Smältning genom induktion i vakuum

Innehållsförteckning

Översikt

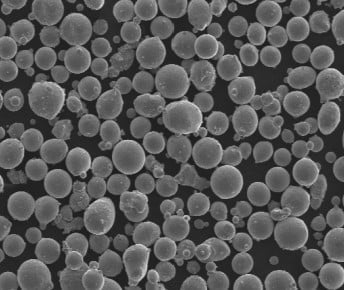

Smältning genom induktion i vakuum (VIM) är en sofistikerad och mycket exakt process som används för att producera högkvalitativa metallegeringar och pulver. Denna metod är avgörande för applikationer som kräver exceptionell renhet och exakt sammansättning, vilket gör den nödvändig i industrier som flyg, medicinsk utrustning och högpresterande teknik. Låt oss fördjupa oss i VIMs krångligheter, utforska dess processer, tillämpningar, fördelar, nackdelar och detaljerad information om olika metallpulvermodeller som produceras med denna teknik.

Vad är vakuuminduktionssmältning?

Vakuuminduktion Smältning innebär smältning av metaller i en vakuummiljö med hjälp av elektromagnetisk induktion. Denna teknik minimerar kontaminering från gaser och föroreningar, vilket säkerställer produktion av metaller med överlägsen renhet och homogenitet. Genom att smälta metaller under vakuum förhindrar VIM oxidation och möjliggör exakt kontroll över slutproduktens sammansättning.

Viktiga detaljer om VIM:

- Process: Smältning av metaller med hjälp av elektromagnetisk induktion i vakuum.

- Syfte: Tillverkar metallegeringar och pulver med hög renhet.

- Applikationer: Flyg, medicinsk utrustning, högpresterande teknik.

Hur vakuuminduktionssmältning fungerar

Föreställ dig ett högteknologiskt kök där du lagar din favoriträtt i en perfekt kontrollerad miljö, fri från alla oönskade lukter eller föroreningar. Det är VIM i ett nötskal, men för metaller! Processen börjar med att råmaterial placeras i en degel i vakuumkammaren. En induktionsspole omger degeln och genererar ett magnetfält när en elektrisk ström passerar genom den. Detta magnetfält inducerar virvelströmmar i metallen, vilket gör att den värms upp och så småningom smälter.

När metallen når den önskade temperaturen kan legeringselement tillsättas för att uppnå den specifika sammansättning som krävs. Vakuummiljön säkerställer att inga gaser fångas i smältan, vilket resulterar i en renare och mer homogen legering.

Typer av producerade metaller och legeringar

VIM är mångsidig och kan producera ett brett utbud av metaller och legeringar. Här är några specifika metallpulvermodeller:

- Nickelbaserade superlegeringar (t.ex. INCONEL 718)

- Sammansättning: Nickel, krom, järn och andra grundämnen.

- Egenskaper: Hög hållfasthet, korrosionsbeständighet och utmärkt prestanda vid hög temperatur.

- Applikationer: Turbinblad, flygkomponenter.

- Titanlegeringar (t.ex. Ti-6Al-4V)

- Sammansättning: Titan, aluminium, vanadin.

- Egenskaper: Högt hållfasthet-till-viktförhållande, utmärkt korrosionsbeständighet.

- Applikationer: Flyg-, medicinska implantat.

- Kobolt-kromlegeringar (t.ex. CoCrMo)

- Sammansättning: Kobolt, Krom, Molybden.

- Egenskaper: Hög slitstyrka, biokompatibilitet.

- Applikationer: Medicinska implantat, dentala apparater.

- Rostfria stål (t.ex. 316L)

- Sammansättning: Järn, krom, nickel, molybden.

- Egenskaper: Korrosionsbeständighet, mekanisk hållfasthet.

- Applikationer: Kirurgiska instrument, marina applikationer.

- Aluminiumlegeringar (t.ex. AlSi10Mg)

- Sammansättning: Aluminium, kisel, magnesium.

- Egenskaper: Lätt, bra termiska egenskaper.

- Applikationer: Bildelar, flygkomponenter.

- Magnesiumlegeringar (t.ex. AZ91D)

- Sammansättning: Magnesium, aluminium, zink.

- Egenskaper: Lätt, hög hållfasthet.

- Applikationer: Fordon, elektronik.

- Kopparlegeringar (t.ex. CuCrZr)

- Sammansättning: Koppar, krom, zirkonium.

- Egenskaper: Hög elektrisk ledningsförmåga, goda mekaniska egenskaper.

- Applikationer: Elektriska komponenter, värmeväxlare.

- Verktygsstål (t.ex. M2 höghastighetsstål)

- Sammansättning: Järn, Volfram, Molybden, Krom.

- Egenskaper: Hög hårdhet, slitstyrka.

- Applikationer: Skärande verktyg, formar.

- Ädelmetalllegeringar (t.ex. PtIr)

- Sammansättning: Platina, Iridium.

- Egenskaper: Hög korrosionsbeständighet, goda mekaniska egenskaper.

- Applikationer: Smycken, medicinsk utrustning.

