Prášek AM

všechny sbírky

FeCoNiCrMn prášek: Konečný průvodce pro rok 2025

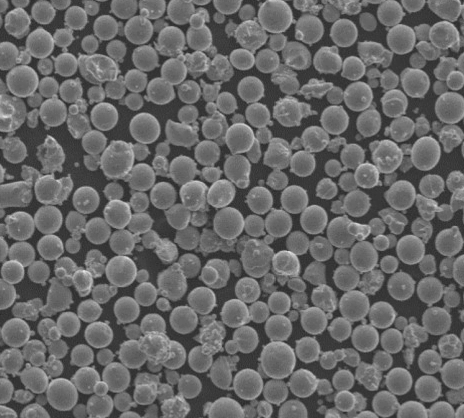

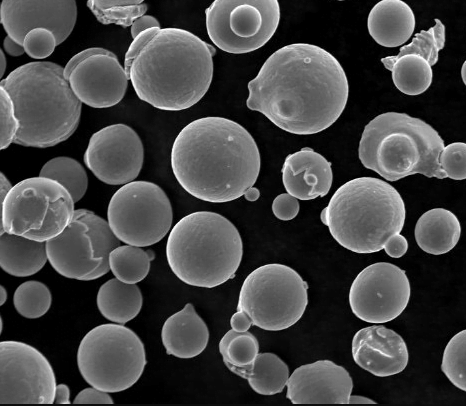

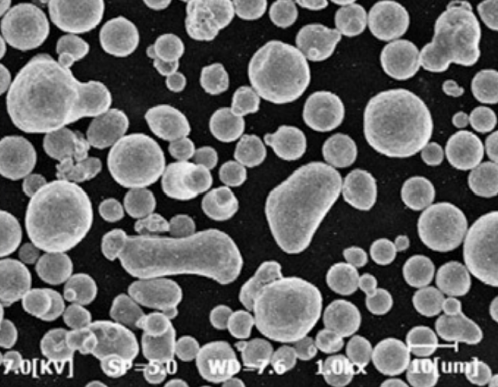

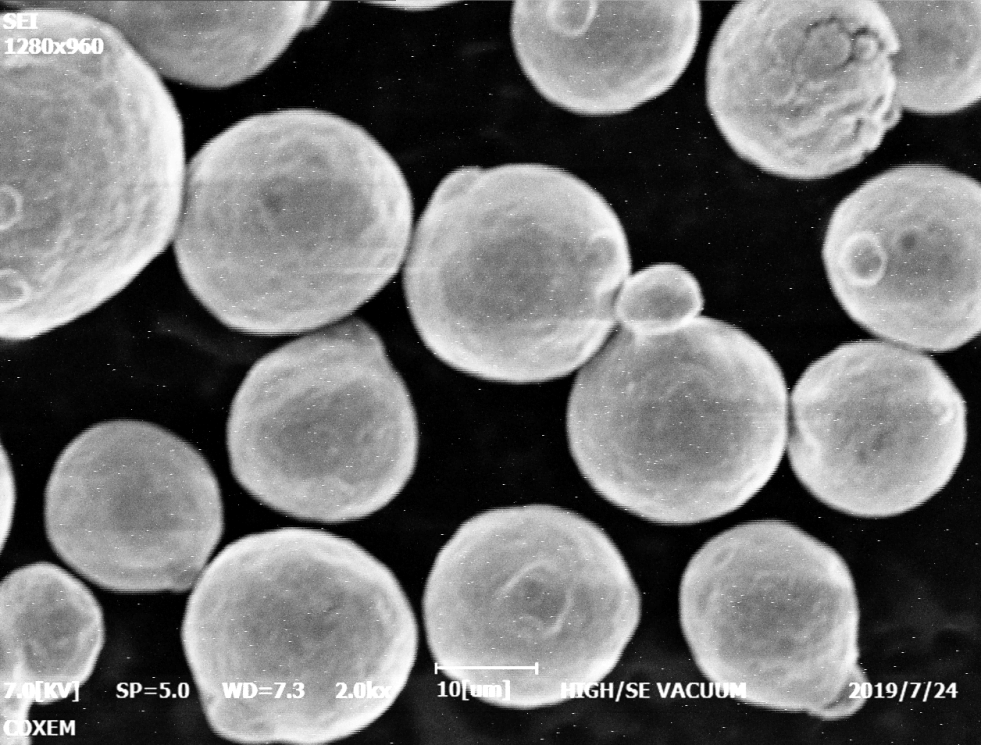

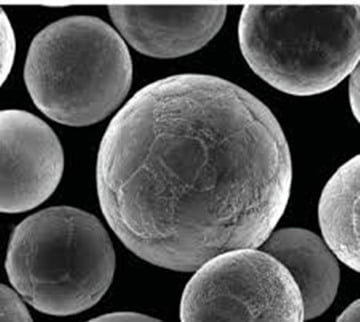

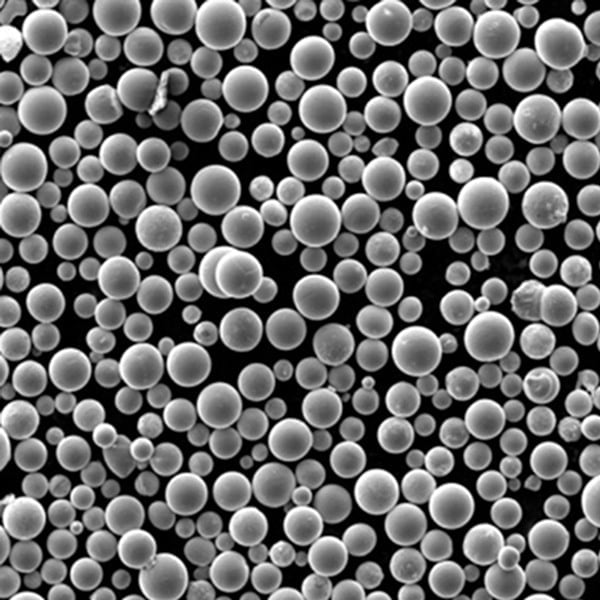

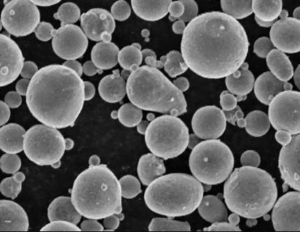

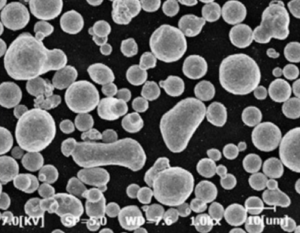

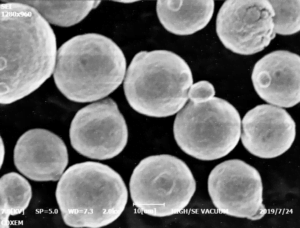

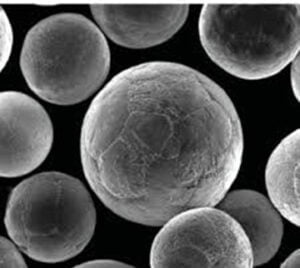

Přehled FeCoNiCrMn prášek je slitina s vysokou entropií (HEA), která vykazuje výjimečnou mechanickou pevnost, vynikající odolnost proti korozi, vynikající tepelnou stabilitu a vynikající odolnost proti opotřebení. Tato slitina, složená ze železa (Fe), kobaltu (Co), niklu (Ni), chrómu (Cr) a manganu (Mn) v téměř ekviatomických poměrech, je široce používána v letectví, lékařských implantátech, lodním inženýrství,

FeCoNiCr prášek: Kompletní průvodce pro rok 2025

Přehled FeCoNiCr prášek je slitina s vysokou entropií (HEA) uznávaná pro své výjimečné mechanické vlastnosti, vynikající odolnost proti korozi a vynikající tepelnou stabilitu. Díky vyváženému složení železa (Fe), kobaltu (Co), niklu (Ni) a chrómu (Cr) je tato slitina široce používána v letectví, lékařských implantátech, průmyslových nátěrech a výrobě vysoce výkonných aditiv.

