GH4169 Prášek pro aditivní výrobu

Prášek GH4169 je precipitačně vytvrzovaný prášek z nerezové oceli navržený tak, aby poskytoval vysokou pevnost, tvrdost a odolnost proti korozi po tepelném zpracování. Obsahuje chrom 17% spolu s přísadami niklu, hliníku, titanu a niobu pro lepší mechanické a korozní vlastnosti.

Nízké MOQ

Poskytněte nízké minimální množství objednávky, abyste splnili různé potřeby.

OEM a ODM

Poskytujte přizpůsobené produkty a designové služby, které splňují jedinečné potřeby zákazníků.

Přiměřená zásoba

Zajistěte rychlé zpracování objednávek a poskytněte spolehlivé a efektivní služby.

Spokojenost zákazníků

Poskytujte vysoce kvalitní produkty s jádrem spokojenosti zákazníků.

sdílet tento produkt

Obsah

Prášek GH4169 je precipitačně vytvrzovaný prášek z nerezové oceli navržený tak, aby poskytoval vysokou pevnost, tvrdost a odolnost proti korozi po tepelném zpracování. Obsahuje chrom 17% spolu s přísadami niklu, hliníku, titanu a niobu pro lepší mechanické a korozní vlastnosti.

| Rozsah velikostí | 15-45um/15-53um/20-63 um | 45-105um |

| Formulář | Sférické | Sférické |

| Schopnost proudění | ≤25s | |

| Zdánlivá hustota | ≥4,0 g/c㎡ | |

| Obsah kyslíku | ≤200 ppm | |

| Obsah dusíku | ≤150ppm | |

Klíčové vlastnosti prášku GH4169:

GH4169 Vlastnosti prášku

| Vlastnosti | Podrobnosti |

|---|---|

| Složení | Fe-17Cr-4Ni-1.5Ti-0.7Al-0.25Nb alloy |

| Hustota | 7,9 g/cc |

| Tvar částic | Nepravidelné, hranaté |

| Rozsah velikostí | 10-150 mikronů |

| Zdánlivá hustota | Až 50% skutečné hustoty |

| Tekutost | Mírný |

| Síla | Velmi vysoká po ošetření stárnutím |

| Odolnost proti korozi | Vynikající, včetně mořského prostředí |

Díky výjimečnému poměru pevnosti a hmotnosti v kombinaci s mimořádnou odolností proti korozi je GH4169 vhodný pro kritické konstrukční díly v letectví, námořnictví, jaderné energetice a dalších náročných aplikacích.

GH4169 Složení prášku

Typické složení nerezové oceli GH4169 pro srážkové kalení:

GH4169 Složení prášku

| Živel | Hmotnost % |

|---|---|

| železo (Fe) | Zůstatek |

| Chrom (Cr) | 16-18% |

| nikl (Ni) | 3.5-5.5% |

| titan (Ti) | 1.2-1.8% |

| hliník (Al) | 0.3-1.2% |

| niob (Nb) | 0.15-0.45% |

| uhlík (C) | 0,04% max |

| Křemík (Si), mangan (Mn) | 1% max. každý |

- Železo tvoří feritickou matrici

- Chrom zvyšuje odolnost proti korozi a oxidaci

- Nikl, hliník, titan a niob usnadňují srážecí kalení

- Uhlík a další prvky omezené jako odpadní nečistoty

Složení je navrženo tak, aby maximalizovalo reakci na precipitační vytvrzování a odolnost proti korozi požadovanou v konstrukčních aplikacích.

GH4169 Prášek Fyzikální vlastnosti

GH4169 Prášek Fyzikální vlastnosti

| Vlastnictví | Hodnoty |

|---|---|

| Hustota | 7,9 g/cc |

| Bod tání | 1400-1450°C |

| Elektrický odpor | 0,80 μΩ-m |

| Tepelná vodivost | 12 W/mK |

| Tepelná roztažnost | 12 x 10^-6 /K |

| Maximální provozní teplota | 650°C |

- Vysoký poměr pevnosti a hmotnosti

- Zachovává pevnost a tvrdost až do 650 °C

- Relativně nízká tepelná vodivost

- Odpor se zvyšuje po srážkovém vytvrzení

- Mírný koeficient roztažnosti

Tyto vlastnosti umožňují použití GH4169 v nosných konstrukčních aplikacích vyžadujících odolnost proti korozi a pevnost při vysokých teplotách.