- Högentropilegeringar (t.ex. CoCrFeNiMn)

- Sammansättning: Kobolt, krom, järn, nickel, mangan.

- Egenskaper: Utmärkta mekaniska egenskaper, hög korrosionsbeständighet.

- Applikationer: Avancerade tekniska applikationer.

Fördelar med Smältning genom induktion i vakuum

Varför är VIM så högt ansedd inom metallurgivärlden? Här är några viktiga fördelar:

- Hög renhet: Vakuummiljön eliminerar gaskontamination, vilket resulterar i metaller med exceptionell renhet.

- Exakt sammansättning: Möjliggör exakt kontroll över legeringselement, vilket ger material med skräddarsydda egenskaper.

- Förbättrade mekaniska egenskaper: Metaller som produceras genom VIM uppvisar överlägsna mekaniska egenskaper.

- Homogenitet: Säkerställer jämn fördelning av legeringselement i metallen.

- Mångsidighet: Kan smälta ett brett utbud av metaller och legeringar.

Nackdelar med vakuuminduktionssmältning

Som alla processer har VIM sina nackdelar. Här är några:

- Kostnad: Utrustnings- och driftskostnaderna för VIM är relativt höga.

- Komplexitet: Processen kräver sofistikerad teknik och expertis.

- Skala: Vanligtvis lämplig för mindre satsstorlekar jämfört med andra smältningsmetoder.

Tillämpningar av Smältning genom induktion i vakuum

VIM är en gamechanger inom många branscher. Låt oss utforska dess nyckelapplikationer:

Aerospace:

- Komponenter: Turbinblad, motordelar.

- Fördelar: Högtemperaturprestanda, hållbarhet.

Medicintekniska produkter:

- Komponenter: Implantat, kirurgiska instrument.

- Fördelar: Biokompatibilitet, korrosionsbeständighet.

Högpresterande teknik:

- Komponenter: Högspänningskomponenter, specialverktyg.

- Fördelar: Styrka, slitstyrka.

Typer av metaller och legeringar som produceras av VIM

| Metall/legering | Sammansättning | Fastigheter | Tillämpningar |

|---|---|---|---|

| INCONEL 718 | Nickel, krom, järn | Hög hållfasthet, korrosionsbeständighet | Turbinblad, komponenter för flyg- och rymdindustrin |

| Ti-6Al-4V | Titan, aluminium, vanadin | Högt förhållande mellan styrka och vikt, korrosionsbeständighet | Flyg- och rymdindustrin, medicinska implantat |

| CoCrMo | Kobolt, krom, molybden | Hög slitstyrka, biokompatibilitet | Medicinska implantat, dentala apparater |

| 316L rostfritt stål | Järn, krom, nickel, molybden | Korrosionsbeständighet, mekanisk hållfasthet | Kirurgiska instrument, marina applikationer |

| AlSi10Mg | Aluminium, kisel, magnesium | Lättvikt, goda termiska egenskaper | Bildelar, komponenter till flyg- och rymdindustrin |

| AZ91D | Magnesium, aluminium, zink | Lättvikt, hög hållfasthet | Fordon, elektronik |

| CuCrZr | Koppar, krom, zirkonium | Hög elektrisk ledningsförmåga, goda mekaniska egenskaper | Elektriska komponenter, värmeväxlare |

| M2 höghastighetsstål | Järn, volfram, molybden, krom | Hög hårdhet, slitstyrka | Skärande verktyg, formar |

| PtIr | Platina, Iridium | Hög korrosionsbeständighet, goda mekaniska egenskaper | Smycken, medicinsk utrustning |

| CoCrFeNiMn | Kobolt, krom, järn, nickel, mangan | Utmärkta mekaniska egenskaper, hög korrosionsbeständighet | Avancerade tekniska applikationer |

Tillämpningar av VIM-producerade metaller

| Industri | Komponenter | Fördelar |

|---|---|---|

| Flyg- och rymdindustrin | Turbinblad, motordelar | Högtemperaturprestanda, hållbarhet |

| Medicintekniska produkter | Implantat, kirurgiska instrument | Biokompatibilitet, korrosionsbeständighet |

| Högpresterande teknik | Högspänningskomponenter, specialverktyg | Hållfasthet, slitstyrka |

Specifikationer och standarder

| Metall/legering | Standard | Betyg | Specifikation |

|---|---|---|---|

| INCONEL 718 | ASTM B637 | Betyg 1 | Hög hållfasthet vid förhöjda temperaturer |

| Ti-6Al-4V | ASTM B348 | Betyg 5 | Högt förhållande mellan styrka och vikt |

| CoCrMo | ASTM F1537 | Betyg 1 | Hög slitstyrka |

| 316L rostfritt stål | ASTM A240 | Klass 316L | Korrosionsbeständighet |

| AlSi10Mg | ASTM B928 | Betyg 1 | Lättvikt, goda termiska egenskaper |

| AZ91D | ASTM B93 | Kvalitet AZ91D | Lättvikt, hög hållfasthet |

| CuCrZr | ASTM B224 | Betyg 1 | Hög elektrisk ledningsförmåga |

| M2 höghastighetsstål | ASTM A600 | Betyg M2 | Hög hårdhet, slitstyrka |

| PtIr | ASTM B563 | Betyg 1 | Hög korrosionsbeständighet |

| CoCrFeNiMn | ASTM E2209 | Betyg 1 | Utmärkta mekaniska egenskaper |

För- och nackdelar med Smältning genom induktion i vakuum

Fördelar

| Fördel | Beskrivning |

|---|---|

| Hög renhet | Eliminerar gaskontamination för överlägsen renhet. |

| Exakt sammansättning | Exakt kontroll över legeringselement för skräddarsydda egenskaper. |

