Kovový prášek ze slitin niklu

Obsah

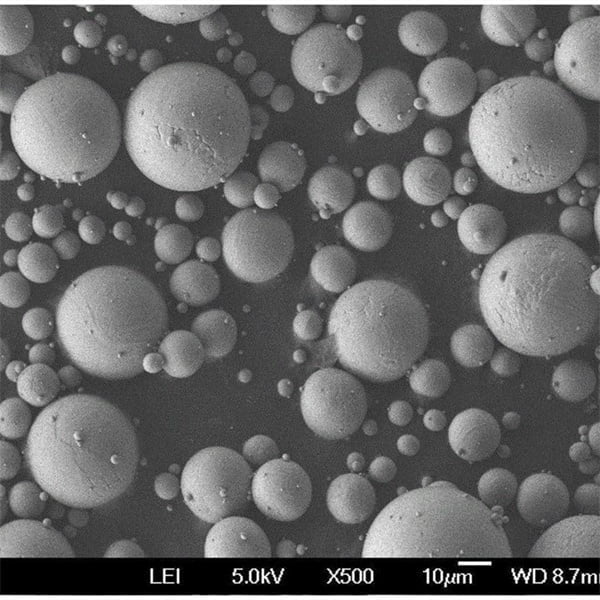

Nickel alloys metal powders refer to powder metallurgy forms of various nickel alloy compositions. These powders can be used to manufacture nickel alloy parts and components through methods like metal injection molding, additive manufacturing, and powder pressing and sintering.

Overview of Nickel Alloys Metal Powder

Nickel alloy powders provide unique properties like high strength, corrosion resistance, and high temperature performance. Key details include:

Výhody

- Vysoká pevnost

- Odolnost proti korozi a oxidaci

- Vysoká teplotní stabilita

- Tailored electrical, magnetic, or thermal properties

- Lower costs than exotic alloy ingots

Výrobní metody

- Rozprašování plynu

- Rozprašování vody

- Karbonylový proces

- Elektrolýza

- Mechanical grinding

Common Alloy Systems

- Nikl-chrom

- Nickel-molybdenum

- Nikl-kobalt

- Nikl-železo-chrom

- Nikl-měď

- Nickel-aluminum

Typické aplikace

- Letecké komponenty

- Průmyslové nástroje

- Automobilové díly

- Elektrické kontakty

- Corrosion resistant structures

- Díly vysokoteplotních pecí

Specifikace

Nickel alloy powders are available in various standard specifications:

- Size range: 1 – 150 microns

- Chemistry per application need

- Spherical, irregular, or blended morphology

- Gas or water atomized varieties

- Custom alloys and particle size possible

Types of Nickel Alloy Metal Powder

Many nickel alloys are available in powder form. Common alloy systems include:

| Typ slitiny | Složení | Klíčové vlastnosti |

|---|---|---|

| Nikl-chrom | Ni-Cr, Ni-Cr-Fe-Mo | Oxidation resistance, strength at high temperatures |

| Nikl-molybden | Ni-Mo | Corrosion resistance, maintain strength at high temperatures |

| Nickel-Cobalt | Ni-Co | High strength, corrosion resistance, tailorable magnetic permeability |

| Nickel-Iron-Chromium | Ni-Fe-Cr, Ni-Cr-Fe-Mo-Cu | Excellent oxidation and corrosion resistance at high temperatures |

| Nickel-Copper | Ni-Cu | High strength, corrosion resistance, tailorable thermal expansion |

| Nikl-hliník | Ni-Al | Lightweight, high temperature strength |

These alloy powder compositions can be customized to achieve application specific properties.

Charakteristika a vlastnosti Kovový prášek ze slitin niklu

Nickel alloy powders offer a versatile range of mechanical, physical, and chemical properties:

Mechanické vlastnosti

- Vysoká pevnost

- Resistance to creep and fatigue

- Withstand repeated heating/cooling cycles

- Nárazová houževnatost

Fyzikální vlastnosti

- Coefficients of thermal expansion similar to steel

- Electrical resistivity tailored with chromium content

- Controlled magnetic permeability with iron and cobalt

Chemické vlastnosti

- Resist corrosion in harsh environs like acids, chlorides etc

- Retain properties in oxidizing atmospheres up to 2000°F

- Welding characteristics similar to wrought nickel alloys

These properties make nickel alloys suitable for demanding applications across industries.

