Prášek ze slitiny TiNbZrSn

Prášek slitiny TiNbZrSn je pokročilý kompozitní materiál s výjimečnými vlastnostmi, díky kterému je vhodný pro širokou škálu náročných aplikací. Tento článek poskytuje komplexní přehled prášku TiNbZrSn včetně jeho složení, charakteristik, výrobních metod, aplikací, dodavatelů a dalších.

Nízké MOQ

Poskytněte nízké minimální množství objednávky, abyste splnili různé potřeby.

OEM a ODM

Poskytujte přizpůsobené produkty a designové služby, které splňují jedinečné potřeby zákazníků.

Přiměřená zásoba

Zajistěte rychlé zpracování objednávek a poskytněte spolehlivé a efektivní služby.

Spokojenost zákazníků

Poskytujte vysoce kvalitní produkty s jádrem spokojenosti zákazníků.

sdílet tento produkt

Obsah

Složení prášku slitiny TiNbZrSn

Prášek slitiny TiNbZrSn se skládá z následujících prvků:

| Živel | Hmotnost % |

|---|---|

| titan (Ti) | 35-40% |

| niob (Nb) | 35-40% |

| zirkonium (Zr) | 5-10% |

| Cín (Sn) | 5-10% |

Díky této přesné kombinaci titanu, niobu, zirkonia a cínu vzniká slitina s mimořádnou pevností, tvrdostí a pružností ve srovnání s běžnými slitinami. Zejména obsah niobu výrazně zvyšuje mechanické vlastnosti.

Pečlivým řízením poměrů jednotlivých kovů lze optimalizovat vlastnosti práškové slitiny pro různé aplikace vyžadující vysokou pevnost v poměru k hmotnosti, odolnost proti korozi, biokompatibilitu nebo odolnost při vysokých teplotách.

Vlastnosti prášku slitiny TiNbZrSn

Prášek ze slitiny TiNbZrSn vykazuje následující výjimečné vlastnosti:

| Vlastnictví | Popis |

|---|---|

| Vysoká pevnost | Pevnost v tahu přes 1400 MPa, srovnatelná s pokročilými leteckými slitinami. |

| Nízká hustota | Hustota kolem 6,5 g/cm3, mnohem nižší než u oceli. |

| Vynikající pružnost | Youngův modul kolem 100 GPa, což umožňuje flexibilitu. |

| Vysoká tvrdost | Tvrdost podle Vickerse vyšší než 450 HV, lepší odolnost proti oděru než nerezová ocel. |

| Dobrá odolnost proti korozi | Odolnost proti korozi v drsném prostředí |

| Biokompatibilita | Netoxické a vhodné pro lékařské implantáty |

| Vysoký bod tání | Tavení při teplotách nad 2500 °C, což umožňuje použití při vysokých teplotách. |

Kombinace vysoké pevnosti, nízké hmotnosti, tvrdosti a pružnosti je vzácná a činí z TiNbZrSn mimořádně univerzální materiál. V mnoha vlastnostech překonává běžné slitiny, jako je nerezová ocel.

Výroba prášku ze slitiny TiNbZrSn

Prášek ze slitiny TiNbZrSn lze vyrábět následujícími pokročilými metodami:

| Metoda | Popis |

|---|---|

| Rozprašování plynu | Roztavená slitina rozprašovaná do jemných kapiček, které tuhnou v prášek. |

| Plazmový proces s rotujícími elektrodami (PREP) | Elektroda se v plazmovém oblouku rychle otáčí a rozpadá se na prášek. |

| Hydrid-dehydrid (HDH) | Slitina je hydrogenována, mechanicky rozdrcena na prášek a poté odhydrogenována. |

Plynová atomizace umožňuje kontrolu nad distribucí velikosti částic a výsledkem je hladký sférický prášek ideální pro aditivní výrobu. Metody PREP a HDH umožňují hospodárnou výrobu nepravidelného prášku vhodného pro lisování a spékání.

Složení slitiny lze při těchto procesech výroby prášku přesně dodržet, což zajišťuje konzistentní vlastnosti. Vysoce čistá atmosféra inertního plynu zabraňuje kontaminaci.

