Metallpulver für Halbleiter

Inhaltsübersicht

In der sich ständig weiterentwickelnden Welt der Halbleiter spielen Metallpulver eine zentrale Rolle. Von der Entwicklung von Mikroprozessoren bis hin zur Entwicklung fortschrittlicher Speichermedien sind Metallpulver die unbesungenen Helden, die diese technologischen Wunder ermöglichen. Dieser Artikel befasst sich mit den Feinheiten von Metallpulver für Halbleiter, ihre Typen, Zusammensetzungen, Anwendungen, Spezifikationen und mehr. Lassen Sie uns dieses faszinierende Thema im Detail erkunden.

Übersicht über Metallpulver für Halbleiter

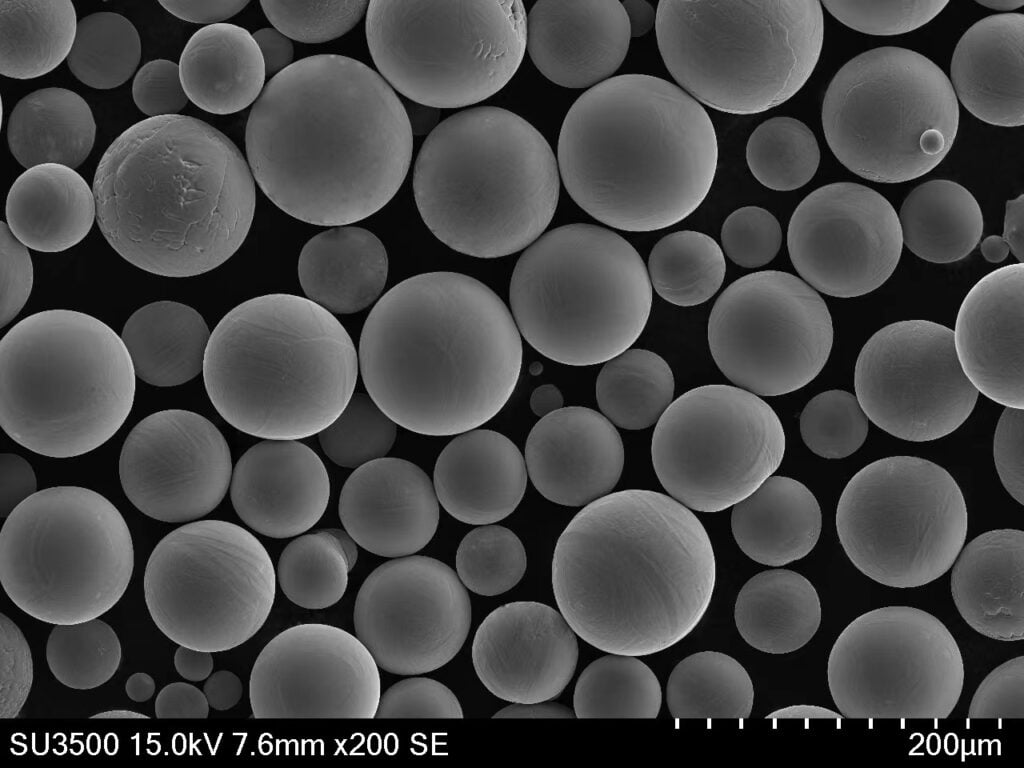

Metallpulver sind fein verteilte Metallpartikel, die in verschiedenen Anwendungen, unter anderem in der Halbleiterindustrie, eingesetzt werden. Ihre Bedeutung liegt in ihren einzigartigen Eigenschaften wie hoher Reinheit, kontrollierter Partikelgröße und spezifischer Oberfläche, die sie ideal für die Herstellung von Halbleiterbauelementen machen.

Wichtige Punkte:

- Metallpulver sind im Herstellungsprozess von Halbleitern von entscheidender Bedeutung.

- Sie bieten hohe Reinheit und kontrollierte Partikelgrößen.

- Wird bei der Herstellung von Mikroprozessoren, Speichermedien und anderen Halbleiterbauelementen verwendet.

