FeCoNiCrTi prášek

Prášek FeCoNiCrTi je slitina složená ze železa (Fe), kobaltu (Co), niklu (Ni), chromu (Cr) a titanu (Ti). Patří do třídy vysokoentropických slitin (HEA), což je relativně nová třída materiálů s jedinečnými vlastnostmi. HEA se vyznačují mimořádnou pevností, tvrdostí a odolností proti opotřebení a korozi. Prášek FeCoNiCrTi se obvykle vyrábí procesem práškové metalurgie, což umožňuje přesnou kontrolu jeho složení a velikosti částic.

Nízké MOQ

Poskytněte nízké minimální množství objednávky, abyste splnili různé potřeby.

OEM a ODM

Poskytujte přizpůsobené produkty a designové služby, které splňují jedinečné potřeby zákazníků.

Přiměřená zásoba

Zajistěte rychlé zpracování objednávek a poskytněte spolehlivé a efektivní služby.

Spokojenost zákazníků

Poskytujte vysoce kvalitní produkty s jádrem spokojenosti zákazníků.

sdílet tento produkt

Obsah

Přehled prášku FeCoNiCrTi

FeCoNiCrTi je vysoce výkonná slitina, která vykazuje dobré mechanické vlastnosti a odolnost proti korozi při zvýšených teplotách. Železo a kobalt jí dodávají vynikající pevnost při vysokých teplotách. Nikl zvyšuje tažnost a houževnatost. Chrom zajišťuje vynikající odolnost proti oxidaci a korozi.

Mezi hlavní vlastnosti prášku FeCoNiCrTi patří:

- Vynikající pevnost při vysokých teplotách a odolnost proti tečení

- Dobrá tažnost, houževnatost a zpracovatelnost

- Vynikající odolnost proti oxidaci a korozi

- Vysoká tepelná stabilita a mikrostrukturní stabilita

- K dispozici v různých distribucích velikosti částic a morfologií

Prášek FeCoNiCrTi je vhodný pro vysokoteplotní konstrukční díly, ochranné povlaky a další náročné aplikace vyžadující teplotní odolnost, pevnost a odolnost vůči životnímu prostředí.

Složení prášku FeCoNiCrTi

Prášek FeCoNiCrTi má následující jmenovité složení:

| Živel | Složení |

|---|---|

| železo (Fe) | Zůstatek |

| Kobalt (Co) | 35-50% |

| nikl (Ni) | 10-30% |

| Chrom (Cr) | 8-12% |

| titan (Ti) | 0.5-2% |

| uhlík (C) | 0,5% max |

| křemík (Si) | 1% max |

| mangan (Mn) | 1% max |

Obsah kobaltu, niklu, chromu a titanu lze upravit podle požadavků aplikace. Nečistoty jako uhlík, křemík a mangan jsou minimalizovány.

Vlastnosti prášku FeCoNiCrTi

Prášek FeCoNiCrTi má následující vlastnosti:

| Vlastnictví | Hodnota |

|---|---|

| Hustota | 8,0-8,5 g/cm3 |

| Bod tání | 1300-1400°C |

| Tepelná vodivost | 10-30 W/mK |

| Elektrický odpor | 70-90 μΩ.cm |

| Youngův modul | 180-220 GPa |

| Poissonův poměr | 0.28-0.32 |

| Pevnost v tahu | 650-1100 MPa |

| Mez kluzu | 450-750 MPa |

| Prodloužení | 10-30% |

| Tvrdost | 25-50 HRC |

Vlastnosti, jako je pevnost v tahu, odolnost proti tečení a mikrostrukturní stabilita, se zachovávají i při teplotách vyšších než 1000 °C, takže je vhodný pro vysokoteplotní aplikace.

