Čistý měděný prášek

Čistý měděný prášek obsahuje 99,5% nebo vyšší obsah mědi. Poskytuje vynikající tepelnou a elektrickou vodivost v kombinaci s dobrou odolností proti korozi, pájitelností a biologickou kompatibilitou.

Nízké MOQ

Poskytněte nízké minimální množství objednávky, abyste splnili různé potřeby.

OEM a ODM

Poskytujte přizpůsobené produkty a designové služby, které splňují jedinečné potřeby zákazníků.

Přiměřená zásoba

Zajistěte rychlé zpracování objednávek a poskytněte spolehlivé a efektivní služby.

Spokojenost zákazníků

Poskytujte vysoce kvalitní produkty s jádrem spokojenosti zákazníků.

sdílet tento produkt

Obsah

Přehled čistého měděného prášku

Čistý měděný prášek obsahuje 99,5% nebo vyšší obsah mědi. Poskytuje vynikající tepelnou a elektrickou vodivost v kombinaci s dobrou odolností proti korozi, pájitelností a biologickou kompatibilitou.

Hlavní vlastnosti a výhody čisté mědi v prášku:

Čistá měď v prášku Vlastnosti a charakteristiky

| Vlastnosti | Podrobnosti |

|---|---|

| Složení | 99,5% nebo vyšší obsah mědi |

| Hustota | 8,94 g/cc |

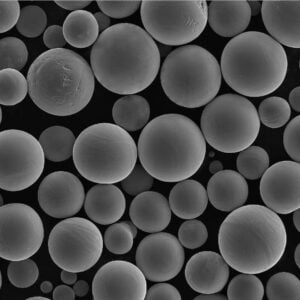

| Tvar částic | Sférické, nepravidelné |

| Rozsah velikostí | 1-150 mikronů |

| Zdánlivá hustota | Až 50% skutečné hustoty |

| Vodivost | Výborný, druhý nejlepší po stříbře |

| Pájitelnost | Vynikající díky odolnosti proti oxidaci |

| Biologická kompatibilita | Vysoká, bezpečná pro styk s potravinami |

Čistý měděný prášek je ideální pro aplikace, jako jsou svařovací výrobky, pájecí slitiny, třecí materiály, diamantové nástroje, elektrické kontakty a vstřikování kovů.

Složení prášku z čisté mědi

Typické složení čistého měděného prášku:

Složení prášku z čisté mědi

| Živel | Hmotnost % |

|---|---|

| měď (Cu) | 99.5% min |

| Kyslík (O) | 0,05% max |

| Olovo (Pb) | 0,005% max |

| Ostatní nečistoty | 0,005% max |

- Měď poskytuje vynikající vodivost a odolnost proti korozi

- Kyslík přítomný jako nečistota ovlivňuje vodivost a spékání

- Pečlivá kontrola olova a dalších nečistot

Vysoký obsah mědi, nízký obsah oxidů a minimum nečistot vedou k vynikající elektrické a tepelné vodivosti v kombinaci s dobrými mechanickými vlastnostmi.

Fyzikální vlastnosti čisté mědi v prášku

Fyzikální vlastnosti čisté mědi v prášku

| Vlastnictví | Hodnoty |

|---|---|

| Hustota | 8,94 g/cc |

| Bod tání | 1083°C |

| Tepelná vodivost | 400 W/mK |

| Elektrický odpor | 1,72 μΩ-cm |

| Teplota rekrystalizace | 200-300°C |

| Curieho teplota | -269°C |

- Vysoká hustota ve srovnání s hořčíkem nebo hliníkem

- Vynikající tepelná vodivost pro odvod tepla

- Nízký elektrický odpor zajišťuje vysokou vodivost

- Rekrystalizace umožňuje spékání a zlepšuje tažnost

- Odpor se zvyšuje nad Curieho bodem

Díky těmto vlastnostem je čistá měď vhodná pro vysoce vodivé součásti, jako jsou elektrické kontakty a kartáče.