Arten von Metallpulver für Halbleiter

Für unterschiedliche Halbleiteranwendungen werden verschiedene Metallpulver verwendet. Jedes Metallpulver verfügt über unterschiedliche Eigenschaften, die es für bestimmte Anwendungen geeignet machen.

| Metallpulver | Zusammensetzung | Eigenschaften | Merkmale |

|---|---|---|---|

| Kupfer (Cu) | Reines Kupfer | Hohe Leitfähigkeit | Korrosionsbeständigkeit, Duktilität |

| Aluminium (Al) | Reines Aluminium | Leicht, hohe Leitfähigkeit | Reflektivität, Formbarkeit |

| Silber (Ag) | Reines Silber | Höchste elektrische Leitfähigkeit | Anlaufbeständig, antimikrobiell |

| Gold (Au) | Reines Gold | Ausgezeichnete Leitfähigkeit | Nicht reaktiv, Duktilität |

| Nickel (Ni) | Reines Nickel | Korrosionsbeständigkeit | Magnetismus, hoher Schmelzpunkt |

| Titan (Ti) | Reines Titan | Stärke, Leichtgewicht | Korrosionsbeständigkeit, Biokompatibilität |

| Wolfram (W) | Reines Wolfram | Hoher Schmelzpunkt | Dichte, Härte |

| Molybdän (Mo) | Reines Molybdän | Hohe Festigkeit | Hohe Wärmeleitfähigkeit, geringe Wärmeausdehnung |

| Palladium (Pd) | Reines Palladium | Korrosionsbeständigkeit | Gute Leitfähigkeit, katalytische Eigenschaften |

| Kobalt (Co) | Reines Kobalt | Magnetische Eigenschaften | Hoher Schmelzpunkt, Festigkeit |

Anwendungen von Metallpulver für Halbleiter

Metallpulver werden in der Halbleiterindustrie in verschiedenen Anwendungen eingesetzt. Hier finden Sie eine Übersicht über die Einsatzgebiete und -methoden dieser Pulver.

| Anmeldung | Verwendete Metallpulver | Beschreibung |

|---|---|---|

| Mikroprozessoren | Kupfer, Gold, Silber | Leitfähige Pfade und Verbindungen |

| Speicher | Aluminium, Nickel | Datenspeicherschichten und magnetische Aufzeichnung |

| Sensoren | Palladium, Kobalt | Empfindliche Elemente in Sensoren |

| Transistoren | Wolfram, Molybdän | Gate- und Verbindungsmaterialien |

| Kondensatoren | Titan, Nickel | Dielektrische und Elektrodenmaterialien |

| LEDs | Aluminium, Gold | Leiterbahnen und Kühlkörper |

| Stromversorgungsgeräte | Kupfer, Silber | Hochstromführende Bauteile |

| Solarzellen | Silber, Aluminium | Leitfähige Gitter und Kontakte |

Spezifikationen, Größen, Güteklassen und Normen

Das Verständnis der Spezifikationen, Größen, Qualitäten und Standards von Metallpulvern ist für ihre effektive Anwendung in Halbleitern von entscheidender Bedeutung.

| Metallpulver | Größen (µm) | Klassen | Normen |

|---|---|---|---|

| Kupfer (Cu) | 0.1 – 10 | Hohe Reinheit (99,99%) | ASTM B170-99 |

| Aluminium (Al) | 0.5 – 15 | Elektronischer Grad | ISO 8000 |

| Silber (Ag) | 0.2 – 5 | 99,999% Rein | ASTM B779-99 |

| Gold (Au) | 0.1 – 3 | Halbleiterqualität | ISO 9208 |

| Nickel (Ni) | 1 – 20 | 99,98% Rein | ASTM B330-03 |

| Titan (Ti) | 2 – 30 | Hohe Reinheit (99,6%) | ASTM B348-19 |

| Wolfram (W) | 0.3 – 15 | Hohe Reinheit | ISO 2768-1 |

| Molybdän (Mo) | 0.5 – 10 | 99,95% Rein | ASTM B386-03 |

| Palladium (Pd) | 0.1 – 5 | 99,9% Rein | ISO 6284 |

| Kobalt (Co) | 1 – 25 | 99,8% Rein | ASTM B330-03 |

Lieferanten und Preisangaben

Für die Planung und Budgetierung in der Halbleiterfertigung ist es von entscheidender Bedeutung, zu wissen, wo Metallpulver bezogen werden können und wie die Preise dafür aussehen.

