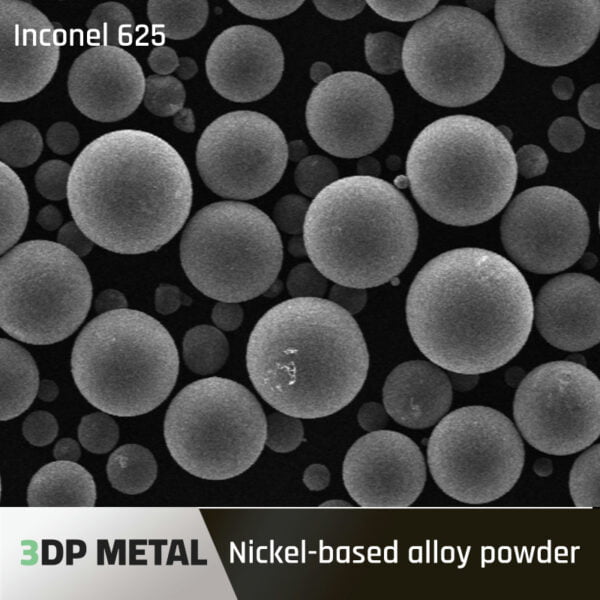

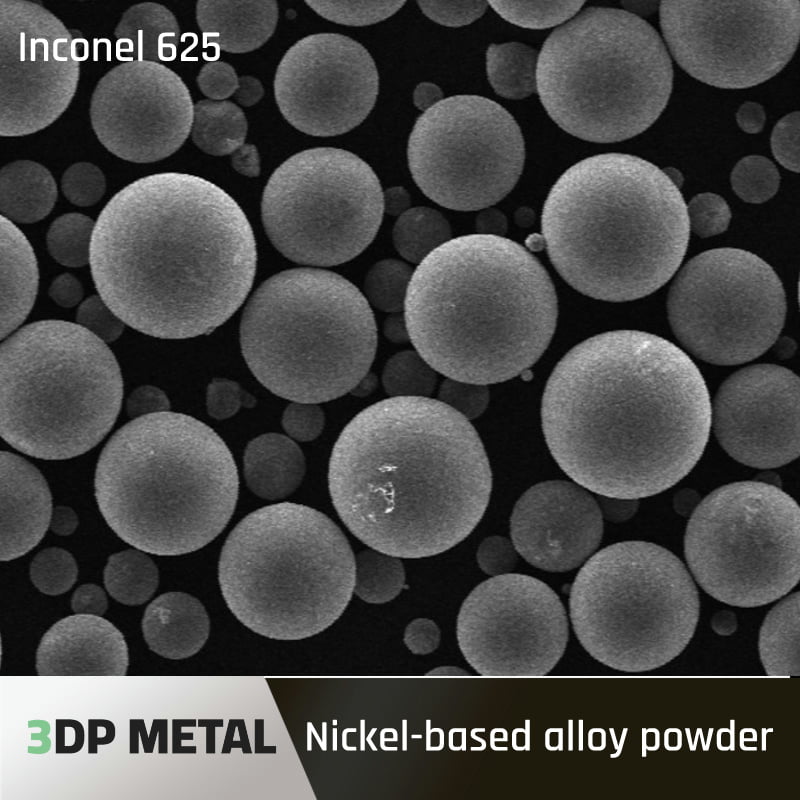

Inconel 625 Powder丨Superslitina na bázi niklu v prášku 625

Prášek In625 je prášková forma nikl-chromové slitiny Inconel 625, která vykazuje vynikající odolnost proti korozi, vysokou pevnost a vynikající tepelnou odolnost. Tato superslitina se skládá z niklu, chrómu, molybdenu a niobu spolu s menším množstvím dalších prvků. Jeho jedinečné složení propůjčuje pozoruhodné mechanické vlastnosti, díky čemuž je vyhledávaným materiálem v mnoha průmyslových odvětvích.

Nízké MOQ

Poskytněte nízké minimální množství objednávky, abyste splnili různé potřeby.

OEM & ODM

Poskytujte přizpůsobené produkty a designové služby, které splňují jedinečné potřeby zákazníků.