CoCrFeNi prášek: Kompletní průvodce pro rok 2025

Přehled CoCrFeNi prášek je slitina s vysokou entropií (HEA) známá pro svou výjimečnou pevnost, odolnost proti korozi, odolnost proti opotřebení a tepelnou stabilitu. Tato slitina je široce používána v letectví, lékařských implantátech, energetice a ve výrobě vysoce výkonných aditiv díky svému dobře vyváženému víceprvkovému složení, které zahrnuje kobalt (Co), chrom (Cr), železo (Fe) a

Prášek AlCrFeCoNiCu: Konečný průvodce pro rok 2025

Přehled AlCrFeCoNiCu prášek je špičková slitina s vysokou entropií (HEA) známá pro svou výjimečnou pevnost, odolnost proti korozi, odolnost proti opotřebení a tepelnou stabilitu. Tato slitina je široce používána v letectví, průmyslových nátěrech, energetice a ve výrobě vysoce výkonných aditiv díky svému jedinečnému složení, které zahrnuje hliník (Al), chrom (Cr), železo (Fe), kobalt

Prášek AlCoCrFeNi: Konečný průvodce pro rok 2025

Přehled AlCoCrFeNi prášek je slitina s vysokou entropií (HEA), která kombinuje výjimečnou mechanickou pevnost, tepelnou stabilitu a odolnost proti korozi. Díky svému jedinečnému víceprvkovému složení je tato slitina široce používána v letectví, energetice, obraně a vysoce výkonných průmyslových aplikacích. Složení ✔ Hliník (Al): Zvyšuje odolnost proti oxidaci a pevnost✔ Kobalt (Co): Zlepšuje opotřebení

CoCrFeMnNi prášek: Konečný průvodce pro rok 2025

Přehled CoCrFeMnNi prášek, běžně označovaný jako slitina s vysokou entropií (HEA), je specializovaný kovový prášek známý pro svou výjimečnou mechanickou pevnost, odolnost proti opotřebení a odolnost proti korozi. Tato slitina je široce používána v letectví, biomedicíně, energetice a vysoce výkonných průmyslových aplikacích díky své jedinečné kombinaci pěti hlavních prvků – kobaltu (Co),

Prášek Ti-6-2-4-6: konečný průvodce pro rok 2025

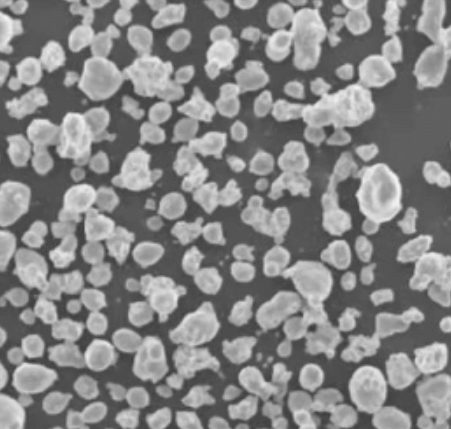

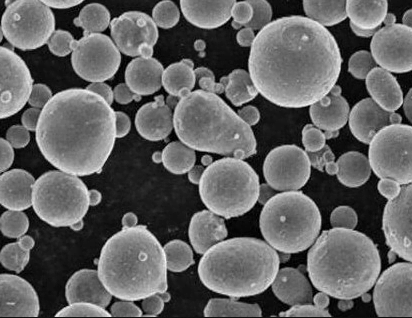

Přehled Ti-6-2-4-6 prášek, také známý jako Ti-6Al-2Sn-4Zr-6Mo, je vysokopevnostní, vysokoteplotní titanová slitina navržená pro letecký, automobilový a průmyslový provoz vyžadující mimořádnou pevnost, odolnost proti oxidaci a odolnost proti tečení při zvýšených teplotách. Tato slitina je široce používána v proudových motorech, součástech draků letadel a vysoce výkonných konstrukčních dílech. Tato slitina se skládá z:✔ 6%

Prášek Ti-6Al-2Sn-4Zr-6Mo: konečný průvodce pro rok 2025

Přehled Ti-6Al-2Sn-4Zr-6Mo prášek je vysoce pevná, vysokoteplotní titanová slitina známá pro své výjimečné mechanické vlastnosti, odolnost proti oxidaci a vynikající odolnost proti tečení. Tato slitina je široce používána v letectví, automobilovém průmyslu a vysoce výkonných průmyslových aplikacích, zejména pro proudové motory, součásti draků letadel a plynové turbíny. Tato slitina se skládá z:✔ 6% hliník (Al) –

Prášek Ti-5Al-2,5Sn: konečný průvodce pro rok 2025

Přehled Ti-5Al-2,5Sn prášek je slitina téměř alfa titanu známá pro svou vysokou pevnost, vynikající odolnost proti oxidaci a vynikající odolnost proti tečení při zvýšených teplotách. Tato slitina je široce používána v leteckém, námořním a vysokoteplotním konstrukčním použití, zejména v leteckých konstrukcích, proudových motorech a vysoce výkonných automobilových součástech. Tato slitina se skládá z:✔ 5%

