Inconel 625 pulver丨Nickelbaserad superlegering in625 pulver

In625-pulver är en pulverform av nickel-kromlegeringen Inconel 625, som uppvisar utmärkt korrosionsbeständighet, hög hållfasthet och enastående värmebeständighet. Denna superlegering består av nickel, krom, molybden och niob, tillsammans med mindre mängder av andra element. Dess unika sammansättning ger anmärkningsvärda mekaniska egenskaper, vilket gör det till ett eftertraktat material i många industrier.

Låg MOQ

Tillhandahålla låg minsta orderkvantitet för att möta olika behov.

OEM & ODM

Tillhandahålla kundanpassade produkter och designtjänster för att tillgodose unika kundbehov.

Tillräckligt lager

Säkerställa snabb orderhantering och tillhandahålla tillförlitlig och effektiv service.

Kundtillfredsställelse

Tillhandahålla högkvalitativa produkter med kundnöjdhet i fokus.

dela denna produkt

Innehållsförteckning

Översikt över Inconel 625 Powder

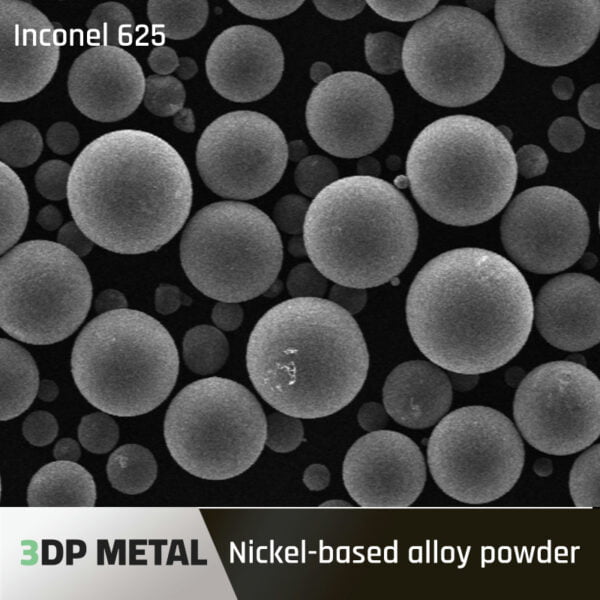

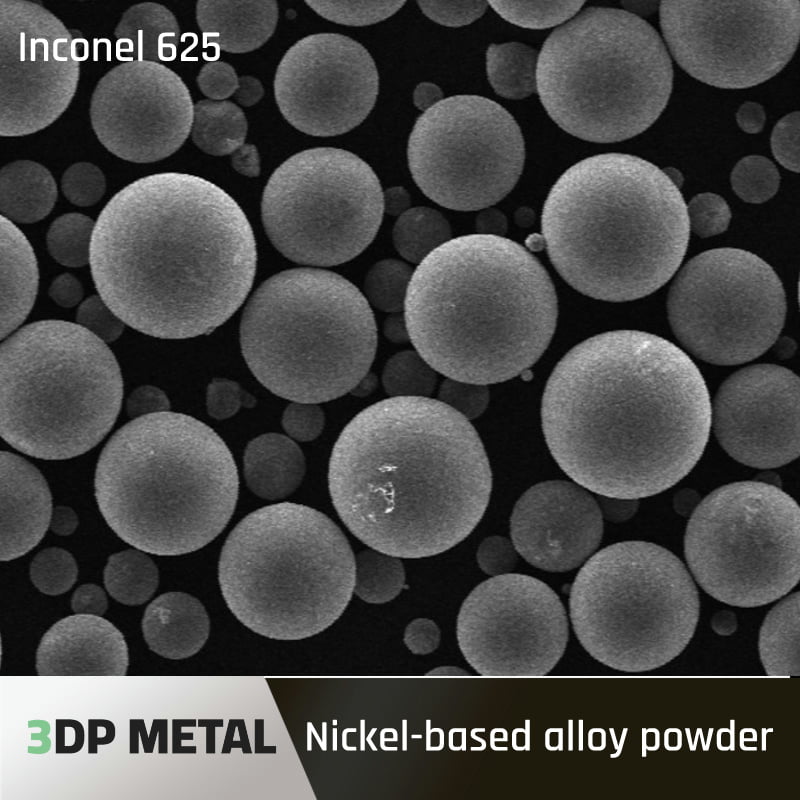

Inconel 625 pulver är en nickelbaserad superlegering som har höga hållfasthetsegenskaper och motståndskraft mot förhöjda temperaturer. Inconel 625 (legering 625, UNS N06625) används ofta för sin höga hållfasthet, utmärkta tillverkningsbarhet (inklusive sammanfogning) och enastående korrosionsbeständighet. Dess servicetemperaturer sträcker sig från kryogen till 1800°F (982°C). Hög drag-, kryp- och brotthållfasthet, enastående utmattnings- och termisk utmattningshållfasthet, oxidationsbeständighet och utmärkt svetsbarhet och lödbarhet är egenskaperna hos INCONEL-legeringen 625 som gör den intressant för flygindustrin.

Inconel 625-pulver är ett högpresterande nickelbaserat superlegeringspulver som ofta används i additiv tillverkning (AM) och traditionella metallbearbetningsprocesser. Känt för sin exceptionella styrka, korrosionsbeständighet och termiska stabilitet, är detta material ett toppval inom industrier som flyg-, energi- och marinteknik.

