GH 3625 prášek

Prášek GH3625 je stárnutím vytvrditelná slitina na bázi niklu a železa obsahující chrom 25% spolu s přísadami molybdenu a hliníku. Poskytuje výjimečnou kombinaci vysoké pevnosti, tvrdosti, odolnosti proti korozi a odolnosti proti oxidaci při zvýšených teplotách.

Nízké MOQ

Poskytněte nízké minimální množství objednávky, abyste splnili různé potřeby.

OEM a ODM

Poskytujte přizpůsobené produkty a designové služby, které splňují jedinečné potřeby zákazníků.

Přiměřená zásoba

Zajistěte rychlé zpracování objednávek a poskytněte spolehlivé a efektivní služby.

Spokojenost zákazníků

Poskytujte vysoce kvalitní produkty s jádrem spokojenosti zákazníků.

sdílet tento produkt

Obsah

Přehled prášku GH3625

Prášek GH 3625 je stárnoucí slitina na bázi niklu a železa obsahující 25% chromu spolu s příměsí molybdenu a hliníku. Poskytuje výjimečnou kombinaci vysoké pevnosti, tvrdosti, odolnosti proti korozi a oxidaci při zvýšených teplotách.

Mezi hlavní vlastnosti a výhody prášku GH3625 patří:

GH3625 Prášek Vlastnosti a charakteristika

| Vlastnosti | Podrobnosti |

|---|---|

| Složení | Slitina Ni-25Cr-4,5Mo-3,5Al |

| Hustota | 8,2 g/cc |

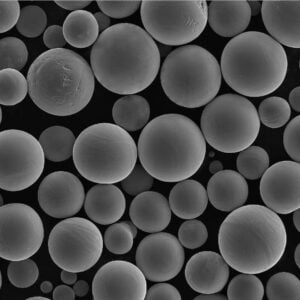

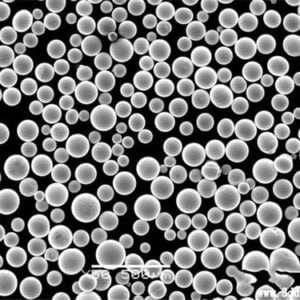

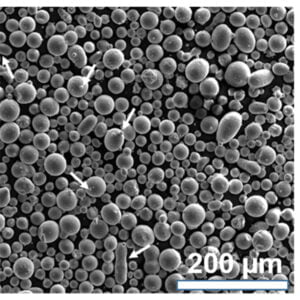

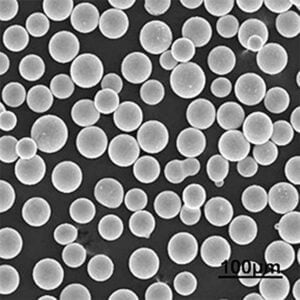

| Tvar částic | Převážně sférické |

| Rozsah velikostí | 15-45 mikronů |

| Zdánlivá hustota | Až 60% skutečné hustoty |

| Tekutost | Dobrý |

| Síla | Velmi vysoká po ošetření stárnutím |

| Odolnost proti korozi | Vynikající, včetně důlkové a štěrbinové koroze |

GH3625 se široce používá v leteckém a kosmickém průmyslu, při zpracování ropy a plynu, v chemickém průmyslu a při výrobě energie, kde je zapotřebí vysoká pevnost a odolnost proti korozi při zvýšených teplotách.

GH3625 Složení prášku

Typické složení prášku ze slitiny niklu a chromu GH3625:

GH3625 Složení prášku

| Živel | Hmotnost % |

|---|---|

| Nikl | Zůstatek |

| Chrom | 24-27% |

| Molybden | 4-5% |

| Hliník | 3-4% |

| Uhlík | 0,1% max |

| Mangan | 1% max |

| Křemík | 0,5% max |

| Síra | 0,015% max |

- Nikl zajišťuje odolnost proti korozi a napomáhá srážkovému kalení.

- Chrom výrazně zvyšuje odolnost proti oxidaci a korozi.

- Molybden a hliník usnadňují srážkové zpevnění

- Uhlík a další prvky omezené jako nečistoty

Složení je optimalizováno tak, aby poskytovalo špičkové zpevnění z precipitačního vytvrzování a vynikající odolnost proti korozi a oxidaci.