Prášek Ti-8Al-1Mo-1V: Konečný průvodce pro rok 2025

Přehled Ti-8Al-1Mo-1V prášek je vysoce pevná, lehká titanová slitina známá pro své vynikající vlastnosti při vysokých teplotách, odolnost proti oxidaci a vynikající mechanické vlastnosti. Tato slitina je široce používána v letectví, automobilovém průmyslu a vysokoteplotních konstrukčních aplikacích, zejména v proudových motorech, součástech draků letadel a plynových turbínách. Tato slitina se skládá z:✔ 8% hliník (Al) –

FeCoNiCrMn prášek: Konečný průvodce pro rok 2025

Přehled FeCoNiCrMn prášek je slitina s vysokou entropií (HEA), která vykazuje výjimečnou mechanickou pevnost, vynikající odolnost proti korozi, vynikající tepelnou stabilitu a vynikající odolnost proti opotřebení. Tato slitina,

FeCoNiCr prášek: Kompletní průvodce pro rok 2025

Přehled FeCoNiCr prášek je slitina s vysokou entropií (HEA) uznávaná pro své výjimečné mechanické vlastnosti, vynikající odolnost proti korozi a vynikající tepelnou stabilitu. S vyváženým složením

CoCrFeNi prášek: Kompletní průvodce pro rok 2025

Přehled CoCrFeNi prášek je slitina s vysokou entropií (HEA) známá pro svou výjimečnou pevnost, odolnost proti korozi, odolnost proti opotřebení a tepelnou stabilitu. Tato slitina je široce používána

Prášek AlCrFeCoNiCu: Konečný průvodce pro rok 2025

Přehled AlCrFeCoNiCu prášek je špičková slitina s vysokou entropií (HEA) známá pro svou výjimečnou pevnost, odolnost proti korozi, odolnost proti opotřebení a tepelnou stabilitu. Tato slitina je široce rozšířena

Prášek AlCoCrFeNi: Konečný průvodce pro rok 2025

Přehled AlCoCrFeNi prášek je slitina s vysokou entropií (HEA), která kombinuje výjimečnou mechanickou pevnost, tepelnou stabilitu a odolnost proti korozi. Díky svému jedinečnému víceprvkovému složení toto

CoCrFeMnNi prášek: Konečný průvodce pro rok 2025

Přehled CoCrFeMnNi prášek, běžně označovaný jako slitina s vysokou entropií (HEA), je specializovaný kovový prášek známý pro svou výjimečnou mechanickou pevnost, odolnost proti opotřebení a

Prášek Ti-6-2-4-6: konečný průvodce pro rok 2025

Přehled Ti-6-2-4-6 prášek, také známý jako Ti-6Al-2Sn-4Zr-6Mo, je vysokopevnostní, vysokoteplotní titanová slitina určená pro použití v letectví, automobilovém průmyslu a průmyslu vyžadující mimořádnou pevnost, odolnost proti oxidaci,

Prášek Ti-6Al-2Sn-4Zr-6Mo: konečný průvodce pro rok 2025

Přehled Ti-6Al-2Sn-4Zr-6Mo prášek je vysoce pevná, vysokoteplotní titanová slitina známá pro své výjimečné mechanické vlastnosti, odolnost proti oxidaci a vynikající odolnost proti tečení. Tato slitina je široce rozšířena

Prášek Ti-5Al-2,5Sn: konečný průvodce pro rok 2025

Přehled Ti-5Al-2,5Sn prášek je slitina téměř alfa titanu známá pro svou vysokou pevnost, vynikající odolnost proti oxidaci a vynikající odolnost proti tečení při zvýšených teplotách. Tato slitina

Prášek Ti-8Al-1Mo-1V: Konečný průvodce pro rok 2025

Přehled Ti-8Al-1Mo-1V prášek je vysoce pevná, lehká titanová slitina známá pro své vynikající vlastnosti při vysokých teplotách, odolnost proti oxidaci a vynikající mechanické vlastnosti. Tato slitina je široce rozšířena

Náš produkt

HORKÝ VÝPRODEJ

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

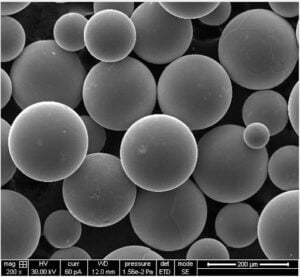

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731