Men vad gör att Inconel 625-pulver sticker ut? Dess unika sammansättning, främst bestående av nickel, krom och molybden, ger enastående motståndskraft mot oxidation, gropfrätning och krypdeformation. Detta gör den idealisk för applikationer med hög temperatur och hög belastning där vanliga material skulle misslyckas.

Med framväxten av metall 3D-utskrift, efterfrågan på hög kvalitet Inconel 625 pulver har skjutit i höjden. Företag gillar Met3DP ligger i framkant och levererar branschledande gas finfördelad och PREP-tillverkade sfäriska pulver optimerade för Selektiv lasersmältning (SLM), Smältning med elektronstråle (EBM), Formsprutning av metall (MIM)och andra avancerad tillverkningsteknik.

Låt oss nu dyka djupare in i toppfaktorer som gör Inconel 625 pulver ett oumbärligt material 2025.

Bästa Inconel 625-pulver för 3D-utskrift

Varför Inconel 625 Powder är perfekt för 3D-utskrift

3D-utskrift, särskilt metalltillsatstillverkning (AM), har revolutionerat industriproduktionen, och Inconel 625 pulver är ett av de mest eftertraktade materialen för denna teknik. De viktigaste fördelarna inkluderar:

- Motståndskraft mot höga temperaturer – Tål extrem värme utan att tappa styrka.

- Utmärkt korrosionsbeständighet – Fungerar bra i tuffa miljöer, som marin och kemisk bearbetning.

- Överlägsna mekaniska egenskaper – Hög draghållfasthet, krypmotstånd och utmattningsprestanda.

- Bra tryckbarhet – Sfäriska pulverpartiklar säkerställer jämnt flöde och enhetlig skiktavsättning i pulverbäddsfusion.

Specifikation för Inconel 625 pulver

| Norminal sammansättning (wt%) | ||||||

|

In625

|

Cr | Mo | Nb | Co | Fe | Al |

| 20-23 | 8-10 | 3.15-4.15 | ≤1 | ≤1 | ≤0.4 | |

| Ti | C | Ni | O | N | ||

| ≤0.4 | ≤0.1 | Bal. | ≤500ppm | ≤100ppm | ||

Common Size:15-45um,15-53um,45-106um,45-150u,-200/-300/-400/-500/-600mesh etc,.