Aplikace prášku ze slitiny TiNbZrSn

Díky svým vyváženým materiálovým vlastnostem se prášek ze slitiny TiNbZrSn používá v následujících aplikacích:

| Průmysl | aplikace |

|---|---|

| Aerospace | Součásti leteckých a raketových motorů, kosmické systémy |

| Automobilový průmysl | Pružiny ventilů, spojovací materiál, pohony |

| Lékařský | Implantáty, protézy, zařízení |

| Obrana | Výzbroj, munice, balistika |

| Aditivní výroba | 3D tištěné díly s vysokou pevností |

| Chemické zpracování | Korozivzdorné nádoby, potrubí |

Díky kombinaci pevnosti, tvrdosti a biokompatibility je TiNbZrSn vhodný pro nosné implantáty, jako jsou kyčelní a kolenní klouby. Jeho odolnost proti korozi je vhodná pro námořní aplikace vystavené mořské vodě. A jeho odolnost při vysokých teplotách je výhodou v proudových motorech a turbínách.

V porovnání s běžnými slitinami umožňuje TiNbZrSn vyrábět lehčí, pevnější a trvanlivější součásti, což mu dává výhodu v náročných průmyslových odvětvích.

Specifikace prášku slitiny TiNbZrSn

Prášek slitiny TiNbZrSn je komerčně dostupný v následujících specifikacích:

| Atribut | Podrobnosti |

|---|---|

| Velikost částic | 15-45 mikronů, 45-106 mikronů, 106-250 mikronů |

| Tvar částic | Sférické, nepravidelné |

| Čistota | Až 99,9% |

| Obsah kyslíku | Pod 2000 ppm |

| Třídy prášku | Třída 5, 23, 23 ELI |

| Dodací formulář | Sypký prášek, slinuté předlisky |

K dispozici je jak sférický prášek rozprašovaný plynem, tak nepravidelný prášek z HDH nebo PREP. Menší prášek o velikosti 15-45 mikronů je vhodný pro aditivní výrobu, která vyžaduje dobrou tekutost a balení. Větší 106-250mikronový prášek se obvykle lisuje a spéká.

Normy jako ASTM F1805 a ISO 5832 stanoví limity složení a požadované vlastnosti pro biomedicínský prášek 23 ELI. Pro splnění požadavků aplikací lze také vyrobit vlastní složení slitiny a velikost částic.

Dodavatelé prášku ze slitiny TiNbZrSn

Mezi přední světové dodavatele práškové slitiny TiNbZrSn patří:

| Dodavatel | Umístění |

|---|---|

| AMETEK | USA |

| Prášek CNPC | Čína |

| GKN Hoeganaes | Evropa |

| Technologie LPW | Spojené království |

| Sandvik Osprey | Spojené království |

Takoví renomovaní dodavatelé mají moderní vlastní zařízení na výrobu prášků pomocí plynové atomizace nebo hydrid-dehydridových procesů. Mohou poskytovat různé distribuce velikosti částic a přizpůsobit složení slitiny podle potřeby.

K dispozici jsou malé série prototypů až po velké komerční objemy. Dodavatelé provádějí přísnou kontrolu kvality a testování, aby zajistili, že prášek splňuje specifikace.

Ceny prášku ze slitiny TiNbZrSn

Prášek TiNbZrSn, jakožto pokročilá speciální slitina, má prémiovou cenu:

| Stupeň prášku | Cenové rozpětí |

|---|---|

| 5. třída | $350-$500 za kg |

| Třída 23 | $450-$650 za kg |

| Třída 23 ELI | $550-$750 za kg |

Cena závisí na objednaném množství, distribuci velikosti částic, tvaru a složení. Menší množství jemného sférického prášku je dražší. Nepravidelný prášek a větší šarže nabízejí úsporu nákladů.

Cena je několikanásobně vyšší než u běžných slitin, jako je prášková nerezová ocel 316L. Vynikající vlastnosti však ospravedlňují vyšší cenu u kritických aplikací vyžadujících maximální výkon.

Manipulace s práškem slitiny TiNbZrSn

Bezpečná manipulace s práškem slitiny TiNbZrSn:

- Skladujte uzavřené nádoby v chladném a suchém prostředí, abyste zabránili oxidaci a hydrataci.

- Zabraňte rozsypání, aby nedošlo k nahromadění prášku jako nebezpečí výbuchu.

- uzemnění všech zařízení pro manipulaci s práškem a přepravních nádob

- Při manipulaci s práškem používejte rukavice a ochranu dýchacích cest.

- Používejte nejiskřící nářadí a vakuové systémy s inertním plynem.

- V případě potřeby použijte větrání a bodové odsávání kouře.