| Anbieter | Verfügbare Metallpulver | Preisgestaltung (pro kg) |

|---|---|---|

| Amerikanische Elemente | Kupfer, Gold, Nickel, Silber | $300 – $10,000 |

| NanoAmor | Aluminium, Wolfram, Titan | $200 – $8,000 |

| SkySpring Nanomaterialien | Palladium, Kobalt, Molybdän | $500 – $12,000 |

| Tekna | Aluminium, Kupfer, Nickel | $250 – $9,000 |

| Goodfellow | Gold, Silber, Titan | $400 – $15,000 |

Vor- und Nachteile von Metallpulvern im Vergleich

Jedes Metallpulver hat seine Vor- und Nachteile. Hier finden Sie eine vergleichende Analyse, die Ihnen hilft herauszufinden, welches Pulver für bestimmte Anwendungen besser geeignet sein könnte.

| Metallpulver | Vorteile | Benachteiligungen |

|---|---|---|

| Kupfer (Cu) | Hohe Leitfähigkeit, kostengünstig | Empfindlich gegen Oxidation |

| Aluminium (Al) | Leichtes Gewicht, gute Leitfähigkeit | Niedrigerer Schmelzpunkt |

| Silber (Ag) | Höchste Leitfähigkeit, anlaufgeschützt | Teuer |

| Gold (Au) | Nicht reaktiv, ausgezeichnete Leitfähigkeit | Sehr teuer |

| Nickel (Ni) | Korrosionsbeständig, magnetisch | Mäßige Leitfähigkeit |

| Titan (Ti) | Stark, leicht, biokompatibel | Teuer, reaktiv |

| Wolfram (W) | Hoher Schmelzpunkt, hart | Sehr dicht, schwer zu verarbeiten |

| Molybdän (Mo) | Hohe Festigkeit, Wärmeleitfähigkeit | Spröde, teuer |

| Palladium (Pd) | Gute Leitfähigkeit, korrosionsbeständig | Sehr teuer |

| Kobalt (Co) | Magnetische Eigenschaften, hoher Schmelzpunkt | Teuer, kann giftig sein |

Zusammensetzung von Metallpulver für Halbleiter

Die Zusammensetzung von Metallpulvern spielt eine entscheidende Rolle für ihre Wirksamkeit und Anwendung in Halbleiterbauelementen. Hier erhalten Sie einen genaueren Einblick in die Zusammensetzungen und ihre Auswirkungen.

Kupferpulver (Cu):

- Zusammensetzung: Reines Kupfer (99,99%)

- Auswirkungen: Bietet eine hervorragende elektrische Leitfähigkeit, die für Verbindungen und Leiterbahnen in Mikroprozessoren und Speichergeräten entscheidend ist.

Aluminiumpulver (Al):

- Zusammensetzung: Reines Aluminium (99,98%)

- Auswirkungen: Leicht und reflektierend, ideal für leitfähige Gitter in Solarzellen und LED-Kühlkörpern.

Silberpulver (Ag):

- Zusammensetzung: Reines Silber (99,999%)

- Auswirkungen: Höchste elektrische Leitfähigkeit, wird in Hochfrequenz- und Hochleistungsgeräten für minimalen Widerstand verwendet.

Goldpulver (Au):

- Zusammensetzung: Reines Gold (99,99%)

- Auswirkungen: Rückwirkungsfreier und hervorragender Leiter, der in kritischen Anwendungen eingesetzt wird, bei denen Zuverlässigkeit und Haltbarkeit von größter Bedeutung sind.