Mechanické vlastnosti práškové čisté mědi

Mechanické vlastnosti práškové čisté mědi

| Vlastnictví | Hodnoty |

|---|---|

| Pevnost v tahu | 220-340 MPa |

| Pevnost v tahu | 69-172 MPa |

| Prodloužení | 35-60% |

| Tvrdost | 45-90 HB |

| Modul pružnosti | 110-130 GPa |

| Pevnost v tlaku | 500-700 MPa |

- Dobrá kombinace pevnosti a velmi vysoké tažnosti

- Relativně nízká tvrdost a vysoká kujnost

- Střední pevnost ve srovnání s vysokopevnostními slitinami

- Vlastnosti závisí na faktorech, jako je pórovitost a velikost zrn.

Díky těmto vlastnostem je čistá měď vhodná pro měkké, vysoce vodivé součásti vyžadující dobrou deformační a tlakovou pevnost.

Aplikace čisté mědi v prášku

Mezi typické aplikace čisté mědi v prášku patří:

Aplikace čisté mědi v prášku

| Průmysl | Používá |

|---|---|

| Elektrická zařízení | Kontakty, kartáče, svařovací elektrody |

| Elektronika | Vodivá lepidla, RF stínění |

| Automobilový průmysl | Kartáče, pouzdra, ložiska |

| Průmyslový | Diamantové nástroje, licí formy |

| Výrobní | Pájení slitin, prášková metalurgie |

| Třecí výrobky | Brzdové destičky, spojkové kotouče |

Některá specifická použití výrobku:

- Posuvné elektrické kontakty a kartáčky

- Chladiče a komponenty tepelného managementu

- Svařovací tyče, pájecí pasty a pájecí přídavné kovy

- Kompozity s kovovou matricí jako diamantové nástroje

- Síťové tvarové díly vyrobené vstřikováním kovů

- Pouzdra čerpadel, oběžná kola a další opotřebitelné díly

Díky vysoké vodivosti, odolnosti proti korozi, biokompatibilitě a střední pevnosti je čistá měď vhodná pro tuto rozmanitou škálu elektrických, tepelných a mírně opotřebitelných aplikací ve všech průmyslových odvětvích.

Specifikace čisté mědi v prášku

Klíčové specifikace čisté mědi v prášku zahrnují:

Specifikace čisté mědi v prášku

| Standard | Popis |

|---|---|

| ASTM B602 | Specifikace elektrolytické mědi ve formě prášku o vysoké čistotě |

| JIS H2111 | Specifikace pro elektrolytickou měď a prášky ze slitin mědi |

| ISO 3497 | Specifikace měděných prášků pro všeobecné použití |

| ASTM B243 | Pokyny ke zdánlivé hustotě a průtoku |

Ty definují:

- Minimální obsah mědi 99,5%

- Limity pro nečistoty, jako je kyslík a olovo

- Požadované vlastnosti prášku

- Zjevná hustota a průtok

- Schválená výrobní metoda - elektrolytická

- Protokoly o odběru vzorků a testování

Splnění těchto specifikací zajišťuje vhodnost pro aplikace, které vyžadují vysokou tepelnou a elektrickou vodivost v kombinaci s dobrými mechanickými vlastnostmi.

Velikost částic čisté mědi v prášku

Distribuce velikosti částic práškové čisté mědi

| Velikost | Charakteristika |

|---|---|

| 1-10 mikronů | Ultrajemná třída používaná v mikroelektronice |

| 10-30 mikronů | Jemná třída vhodná pro spékání |

| 30-150 mikronů | Hrubá třída má dobrý průtok pro lisování |

- Jemnější velikosti zajišťují vyšší hustotu spékání

- Hrubší prášek má lepší tekutost

- Rozsah velikostí přizpůsobený cílové aplikaci

- K dispozici jsou kulovité i nepravidelné tvary

Řízení distribuce velikosti částic optimalizuje chování při lisování, hustotu spékání a konečné vlastnosti dílů.

Prášek z čisté mědi Zdánlivá hustota

Prášek z čisté mědi Zdánlivá hustota

| Zdánlivá hustota | Podrobnosti |

|---|---|

| Až 50% skutečné hustoty | Pro nepravidelnou morfologii prášku |

| 3,5-5,0 g/cc typicky | Zlepšuje se s větší hustotou balení |

- Vyšší zdánlivá hustota zlepšuje tok a stlačitelnost prášku.