Přiměřená zásoba

Zajistěte rychlé zpracování objednávek a poskytněte spolehlivé a efektivní služby.

Spokojenost zákazníků

Poskytujte vysoce kvalitní produkty s jádrem spokojenosti zákazníků.

sdílet tento produkt

Obsah

Přehled prášku Inconel 625

Prášek Inconel 625 je superslitina na bázi niklu, která se vyznačuje vysokou pevností a odolností vůči zvýšeným teplotám. Inconel 625 (Alloy 625, UNS N06625) je široce používán pro svou vysokou pevnost, vynikající zpracovatelnost (včetně spojování) a vynikající odolnost proti korozi. Jeho provozní teploty se pohybují od kryogenní až 1800 °F (982 °C). Vysoká pevnost v tahu, tečení a přetržení, vynikající únavová a tepelně-únavová pevnost, odolnost proti oxidaci a vynikající svařitelnost a pájitelnost jsou vlastnosti slitiny INCONEL 625, které ji činí zajímavou pro letecký průmysl.

Prášek Inconel 625 je vysoce výkonný prášek ze superslitiny na bázi niklu široce používaný v aditivní výrobě (AM) a tradičních procesech zpracování kovů. Známý pro svou výjimečnou pevnost, odolnost proti korozi a tepelnou stabilitu, tento materiál je nejlepší volbou v průmyslových odvětvích, jako je letecký, energetický a námořní strojírenství.

Čím ale prášek Inconel 625 vyniká? Jeho unikátní složení, sestávající především z niklu, chrómu a molybdenu, poskytuje vynikající odolnost proti oxidaci, důlkové a creepové deformaci. Díky tomu je ideální pro vysokoteplotní a vysoce namáhané aplikace, kde by běžné materiály selhaly.

Se vzestupem kovového 3D tisku se zvyšuje poptávka po vysoké kvalitě Prášek Inconel 625 raketově vzrostl. Firmy jako Met3DP jsou v popředí a dodávají přední společnost rozprašovaný plyn a Vyrobeno PREP sférické prášky optimalizované pro Selektivní laserové tavení (SLM), Tavení elektronovým paprskem (EBM), Vstřikování kovů (MIM)a další pokročilé výrobní techniky.

Nyní se pojďme ponořit hlouběji do top faktory které vytvářejí Prášek Inconel 625 nepostradatelný materiál v roce 2025.

Nejlepší prášek Inconel 625 pro 3D tisk

Proč je Inconel 625 Powder ideální pro 3D tisk

Zejména 3D tisk výroba aditiv kovů (AM), způsobil revoluci v průmyslové výrobě a Prášek Inconel 625 je jedním z nejžádanějších materiálů pro tuto technologii. Mezi klíčové výhody patří:

- Odolnost vůči vysokým teplotám - Odolává extrémnímu teplu bez ztráty pevnosti.

- Vynikající odolnost proti korozi – Dobře funguje v drsných prostředích, jako je námořní a chemické zpracování.

- Vynikající mechanické vlastnosti - Vysoká pevnost v tahu, odolnost proti tečení a únavový výkon.

- Dobrá tisknutelnost – Sférické částice prášku zajišťují hladký tok a rovnoměrné nanášení vrstvy při tavení práškového lože.

Specifikace prášku Inconel 625

| Normální složení(wt%) | ||||||

|

In625

|

Cr | Mo | Nb | Co | Fe | Al |

| 20-23 | 8-10 | 3.15-4.15 | ≤1 | ≤1 | ≤0.4 | |

| Ti | C | Ni | O | N | ||

| ≤0.4 | ≤0.1 | Bal. | ≤500ppm | ≤100ppm | ||

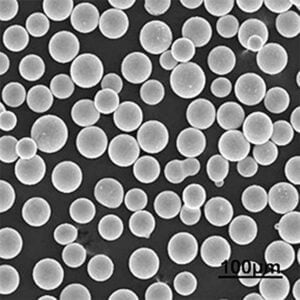

Common Size:15-45um,15-53um,45-106um,45-150u,-200/-300/-400/-500/-600mesh etc,.