GH4169 Mechanické vlastnosti prášku

GH4169 Mechanické vlastnosti prášku

| Vlastnictví | Stav | Hodnoty |

|---|---|---|

| Tvrdost | Žíhání v roztoku | 90 HRB |

| Tvrdost | Špičkové stáří | 40-45 HRC |

| Pevnost v tahu | Žíhané | 550-750 MPa |

| Pevnost v tahu | Špičkové stáří | 1300-1600 MPa |

| Pevnost v tahu | Špičkové stáří | 1100-1400 MPa |

| Prodloužení | Špičkové stáří | 8-13% |

- Stárne do vysokých hodnot pevnosti, které překonávají ostatní precipitačně kalené nerezové oceli.

- Zachovává si dobrou tažnost ve špičkovém stavu stárnutí

- Výrazné zvýšení tvrdosti po ošetření stárnutím

- Pevnost lze přizpůsobit dobou a teplotou stárnutí.

Díky těmto vlastnostem je GH4169 vhodný pro lehké konstrukční díly s vysokou pevností a odolností proti korozi.

GH4169 Práškové aplikace

Mezi typické aplikace prášku z nerezové oceli GH4169 pro srážkové kalení patří:

GH4169 Práškové aplikace

| Průmysl | Příklad použití |

|---|---|

| Aerospace | Součásti draku a motoru, spojovací materiál |

| Námořní | Hřídele, přípravky, solenoidy, ventily |

| Jaderné | Obložení palivových prvků, vnitřní konstrukce |

| Ropa a plyn | Konstrukční díly pro hlavice vrtů, plošiny na moři |

| Chemické | Procesní zařízení, jako jsou nádoby a potrubí |

Některá specifická použití:

- Šrouby, matice, vruty a svorníky s vysokou pevností

- Kritické součásti rotujících hřídelí

- tělesa ventilů a čerpadel používaných v korozivním prostředí

- Míchací zařízení jako oběžná kola a míchadla

- Plášť jaderného palivového článku a vnitřní části nádoby

GH4169 poskytuje výjimečnou kombinaci pevnosti, tvrdosti a odolnosti proti korozi, která je vyžadována u kritických konstrukčních dílů v náročných průmyslových odvětvích.

Specifikace prášku GH4169

Klíčové specifikace prášku GH4169 zahrnují:

GH4169 Práškové standardy

| Standard | Popis |

|---|---|

| AMS 5922 | Prášek z nerezové oceli pro srážkové kalení pro letecké díly |

| ASTM A580 | Standard pro drát z nerezové oceli kalený srážením |

| ASTM A638 | Norma pro srážecí kalení superslitin na bázi železa |

| AMS 5898 | Tyče, výkovky, kroužky z nerezavějících ocelí kalených srážením |

Ty definují:

- Chemické složení slitiny GH4169

- Přípustné nečistoty jako C, S a P

- Požadované mechanické vlastnosti za různých podmínek

- Schválené metody výroby prášku

- Protokoly o testování shody

- Požadavky na zajištění kvality

Prášek vyrobený podle těchto norem zajišťuje optimální reakci na stárnutí, tažnost a odolnost proti korozi.

GH4169 Velikost částic prášku

GH4169 Distribuce velikosti částic prášku

| Velikost částic | Charakteristika |

|---|---|

| 10-22 mikronů | Ultrajemná třída pro vysokou hustotu |

| 22-75 mikronů | Nejčastěji používaný rozsah velikostí |

| 75-150 mikronů | Hrubší velikosti pro lepší průtočnost |

- Jemnější částice podporují vyšší hustotu spékání

- Hrubší částice zlepšují tok prášku do dutin matrice

- Používá se plynová i vodní atomizace

- Rozložení velikosti přizpůsobené potřebným vlastnostem konečného dílu

Řízení distribuce velikosti částic optimalizuje chování při lisování, konečnou hustotu a mechanické vlastnosti.

GH4169 Prášek Zdánlivá hustota

GH4169 Prášek Zdánlivá hustota

| Zdánlivá hustota | Podrobnosti |

|---|---|

| Až 50% skutečné hustoty | Pro nepravidelnou morfologii prášku |

| 4,5-5,5 g/cc | Vyšší pro sférické prášky |

- Sférické prášky poskytují vyšší zdánlivou hustotu

- Nepravidelné částice mají hustotu kolem 45%

- Vyšší zdánlivá hustota zlepšuje tok a stlačitelnost prášku.