| Nej | Namn | Relaterad pulversammansättning (wt%) |

| 1 | 18Ni300 | Ni17-19,Mo4.5-5.2,Co8.5-9.5,Ti0.6-0.8,Al0.05-0.15,Fe(Bal.) |

| 2 | Hastelloy-legering | Fe17-20,Cr20.5-23,Mo8-10,W0.2-1,Co0.5-2.5,C0.05-0.15,Ni(Bal.) |

| 3 | AlSi10Mg | Si9-11,Mg0.2-0.45,Al(Bal.) |

| 4 | CoCrW | Cr26.5-29,W7-9,Si1.2-1.9,Co(Bal.) |

| 5 | Co28Cr6Mo | Cr27-29,Mo5-7,Co(Bal.) |

| 6 | Sfäriskt ti-pulver | Ti≥99,9 |

| 7 | TC4 | Al5.5-6.8,V3.5-4.5,Ti(Bal.) |

| 8 | TA15 | Al5.5-7.1,V0.8-2.5,Mo0.8-2,Zr1.5-2.5,Al(Bal.) |

| 9 | 316L | Cr16.00-18.00, Ni10.00-14.00,Mo2.00-3.00,Fe(Bal.) |

| 10 | S136 | Cr12.0-14.0,Si0.8-1.0,V0.15-0.4,C0.2-0.45,Fe(Bal.) |

| 11 | In625 | Cr20-23 , Mo8-10 , Nb 3,15-4,15 , Co≤1, Fe≤1 , Ni (bal.) |

| 12 | In718 | Cr17-21 , Mo2,8-3,3 , Nb 4,75-5,5 , Co≤1, Ni50-51 , Fe(Bal.) |

| 13 | Spherica WC | C3,7-4,2,W(Bal.) |

| 14 | Sfäriskt Cr-pulver | Cr≥99,9 |

| 15 | Sfäriskt Mo-pulver | Mo≥99,9 |

| 16 | Sfäriskt Ta-pulver | Ta≥99,9 |

| 17 | Spherica W Pulver | W≥99.9 |

Att välja rätt pulver för olika 3D-utskriftsmetoder

Alla Inconel 625-pulver är inte likadana. Pulvrets egenskaper beror på produktionsmetoder och fördelning av partikelstorlek, som påverkar deras lämplighet för olika 3D-utskriftstekniker.

| Tryckmetod | Idealisk pulverstorlek (µm) | Rekommenderad pulvertyp | Fördelar |

|---|---|---|---|

| Selektiv lasersmältning (SLM) | 15-45 | Gas Atomiserad | Hög precision, fina detaljer |

| Smältning med elektronstråle (EBM) | 45-106 | Process med roterande elektrod och plasma (PREP) | Bättre för stora, starka delar |

| Binder Jetting | 20-50 | Vatten atomiserat | Kostnadseffektiv, hög genomströmning |

| Deposition med direkt energi (DED) | 50-150 | Gas Atomiserad | Bra för reparation och storskalig utskrift |

Met3DP:s avancerade pulverlösningar

På Met3DP, tillhandahåller vi hög renhet, sfärisk Inconel 625 pulver speciellt skräddarsydda för SLM, EBM och annan 3D-utskrift av metall metoder. Våra pulver tillverkas med hjälp av Vakuuminduktionsgasatomisering (VIGA) och PREP-teknik, säkerställa optimal flytbarhet, packningsdensitet och tryckbarhet.

Egenskaper hos pulver av Inconel 625

Förståelse för kemiska och fysikaliska egenskaper hos Inconel 625-pulver är avgörande för att välja rätt material för din applikation.

Kemisk sammansättning av Inconel 625-pulver

Den unika kemiska sammansättningen ger Inconel 625 dess enastående korrosionsbeständighet och hög temperaturhållfasthet.

| Element | Procentuell andel (%) |

|---|---|

| Nickel (Ni) | 58,0 min |

| Krom (Cr) | 20.0-23.0 |

| Molybden (Mo) | 8.0-10.0 |

| Järn (Fe) | 5,0 max |

| Niob (Nb) och tantal (Ta) | 3.15-4.15 |

| Kobolt (Co) | 1,0 max |

| Mangan (Mn) | 0,50 max |

| Kisel (Si) | 0,50 max |

| Kol (C) | 0,10 max |

| Svavel (S) | 0,015 max |

Fysikaliska och mekaniska egenskaper

Inconel 625 pulver utställningar exceptionella mekaniska egenskapervilket gör den idealisk för hög stress och hög temperatur applikationer.