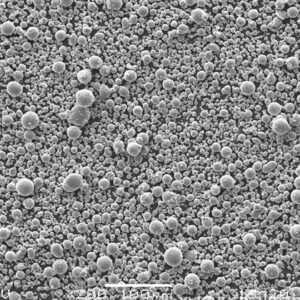

Metoda výroby prášku FeCoNiCrTi

Mezi běžné metody výroby prášku FeCoNiCrTi patří:

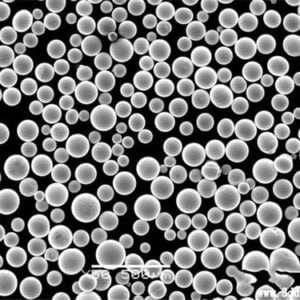

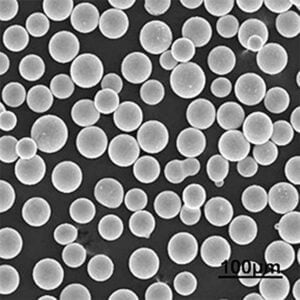

- Atomizace plynu - Vysokotlaký proud inertního plynu slouží k rozpadu proudu roztavené slitiny na jemné sférické částice prášku, které zajišťují dobrý tok a hustotu balení.

- Atomizace vody - Vysokorychlostní vodní paprsek naráží do roztaveného proudu a rozkládá jej, čímž vzniká jemný nepravidelný prášek. Nižší náklady, ale vyšší odběr kyslíku.

- Mechanické legování - Kuličkové mletí kovových prášků s následným spékáním za účelem syntézy prášku slitiny.

Plynová atomizace poskytuje nejlepší kontrolu nad vlastnostmi prášku. Distribuci velikosti částic lze přizpůsobit podle požadavků aplikace.

Aplikace prášku FeCoNiCrTi

Prášek FeCoNiCrTi se používá ve vysokoteplotních aplikacích, jako jsou:

- Aditivní výroba - Selektivní laserové tavení, tavení elektronovým paprskem k výrobě složitých dílů pro extrémní prostředí vyžadující vysokou teplotní pevnost.

- Tepelné nástřiky - Obloukové stříkání drátem k nanášení silných povlaků zajišťujících odolnost proti opotřebení a korozi při zvýšených teplotách.

- Pájecí plnivo - Pro spojování vysokoteplotních slitin a keramiky vyžadující odolnost proti oxidaci.

- Zpracování skla - Dopravní válce pro práškovou metalurgii s vysokou teplotní pevností používané v pecích na tavení skla.

- Prášková metalurgie - Vysokopevnostní konstrukční díly, jako jsou lopatky turbín a lopatky, vyráběné lisováním a spékáním.

- Svařovací spotřební materiál - Používá se jako přídavný materiál pro zajištění vynikající pevnosti svaru a odolnosti proti korozi.

Specifikace prášku FeCoNiCrTi

Prášek FeCoNiCrTi je k dispozici v různých rozměrových řadách, morfologiích a třídách:

- Velikost částic: V rozmezí 10-45 mikronů u metod AM a až 150 mikronů u procesů tepelného nástřiku.

- Morfologie: Sférické, nepravidelné a smíšené tvary prášku. Sférický prášek zajišťuje optimální tok a balení.

- Čistota: Od komerčních až po vysoce čisté třídy podle úrovně nečistot a požadavků na použití.

- Plocha povrchu: Preferuje se nízký povrch, aby se minimalizovala oxidace při manipulaci a skladování.

- stupně: Přizpůsobení složení a vlastností prášku na základě zamýšlené aplikace a způsobu zpracování.

Globální dodavatelé prášku FeCoNiCrTi

Mezi hlavní světové dodavatele prášku FeCoNiCrTi patří:

- Sandvik Osprey (Velká Británie)

- Hoganas (Švédsko)

- Praxair (USA)

- CNPC Powder (Čína)

- Erasteel (Francie)

- Tekna (Kanada)

- AMETEK (USA)

Tyto společnosti vyrábějí různé druhy prášku FeCoNiCrTi pomocí plynové atomizace, vodní atomizace a dalších technik přizpůsobených pro aditivní výrobu, tepelné stříkání, pájení a další vysokoteplotní aplikace.

Ceny prášku FeCoNiCrTi

Ceny prášku FeCoNiCrTi závisí na faktorech, jako jsou:

- Složení a úrovně čistoty

- Rozložení velikosti částic a morfologie

- Způsob výroby

- Objednané množství

- Dodavatel a umístění

| Třída | Cenové rozpětí |

|---|---|

| Komerční | $50-100 za kg |

| Vysoká čistota | $100-250 za kg |

| Ultrafine | $250-450 za kg |

| Speciální třída | $450-850 za kg |

Plynové rozprašování, vysoká čistota a jemné velikosti prášku mají mnohem vyšší ceny ve srovnání s jednoduchými komerčními třídami.