| Ne | Název | Související složení prášku (wt%) |

| 1 | 18Ni300 | Ni17-19,Mo4.5-5.2,Co8.5-9.5,Ti0.6-0.8,Al0.05-0.15,Fe(Bal.) |

| 2 | Slitina Hastelloy | Fe17-20,Cr20.5-23,Mo8-10,W0.2-1,Co0.5-2.5,C0.05-0.15,Ni(Bal.) |

| 3 | AlSi 10Mg | Si9-11,Mg0.2-0.45,Al(Bal.) |

| 4 | CoCrW | Cr26.5-29,W7-9,Si1.2-1.9,Co(Bal.) |

| 5 | Co28Cr6Mo | Cr27-29,Mo5-7,Co(Bal.) |

| 6 | Sférický Ti prášek | Ti≥99,9 |

| 7 | TC4 | Al5.5-6.8,V3.5-4.5,Ti(Bal.) |

| 8 | TA15 | Al5.5-7.1,V0.8-2.5,Mo0.8-2,Zr1.5-2.5,Al(Bal.) |

| 9 | 316L | Cr16.00-18.00, Ni10.00-14.00,Mo2.00-3.00,Fe(Bal.) |

| 10 | S136 | Cr12.0-14.0,Si0.8-1.0,V0.15-0.4,C0.2-0.45,Fe(Bal.) |

| 11 | In625 | Cr20-23 , Mo8-10 , Nb 3,15-4,15 , Co≤1, Fe≤1 , Ni (bal.) |

| 12 | In718 | Cr17-21 , Mo2,8-3,3 , Nb 4,75-5,5 , Co≤1 , Ni50-51 , Fe(Bal.) |

| 13 | Spherica WC | C3.7-4.2,W(Bal.) |

| 14 | Sférický Cr prášek | Cr≥99,9 |

| 15 | Sférický prášek Mo | Mo≥99,9 |

| 16 | Spherica Ta prášek | Ta≥99,9 |

| 17 | Spherica W Prášek | W≥99.9 |

Výběr správného prášku pro různé metody 3D tisku

Ne všechny prášky Inconel 625 jsou stejné. Vlastnosti prášku závisí na výrobní metody a distribuce velikosti částic, které ovlivňují jejich vhodnost pro různé techniky 3D tisku.

| Způsob tisku | Ideální velikost prášku (µm) | Doporučený typ prášku | Výhody |

|---|---|---|---|

| Selektivní laserové tavení (SLM) | 15-45 | Rozprašovaný plyn | Vysoká přesnost, jemné detaily |

| Tavení elektronovým paprskem (EBM) | 45-106 | Proces plazmové rotující elektrody (PREP) | Lepší pro velké, silné části |

| Tryskání pojiva | 20-50 | Atomizovaná voda | Cenově efektivní, vysoká propustnost |

| Přímá energetická depozice (DED) | 50-150 | Rozprašovaný plyn | Dobré pro opravy a velkoplošný tisk |

Pokročilá prášková řešení Met3DP

Na Met3DP, poskytujeme vysoce čisté, kulovité Inconel 625 prášky speciálně přizpůsobené pro SLM, EBM a další kovový 3D tisk metody. Naše prášky jsou vyráběny za použití Vakuová indukční atomizace plynem (VIGA) a PREP technologie, čímž se zajistí optimální tekutost, hustota balení a potiskovatelnost.

Vlastnosti prášku Inconel 625

Porozumění chemické a fyzikální vlastnosti prášku Inconel 625 je rozhodující pro výběr správného materiálu pro vaši aplikaci.

Chemické složení prášku Inconel 625

Jedinečné chemické složení dává Inconelu 625 jeho vynikající odolnost proti korozi a pevnost při vysokých teplotách.

| Živel | Procento (%) |

|---|---|

| nikl (Ni) | 58,0 min |

| Chrom (Cr) | 20.0-23.0 |

| molybden (Mo) | 8.0-10.0 |

| železo (Fe) | 5,0 max |

| Niob (Nb) a tantal (Ta) | 3.15-4.15 |

| Kobalt (Co) | 1,0 max |

| mangan (Mn) | 0,50 max |

| křemík (Si) | 0,50 max |

| uhlík (C) | 0,10 max |

| síra (S) | 0,015 max |

Fyzikální a mechanické vlastnosti

Exponáty prášku Inconel 625 výjimečné mechanické vlastnosti, takže je ideální pro vysoce zátěžové a vysokoteplotní aplikace.

