konstruktionsdelar i krävande industrier.

GH4169 Pulver Specifikationer

Viktiga specifikationer för GH4169 pulver inkluderar:

GH4169 Pulverstandarder

| Standard | Beskrivning |

|---|---|

| AMS 5922 | Pulver av utskiljningshärdat rostfritt stål för delar till flygindustrin |

| ASTM A580 | Standard för utskiljningshärdande tråd av rostfritt stål |

| ASTM A638 | Standard för utskiljningshärdande järnbaserade superlegeringar |

| AMS 5898 | Stång, smide, ringar av utskiljningshärdande rostfritt stål |

Dessa definierar:

- Kemisk sammansättning av legeringen GH4169

- Tillåtna orenheter som C, S och P

- Nödvändiga mekaniska egenskaper under olika förhållanden

- Godkända produktionsmetoder för pulver

- Protokoll för test av efterlevnad

- Krav på kvalitetssäkring

Pulver som produceras enligt dessa standarder säkerställer optimal åldringsrespons, duktilitet och korrosionsbeständighet.

GH4169 Pulver Partikelstorlekar

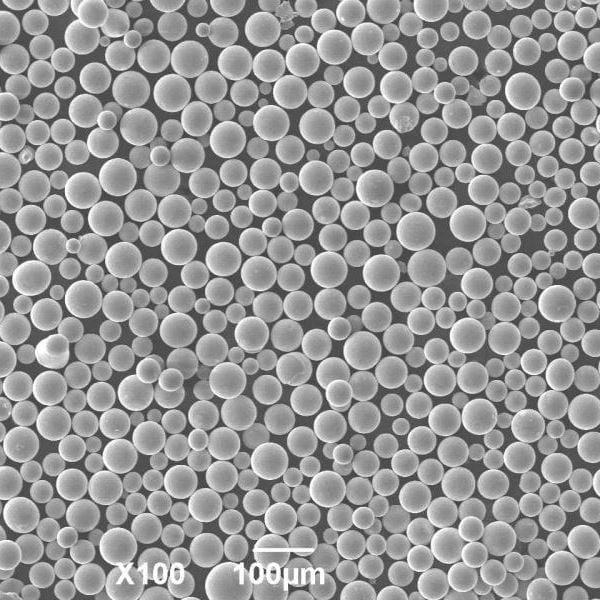

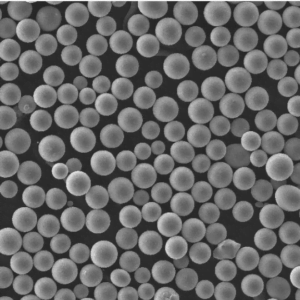

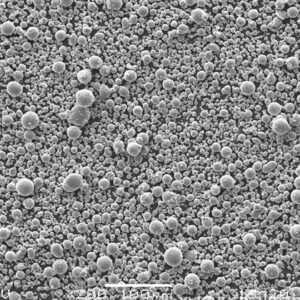

GH4169 Partikelstorleksfördelning för pulver

| Partikelstorlek | Egenskaper |

|---|---|

| 10-22 mikrometer | Ultrafin kvalitet för hög densitet |

| 22-75 mikrometer | Vanligast förekommande storleksintervall |

| 75-150 mikrometer | Grövre storlekar för förbättrad flytbarhet |

- Finare partiklar ger högre sintrad densitet

- Grovare partiklar förbättrar pulverflödet in i verktygshålrummen

- Både gas- och vattenförstoftning används

- Storleksfördelning skräddarsydd för de egenskaper som krävs för den slutliga detaljen

Genom att kontrollera partikelstorleksfördelningen optimeras pressbeteendet, den slutliga densiteten och den mekaniska prestandan.

