Úvod do kovových prášků

Obsah

Kovové prášky jsou jemné kovové částice používané v různých výrobních procesech k výrobě kovových dílů a výrobků. Tento článek poskytuje podrobného průvodce kovovými prášky, který se zabývá jejich klíčovými vlastnostmi, výrobními metodami, aplikacemi, dodavateli, náklady a dalšími informacemi.

Přehled o Kovové prášky

Kovové prášky se skládají z jemných částic kovových materiálů, které lze použít k výrobě hustých a složitých dílů pro různá průmyslová odvětví. Zde je jejich stručný přehled:

Vlastnosti kovového prášku

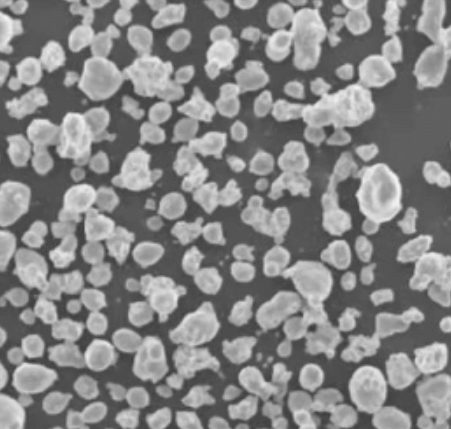

- Rozsah velikosti částic: 1 mikron až 1000 mikronů

- Morfologie: Sférické, nepravidelné, vločky, vlákna

- Běžné materiály: Železo, měď, hliník, titan, nikl, kobalt

- Klíčové vlastnosti: Tekutost, kompaktnost, spékavost

Výrobní metody

- Atomizace

- Elektrolýza

- Rozklad karbonylu

- Frézování

Hlavní aplikace

- Prášková metalurgie

- Vstřikování kovů

- Aditivní výroba

- Svařování

- Pájení a letování

Dodavatelé a náklady

- Hlavní světoví dodavatelé

- Náklady závisí na materiálu, čistotě a způsobu výroby.

- Rozsah od $5/kg do $500/kg

Výhody oproti kovanému kovu

- Složité a komplexní tvary

- Vysoká rozměrová přesnost

- Téměř síťová výroba

- Nové vlastnosti materiálu

Typy kovových prášků

Existují různé způsoby kategorizace kovových prášků na základě složení, způsobu výroby, morfologie a velikosti částic.

Tabulka 1: Typy kovových prášků

| Typ | Charakteristika | Běžné materiály | Typický rozsah velikostí |

|---|---|---|---|

| Elementární | Jednoduchý kov, vysoká čistota | Železo, měď, nikl, kobalt | 1-150 mikronů |

| Slitiny | Směsi kovů | Nerezové oceli, nástrojové oceli, superslitiny | 10-1000 mikronů |

| Kompozity | Směsi s jinými prášky | WC-Co, Cu-Diamant | 1-500 mikronů |

| Podle způsobu výroby | Jedinečná velikost a morfologie na základě výrobního procesu | Viz další oddíl | Záleží na procesu |

| Sférické | Hladké, zaoblené částice | Rozprašování plynu nebo vody | 5-150 mikronů |

| Nepravidelné | Zubaté, nerovnoměrné tvary | Mechanické drcení | 1-1000 mikronů |

Výběr typu kovového prášku závisí na konkrétní aplikaci a požadovaných konečných vlastnostech. Proces práškové metalurgie umožňuje širokou škálu kombinací.

Způsoby výroby kovových prášků

Existuje několik zavedených výrobních metod, z nichž každá vede k výrobě prášků s jedinečnými vlastnostmi optimalizovanými pro určité aplikace:

Tabulka 2: Způsoby výroby kovového prášku

| Metoda | Popis procesu | Morfologie částic | Typický rozsah velikostí |

|---|---|---|---|

| Atomizace plynu | Proud roztaveného kovu rozkládaný vysokotlakými proudy plynu | Vysoce sférický | 5-150 mikronů |

| Atomizace vody | Používá proud vody místo plynu | Nepravidelné tvary | 10-300 mikronů |

| Elektrolýza | Ionty kovů v roztoku usazené na katodě | Dendritické, špičaté | 1-100 mikronů |

| Rozklad karbonylu | Tepelný rozklad těkavých kovových karbonylů | Sférické, hladké | 1-10 mikronů |

| Mechanické frézování | Kulové mlýny nebo atritory používané k drcení kovových částic | Zploštělé, nepravidelné | 1-300 mikronů |

Výsledkem každého procesu jsou prášky vhodné pro určité aplikace v závislosti na jejich vlastnostech. Například prášky rozprašované plynem s hladkými, sférickými částicemi umožňují vynikající hustotu balení a spékavost. Zatímco mechanicky frézované částice poskytují vyšší pevnost v zeleném stavu.