Nickel (Ni)-Pulver:

- Zusammensetzung: Reines Nickel (99,98%)

- Auswirkungen: Korrosionsbeständig und magnetisch, geeignet für Datenspeicher und Sensoren.

Titanpulver (Ti):

- Zusammensetzung: Reines Titan (99,6%)

- Auswirkungen: Robust und leicht, wird in Kondensatoren und modernen Leistungsgeräten verwendet.

Wolframpulver (W):

- Zusammensetzung: Reines Wolfram (99,95%)

- Auswirkungen: Hoher Schmelzpunkt und hohe Dichte, ideal für Transistoren und Hochtemperaturanwendungen.

Molybdän (Mo)-Pulver:

- Zusammensetzung: Reines Molybdän (99,95%)

- Auswirkungen: Hohe Festigkeit und Wärmeleitfähigkeit, wird in Leistungsgeräten und im Wärmemanagement verwendet.

Palladium (Pd)-Pulver:

- Zusammensetzung: Reines Palladium (99,9%)

- Auswirkungen: Hervorragende Leitfähigkeit und Korrosionsbeständigkeit, wird in Hochleistungssensoren und katalytischen Anwendungen verwendet.

Kobaltpulver (Co):

- Zusammensetzung: Reines Kobalt (99,8%)

- Auswirkungen: Magnetische Eigenschaften und hoher Schmelzpunkt, Verwendung in magnetischen Speichern und fortschrittlichen Sensoranwendungen.

Eigenschaften von Metallpulver für Halbleiter

Die einzigartigen Eigenschaften jedes Metallpulvers machen es für unterschiedliche Halbleiteranwendungen geeignet. Hier ist eine Aufschlüsselung dieser Eigenschaften.

| Metallpulver | Charakteristisch | Beschreibung |

|---|---|---|

| Kupfer (Cu) | Leitfähigkeit | Hohe elektrische Leitfähigkeit, unerlässlich für Mikroprozessoren. |

| Aluminium (Al) | Leichtgewicht | Reduziert das Gesamtgewicht des Geräts, vorteilhaft für tragbare elektronische Geräte. |

| Silber (Ag) | Leitfähigkeit | Höchste elektrische Leitfähigkeit, optimal für Hochfrequenzgeräte. |

| Gold (Au) | Nicht reaktiv | Läuft nicht an und korrodiert nicht, ideal für kritische Verbindungen. |

| Nickel (Ni) | Magnetismus | Magnetische Eigenschaften, nützlich für die Datenspeicherung. |

| Titan (Ti) | Stärke | Hohes Verhältnis von Festigkeit zu Gewicht, wird in langlebigen Komponenten verwendet. |

| Wolfram (W) | Hoher Schmelzpunkt | Geeignet für Hochtemperaturanwendungen wie Transistoren. |

| Molybdän (Mo) | Wärmeleitfähigkeit | Hervorragend geeignet für das Wärmemanagement in Leistungsgeräten. |

| Palladium (Pd) | Korrosionsbeständigkeit | Korrosionsbeständig, wird in Sensoren und Hochleistungsgeräten verwendet. |

| Kobalt (Co) | Magnetische Eigenschaften | Hoher Schmelzpunkt und Magnetismus, nützlich für Speicheranwendungen. |

Metallpulverqualitäten für Halbleiter

Die Qualität von Metallpulvern gibt Aufschluss über deren Reinheit und Eignung für verschiedene Anwendungen. Hier finden Sie eine detaillierte Übersicht über die verfügbaren Qualitäten verschiedener Metallpulver.