Skladování a manipulace s práškem FeCoNiCrTi

Prášek FeCoNiCrTi vyžaduje pečlivé skladování a manipulaci:

- Měly by být skladovány v uzavřených nádobách pod inertním plynem, aby se zabránilo oxidaci.

- Zabraňte hromadění jemného prášku, abyste minimalizovali riziko výbuchu prachu.

- Při manipulaci používejte vhodné osobní ochranné prostředky, větrání a bezpečnostní postupy.

- Zabraňte kontaktu prášku s neslučitelnými materiály.

- Postupujte podle platného bezpečnostního listu dodavatele

Při manipulaci s touto reaktivní práškovou slitinou je třeba dbát na řádné uzemnění, přikrytí a opatrnost.

Kontrola a zkoušení prášku FeCoNiCrTi

Klíčové testy používané pro kontrolu kvality prášku FeCoNiCrTi zahrnují:

- Chemická analýza pomocí OES nebo XRF, aby se zajistilo, že složení odpovídá specifikacím.

- Analýza distribuce velikosti částic podle normy ASTM B822

- Morfologická analýza pomocí SEM

- Měření průtoku prášku pomocí Hallova průtokoměru podle normy ASTM B213

- Měření hustoty pomocí heliové pyknometrie

- Testování nečistot pomocí ICP-MS

- Charakterizace mikrostruktury pomocí rentgenové difrakce

Důkladné testování a kontrola zajišťují spolehlivou a konzistentní kvalitu prášku splňující požadavky na výkon.

Srovnání prášku FeCoNiCrTi a Inconel 718

FeCoNiCrTi a Inconel 718 jsou dva porovnávané prášky z vysokoteplotních slitin:

| Parametr | FeCoNiCrTi | Inconel 718 |

|---|---|---|

| Složení | Čtyřkomorová slitina | Slitina Ni-Cr-Fe-Nb |

| Náklady | Vyšší | Dolní |

| Síla | Vyšší při velmi vysokých teplotách | Vynikající do 700 °C |

| Odolnost proti oxidaci | Srovnatelné | Srovnatelné |

| Zpracovatelnost | Mírný | Vynikající |

| Aplikace | Tepelný nástřik, svařování | Letecké komponenty, pružiny |

| Dostupnost | Mírný | Snadno dostupné |

FeCoNiCrTi nabízí lepší pevnost při vysokých teplotách, zatímco Inconel 718 je dobře vyrobitelný a dostupný.

FeCoNiCrTi prášek Často kladené otázky

Otázka: Jak se vyrábí prášek FeCoNiCrTi?

Odpověď: Prášek FeCoNiCrTi se komerčně vyrábí pomocí plynové atomizace, vodní atomizace a mechanického legování s následným spékáním. Plynová atomizace poskytuje nejlepší kontrolu vlastností částic.

Otázka: K čemu se používá prášek FeCoNiCrTi?

Odpověď: FeCoNiCrTi nachází uplatnění ve vysokoteplotních aplikacích, jako je aditivní výroba, povlaky tepelného nástřiku, plnivo pro pájení, součásti práškové metalurgie, svařovací materiály, kde je zapotřebí teplotní odolnost, pevnost a odolnost vůči životnímu prostředí.

Otázka: Jaká je doporučená velikost prášku pro tepelné stříkání?

Odpověď: Pro většinu procesů tepelného nástřiku se pro prášek FeCoNiCrTi upřednostňuje velikost částic v rozmezí 45-150 mikronů, aby se maximalizovala účinnost nanášení a vlastnosti povlaku.

Otázka: Vyžaduje prášek FeCoNiCrTi zvláštní opatření pro manipulaci?

Odpověď: Ano, doporučuje se s tímto reaktivním práškem z jemné slitiny zacházet opatrně, za použití inertní atmosféry, řádného uzemnění, větrání a osobních ochranných pomůcek pro kontrolu nebezpečí.

Otázka: Kde lze koupit prášek FeCoNiCrTi vhodný pro aditivní výrobu?

Odpověď: Jemný plynem atomizovaný prášek FeCoNiCrTi splňující požadavky AM lze zakoupit od předních výrobců, jako jsou Sandvik, Hoganas, Praxair a Erasteel.

Získejte nejnovější cenu

O Met3DP

kategorie produktů

ŽHAVÁ SLEVA

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731