| Vlastnictví | Hodnota |

|---|---|

| Hustota | 8,44 g/cm³ |

| Bod tání | 1290-1350°C |

| Pevnost v tahu | 827 MPa (120 ksi) |

| Mez kluzu | 414 MPa (60 ksi) |

| Prodloužení | 30% |

| Tvrdost (Rockwell B) | 85 |

Aplikace prášku Inconel 625 v průmyslu

Vzhledem ke svým vynikajícím vlastnostem, Prášek Inconel 625 se hojně používá v letecké, námořní, energetické a chemické zpracování průmyslová odvětví.

Klíčové průmyslové aplikace

| Průmysl | Případ použití | Důvod použití |

|---|---|---|

| Aerospace | Proudové motory, výfukové systémy, tepelné štíty | Extrémní tepelná odolnost, odolnost proti oxidaci |

| Námořní | Části ponorek, součásti pro vrtání na moři | Odolnost proti korozi mořské vody |

| Energie | Plynové turbíny, jaderné reaktory | Pevnost při vysokých teplotách, odolnost proti tečení |

| Chemické zpracování | Výměníky tepla, potrubní systémy | Odolnost proti korozi proti kyselinám a zásadám |

| Lékařský | Implantáty, protetika | Biokompatibilita, pevnost, odolnost proti korozi |

Jak Inconel 625 prášek překonává ostatní slitiny niklu

Ve srovnání s jinými superslitinami na bázi niklu jako Inconel 718 a Hastelloy X, Inconel 625 nabízí:

- Lepší odolnost proti korozi než Inconel 718

- Vyšší teplotní výkon než Hastelloy X

- Více flexibility v aplikacích kovového 3D tisku

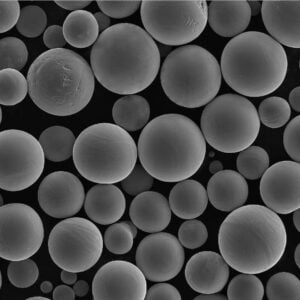

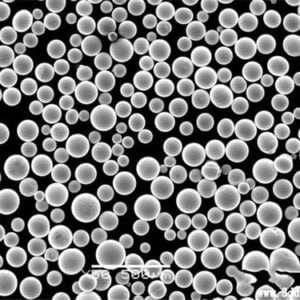

Způsoby výroby prášku Inconel 625

The způsob výroby prášku Inconel 625 výrazně ovlivňuje jeho kvalitu, tekutost a výkon. Existují tři základní výrobní techniky:

Srovnání výrobních metod

| Způsob výroby | Popis procesu | Výhody | Nevýhody |

|---|---|---|---|

| Atomizace plynu | Kov se taví a atomizuje pomocí trysek inertního plynu | Sférický prášek, dobrá tekutost | Vyšší náklady |

| Proces plazmové rotující elektrody (PREP) | Kovová elektroda se spřádá a taví pomocí plazmy | Vysoká čistota, vynikající sféricita | Drahé, nižší výnos |

| Atomizace vody | Roztavený kov je atomizován vodními paprsky | Nákladově efektivní, velkosériová výroba | Nepravidelný tvar částic, nižší tekutost |

Pro špičkové aplikace, jako je letectví a 3D tisk, atomizovaný plyn a PREP prášky jsou preferovány kvůli jejich vysoká kulovitost a čistota.

Proč Met3DP používá atomizaci plynu a PREP

Na Met3DP, zaměstnáváme nejmodernější technologie VIGA a PREP vyrábět vysoce kvalitní prášek Inconel 625 s konzistentní velikost částic, vynikající tekutost a minimální nečistoty.

Normy kvality pro prášek Inconel 625

Při výběru Prášek Inconel 625 pro průmyslové aplikace, setkání přísné normy kvality je zásadní. Různé mezinárodní organizace zavedly směrnice k zajištění konzistence, bezpečnosti a výkonu. Zde je to, co potřebujete vědět.