- Nepravidelná morfologie omezuje maximální hustotu balení

- Hodnoty až 60% dosažitelné se sférickým práškem

- Vysoká zdánlivá hustota umožňuje snadnější zhutňování

Vyšší zdánlivá hustota vede k účinnějšímu lisování prášku a spékání na plnou hustotu.

Výroba prášku z čisté mědi

Výroba prášku z čisté mědi

| Metoda | Podrobnosti |

|---|---|

| Elektrolýza | Měděné katody anodicky rozpuštěné na ionty Cu+ a nanesené na katody z nerezové oceli |

| Kulové frézování | Hrubý prášek rozdělený a roztříděný do určitých velikostí |

| Žíhání | Změkčuje částice prášku a zlepšuje stlačitelnost. |

| Snižování atmosféry | Zabraňuje oxidaci částic během výroby |

- Automatizovaný elektrolytický proces umožňuje výrobu ve velkém měřítku

- Mletí a prosévání zajišťuje řízenou distribuci velikosti částic

- Žíhání usnadňuje lisování a manipulaci

- Přísná kontrola procesu zajišťuje vysokou čistotu a opakovatelnou kvalitu.

Ceny čisté mědi v prášku

Ceny čisté mědi v prášku

| Faktor | Dopad na cenu |

|---|---|

| Stupeň čistoty | Vyšší čistota zvyšuje náklady |

| Velikost částic | Ultrajemný prášek je dražší |

| Objednané množství | Hromadné objednávky mají nižší ceny za jednotku |

| Způsob výroby | Další zpracování zvyšuje náklady |

| Balení | Speciální balení, jako je vakuové uzavírání, zvyšuje náklady |

Orientační ceny

- Ultrajemný čistý měděný prášek: $15-25 za kg

- Hrubý čistý měděný prášek: $10-15 za kg

- Velkoobjemové ceny mohou být 40% nižší

Cena závisí na čistotě, velikosti částic, způsobu výroby, objednaném množství, balení atd.

Dodavatelé čisté mědi v prášku

Dodavatelé čisté mědi v prášku

| Společnost | Umístění |

|---|---|

| Kymera International | USA |

| GGP Metalpowder | Německo |

| American Chemet Corporation | USA |

| Šanghaj CNPC Práškový materiál | Čína |

| Mitsui Kinzoku | Japonsko |

| Nuclead | Francie |

Faktory výběru dodavatelů:

- Nabízené úrovně a stupně čistoty

- Výrobní kapacita a dodací lhůty

- Průměrná velikost částic

- Přizpůsobení rozdělení velikosti

- Možnosti balení a objednací množství

- Úrovně cen na základě objemu

- Soulad s mezinárodními specifikacemi

Manipulace s práškovou čistou mědí a její skladování

Manipulace s práškem z čisté mědi

| Doporučení | Důvod |

|---|---|

| Zajistěte správné větrání | Zabraňte expozici jemným částicím |

| Používejte vhodné osobní ochranné prostředky | Zabraňte náhodnému požití |

| Dodržujte bezpečné protokoly | Snížení zdravotních rizik |

| Vyhněte se zdrojům vznícení | Nebezpečí hořlavého prachu |

| Pozemní zařízení | Zabraňte statickému výboji |

| Používejte nejiskřící nástroje | Zabránění možnosti vznícení |

Doporučení pro ukládání

- Skladujte ve stabilních nádobách na chladném a suchém místě.

- Omezte expozici kyselinám, čpavku, acetylenu.

- Udržování teplot pod 30 °C

Správná opatření při manipulaci a skladování pomáhají zachovat čistotu a předcházet bezpečnostním problémům.