Použití kovových prášků

Mezi hlavní aplikace využívající jedinečné vlastnosti kovových prášků patří:

Tabulka 3: Aplikace kovových prášků

| aplikace | Popis | Typické použité materiály |

|---|---|---|

| Prášková metalurgie | Proces lisování a spékání pro vytvoření dílů v čistém tvaru | Železo, ocel, měď, hliník |

| Vstřikování kovů | Smíchejte prášky s pojivy a vstříkněte je do forem. | Nerezové oceli, nástrojové oceli, těžké slitiny wolframu |

| Aditivní výroba | 3D tisk složitých dílů z kovových prášků | Slitiny titanu, kobalt-chrom, superslitiny niklu |

| Svařování | Usazování kovových prášků ve svařovací zóně | Nerezová ocel, nikl, kobaltové slitiny |

| Pájení a pájení | Lepení kovových spojů pomocí práškových mezivrstev | Stříbro, měď, slitiny hliníku |

Flexibilita vlastností dosažená různým složením prášku a následným zpracováním umožňuje přizpůsobit kovové prášky těmto kritickým výrobním odvětvím.

Globální dodavatelé Kovové prášky

Existuje řada velkých globálních dodavatelů i menších regionálních výrobců prášku:

Tabulka 4: Hlavní společnosti vyrábějící kovové prášky

| Společnost | Sídlo | Nabízené materiály |

|---|---|---|

| Höganäs | Švédsko | Železo, ocel, legované oceli |

| GKN | Spojené království | Nerezové oceli, nástrojové oceli, superslitiny |

| Sandvik | Švédsko | Nerezové oceli, vysoce legované oceli, slitiny titanu |

| Praxair (tesařský prášek) | USA | Nástrojové oceli, nerezové oceli, superslitiny |

| Kovové prášky Rio Tinto | Kanada | Hliník, slitiny hliníku, železo |

Kromě toho existuje mnoho dalších menších společností rozptýlených po celém světě, které nabízejí speciální kovové prášky. Při výběru dodavatele je důležité zvážit faktory, jako jsou:

- Složení prášku a vlastnosti částic

- Normy kvality a konzistence

- Výrobní kapacita a dodací lhůty

- Stanovení cen

- Technická podpora

Analýza nákladů na kovové prášky

Náklady na kovové prášky do značné míry závisí na základním materiálu, čistotě, velikosti částic a tvaru prášku:

Tabulka 5: Přehled nákladů na kovový prášek

| Materiál | Cenové rozpětí |

|---|---|

| Železo a ocel | $2-10 na kg |

| Měď a hliník | $5-30 na kg |

| Slitiny niklu | $10-50 za kg |

| Kobaltové slitiny | $50-150 za kg |

| Slitiny titanu | $100-500 za kg |

Obecně platí, že vyšší čistota, jemnější rozměry a schopnost těsného balení mají za následek vyšší náklady. Přidávají se také náklady na atomizaci a speciální manipulaci s reaktivními prášky.

Při sestavování rozpočtu pro projekt s kovovým práškem je důležité úzce spolupracovat s dodavateli, abyste pochopili dopad výběru materiálu, poměru nákupu a prodeje, možností recyklace a řízení zásob na celkové náklady.

Instalace a provoz zařízení na výrobu kovového prášku

Pro společnosti, které chtějí zavést vlastní výrobu kovových prášků, jsou důležité úvahy o instalaci a provozu zařízení:

Tabulka 6: Nastavení výroby kovového prášku

| Parametr | Podrobnosti |

|---|---|

| Uspořádání a průtok v závodě | - Logické oddělení procesů; přeprava materiálu a manipulace s práškem |

| Služby a veřejné služby | - Dodávky elektřiny, chladicí vody a plynu |

| Uvedení do provozu a školení | - Ověření správné instalace a funkčnosti; školení zaměstnanců o provozních postupech. |

| Bezpečnost | - Prevence a omezení výbuchu; důkladná ventilace; protokoly o osobních ochranných prostředcích. |

| Monitorování procesů | - Sběr a analýza dat o klíčových parametrech, jako je velikost, tvar, čistota. |

| Údržba a údržba | - Pravidelné kontroly, výměna opotřebitelných součástí |

| Kontrola kvality | - Metody odběru vzorků a testování; statistická kontrola; požadavky zákazníka |

Důrazně se doporučuje mít k dispozici technické odborníky pro dohled během náběhu a specializovaný personál pro výrobu. Nejkritičtější vlastnosti prášku by měly být průběžně měřeny, aby byla zajištěna konzistence.

