T15 prášek

Prášek T15 je prášek z cementovaného karbidu wolframu a kobaltu, který poskytuje výjimečnou kombinaci tvrdosti, pevnosti a houževnatosti. Obsahuje vysoký podíl karbidu wolframu spolu s kobaltem 15% jako pojivovou fází.

Nízké MOQ

Poskytněte nízké minimální množství objednávky, abyste splnili různé potřeby.

OEM a ODM

Poskytujte přizpůsobené produkty a designové služby, které splňují jedinečné potřeby zákazníků.

Přiměřená zásoba

Zajistěte rychlé zpracování objednávek a poskytněte spolehlivé a efektivní služby.

Spokojenost zákazníků

Poskytujte vysoce kvalitní produkty s jádrem spokojenosti zákazníků.

sdílet tento produkt

Obsah

Přehled prášku T15

Prášek T15 je prášek z cementovaného karbidu wolframu a kobaltu, který poskytuje výjimečnou kombinaci tvrdosti, pevnosti a houževnatosti. Obsahuje vysoký podíl karbidu wolframu spolu s kobaltem 15% jako pojivovou fází.

Hlavní vlastnosti a výhody prášku T15:

Vlastnosti a charakteristika prášku T15

| Vlastnosti | Podrobnosti |

|---|---|

| Složení | 85% WC s pojivem 15% Co |

| Hustota | 13,0-14,5 g/cc |

| Tvar částic | Zaoblené, mnohostranné |

| Rozsah velikostí | 0,5-15 mikronů |

| Tvrdost | 88-93 HRA při spékání |

| Pevnost v příčném zlomu | 550-650 MPa |

Díky ultra tvrdým částicím karbidu wolframu v kobaltové matrici je T15 ideální pro nejextrémnější podmínky opotřebení a otěru v průmyslových, těžebních a stavebních odvětvích.

Složení prášku T15

Typické složení práškového cementovaného karbidu T15:

Složení prášku T15

| Komponent | Hmotnost % |

|---|---|

| Karbid wolframu (WC) | 84-86% |

| Kobalt (Co) | 14-16% |

| uhlík (C) | 0,8% max |

| Kyslík (O) | 0,5% max |

| železo (Fe) | 0,3% max |

| nikl (Ni) | 0,3% max |

- Karbid wolframu poskytuje extrémní tvrdost a odolnost proti opotřebení.

- Kobalt působí jako houževnaté a tvárné pojivo, které drží částice WC pohromadě.

- Uhlík a kyslík přítomné jako nečistoty

- Stopové množství železa, niklu ze surovin

Optimalizovaný poměr WC-Co poskytuje nejlepší kombinaci tvrdosti, lomové houževnatosti a rázové houževnatosti potřebnou pro opotřebení.

T15 Prášek Fyzikální vlastnosti

T15 Prášek Fyzikální vlastnosti

| Vlastnictví | Hodnoty |

|---|---|

| Hustota | 13,0-14,5 g/cc |

| Bod tání | 2870 °C (WC) a 1495 °C (Co) |

| Tepelná vodivost | 60-100 W/mK |

| Elektrický odpor | 25-35 μΩ-cm |

| Koeficient tepelné roztažnosti | 4,5-6,0 x 10^-6 /K |

| Maximální provozní teplota | 500 °C na vzduchu |

- Velmi vysoká hustota umožňuje použití v kompaktních, miniaturizovaných komponentech.

- Velmi nízká CTE snižuje tepelné namáhání a deformace.

- Snáší nepřetržitý provoz až do 500 °C

- Dobrá tepelná vodivost snižuje teplotní gradienty

Díky těmto vlastnostem je T15 vhodný pro těžké podmínky otěru a opakovaných nárazů, které se vyskytují v důlním, vrtném a stavebním prostředí.