| Förbättrade mekaniska egenskaper | Överlägsna mekaniska egenskaper i slutprodukter. |

| Homogenitet | Jämn fördelning av legeringselement. |

| Mångsidighet | Lämplig för ett brett utbud av metaller och legeringar. |

Nackdelar

| Nackdel | Beskrivning |

|---|---|

| Kostnad | Höga utrustnings- och driftskostnader. |

| Komplexitet | Kräver sofistikerad teknik och expertis. |

| Skala | Vanligtvis begränsad till mindre batchstorlekar jämfört med andra metoder. |

Leverantörer och prisuppgifter

Ledande leverantörer av VIM-utrustning

| Leverantör | Produktsortiment | Prissättning | Region |

|---|---|---|---|

| Inductotherm Group | VIM-ugnar, tillbehör | $100,000 – $1,000,000 | Globalt |

| ALD Vacuum Technologies | VIM-system, skräddarsydda lösningar | $150,000 – $2,000,000 | Globalt |

| Seco/Warwick | VIM-ugnar, service efter försäljning | $120,000 – $900,000 | Nordamerika, Europa |

| Consarc | VIM och VAR ugnar | $200,000 – $1,500,000 | Globalt |

| ECM Technologies | VIM-system | $100,000 – $850,000 | Europa, Asien |

Jämförelse av VIM vs. andra smältmetoder

| Aspekt | Vakuuminduktionssmältning (VIM) | Bågsmältning | Electroslag Remelting (ESR) |

|---|---|---|---|

| Renhet | Hög på grund av vakuummiljö | Måttlig | Hög |

| Kostnad | Hög | Lägre | Hög |

| Komplexitet | Hög | Måttlig | Hög |

| Batchstorlek | Liten till medelstor | Medium till stor | Medium |

| Tillämpning | Högpresterande legeringar | Allmänt syfte | Applikationer med hög renhet |

Vanliga frågor

| Fråga | Svar |

|---|---|

| Vad är vakuuminduktionssmältning (VIM)? | VIM är en process som smälter metaller med hjälp av elektromagnetisk induktion i vakuum för att producera legeringar med hög renhet. |

| Varför använda VIM framför andra smältningsmetoder? | VIM erbjuder överlägsen renhet, exakt sammansättningskontroll och förbättrade mekaniska egenskaper. |

| Vilka metaller kan tillverkas med VIM? | VIM kan producera ett brett utbud av metaller, inklusive nickelbaserade superlegeringar, titanlegeringar och mer. |

| Vilka är de viktigaste tillämpningarna för VIM? | Nyckelapplikationer inkluderar flygkomponenter, medicinsk utrustning och högpresterande tekniska delar. |

| Vilka är nackdelarna med VIM? | Nackdelar inkluderar höga kostnader, komplexitet och vanligtvis mindre batchstorlekar. |

| Vilka är de ledande leverantörerna av VIM-utrustning? | Ledande leverantörer inkluderar Inductotherm Group, ALD Vacuum Technologies och Seco/Warwick. |

| Hur jämför VIM med Arc Melting? | VIM ger högre renhet men till en högre kostnad och komplexitet jämfört med Arc Melting. |

Slutsats

Vakuuminduktionssmältning är en höjdpunkt av modern metallurgi, som ger oöverträffad renhet och precision i metallproduktion. Dess applikationer spänner över kritiska branscher där prestanda och tillförlitlighet inte är förhandlingsbara. Även om det kommer med högre kostnader och komplexitet, uppväger fördelarna ofta dessa utmaningar, vilket gör VIM till en ovärderlig process inom avancerad materialtillverkning.

Dela på

MET3DP Technology Co, LTD är en ledande leverantör av lösningar för additiv tillverkning med huvudkontor i Qingdao, Kina. Vårt företag är specialiserat på 3D-utskriftsutrustning och högpresterande metallpulver för industriella tillämpningar.

Förfrågan för att få bästa pris och anpassad lösning för ditt företag!

Relaterade artiklar

Högpresterande segment för munstycksvingar: Revolutionerande turbineffektivitet med 3D-utskrift i metall

Läs mer "Om Met3DP

Senaste uppdateringen

Vår produkt

KONTAKTA OSS

Har du några frågor? Skicka oss meddelande nu! Vi kommer att betjäna din begäran med ett helt team efter att ha fått ditt meddelande.

Metallpulver för 3D-printing och additiv tillverkning

FÖRETAG

PRODUKT

cONTACT INFO

- Qingdao City, Shandong, Kina

- [email protected]

- [email protected]

- +86 19116340731