Applications and Uses of Nickel Alloy Metal Powder

Nickel alloy powders are used across industries where combination of properties is needed:

| Průmysl | Aplikace | Benefits Provided |

|---|---|---|

| Aerospace | Turbine blades, engine parts, airframe components | Strength at high temperatures, corrosion resistance |

| Ropa a plyn | Valves, fittings, wellhead components | Strength, wear resistance, corrosion resistance at high temperatures and pressures |

| Automobilový průmysl | Gears, shafts, exhaust components, turbocharger parts | Heat and wear resistance for powertrain parts |

| Průmyslový | Food processing equipment, pulp and paper machine parts, radiation shields | Corrosion resistance, high temperature strength, safety |

| Elektronika | Connectors, lead frames, switches, shields | Conductivity, magnetism control, resistance welding |

| Chemické | Pumps, valves, piping | Corrosion resistance against various chemicals |

These applications utilize the balanced mechanical and chemical properties of nickel alloys.

Specifications of Nickel Alloy Metal Powder

Nickel alloy powders are produced in various standard specifications suitable for different manufacturing techniques:

| Spec | Možnosti |

|---|---|

| Stupeň slitiny | IN, N, CN nickel grades plus proprietary compositions |

| Velikost částic | 1-10 μm, 10-45 μm, 45-100 μm, 15-150 μm |

| Morfologie | Spherical, irregular/angular |

| Způsob výroby | Gas atomized, water atomized, carbonyl |

| Čistota | Nickel + alloying elements, low oxygen + nitrogen, custom impurity limits |

| Balení | Jars, bags, drums under inert atmosphere |

These specifications allow selection of optimal powder for given production method like metal injection molding, pressing and sintering, additive manufacturing etc.

Suppliers and Pricing of Nickel Alloy Metal Powder

Most major metal powder producers offer various nickel alloy powder compositions and size ranges suitable for industrial production. Some leading global suppliers are:

| Společnost | Značky | Výrobní metody | Typické ceny |

|---|---|---|---|

| Sandvik | Osprey | Rozprašování plynu, vody | $$$ |

| Tesařská technologie | Různé | Rozprašování plynu, vody | $$$ |

| Práškové kovy ATI | Různé | Rozprašování plynu, vody | $$$ |

| Technologie povrchů Praxair | Různé | Rozprašování plynu | $$$ |

| Hoganas | Různé | Rozprašování plynu, vody | $$-$$$ |

| Skupina CNPC Powder | Různé | Rozprašování plynu, vody | $-$$ |

Pricing can range widely based on alloy chemistry, powder size, quality levels, production method etc. Typical range is $50-$150 per kg for common alloys and sizes.

Pros and Cons of Nickel Alloy Metal Powder

vs Wrought Materials

Nickel alloy powder offers some distinct advantages but also limitations compared to wrought forms:

Výhody

- Components with complex shapes made easily

- Homogeneous microstructure from rapid solidification

- Near shape construction lowers machining needs

- Lower costs than equivalent alloy mill shapes

Nevýhody

- Post-processing may be needed after part making

- Size and geometry constraints for some methods

- Powder production has higher energy needs

- Secondary operations add cost versus castings

- Lower maximum strength level than wrought alloys

The balance of properties and economics determines optimal material form for a given application.

Nejčastější dotazy

Q: What are the main alloying elements used in nickel powders?

A: The most common alloy additions are chromium, molybdenum, iron, cobalt, copper, and aluminum to achieve desired properties.

Q: What powder production methods are used for nickel alloys?

A: Gas atomization and water atomization are the primary techniques. Some nickel alloys are also made via carbonyl powder production.

Q: What particle size range is typical for nickel alloy powder?

A: Most powders fall between 1 micron to 150 microns. Finer powders below 45 microns are used for sintering and metal injection molding. Coarser particles from 45-150 microns suit pressing and extrusion or additive manufacturing.

Q: How do costs of nickel alloy powder compare to wrought materials?

A: Nickel alloy powders can offer 30-50% cost savings over forged billets or bar. But secondary processing after powder consolidation may lower the cost benefit ratio.

Q: What standards apply to nickel alloy powders?

A: ASTM, ISO, and other national standards help define chemistry, impurity limits, particle size distribution, and sampling methods for quality control.

Závěr

Nickel alloy metal powders provide a versatile material option combining high strength, corrosion resistance, thermal stability and other tailored properties. Key alloy systems include nickel-chromium, nickel-molybdenum and nickel-iron-chromium among others. These advanced powders enable manufacturing of critical components across aerospace, oil and gas, automotive and industrial sectors. With expanded use of powder metallurgy techniques, nickel alloys continue seeing rapid adoption via metal injection molding, additive techniques and press-and-sinter methods.

Sdílet na

MET3DP Technology Co., LTD je předním poskytovatelem řešení aditivní výroby se sídlem v Qingdao v Číně. Naše společnost se specializuje na zařízení pro 3D tisk a vysoce výkonné kovové prášky pro průmyslové aplikace.

Dotaz k získání nejlepší ceny a přizpůsobeného řešení pro vaše podnikání!

Související články

Vysoce výkonné segmenty lopatek trysek: Revoluce v účinnosti turbín díky 3D tisku z kovu

Přečtěte si více "O Met3DP

Nedávná aktualizace

Náš produkt

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731