Klíčové standardy kvality pro Inconel 625 Powder

| Standard | Popis | Použitelná odvětví |

|---|---|---|

| ASTM B443 | Specifikace pro listy, pásy a desky Inconel 625 | Letectví, námořní průmysl, chemické zpracování |

| AMS 5666 | Specifikace leteckého materiálu pro kovaný Inconel 625 | Letectví a kosmonautika, obrana |

| ISO 9001 | Certifikace systému managementu kvality | Obecná výroba |

| ASTM F3055 | Standard pro aditivní výrobu slitin na bázi Ni | 3D tisk, lékařské implantáty |

| AMS 5892 | Tepelně odolný Inconel 625 pro plynové turbíny | Energie, výroba elektřiny |

Splnění těchto norem zajišťuje, že materiál spolehlivě funguje vysoce namáhané prostředí, extrémní teploty a korozní podmínky.

Proč Met3DP Inconel 625 Powder splňuje ty nejvyšší standardy

Na Met3DP, dodržujeme Systémy řízení jakosti s certifikací ISO 9001, zajištění každé šarže Prášek Inconel 625 splňuje nebo překračuje Specifikace ASTM F3055 a AMS 5666. Náš výrobní proces zahrnuje přísná analýza chemického složení, kontrola morfologie částic a testování tekutosti doručit prvotřídní prášky pro průmyslové aplikace.

Analýza nákladů na prášek Inconel 625

The cena prášku Inconel 625 závisí na různé faktory, včetně výrobní metoda, distribuce velikosti částic, pověst dodavatele a objem objednávky.

Faktory, které ovlivňují cenu prášku Inconel 625

| Faktor | Dopad na náklady |

|---|---|

| Způsob výroby | PREP a atomizace plynu vést k vyšším nákladům díky lepší kvalitě |

| Čistota a složení | Prášky s vyšší čistotou jsou dražší, ale nabízejí lepší výkon |

| Distribuce velikosti částic | Jemné prášky optimalizované pro SLM a EBM jsou dražší než hrubší prášky |

| Objem objednávky | Hromadné objednávky snižují náklady díky úsporám z rozsahu |

| Reputace dodavatele | Zavedení dodavatelé s Certifikováno ISO procesy mohou účtovat více za zajištění kvality |

Porovnání cen: Inconel 625 vs. jiné prášky na bázi niklu

| Materiál | Průměrná cena za kg (2025) | Primární aplikace |

|---|---|---|

| Inconel 625 prášek | $80 – $150 | Letectví, energetika, 3D tisk |

| Inconel 718 prášek | $70 – $130 | Letecký a automobilový průmysl |

| Hastelloy X prášek | $90 – $160 | Vysokoteplotní aplikace |

| Prášek z nerezové oceli 316L | $20 – $50 | Obecná výroba |

Zatímco Prášek Inconel 625 je dražší než nerezová ocel, jeho vynikající tepelná odolnost a odolnost proti korozi udělat z něj nákladově efektivní volba pro kritické aplikace.

Jak získat nejlepší cenu za prášek Inconel 625

- Koupit ve velkém – Dodavatelé často poskytují slevy na velkoobjemové nákupy.

- Vyberte si správného dodavatele – Důvěryhodné společnosti jako Met3DP nabídka vysoce kvalitní prášky za konkurenceschopné ceny.

- Vyberte správnou velikost částic – Vyhněte se přeplácení za ultrajemné prášky, pokud je váš proces nevyžaduje.

Inconel 625 Powder for Powder Bed Fusion vs. Binder Jetting

Dvě hlavní Technologie 3D tisku použít Prášek Inconel 625: Fúze v práškovém loži (PBF) a Binder Jetting (BJ). Každý má jedinečné výhody a je vhodný pro různé aplikace.