| Fastighet | Värde |

|---|---|

| Täthet | 8,44 g/cm³ |

| Smältpunkt | 1290-1350°C |

| Draghållfasthet | 827 MPa (120 ksi) |

| Utbyteshållfasthet | 414 MPa (60 ksi) |

| Töjning | 30% |

| Hårdhet (Rockwell B) | 85 |

Tillämpningar av Inconel 625 Powder inom industrin

Med tanke på dess överlägsna egenskaper, Inconel 625 pulver används i stor utsträckning i flyg-, marin-, energi- och kemisk bearbetning industrier.

Viktiga industriella tillämpningar

| Industri | Användningsfall | Anledning till användning |

|---|---|---|

| Flyg- och rymdindustrin | Jetmotorer, avgassystem, värmesköldar | Extrem värmebeständighet, oxidationsbeständighet |

| Marin | Ubåtsdelar, offshore-borrningskomponenter | Motståndskraft mot korrosion av havsvatten |

| Energi | Gasturbiner, kärnreaktorer | Hållfasthet vid höga temperaturer, krypbeständighet |

| Kemisk bearbetning | Värmeväxlare, rörsystem | Korrosionsbeständighet mot syror och alkalier |

| Medicinsk | Implantat, proteser | Biokompatibilitet, styrka, korrosionsbeständighet |

Hur Inconel 625 Powder överträffar andra nickellegeringar

Jämfört med andra nickelbaserade superlegeringar som Inconel 718 och Hastelloy X, Inconel 625 erbjuder:

- Bättre korrosionsbeständighet än Inconel 718

- Högre temperaturprestanda än Hastelloy X

- Mer flexibilitet i 3D-utskriftsapplikationer av metall

Produktionsmetoder för Inconel 625-pulver

Den tillverkningsmetod av Inconel 625-pulver påverkar dess kvalitet, flytbarhet och prestanda. Det finns tre primära produktionstekniker:

Jämförelse av produktionsmetoder

| Produktionsmetod | Processbeskrivning | Fördelar | Nackdelar |

|---|---|---|---|

| Atomisering av gas | Metall smälts och finfördelas med inertgasstrålar | Sfäriskt pulver, bra flytbarhet | Högre kostnad |

| Process med roterande elektrod och plasma (PREP) | Metallelektroden snurras och smälts med hjälp av plasma | Hög renhet, utmärkt sfäricitet | Dyrt, lägre avkastning |

| Atomisering av vatten | Smält metall finfördelas med vattenstrålar | Kostnadseffektiv, storskalig produktion | Oregelbunden partikelform, lägre flytbarhet |

För avancerade applikationer som flyg- och 3D-utskrift, gasatomiserade och PREP-pulver föredras på grund av deras hög sfäricitet och renhet.

Varför Met3DP använder gasatomisering och PREP

På Met3DP, vi anställer toppmodern VIGA- och PREP-teknik för att producera högkvalitativt Inconel 625-pulver med konsekvent partikelstorlek, utmärkt flytbarhet och minimala föroreningar.

Kvalitetsstandarder för Inconel 625-pulver

När du väljer Inconel 625 pulver för industriella tillämpningar, möte stränga kvalitetsstandarder är avgörande. Olika internationella organisationer har fastställt riktlinjer för att säkerställa konsekvens, säkerhet och prestanda. Här är vad du behöver veta.