- Umožňuje vyšší hustotu zeleně po zhutnění

Vyšší zdánlivá hustota prášku vede k vyšší produktivitě výroby a lepšímu výkonu dílů.

GH4169 Metoda výroby prášku

GH4169 Výroba prášku

| Metoda | Podrobnosti |

|---|---|

| Rozprašování plynu | Vysokotlaký inertní plyn rozbíjí proud roztaveného kovu na jemné kapičky. |

| Rozprašování vody | Vysokotlaký vodní paprsek rozbíjí kov na jemné částice |

| Vakuové indukční tavení | Vstupní materiály vysoké čistoty tavené ve vakuu |

| Vícenásobné přetavení | Zlepšuje chemickou homogenitu |

| Sítování | Třídí prášek do různých velikostí částic |

- Plynová atomizace zajišťuje sférický tvar prášku

- Rozprašování vodou je levnější, ale s nepravidelnými částicemi.

- Vakuové zpracování minimalizuje plynné nečistoty

- Následné zpracování umožňuje kontrolu velikosti částic

Plně automatizované metody v kombinaci s přísnou kontrolou kvality zajišťují spolehlivý a konzistentní prášek vhodný pro kritické aplikace.

GH4169 Ceny prášku

GH4169 Ceny prášku

| Faktor | Dopad na cenu |

|---|---|

| Třída prášku | Vyšší čistota zvyšuje náklady |

| Velikost a tvar částic | Jemný sférický prášek nejdražší |

| Objednané množství | Cena klesá s většími objemy |

| Další zpracování | Služby jako prosévání zvyšují náklady |

| Požadavky na testování | Přísnější testování zvyšuje náklady |

Orientační ceny

- Nepravidelný prášek GH4169: $18-24 na kg

- Sférický prášek GH4169: $22-30 na kg

- Velkoobjemové ceny mohou být o 25-35% nižší.

Cena závisí na stupni čistoty, vlastnostech prášku, objemu objednávky a požadovaném dalším zpracování.

GH4169 Dodavatelé prášku

GH4169 Dodavatelé prášku

| Společnost | Umístění |

|---|---|

| Přísada pro tesaře | USA |

| Erasteel | USA, Evropa |

| Sandvik Osprey | Spojené království |

| Aubert & Duval | Francie |

| Skupina CNPC Powder | Čína |

| Jingdong Nový materiál | Čína |

Mezi faktory výběru patří:

- Vyráběné druhy prášku

- Výrobní kapacita a dodací lhůty

- Kvalita a konzistence prášku

- Schopnost testování a podávání zpráv

- Ceny a minimální objednací množství

- Zkušenosti s cílovými odvětvími

GH4169 Manipulace s prášky a jejich skladování

GH4169 Manipulace s práškem

| Doporučení | Důvod |

|---|---|

| Zajistěte správné větrání | Zabraňte expozici jemným kovovým částicím |

| Vyhněte se zdrojům vznícení | Prášek může v kyslíkové atmosféře hořet |

| Dodržujte bezpečné protokoly | Snížení zdravotních a požárních rizik |

| Používejte nejiskřící nástroje | Zabránění možnosti vznícení |

| Skladujte uzavřené nádoby | Zabránit kontaminaci nebo oxidaci |

Doporučení pro ukládání

- Skladujte ve stabilních nádobách na suchém a chladném místě.

- Omezte působení vlhkosti a kyselin

- Udržování teplot pod 30 °C

Při správných opatřeních při manipulaci a skladování zůstává prášek GH4169 stabilní a práce s ním je bezpečná.