Mechanické vlastnosti prášku T15

Mechanické vlastnosti prášku T15

| Vlastnictví | Hodnoty |

|---|---|

| Tvrdost | 88-93 HRA |

| Pevnost v příčném zlomu | 550-650 MPa |

| Pevnost v tlaku | 5500-6200 MPa |

| Lomová houževnatost | 10-12 MPa.m^1/2 |

| Youngův modul | 550-650 GPa |

| Pevnost v nárazu | 350-900 kJ/m2 |

- Extrémní tvrdost zajišťuje odolnost proti opotřebení a oděru.

- Velmi vysoká pevnost v tlaku odolává tlakovým silám.

- Přiměřená lomová houževnatost a rázová pevnost

- Tvrdost a pevnost podle velikosti a rozložení částic WC

Díky této výjimečné kombinaci tvrdosti, pevnosti a houževnatosti je T15 vhodný pro nejtěžší podmínky opotřebení v důsledku úderů, otěru a drážkování.

Aplikace prášku T15

Mezi typické aplikace prášku z karbidu wolframu a kobaltu T15 patří:

Aplikace prášku T15

| Průmysl | Příklad použití |

|---|---|

| Těžba | Vrtáky do kamene, trysky pro tryskání pískem |

| Konstrukce | Demoliční nářadí, drtiče kamene |

| Výrobní | Tvářecí formy, díly pro tažení kovů |

| Ropa a plyn | Stabilizátory, motory do vrtu |

| Obecné | Řezné a obráběcí nástroje |

Některá specifická použití výrobku:

- Příklepové vrtáky do hornin, důlní vrtací nástroje

- Vysoce abrazivní díly kalových čerpadel, jako jsou hřídele, oběžná kola.

- Vytlačovací formy pro výrobu cihel a keramiky

- Komponenty odolné proti opotřebení v pískovacích zařízeních

- Řezné čepele, nože, pilové zuby vyžadující extrémní tvrdost

Díky své bezkonkurenční tvrdosti a opotřebení je T15 nejlepší volbou pro zařízení používaná v nejtěžších podmínkách otlaků a oděru v průmyslových odvětvích.

Specifikace prášku T15

Klíčové specifikace pro práškový cementovaný karbid T15:

Práškové normy T15

| Standard | Popis |

|---|---|

| ISO 513 | Klasifikace a použití cementovaných karbidů |

| ASTM B276 | Prášky z karbidu kobaltu a wolframu a tvrdé kovy |

| JIS G 4053 | Spékané tvrdé kovy |

| GB/T 4661-2006 | Čínská norma pro cementované karbidy |

Ty definují:

- Chemické složení - obsah Co a WC

- Velikost zrn karbidu a distribuce velikosti částic prášku

- Požadované mechanické vlastnosti

- Přípustné nečistoty

- Schválené výrobní metody jako nauhličování a redukční difúze

Splnění těchto specifikací zajišťuje optimální kombinaci tvrdosti, pevnosti a houževnatosti pro maximální výkon při opotřebení.

Velikost částic prášku T15

T15 Distribuce velikosti částic prášku

| Velikost částic | Charakteristika |

|---|---|

| 0,5-2 mikronů | Ultrajemná třída poskytuje superfiniš |

| 0,5-5 mikronů | Submikronový rozsah zvyšuje houževnatost |

| 3-15 mikronů | Nejčastěji používaná velikost pro optimální vlastnosti |

- Jemnější prášky zvyšují tvrdost a povrchovou úpravu

- Hrubší prášky zvyšují pevnost v lomu a odolnost proti nárazu

- Rozložení velikosti částic je optimalizováno na základě provozních podmínek.

- Použité drcené i slinuté karbidové prášky

Řízení distribuce velikosti částic a morfologie optimalizuje vlastnosti a výkonnost finální součásti.