Viktiga kvalitetsstandarder för Inconel 625-pulver

| Standard | Beskrivning | Tillämpliga industrier |

|---|---|---|

| ASTM B443 | Specifikation för Inconel 625 ark, remsa och plåt | Flyg- och rymdindustrin, marinindustrin, kemisk bearbetning |

| AMS 5666 | Flygmaterialspecifikation för smidd Inconel 625 | Flyg- och rymdindustrin, försvarsindustrin |

| ISO 9001 | Certifiering av kvalitetsledningssystem | Allmän tillverkning |

| ASTM F3055 | Standard för additiv tillverkning av Ni-baserade legeringar | 3D-utskrift, medicinska implantat |

| AMS 5892 | Värmebeständig Inconel 625 för gasturbiner | Energi, kraftproduktion |

Att uppfylla dessa standarder säkerställer att materialet fungerar tillförlitligt under miljöer med hög stress, extrema temperaturer och korrosiva förhållanden.

Varför Met3DP:s Inconel 625 Powder uppfyller de högsta standarderna

På Met3DP, håller vi oss till ISO 9001-certifierade kvalitetskontrollsystem, vilket säkerställer varje sats av Inconel 625 pulver uppfyller eller överträffar ASTM F3055 och AMS 5666 specifikationer. Vår produktionsprocess inkluderar strikt kemisk sammansättningsanalys, partikelmorfologikontroll och flytbarhetstestning att leverera top-tier puder för industriella tillämpningar.

Kostnadsanalys av Inconel 625-pulver

Den kostnad för Inconel 625 pulver beror på olika faktorer, inklusive tillverkningsmetod, partikelstorleksfördelning, leverantörsrykte och ordervolym.

Faktorer som påverkar priset på Inconel 625-pulver

| Faktor | Påverkan på kostnader |

|---|---|

| Produktionsmetod | PREP och gasatomisering leda till högre kostnader på grund av bättre kvalitet |

| Renhet och sammansättning | Pulver med högre renhet kostar mer men ger bättre prestanda |

| Fördelning av partikelstorlek | Fina puder optimerade för SLM och EBM är dyrare än grövre pulver |

| Ordervolym | Bulkorder minskar kostnaderna på grund av stordriftsfördelar |

| Leverantörens rykte | Etablerade leverantörer med ISO-certifierad processer kan ta mer betalt för kvalitetssäkring |

Prisjämförelse: Inconel 625 vs. andra nickelbaserade pulver

| Material | Genomsnittligt pris per kg (2025) | Primär tillämpning |

|---|---|---|

| Inconel 625 pulver | $80 – $150 | Flyg, energi, 3D-utskrift |

| Inconel 718 Pulver | $70 – $130 | Flyg- och rymdindustrin, fordonsindustrin |

| Hastelloy X Pulver | $90 – $160 | Tillämpningar för höga temperaturer |

| Rostfritt stål 316L Pulver | $20 – $50 | Allmän tillverkning |

Medan Inconel 625 pulver är dyrare än rostfritt stål, dess överlägsen värme- och korrosionsbeständighet göra det till en kostnadseffektivt val för verksamhetskritiska tillämpningar.

Så får du det bästa priset för Inconel 625 Powder

- Köp i bulk – Leverantörer ger ofta rabatter vid köp av stora volymer.

- Välj rätt leverantör – Pålitliga företag som Met3DP erbjuda Pulver av hög kvalitet till konkurrenskraftiga priser.

- Välj rätt partikelstorlek – Undvik att betala för mycket för ultrafina pulver om din process inte kräver dem.

Inconel 625 Powder for Powder Bed Fusion vs. Binder Jetting

Två stora 3D-utskriftsteknik användning Inconel 625 pulver: Fusion av pulverbäddar (PBF) och Binder Jetting (BJ). Var och en har unika fördelar och lämpar sig för olika applikationer.

Jämförelse: Inconel 625 Powder för PBF vs. Binder Jetting

| Funktion | Fusion av pulverbäddar (PBF) | Binder Jetting (BJ) |

|---|---|---|

| Tryckprocessen | Använder en laser- eller elektronstråle för att smälta och smälta pulver | Använder ett bindemedel för att limma pulverpartiklar före sintring |

| Idealisk partikelstorlek | 15-45 µm (SLM), 45-106 µm (EBM) | 20-50 um |

| Styrka i sista delen | Högdensitet, starka delar | Lägre styrka, kräver efterbearbetning |

| Bäst för komplexa geometrier? | Ja, stöder intrikata mönster | Begränsad komplexitet |

| Kostnad | Högre pga laser/elektronstråleteknik | Lägre pga snabbare utskrift och billigare material |

| Tillämpning | Flyg, medicinska implantat, energikomponenter | Prototypframställning, lågkostnadstillverkning |

Om du behöver höghållfasta precisionsdelar, PBF är det bästa valet. Men om du letar efter kostnadseffektiv produktion med hög hastighet, Binder Jetting kanske passar bättre.