Volba mezi outsourcingem a vlastní výrobou

Společnosti musí zvážit výhody a nevýhody outsourcingu výroby kovových prášků oproti vytvoření interní výrobní kapacity:

Tabulka 7: Srovnání outsourcingu a vlastní výroby

| Úvahy | Outsourcing | Vlastní |

|---|---|---|

| Počáteční kapitálové náklady | Nízký | Velmi vysoké náklady na nákup vybavení a výstavbu zařízení |

| Provozní náklady | Vyšší jednotkové ceny | Nižší jednotkové náklady, ale je třeba počítat s náklady na pracovní sílu, služby a údržbu. |

| Ovládání a přizpůsobení | Omezený vliv; závisí na schopnostech dodavatele | Plná kontrola materiálů, parametrů, harmonogramu a množství |

| Kvalita a konzistence | Velmi rozdílné; závisí na dodavateli | Dokáže zavést přísné normy a kontrolu |

| Technické znalosti | Dodává prodejce | Potřeba náboru a školení specializovaného personálu |

| Zásoby a dodací lhůty | Potřeba mít zásoby; delší dodací lhůty | Lepší plánování a flexibilita; minimalizace zásob |

Souhrnně lze říci, že outsourcing přináší nižší investice, ale vyšší průběžné náklady, zatímco vlastní výroba vyžaduje vysoké počáteční kapitálové výdaje, ale poskytuje větší flexibilitu a kontrolu během každodenního provozu.

Výhody Kovové prášky vs Kované kovy

Navzdory vyšším nákladům nabízí kovové prášky určité výhody oproti tradičnímu zpracování tepaného kovu:

Tabulka 8: Srovnání kovového prášku a tepaného kovu

| Parametr | Kovové prášky | Kované kovy |

|---|---|---|

| Složitost tvaru | Lze vyrábět složité a komplexní tvary pomocí cest práškového zpracování. | Omezený počet vyrobitelných tvarů a prvků |

| Rozměrová přesnost | Konzistentní tolerance až ±0,1% s využitím možností práškového tvaru netto | Větší variabilita; nutnost dalšího obrábění |

| Možnosti materiálu | Vlastní slitiny a mikrostruktury přizpůsobené požadavkům aplikace | Omezeno na dostupné plechy, desky, lisované profily |

| Mechanické vlastnosti | Příznivé kombinace pevnosti, tvrdosti a tažnosti | Různé v závislosti na mechanickém zpracování a tepelné historii |

| Konsolidace shromáždění | Zjednodušení sestav snížením počtu dílů | Je třeba provést další montážní kroky |

Práškový stav nabízí jedinečné výhody, které si zaslouží zvážení tam, kde stávající výrobní techniky nedostačují. Pokračující vývoj pokročilých práškových procesů zvyšuje konkurenceschopnost.

FAQ

Zde je několik často kladených otázek o kovových prášcích:

Tabulka 9: Časté dotazy týkající se kovového prášku

| Otázka | Odpovědět |

|---|---|

| Jak se vyrábí kovové prášky? | Mezi hlavní metody patří atomizace plyn/voda, elektrolýza, mletí - roztavený kov nebo volně ložené kovy jsou mechanickými a chemickými procesy redukovány na jemný prášek. |

| Jaký je typický rozsah velikostí? | Nejčastěji se používá rozmezí 1 mikron až 1000 mikronů, ale některé speciální nanoprášky a velké částice používané při tepelném stříkání přesahují toto rozmezí. |

| Co je morfologie prášku a proč je důležitá? | Morfologie se týká tvaru/textury prášku - hladké, kulovité prášky poskytují lepší hustotu balení a tok, zatímco nepravidelné, dendritické tvary zlepšují pevnost v zeleném stavu. |

| Jak se používají kovové prášky? | Hlavní aplikace zahrnují lisování a spékání práškových kovů, vstřikování kovů, aditivní výrobu, svařování, pájení/pájení. |

| Kolik stojí kovové prášky? | Cena je značně závislá na základním materiálu, čistotě a vlastnostech částic a pohybuje se v rozmezí od $5/kg do $500/kg. |

| Proč používat kovové prášky místo kovaných kovů? | Mezi výhody patří tvarová složitost, rozměrová přesnost, složení na míru, nové vlastnosti, konsolidované sestavy. |

| Co bych měl hledat u dodavatele kovového prášku? | Klíčové vlastnosti dodavatele zahrnují konzistentní kvalitu, přísné testování, nabídky na míru, rychlé dodací lhůty, technické znalosti v oblasti výroby prášků a aplikací. |

Sdílet na

MET3DP Technology Co., LTD je předním poskytovatelem řešení aditivní výroby se sídlem v Qingdao v Číně. Naše společnost se specializuje na zařízení pro 3D tisk a vysoce výkonné kovové prášky pro průmyslové aplikace.

Dotaz k získání nejlepší ceny a přizpůsobeného řešení pro vaše podnikání!

Související články

Vysoce výkonné segmenty lopatek trysek: Revoluce v účinnosti turbín díky 3D tisku z kovu

Přečtěte si více "O Met3DP

Nedávná aktualizace

Náš produkt

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731