Srovnání: Inconel 625 Powder pro PBF vs. Binder Jetting

| Vlastnosti | Fúze v práškovém loži (PBF) | Binder Jetting (BJ) |

|---|---|---|

| Proces tisku | Používá laserový nebo elektronový paprsek k roztavení a roztavení prášku | Používá pojivo ke slepení částic prášku před slinováním |

| Ideální velikost částic | 15-45 µm (SLM), 45-106 µm (EBM) | 20-50 um |

| Síla závěrečné části | Silné části s vysokou hustotou | Nižší pevnost, vyžaduje dodatečné zpracování |

| Nejlepší pro komplexní geometrie? | Ano, podporuje složité návrhy | Omezená složitost |

| Náklady | Vyšší kvůli technologie laserového/elektronového paprsku | Nižší kvůli rychlejší tisk a levnější materiály |

| aplikace | Letectví, lékařské implantáty, energetické komponenty | Prototypování, nízkonákladová výroba |

Pokud potřebujete vysoce pevné, přesné díly, PBF je nejlepší volbou. Ale pokud hledáte nákladově efektivní, vysokorychlostní výroba, Tryskání pojiva může být vhodnější.

Odbornost Met3DP v oblasti práškové fúze

Na Met3DP, specializujeme se vysoce kvalitní sférické prášky Inconel 625 optimalizované pro Technologie SLM a EBM. Náš plynem atomizované prášky poskytnout vynikající tekutost, zajišťující konzistentnost a spolehlivost Výsledky 3D tisku.

Atomizovaný vodou vs. Atomizovaný plynem vs. PREP Inconel 625 Powder: Co je lepší?

The způsob výroby prášku přímo ovlivňuje její morfologie, čistota a vhodnost pro různé výrobní procesy.

Porovnání způsobů výroby prášku Inconel 625

| Metoda | Tvar částice | Čistota | Nejlepší aplikace |

|---|---|---|---|

| Atomizace vody | Nepravidelné | Dolní | Lisované a slinuté díly |

| Atomizace plynu | Sférické | Vysoký | Laserový 3D tisk (SLM, EBM) |

| Proces plazmové rotující elektrody (PREP) | Dokonale sférické | Velmi vysoká | Špičkový letecký, lékařský |

Proč jsou plynem atomizované a PREP prášky vynikající

- Lepší tekutost: Zajišťuje hladké roztírání prášku pro 3D tisk.

- Vyšší čistota: PREP prášky mají minimální kontaminaci kyslíkem.

- Konzistentní distribuce velikosti částic: Kritické pro Aplikace SLM a EBM.

Na Met3DP, používáme pokročilé techniky atomizace plynu a PREP vyrábět prvotřídní prášek Inconel 625 pro nejnáročnější aplikace.

FAQ: Vše, co potřebujete vědět o prášku Inconel 625

| Otázka | Odpovědět |

|---|---|

| V čem je prášek Inconel 625 jedinečný? | Jeho vysoký obsah niklu, v kombinaci s chrom a molybden, poskytuje výjimečná odolnost proti korozi a pevnost při vysokých teplotách. |

| Jaká průmyslová odvětví používají prášek Inconel 625? | Letecký, námořní, energetický, chemické zpracování a lékařské implantáty. |

| Jaká je ideální velikost částic pro tisk SLM? | Mezi 15-45 um, zajišťující hladký tok prášku a optimální kvalitu tisku. |

| Je plynem atomizovaný prášek lepší než vodou atomizovaný prášek? | Ano, plynem atomizované prášky jsou sféričtější, čistší a vhodnější pro 3D tisk. |

| Kolik stojí prášek Inconel 625 v roce 2025? | Ceny se pohybují od $80 až $150 na kg, v závislosti na čistota, velikost částic a dodavatel. |

| Kde mohu koupit vysoce kvalitní prášek Inconel 625? | Met3DP nabízí špičkové plynové atomizované a PREP prášky pro 3D tisk a průmyslové aplikace. |

Závěrečné myšlenky

Zůstává prášek Inconel 625 jeden z nejuniverzálnějších a nejvýkonnějších prášků na bázi niklu k dispozici v roce 2025. Ať už to potřebujete 3D tisk, letecký průmysl, energetická nebo korozivzdorná prostředí, výběr správného dodavatele a zajištění splnění standardů kvality je zásadní.

Na Met3DP, poskytujeme špičkové kovové prášky optimalizované pro SLM, EBM a další pokročilé výrobní technologie. Kontaktujte nás ještě dnes najděte perfektní prášek pro vaši aplikaci!

Získejte nejnovější cenu

O Met3DP

kategorie produktů

ŽHAVÁ SLEVA

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.