Metoda výroby prášku T15

Výroba prášku T15

| Metoda | Podrobnosti |

|---|---|

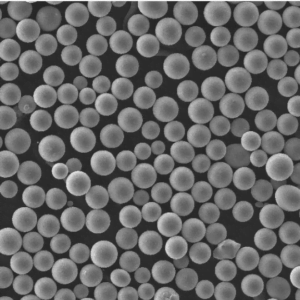

| Karbonizace a redukční difúze | Vyrábí jemné sférické prášky |

| Drcení slinutého materiálu | Nižší náklady, nepravidelné úhlové částice |

| Frézování | Kulové mletí používané ke zmenšování velikosti částic |

| Sušení rozprašováním | Proces granulace a sféroidizace |

| Odplyňování | Odstraňuje plynné nečistoty |

- Sférická morfologie prášku zajišťuje vysokou hustotu balení

- Drcené prášky mají nižší výrobní náklady

- Frézování, sušení rozprašováním používané pro kontrolu velikosti částic

- Odplynění optimalizuje čistotu prášku a spékané mikrostruktury

Výsledkem automatizovaných velkoobjemových výrobních procesů jsou konzistentní vstupní suroviny optimalizované pro výkonnost dílů.

Ceny prášku T15

Ceny prášku T15

| Faktor | Dopad na cenu |

|---|---|

| Třída prášku | Vyšší stupně čistoty jsou dražší |

| Velikost částic | Ultrajemný prášek je dražší |

| Objednané množství | Cena klesá s většími objemy |

| Způsob výroby | Složité metody zvyšují náklady |

| Balení | Speciální sáčky nebo plechovky zvyšují náklady |

Orientační ceny

- Sférický prášek T15: $45-60 na kg

- T15 drcený prášek: $35-45 na kg

- Velkoobjemové ceny mohou být o 20-30% nižší.

Cena závisí na vlastnostech prášku, způsobu výroby, velikosti objednávky, balení a době dodání.

Dodavatelé prášku T15

Dodavatelé prášku T15

| Společnost | Umístění |

|---|---|

| Sandvik | Švédsko |

| Kennametal | USA |

| HC Starck | Německo |

| Jingdong Nový materiál | Čína |

| Skupina Zhuzhou Cemented Carbide Group | Čína |

| Materiály společnosti Toshiba | Japonsko |

Výběrové faktory:

- Třídy prášku a morfologie částic

- Výrobní kapacita a dodací lhůty

- Technické znalosti a zákaznický servis

- Postupy odběru vzorků, testování a kontroly kvality

- Cenové úrovně a platební podmínky

- Soulad s mezinárodními normami pro materiály

T15 Manipulace s práškem a jeho skladování

T15 Manipulace s práškem

| Doporučení | Důvod |

|---|---|

| Používejte osobní ochranné prostředky a ventilaci | Zabraňte expozici jemným částicím |

| Vyhněte se zdrojům vznícení | Prášek se může při přehřátí na vzduchu vznítit. |

| Dodržujte bezpečné protokoly | Snížení zdravotních a požárních rizik |

| Použití inertní atmosféry | Zabránění oxidaci při zpracování prášku |

| Skladujte uzavřené nádoby | Zabránit kontaminaci nebo absorpci |

Doporučení pro ukládání

- Skladujte ve stabilních obalech a při okolní teplotě

- Omezte působení vlhkosti, kyselin, chlóru

- Zabraňte křížové kontaminaci jinými prášky

Správná opatření zachovávají čistotu prášku a zabraňují bezpečnostním problémům při manipulaci a skladování.