Díky jemné velikosti částic je prášek TiNbZrSn při rozptýlení hořlavý. Je nutné s ním zacházet opatrně a dodržovat bezpečnostní protokoly. Doporučuje se automatizovaná manipulace v rukavicových skříňkách a ochranné systémy.

Kontrola prášku slitiny TiNbZrSn

Prášek slitiny TiNbZrSn by měl být kontrolován z hlediska:

| Parametr | Metoda | Kritéria přijatelnosti |

|---|---|---|

| Distribuce velikosti částic | Laserová difrakce, prosévání | Splňuje stanovený rozsah |

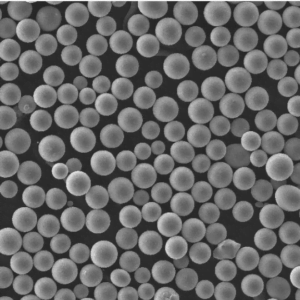

| Tvar částic | Zobrazování pomocí SEM | Sférické, hladké povrchy |

| Chemie částic | EDX/EDS, ICP-OES | Odpovídá stanovenému složení |

| Kyslík/dusík | Fúze inertních plynů | Pod 2000 ppm kyslíku |

| Zdánlivá hustota | Hallův průtokoměr | Lepší průtok pro vyšší hustotu |

| Průtoková rychlost | Hallův průtokoměr | Volně protéká otvorem |

Tyto testy zajišťují, že prášek splňuje specifikace týkající se velikosti, tvaru, chemického složení, čistoty a tekutosti, které jsou vyžadovány pro použití při AM nebo lisování a spékání.

Testování práškové slitiny TiNbZrSn

Pro kvalifikaci prášku slitiny TiNbZrSn lze provést následující další zkoušky:

| Test | Metoda | Účel |

|---|---|---|

| Stlačitelnost | Jednoosé lisování | Vyhodnocení reakce na zhutnění |

| Síla zelené barvy | Pevnost v příčném zlomu | Měření pevnosti před spékáním |

| Hustota po spékání | Měření rozměrů | Zajištění úplné konsolidace |

| Mikrostruktura | Optická mikroskopie, SEM | Hodnocení tání, pórovitosti, zrn |

| Tvrdost | Testy Vickers/Rockwell | Ověření mechanických vlastností |

| Pevnost v tahu | ASTM E8 | Měření UTS, kluzu, prodloužení |

Testování stlačených a slinutých vzorků je vhodné pro potvrzení zpracovatelnosti prášku a konečných mechanických vlastností v porovnání s konstrukčními požadavky.

Prášek ze slitiny TiNbZrSn Výhody a nevýhody

| Výhody | Nevýhody |

|---|---|

| Výjimečný poměr pevnosti a hmotnosti | Drahé ve srovnání s běžnými slitinami |

| Vyšší pružnost než u jiných vysokopevnostních slitin | Nižší tažnost než u slitin titanu |

| Vynikající tvrdost a odolnost proti opotřebení | Vyžaduje opatrné zacházení kvůli reaktivitě |

| Odolnost proti korozi v drsném prostředí | Obtížné obrábění a broušení |

| Biokompatibilní pro lékařské použití | Omezení dodavatelé a dostupnost |

| Odolává extrémně vysokým teplotám | Pro úplnou konsolidaci je nutné lisování za tepla. |

Pro kritické aplikace, kde výkon převažuje nad náklady, poskytuje prášek ze slitiny TiNbZrSn vlastnosti, které jsou nesrovnatelné s jinými slitinami. Hlavními omezeními jsou cena a dostupnost.

Srovnání TiNbZrSn s jinými slitinami

Jak si TiNbZrSn stojí v porovnání s jinými vysoce výkonnými slitinovými prášky?

Oproti nerezové oceli:

- 2x vyšší pevnost

- 70% nižší hustota

- 5x vyšší tvrdost

- Lepší odolnost proti korozi

Oproti slitinám titanu:

- 50% vyšší pružnost

- 20% vyšší tvrdost

- Lepší odolnost proti tečení

- Nižší tažnost

Oproti kobalt-chromovým slitinám:

- Nižší hustota

- Žádné toxické účinky

- Vyšší provozní teplota

- Nižší houževnatost

Oproti superslitinám na bázi Ni:

- Snadnější zpracování

- Nižší náklady

- Schopnost pracovat při nižších teplotách

- Nižší pevnost v tahu

TiNbZrSn tak představuje optimální poměr vlastností, které u jiných slitin nenajdete, a je tak vhodný pro nejnáročnější aplikace.