GH3625 Prášek Fyzikální vlastnosti

GH3625 Prášek Fyzikální vlastnosti

| Vlastnictví | Hodnoty |

|---|---|

| Hustota | 8,2 g/cc |

| Bod tání | 1390-1440°C |

| Tepelná vodivost | 11 W/mK |

| Elektrický odpor | 52 μΩ-cm |

| Koeficient tepelné roztažnosti | 13,0 x 10^-6 /K |

- Vysoká hustota ve srovnání s ocelí a slitinami titanu

- Zachovává si vysokou pevnost při teplotách vyšších než 1000 °C

- Relativně nízká tepelná vodivost vyžaduje zohlednění konstrukce.

- CTE je mírná a podobná nerezovým ocelím.

Díky těmto vlastnostem je GH3625 vhodný pro vysokopevnostní aplikace při zvýšených teplotách, které vyžadují odolnost proti korozi.

GH3625 Mechanické vlastnosti prášku

GH3625 Mechanické vlastnosti prášku

| Vlastnictví | Stav | Hodnoty |

|---|---|---|

| Tvrdost | Žíhání v roztoku | 35 HRC |

| Tvrdost | Špičkové stáří | 50-56 HRC |

| Pevnost v tahu | Žíhané | 1000 MPa |

| Pevnost v tahu | Stáří | 1500-1800 MPa |

| Pevnost v tahu | Stáří | 1200-1600 MPa |

| Prodloužení | Stáří | 10-15% |

- Stárne do velmi vysokých pevností, které překonávají ostatní srážecí vytvrzování slitin.

- Zachovává si přiměřenou tažnost ve špičkovém stavu stárnutí

- Tvrdost se po ošetření stárnutím výrazně zvyšuje

- Pevnost lze přizpůsobit dobou a teplotou stárnutí.

Díky těmto vlastnostem je GH3625 vhodný pro komponenty, které vyžadují vysokou pevnost v kombinaci s odolností proti korozi.

GH3625 Práškové aplikace

Mezi typické aplikace práškové slitiny niklu a chromu GH3625 patří:

GH3625 Práškové aplikace

| Průmysl | Používá |

|---|---|

| Aerospace | Lopatky turbíny, šrouby, spojovací materiál |

| Ropa a plyn | Ventily na hlavě vrtu, nástroje pro vrtání |

| Chemické zpracování | Šrouby extrudéru, součásti ventilů |

| Výroba energie | Součásti kotlů, parních a plynových turbín |

Některé konkrétní aplikace výrobků zahrnují:

- Lopatky, disky a spojovací prvky leteckých turbínových motorů

- Šrouby pro vysokoteplotní petrochemické potrubí

- Součásti ventilů používané v korozivních chemických prostředích

- Trubky a hlavice přehříváku kotle

- Lopatky a spojovací prvky parních turbín

GH3625 poskytuje výjimečnou pevnost a odolnost proti korozi pro kritické součásti používané při zvýšených teplotách v náročných průmyslových odvětvích.

Specifikace prášku GH3625

Klíčové specifikace prášku GH3625 zahrnují:

GH3625 Práškové standardy

| Standard | Popis |

|---|---|

| AMS 5815 | Složení práškové slitiny niklu |

| AMS 5408 | Dráty, tyče a pruty ze slitin niklu vytvrzených srážením |

| AMS 5698 | Investiční odlitky z PH niklových slitin |

| AMS 5772 | Výkovky ze slitin niklu |

| AMS 5634 | Lisované tvary ze slitiny niklu |

Ty definují:

- Limity chemického složení GH3625

- Požadované mechanické vlastnosti při různých podmínkách tepelného zpracování

- Schválená metoda výroby prášku - atomizace inertním plynem

- Limity nečistot pro kritické prvky

- Protokoly o testování shody

- Pokyny pro správnou manipulaci a skladování

Splnění těchto certifikačních požadavků zajišťuje optimální výkon.