GH4169 Pulver skenbar densitet

GH4169 Pulver skenbar densitet

| Skenbar densitet | Detaljer |

|---|---|

| Upp till 50% av verklig densitet | För oregelbunden pulvermorfologi |

| 4,5-5,5 g/cc | Högre för sfäriska pulver |

- Sfäriska pulver ger högre skenbar densitet

- Oregelbundna partiklar har densitet runt 45%

- Högre skenbar densitet förbättrar pulverflöde och kompressibilitet

- Ger högre gröndensitet efter komprimering

Högre pulverdensitet leder till högre tillverkningsproduktivitet och bättre detaljprestanda.

GH4169 Produktionsmetod för pulver

GH4169 Pulverproduktion

| Metod | Detaljer |

|---|---|

| Atomisering av gas | Inert gas under högt tryck bryter upp smält metallström i fina droppar |

| Atomisering av vatten | Högtrycksvattenstråle bryter ner metall till fina partiklar |

| Induktionssmältning i vakuum | Insatsmaterial med hög renhet som smälts under vakuum |

| Flera omsmältningar | Förbättrar den kemiska homogeniteten |

| Siktning | Klassificerar pulver i olika partikelstorleksintervall |

- Gasatomisering ger sfärisk pulverform

- Vattenförstoftning är billigare men ger oregelbundna partiklar

- Vakuumbearbetning minimerar gasformiga föroreningar

- Efterbearbetning möjliggör kontroll av partikelstorlek

Helautomatiserade metoder i kombination med strikt kvalitetskontroll säkerställer tillförlitligt och konsekvent pulver som lämpar sig för kritiska applikationer.

GH4169 Prissättning för pulver

GH4169 Prissättning för pulver

| Faktor | Påverkan på priset |

|---|---|

| Pulverkvalitet | Högre renhet ökar kostnaden |

| Partikelstorlek och -form | Fint sfäriskt pulver dyrast |

| Orderkvantitet | Priset sjunker med större volymer |

| Ytterligare bearbetning | Tjänster som siktning ökar kostnaden |

| Krav för testning | Mer rigorösa tester ökar kostnaderna |

Indikativ prissättning

- Oregelbundet GH4169-pulver: $18-24 per kg

- Sfäriskt GH4169-pulver: $22-30 per kg

- Priset för stora volymer kan vara 25-35% lägre

Priset beror på renhetsgrad, pulveregenskaper, ordervolym och ytterligare bearbetning som krävs.

GH4169 Pulver Leverantörer

GH4169 Pulver Leverantörer

| Företag | Plats |

|---|---|

| Snickare Tillsats | USA |

| Erasteel | USA, Europa |

| Sandvik Osprey | STORBRITANNIEN |

| Aubert & Duval | Frankrike |

| CNPC Powder Group | Kina |

| Jingdong nytt material | Kina |

Urvalsfaktorer inkluderar:

- Producerade pulverkvaliteter

- Produktionskapacitet och ledtider

- Pulverets kvalitet och konsistens

- Testkapacitet och rapportering

- Prissättning och minsta orderkvantitet

- Erfarenhet av att betjäna utvalda branscher

GH4169 Hantering och lagring av pulver

GH4169 Pulverhantering

| Rekommendation | Anledning |

|---|---|

| Säkerställ korrekt ventilation | Förhindra exponering för fina metallpartiklar |

| Undvik antändningskällor | Pulver kan antändas i syrehaltig atmosfär |

| Följ säkra protokoll | Minska hälso- och brandriskerna |

| Använd verktyg som inte slår gnistor | Förhindra risken för antändning |

| Förvara förseglade behållare | Förhindrar kontaminering eller oxidation |

Rekommendationer för lagring

- Förvaras i stabila behållare på en torr och sval plats

- Begränsa exponeringen för fukt och syror

- Håll temperaturen under 30°C

Med lämpliga försiktighetsåtgärder under hantering och lagring förblir GH4169-pulver stabilt och säkert att arbeta med.