GH4169 Kontrola a testování prášků

GH4169 Testování prášku

| Test | Podrobnosti |

|---|---|

| Chemická analýza | ICP a XRF ověřují složení |

| Analýza velikosti částic | Určuje distribuci velikosti částic |

| Zdánlivá hustota | Měřeno podle normy ASTM B212 |

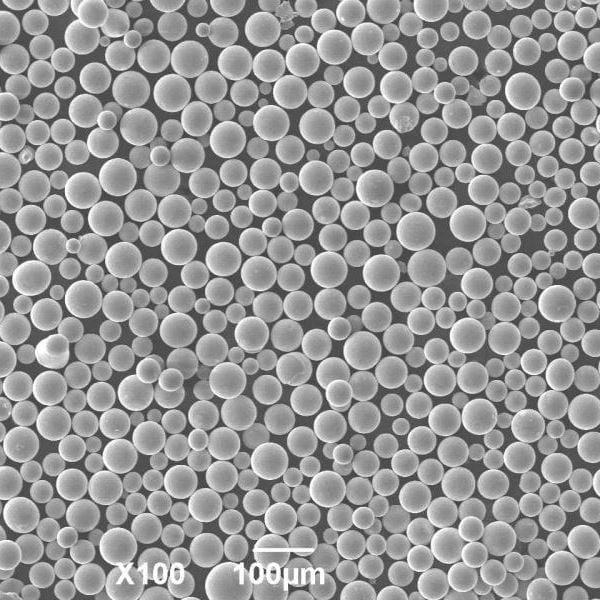

| Morfologie prášku | Zobrazení tvaru částic pomocí SEM |

| Testování průtoku | Gravitační průtok určenou nálevkou |

| Ztráta při zapálení | Určuje obsah vlhkosti |

Testování zajišťuje, že prášek splňuje požadované složení, vlastnosti částic, specifikace hustoty, morfologii a rychlost toku podle platných norem.

GH4169 Prášek klady a zápory

Výhody prášku GH4169

- Výjimečná pevnost po vytvrzení srážením

- Zachovává si dobrou tažnost ve špičkovém stavu stárnutí

- Vynikající odolnost proti korozi včetně mořského prostředí

- Vysoká pevnost udržovaná až do 650 °C

- Dobré kombinace vlastností pro kritické konstrukční díly

- Cenově výhodnější než superslitiny

Omezení prášku GH4169

- Vyžaduje pečlivé tepelné zpracování pro dosažení optimálních vlastností

- Nižší lomová houževnatost než u austenitických ocelí

- Podléhá senzibilizaci při nesprávném svařování

- Omezené možnosti tváření a tváření za studena

- Pevnost a odolnost proti korozi není tak vysoká jako u superslitin

- Cena vyšší než u běžných druhů nerezové oceli

Srovnání s práškem 17-4PH a 15-5PH

GH4169 vs. prášek 17-4PH a 15-5PH

| Parametr | GH4169 | 17-4PH | 15-5 PH |

|---|---|---|---|

| Hustota | 7,9 g/cc | 7,7 g/cc | 7,8 g/cc |

| Tvrdost | 40-45 HRC | 38-45 HRC | 36-42 HRC |

| Pevnost v tahu | 1300-1600 MPa | 1200-1450 MPa | 1050-1400 MPa |

| Odolnost proti korozi | Vynikající | Velmi dobré | Dobrý |

| Náklady | Vysoký | Mírný | Nízký |

- GH4169 má nejvyšší pevnost po ošetření stárnutím

- Poskytuje také nejlepší odolnost proti korozi

- 17-4PH je mírně silnější než 15-5PH.

- 15-5PH je nejúspornější ze všech tří typů.

- GH4169 se upřednostňuje pro kritické konstrukční aplikace

GH4169 Prášek Časté dotazy

Otázka: Jaké jsou hlavní aplikace prášku z nerezové oceli GH4169?

A: Hlavní aplikace zahrnují letecké konstrukce, námořní komponenty, jako jsou hřídele a ventily, opláštění jaderných palivových článků, části ropných a plynových vrtů, zařízení pro chemické procesy a další konstrukční díly vyžadující vysokou pevnost a odolnost proti korozi.

Otázka: Jaká je role hliníku a titanu ve složení GH4169?

Odpověď: Hliník a titan usnadňují precipitační kalení tím, že během stárnutí vytvářejí jemné souvislé sraženiny. Tím se dosáhne značného zpevnění při zachování přiměřené tažnosti.

Otázka: Jaká bezpečnostní opatření jsou nutná při práci s práškem GH4169?

Odpověď: Doporučená bezpečnostní opatření zahrnují větrání, vyhýbání se zdrojům vznícení, používání nejiskřivých nástrojů, ochranných pomůcek, dodržování bezpečných protokolů a skladování uzavřených nádob mimo dosah kontaminantů nebo vlhkosti.

Otázka: Jak se GH4169 liší od martenzitických a feritických nerezových ocelí?

Odpověď: GH4169 lze ve srovnání s martenzitickými nebo feritickými třídami zestárnout na mnohem vyšší pevnost. Na rozdíl od martenzitických tříd poskytuje také vynikající odolnost proti korozi, a to i v mořském prostředí.

Získejte nejnovější cenu

O Met3DP

kategorie produktů

ŽHAVÁ SLEVA

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731