Kontrola a testování práškové čisté mědi

Testování čisté mědi v prášku

| Test | Podrobnosti |

|---|---|

| Chemická analýza | ICP nebo XRF ověřuje složení |

| Distribuce velikosti částic | Laserová difrakční analýza |

| Zdánlivá hustota | Zkouška Hallovým průtokoměrem podle normy ASTM B212 |

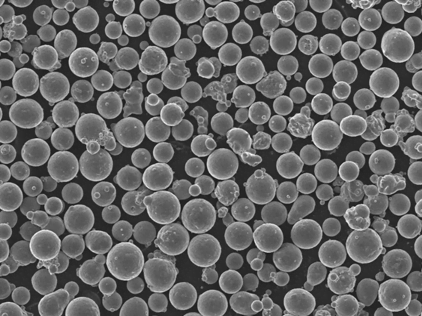

| Morfologie prášku | Zobrazení tvaru částic pomocí SEM |

| Zkouška hustoty kohoutku | Hustota měřená po mechanickém vyklepání |

| Analýza průtoku | Gravitační průtok určenou nálevkou |

Testování zajišťuje, že prášek splňuje požadované úrovně čistoty, charakteristiky částic, specifikace hustoty, morfologie a tekutosti podle platných norem.

Čistá měď v prášku klady a zápory

Výhody čisté mědi v prášku

- Vynikající tepelná a elektrická vodivost

- Dobrá odolnost proti korozi a biokompatibilita

- Vysoká čistota zajišťuje optimální výkon

- Snadné spékání a lisování do komponentů s vysokou hustotou

- Tažné a kujné

- Recyklovatelné a ekologicky udržitelné

Omezení čisté mědi v prášku

- Nižší pevnost než u mnoha práškových slitin

- Mírná odolnost proti oxidaci při vysokých teplotách

- Těžké ve srovnání s hořčíkem nebo hliníkem

- Nevhodné pro aplikace s vysokým opotřebením nebo zatížením

- Citlivé na kontaminaci zinkem a sírou

- Pokud není potažen, postupně se časem matuje.

Srovnání s mosaznými a bronzovými prášky

Čistá měď vs. mosazné a bronzové prášky

| Parametr | Čistá měď | Mosaz/bronz |

|---|---|---|

| Hustota | 8,94 g/cc | 8,7-8,8 g/cc |

| Síla | 220-340 MPa | 350-550 MPa |

| Vodivost | Vynikající | Dobrý |

| Odolnost proti korozi | Vynikající | Dobrý |

| Náklady | Nízký | Mírný |

| Používá | Elektrické, tepelné | Hardware, dekorativní |

- Čistá měď má vyšší vodivost a tažnost.

- Vyšší pevnost mosazi/bronzu

- Čistá měď je vhodnější pro tepelný management

- Mosaz/bronz používaný na kování a dekorativní předměty

Nejčastější dotazy týkající se čisté mědi

Otázka: Jaké jsou hlavní aplikace čisté mědi v prášku?

Odpověď: Mezi hlavní aplikace patří elektrické kontakty a kartáče, svařovací tyče, pájecí slitiny, diamantové nástroje, chladiče, síťové tvarové součásti vyrobené práškovou metalurgií, třecí materiály a vodivá lepidla.

Otázka: Jaká opatření je třeba dodržovat při práci s čistým měděným práškem?

Odpověď: Doporučená bezpečnostní opatření zahrnují řádné větrání, vhodné osobní ochranné prostředky, protokoly o bezpečné manipulaci, uzemnění zařízení, vyhýbání se zdrojům vznícení, používání nejiskřivých nástrojů a skladování ve stabilních inertních nádobách mimo dosah kontaminantů.

Otázka: Jak se liší čistá prášková měď od elektrolytické houževnaté mědi (ETP)?

Odpověď: Čistý měděný prášek má obsah mědi 99,5% nebo vyšší, zatímco měděný prášek ETP má minimálně 99,5% mědi. Čistá měď poskytuje o něco vyšší vodivost, ale pro běžné aplikace jsou tyto dvě mědi většinou zaměnitelné.

Otázka: Co ovlivňuje vlastnosti dílů vyrobených z čistého měděného prášku?

Odpověď: Klíčovými faktory jsou zdánlivá hustota, složení prášku, distribuce velikosti částic, hutnící tlak, parametry spékání, přítomnost nečistot a pórovitost konečného dílu.

Získejte nejnovější cenu

O Met3DP

kategorie produktů

ŽHAVÁ SLEVA

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731