T15 Kontrola a testování prášku

Testování prášku T15

| Test | Podrobnosti |

|---|---|

| Chemická analýza | Ověřuje složení pomocí ICP, EDX nebo XRF. |

| Distribuce velikosti částic | Laserová difrakční nebo sedimentační analýza |

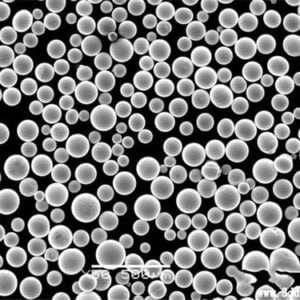

| Morfologie prášku | Zobrazení tvaru částic pomocí SEM |

| Zdánlivá hustota | Měřeno podle normy ASTM B212 |

| Hustota poklepání | Hustota měřená po mechanickém vyklepání |

| Hallův průtok | určuje sypkost prášku |

Testování zajišťuje, že prášek splňuje požadované chemické složení, vlastnosti částic, morfologii, specifikace hustoty a tekutost podle příslušných norem.

Výhody a nevýhody prášku T15

Výhody prášku T15

- Výjimečná tvrdost, odolnost proti opotřebení a pevnost

- Odolává vysokému stlačení bez porušení

- Dobrá lomová houževnatost a odolnost proti nárazu

- Rozměrová stabilita při velkém zatížení

- Odolává deformaci při zvýšených teplotách

- Umožňuje použití menších a lehčích součástí

Omezení prášku T15

- Obtížné obrábění po spékání

- Nevhodné pro aplikace s dynamickými ložisky

- Relativně křehké chování

- Oxidace při vysokých teplotách bez odolných povlaků

- Vyšší náklady na suroviny než u ocelových prášků

- Pro optimální použití jsou nutné odborné zkušenosti

Srovnání s karbidem wolframu, karbidem titanu a karbidem tantalu

T15 vs WC-TiC-TaC

| Parametr | T15 | WC-TiC-TaC |

|---|---|---|

| Tvrdost | 88-93 HRA | 92-96 HRA |

| Lomová houževnatost | 10-12 MPa.m^1/2 | 8-9 MPa.m^1/2 |

| Síla | Velmi vysoko | Extrémně vysoká |

| Náklady | Mírný | Velmi vysoko |

| Odolnost proti korozi | Veletrh | Vynikající |

| Aplikace | Obecné opotřebitelné díly | Extrémní otěr a koroze |

- WC-TiC-TaC má mírně vyšší tvrdost a pevnost.

- T15 poskytuje výrazně lepší lomovou houževnatost

- WC-TiC-TaC nabízí vynikající odolnost proti korozi

- T15 je nákladově efektivnější

- WC-TiC-TaC pro kritičtější a dražší aplikace

Nejčastější dotazy k prášku T15

Otázka: Jaké jsou hlavní aplikace kobaltového prášku z karbidu wolframu T15?

Odpověď: Hlavní aplikace zahrnují důlní nástroje, jako jsou vrtáky, drtiče hornin a bagrovací zařízení; stavební nástroje, jako jsou demoliční a drticí zařízení; zápustky, výkresové díly, vytlačovací nástroje; součásti odolné proti otěru; a obecné řezné a obráběcí nástroje.

Otázka: Proč se kobalt používá jako pojivo ve třídách karbidu wolframu?

Odpověď: Kobalt zajišťuje dobrou odolnost proti korozi, vysokou pevnost a houževnatost a usnadňuje slinování částic karbidu wolframu v kapalné fázi během zhušťování, aby se dosáhlo plné hustoty a optimálních vlastností.

Otázka: Jaké tepelné zpracování se používá pro díly z karbidu wolframu a kobaltu T15?

Odpověď: T15 nevyžaduje tepelné zpracování po spékání. Proces spékání v kapalné fázi umožňuje dosáhnout plné hustoty a požadovaných vlastností během samotné konsolidace prášku.

Otázka: Jak se vyrábí kobaltový prášek z karbidu wolframu T15?

A: Mezi hlavní výrobní metody patří nauhličování a redukční difúze pro výrobu sférických prášků nebo drcení a frézování slinutého materiálu karbidu wolframu na nepravidelné částice. Tyto prášky se pak smíchají s kobaltovým práškem v požadovaném poměru.

Získejte nejnovější cenu

O Met3DP

kategorie produktů

ŽHAVÁ SLEVA

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731