GH3625 Velikost částic prášku

GH3625 Distribuce velikosti částic prášku

| Velikost částic | Charakteristika |

|---|---|

| 15-25 mikronů | Ultrajemný prášek používaný v procesech laserové AM |

| 25-45 mikronů | Rozsah velikostí pro většinu systémů AM s práškovým ložem |

| 45-75 mikronů | Větší velikosti používané při laserovém plátování |

- Jemnější prášek zajišťuje vyšší rozlišení a povrchovou úpravu

- Hrubší prášek vhodný pro procesy s vysokou rychlostí nanášení

- Rozložení velikostí přizpůsobené na základě použité metody AM

- Sférická morfologie zachována ve všech velikostech

Kontrola distribuce velikosti částic a morfologie je rozhodující pro výkonnost AM, vlastnosti a kvalitu finálních dílů.

GH3625 Prášek Zdánlivá hustota

GH3625 Prášek Zdánlivá hustota

| Zdánlivá hustota | Podrobnosti |

|---|---|

| Až 60% skutečné hustoty | Pro sférickou morfologii prášku |

| 4,5 - 5,2 g/cc | Zlepšuje se s větší hustotou balení |

- Sférický tvar prášku zajišťuje vysokou zdánlivou hustotu

- Vyšší hustota zlepšuje tok prášku a ucpávání lože v AM

- Snižuje pórovitost zachyceného plynu v konečném dílu

- Maximalizace hustoty minimalizuje dobu lisovacího cyklu

Vyšší zdánlivá hustota vede k vyšší produktivitě výroby a lepšímu výkonu dílů.

GH3625 Metoda výroby prášku

GH3625 Výroba prášku

| Metoda | Podrobnosti |

|---|---|

| Rozprašování plynu | Vysokotlaký inertní plyn rozbíjí proud roztaveného kovu na jemné kapičky. |

| Vakuové indukční tavení | Vstupní materiály vysoké čistoty tavené ve vakuu |

| Vícenásobné přetavení | Zlepšuje chemickou homogenitu |

| Sítování | Třídí prášek na různé frakce podle velikosti částic. |

- Plynová atomizace inertním plynem vytváří čistý sférický prášek.

- Vakuové zpracování minimalizuje plynné nečistoty

- Vícenásobné přetavení zlepšuje jednotnost složení

- Následné zpracování umožňuje kontrolu distribuce velikosti částic

Výsledkem automatizovaných metod v kombinaci s přísnou kontrolou kvality je konzistentní prášek GH3625 vhodný pro kritické aplikace.

GH3625 Cena prášku

GH3625 Cena prášku

| Faktor | Dopad na cenu |

|---|---|

| Třída prášku | Vyšší čistota zvyšuje náklady |

| Velikost částic | Ultrajemný prášek je dražší |

| Objednané množství | Cena klesá s většími objemy |

| Způsob výroby | Vícenásobné přetavení zvyšuje náklady |

| Balení | Speciální balení zvyšuje náklady |

Orientační ceny

- GH3625 prášek: $100-150 za kg

- Velkoobjemové ceny mohou být 30%+ nižší

Cena závisí na čistotě, velikosti částic, způsobu výroby, objemu objednávky, balení a požadavcích na dodání.

GH3625 Dodavatelé prášku

GH3625 Dodavatelé prášku

| Společnost | Umístění |

|---|---|

| Sandvik Osprey | Spojené království |

| Přísada pro tesaře | USA |

| Erasteel | Švédsko |

| Aubert & Duval | Francie |

| cn.koowe.powder | Čína |

| Shanghai STAL Precision | Čína |

Faktory výběru dodavatelů:

- Vyráběné druhy prášku a nabízené velikosti částic

- Výrobní kapacita a dodací lhůty

- Kontrola kvality, konzistence a dodržování předpisů

- Technické znalosti a zákaznická podpora

- Úrovně cen na základě objemu objednávek

- Zkušenosti se službami v cílovém odvětví

GH3625 Manipulace s prášky a jejich skladování

GH3625 Manipulace s práškem

| Doporučení | Důvod |

|---|---|

| Zajistěte správné větrání | Vyhněte se působení jemných kovových částic. |

| Používejte vhodné osobní ochranné prostředky | Zabraňte náhodnému vdechnutí nebo požití. |

| Dodržujte bezpečné protokoly | Snížení zdravotních a požárních rizik |

| Skladujte uzavřené nádoby | Zabránit kontaminaci nebo oxidaci |

Prášek GH3625 je relativně stabilní, ale přesto se doporučují obecná bezpečnostní opatření pro bezpečnou manipulaci a zachování čistoty.