GH4169 Inspektion och provning av pulver

GH4169 Testning av pulver

| Test | Detaljer |

|---|---|

| Kemisk analys | ICP och XRF verifierar sammansättningen |

| Analys av partikelstorlek | Bestämmer partikelstorleksfördelningen |

| Skenbar densitet | Mätt enligt standarden ASTM B212 |

| Morfologi för pulver | SEM-avbildning av partikelform |

| Test av flödeshastighet | Gravitationsflöde genom specificerad tratt |

| Förlust vid tändning | Fastställer fukthalt |

Testningen säkerställer att pulvret uppfyller kraven på sammansättning, partikelegenskaper, densitetsspecifikationer, morfologi och flödeshastighet enligt gällande standarder.

GH4169 Pulver Fördelar och nackdelar

Fördelar med GH4169-pulver

- Exceptionell hållfasthet efter utskiljningshärdning

- Bibehåller god duktilitet i åldrat tillstånd

- Utmärkt korrosionsbeständighet även i marina miljöer

- Hög hållfasthet bibehålls upp till 650°C

- Bra kombinationer av egenskaper för kritiska konstruktionsdelar

- Mer kostnadseffektiva än superlegeringar

Begränsningar av GH4169-pulver

- Kräver noggrann värmebehandling för optimala egenskaper

- Lägre brottseghet än austenitiska stål

- Kan bli överkänslig vid felaktig svetsning

- Begränsad kapacitet för kallbearbetning och formning

- Styrka och korrosionsbeständighet inte lika hög som hos superlegeringar

- Högre pris än vanliga rostfria stålkvaliteter

Jämförelse med 17-4PH- och 15-5PH-pulver

GH4169 jämfört med 17-4PH och 15-5PH pulver

| Parameter | GH4169 | 17-4PH | 15-5PH |

|---|---|---|---|

| Täthet | 7,9 g/cc | 7,7 g/cc | 7,8 g/cc |

| Hårdhet | 40-45 HRC | 38-45 HRC | 36-42 HRC |

| Draghållfasthet | 1300-1600 MPa | 1200-1450 MPa | 1050-1400 MPa |

| Korrosionsbeständighet | Utmärkt | Mycket bra | Bra |

| Kostnad | Hög | Måttlig | Låg |

- GH4169 har högsta hållfasthet efter åldringsbehandling

- Det ger också bästa möjliga korrosionsbeständighet

- 17-4PH är måttligt starkare än 15-5PH

- 15-5PH är den mest ekonomiska av de tre

- GH4169 föredras för kritiska strukturella applikationer

GH4169 Pulver Vanliga frågor

F: Vilka är de viktigaste tillämpningarna av GH4169 utfällningshärdande rostfritt stålpulver?

A: Huvudapplikationerna omfattar flyg- och rymdkonstruktioner, marina komponenter som axlar och ventiler, beklädnad av kärnbränsleelement, delar till olje- och gasbrunnar, kemisk processutrustning och andra konstruktionsdelar som kräver hög hållfasthet och korrosionsbeständighet.

F: Vilken roll spelar aluminium och titan i GH4169-sammansättningen?

A: Aluminium och titan underlättar utskiljningshärdning genom att bilda fina sammanhängande utfällningar under åldringsbehandlingen. Detta ger betydande förstärkning samtidigt som den rimliga duktiliteten bibehålls.

F: Vilka försiktighetsåtgärder behövs när du arbetar med GH4169-pulver?

S: Rekommenderade försiktighetsåtgärder omfattar ventilation, undvikande av antändningskällor, användning av gnistfria verktyg, skyddsutrustning, säker förvaring och förvaring av förseglade behållare på avstånd från föroreningar eller fukt.

F: Hur skiljer sig GH4169 från martensitiska och ferritiska rostfria stålsorter?

S: GH4169 kan åldras till mycket högre hållfasthetsnivåer jämfört med martensitiska eller ferritiska kvaliteter. Den ger också utmärkt korrosionsbeständighet, även i marina miljöer, till skillnad från martensitiska kvaliteter.

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731