Prášek ze slitiny TiNbZrSn - přehled o použití

Zde je několik klíčových informací o efektivním použití TiNbZrSn:

- Plynem rozprašovaný prášek s řízenou distribucí velikosti částic nejlépe teče a balí se pro AM

- Nepravidelný prášek vyžaduje vyšší tlaky pro zhutnění a spékání.

- Izostatické lisování za tepla pomáhá dosáhnout maximální hustoty a vlastností.

- Žíhání lze použít k přizpůsobení tažnosti a houževnatosti podle potřeby.

- Díly s téměř čistým tvarem minimalizují nákladné obrábění spékaných součástí.

- Povrchové úpravy zvyšují odolnost proti opotřebení pro aplikace s kluzným kontaktem

- Spojování nepodobných materiálů s TiNbZrSn vyžaduje volbu vhodného postupu.

- Přísná kvalifikace a testování dodavatelů pomáhá zajistit kvalitu a výkon prášku.

Pro plné využití potenciálu této výjimečné slitiny je důležité porozumět vztahům mezi zpracováním, mikrostrukturou a vlastnostmi.

Často kladené otázky

Zde je několik nejčastějších dotazů týkajících se práškové slitiny TiNbZrSn:

Otázka: Je prášek TiNbZrSn kompatibilní s 3D tiskem?

Odpověď: Ano, TiNbZrSn rozprašovaný plynem s řízenou velikostí částic a vysokou sféricitou lze použít pro procesy AM s tavením v práškovém loži a usměrněnou energetickou depozicí. Pro dosažení vysoké hustoty je třeba optimalizovat parametry.

Otázka: Jaká velikost částic je nejlepší pro aditivní výrobu?

Odpověď: Doporučuje se 15-45 mikronů, což zajišťuje dobrý tok prášku a jeho balení. Pro některé aplikace vyžadující silnější vrstvy byly úspěšně vytištěny i větší velikosti až 106 mikronů.

Otázka: Vyžaduje TiNbZrSn po AM lisování za tepla izostatické lisování?

Odpověď: HIP pomáhá maximalizovat hustotu, eliminovat vnitřní póry a zlepšit mechanické vlastnosti. Pro některé méně náročné aplikace však mohou díly vytištěné as-printem z TiNbZrSn splňovat požadavky i bez HIP.

Otázka: Můžete obrábět a brousit slitinu TiNbZrSn?

Odpověď: Ano, ale vyžaduje pevné nastavení, vysokotlakou chladicí kapalinu, ostré karbidové nástroje a jemné brusivo. Rychlosti posuvu a otáčky musí být nižší než u běžných slitin kvůli jejich tvrdosti.

Otázka: Je TiNbZrSn vhodný pro biomedicínské implantáty?

Odpověď: Ano, díky své biokompatibilitě, nízkému modulu a vysoké pevnosti, která je ideální pro nosná zařízení, se používá pro kostní destičky, kyčelní a kolenní implantáty. Prášek ELI třídy 23 poskytuje potřebnou čistotu.

Otázka: Jaké jsou typické aplikace slitiny TiNbZrSn?

Odpověď: Letecké komponenty, jako jsou podvozky, automobilové pružiny a spojovací prvky, biomedicínské implantáty, pancéřové desky, turbíny pro výrobu energie a nástroje pro lisování a lisování plechů.

Závěr

Souhrnně lze říci, že prášková slitina TiNbZrSn nabízí mimořádnou pevnost spojenou s nízkou hustotou, pružností a tvrdostí, která se nepodobá žádným jiným běžným ani pokročilým slitinám. Ačkoli jsou náklady vyšší, mnoho aplikací s kritickým výkonem ospravedlňuje tyto výdaje tam, kde jsou optimalizované vlastnosti materiálu prvořadé. Díky rozšířené dostupnosti a probíhajícím inovacím budou jedinečné schopnosti TiNbZrSn v příštích letech využívány ve více průmyslových odvětvích.

Získejte nejnovější cenu

O Met3DP

kategorie produktů

ŽHAVÁ SLEVA

KONTAKTUJTE NÁS

Nějaké otázky? Pošlete nám zprávu hned teď! Po obdržení vaší zprávy obsloužíme vaši žádost s celým týmem.

Kovové prášky pro 3D tisk a aditivní výrobu

SPOLEČNOST

PRODUKT

kontaktní informace

- Město Qingdao, Shandong, Čína

- [email protected]

- [email protected]

- +86 19116340731