Met3DP:s expertis inom pulverbäddsfusion

På Met3DP, vi är specialiserade på högkvalitativa sfäriska Inconel 625-pulver optimerad för SLM- och EBM-teknologier. Vår gasatomiserade pulver förse utmärkt flytbarhet, vilket säkerställer konsekvent och pålitlig 3D-utskriftsresultat.

Vatten Atomized vs. Gas Atomized vs. PREP Inconel 625 Powder: Vilket är bättre?

Den pulverproduktionsmetod påverkar direkt dess morfologi, renhet och lämplighet för olika tillverkningsprocesser.

Jämförelse av Inconel 625 pulverproduktionsmetoder

| Metod | Partikelform | Renhet | Bästa applikationen |

|---|---|---|---|

| Atomisering av vatten | Oregelbunden | Lägre | Pressade & sintrade delar |

| Atomisering av gas | Sfärisk | Hög | Laserbaserad 3D-utskrift (SLM, EBM) |

| Process med roterande elektrod och plasma (PREP) | Perfekt sfärisk | Mycket hög | Avancerat flyg, medicinsk |

Varför gasatomiserade och PREP-pulver är överlägsna

- Bättre flytbarhet: Säkerställer jämn pulverspridning för 3D-utskrifter.

- Högre renhet: PREP-pulver har minimal syreförorening.

- Konsekvent partikelstorleksfördelning: Kritiskt för SLM- och EBM-applikationer.

På Met3DP, vi använder avancerad gasatomisering och PREP-tekniker att tillverka Inconel 625 pulver av högsta kvalitet för de mest krävande tillämpningarna.

FAQ: Allt du behöver veta om Inconel 625 Powder

| Fråga | Svar |

|---|---|

| Vad gör Inconel 625 puder unikt? | Dess hög nickelhalt, i kombination med krom och molybden, tillhandahåller exceptionell korrosionsbeständighet och hållfasthet vid höga temperaturer. |

| Vilka industrier använder Inconel 625-pulver? | Flyg-, marin-, energi-, kemisk bearbetning och medicinska implantat. |

| Vilken är den idealiska partikelstorleken för SLM-utskrift? | Mellan 15-45 um, vilket säkerställer jämnt pulverflöde och optimal utskriftskvalitet. |

| Är gas atomiserat pulver bättre än vatten atomiserat pulver? | Ja, gasatomiserade pulver är mer sfärisk, renare och bättre lämpad för 3D-utskrift. |

| Hur mycket kostar Inconel 625 pulver 2025? | Priserna varierar från $80 till $150 per kg, beroende på renhet, partikelstorlek och leverantör. |

| Var kan jag köpa högkvalitativt Inconel 625-pulver? | Met3DP erbjudanden top-tier gas atomized och PREP pulver för 3D-utskrift och industriella tillämpningar. |

Slutliga tankar

Inconel 625-pulver finns kvar ett av de mest mångsidiga och högpresterande nickelbaserade pulvren tillgänglig 2025. Oavsett om du behöver den till 3D-utskrift, flyg-, energi- eller korrosionsbeständiga miljöer, att välja rätt leverantör och säkerställa att kvalitetsstandarder uppfylls är avgörande.

På Met3DP, tillhandahåller vi branschledande metallpulver optimerad för SLM, EBM och andra avancerade tillverkningstekniker. Kontakta oss idag för att hitta det perfekta pudret för din applikation!

Få det senaste priset

Om Met3DP

Produktkategori

HOT SALE

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.