Doporučení pro ukládání

- Skladujte ve stabilních nádobách na suchém a chladném místě.

- Omezte vystavení vlhkosti, která může zhoršit vlastnosti

- Udržování teplot pod 30 °C

Správná opatření zachovávají stav prášku a zabraňují bezpečnostním problémům.

GH3625 Kontrola a testování prášku

GH3625 Testování prášku

| Test | Podrobnosti |

|---|---|

| Chemická analýza | OES nebo XRF spektroskopie použitá k ověření složení |

| Distribuce velikosti částic | Laserová difrakční analýza |

| Zdánlivá hustota | Měřeno podle normy ASTM B212 |

| Morfologie prášku | Zobrazení tvaru částic pomocí SEM |

| Analýza průtoku | Gravitační průtok určenou tryskou |

| Měření vlhkosti | Analýza ztráty sušením |

Zkoušky zajišťují, že prášek splňuje požadovanou chemickou čistotu, vlastnosti částic, specifikace hustoty, morfologii a tekutost podle příslušných norem.

GH3625 Prášek klady a zápory

Výhody prášku GH3625

- Výjimečná pevnost při vysokých teplotách a odolnost proti tečení

- Zachovává pevnost a tvrdost až do 1100 °C

- Vynikající odolnost proti korozi v různých prostředích

- Dobrá únavová pevnost a lomová houževnatost

- Vysoká tvrdost v kombinaci s přiměřenou tažností

- Menší hustota než u niklových superslitin

Omezení prášku GH3625

- Dražší než prášky z nerezové oceli

- Vyžaduje řízené tepelné zpracování pro dosažení optimálních vlastností

- nižší odolnost proti opotřebení než kobaltové slitiny

- Obtížné obrábění po spékání

- Omezené možnosti tváření a tváření za studena

- Podléhá důlkové korozi v silně oxidujících kyselinách

Srovnání s práškem Inconel 718

GH3625 vs Inconel 718 prášek

| Parametr | GH3625 | Inconel 718 |

|---|---|---|

| Hustota | 8,2 g/cc | 8,2 g/cc |

| Síla | Vyšší | Dolní |

| Odolnost proti korozi | Vynikající | Vynikající |

| Náklady | Mírný | Velmi vysoko |

| Používá | Ropa a plyn, chemické zpracování | Letectví a kosmonautika, jaderná energetika |

- GH3625 poskytuje vyšší pevnost v tahu

- Inconel 718 nabízí lepší celkovou odolnost proti korozi

- GH3625 je cenově výhodnější

- Inconel 718 je vhodnější pro extrémní prostředí.

- GH3625 poskytuje optimální rovnováhu mezi pevností a náklady

GH3625 Prášek Časté dotazy

Otázka: Jaké jsou hlavní aplikace práškové slitiny niklu GH3625?

Odpověď: Mezi hlavní aplikace patří součásti leteckých turbín, ventily a nástroje pro vrtání ropných a plynových vrtů, součásti pro výrobu energie, zařízení pro zpracování chemikálií a další vysokoteplotní součásti vyžadující pevnost a odolnost proti korozi.

Otázka: Proč je GH3625 vhodnější než prášky z nerezové oceli pro vysokoteplotní aplikace?

Odpověď: GH3625 si při teplotách vyšších než 650 °C zachovává výrazně vyšší pevnost než nerezové oceli. Poskytuje také vynikající odolnost proti korozi v horkém korozivním prostředí.

Otázka: Jaká opatření je třeba dodržovat při práci s práškem GH3625?

Odpověď: Doporučená opatření zahrnují větrání, vhodné osobní ochranné prostředky, vyhýbání se zdrojům vznícení, dodržování protokolů o bezpečné manipulaci a skladování uzavřených nádob mimo dosah vlhkosti, vzduchu a kontaminace.

Otázka: Jak ovlivňuje hliník vlastnosti slitiny GH3625?

Odpověď: Hliník zvyšuje precipitační kalení tím, že během stárnutí vytváří nikl-hliníkové precipitáty. Tím se dosáhne výrazného zpevnění při zachování přiměřené tažnosti.

Získejte nejnovější cenu

O Met3DP

kategorie produktů

ŽHAVÁ SLEVA

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731