| Metallpulver | Klasse | Reinheit | Anmeldung |

|---|---|---|---|

| Kupfer (Cu) | Hohe Reinheit | 99.99% | Verbindungen, Leiterbahnen |

| Aluminium (Al) | Elektronischer Grad | 99.98% | Solarzellen, LEDs |

| Silber (Ag) | 99,999% Rein | 99.999% | Hochfrequenzgeräte |

| Gold (Au) | Halbleiterqualität | 99.99% | Kritische Verbindungen |

| Nickel (Ni) | 99,98% Rein | 99.98% | Datenspeicherung, Sensoren |

| Titan (Ti) | Hohe Reinheit | 99.6% | Kondensatoren, Leistungsbauelemente |

| Wolfram (W) | Hohe Reinheit | 99.95% | Transistoren, Hochtemperaturanwendungen |

| Molybdän (Mo) | 99,95% Rein | 99.95% | Thermisches Management |

| Palladium (Pd) | 99,9% Rein | 99.9% | Hochleistungssensoren |

| Kobalt (Co) | 99,8% Rein | 99.8% | Magnetspeicher, Sensoren |

Lieferanten und Preise für Metallpulver für Halbleiter

Für die Herstellung von Halbleitern ist es von entscheidender Bedeutung, zu wissen, wo Metallpulver bezogen werden können und wie die Preise sind.

| Anbieter | Verfügbare Metallpulver | Preisgestaltung (pro kg) |

|---|---|---|

| Amerikanische Elemente | Kupfer, Gold, Nickel, Silber | $300 – $10,000 |

| NanoAmor | Aluminium, Wolfram, Titan | $200 – $8,000 |

| SkySpring Nanomaterialien | Palladium, Kobalt, Molybdän | $500 – $12,000 |

| Tekna | Aluminium, Kupfer, Nickel | $250 – $9,000 |

| Goodfellow | Gold, Silber, Titan | $400 – $15,000 |

Vergleich von Metallpulver für Halbleiter: Vorteile und Beschränkungen

Jedes Metallpulver hat seine eigenen Vorteile und Nachteile. Hier finden Sie eine vergleichende Analyse, die Ihnen bei der Entscheidung hilft, welches Metallpulver am besten zu Ihren Anforderungen passt.

| Metallpulver | Vorteile | Benachteiligungen |

|---|---|---|

| Kupfer (Cu) | Hohe Leitfähigkeit, kostengünstig | Empfindlich gegen Oxidation |

| Aluminium (Al) | Leichtes Gewicht, gute Leitfähigkeit | Niedrigerer Schmelzpunkt |

| Silber (Ag) | Höchste Leitfähigkeit, anlaufgeschützt | Teuer |

| Gold (Au) | Nicht reaktiv, ausgezeichnete Leitfähigkeit | Sehr teuer |

| Nickel (Ni) | Korrosionsbeständig, magnetisch | Mäßige Leitfähigkeit |

| Titan (Ti) | Stark, leicht, biokompatibel | Teuer, reaktiv |

| Wolfram (W) | Hoher Schmelzpunkt, hart | Sehr dicht, schwer zu verarbeiten |

| Molybdän (Mo) | Hohe Festigkeit, Wärmeleitfähigkeit | Spröde, teuer |

| Palladium (Pd) | Gute Leitfähigkeit, korrosionsbeständig | Sehr teuer |

| Kobalt (Co) | Magnetische Eigenschaften, hoher Schmelzpunkt | Teuer, kann giftig sein |

FAQs

F1: Welche Metallpulver werden bei der Halbleiterherstellung am häufigsten verwendet?

A1: Zu den am häufigsten verwendeten Metallpulvern in der Halbleiterherstellung gehören Kupfer (Cu), Aluminium (Al), Silber (Ag), Gold (Au), Nickel (Ni), Titan (Ti), Wolfram (W), Molybdän (Mo), Palladium (Pd) und Kobalt (Co).

F2: Warum ist Reinheit wichtig in Metallpulver für Halbleiter?

A2: Reinheit ist entscheidend, da Verunreinigungen die elektrischen Eigenschaften, die Leistung und die Zuverlässigkeit von Halbleiterbauelementen beeinträchtigen können. Hochreine Metallpulver gewährleisten optimale Leitfähigkeit und minimieren Defekte.

F3: Wie werden Metallpulver in Mikroprozessoren verwendet?

A3: Metallpulver wie Kupfer und Gold werden verwendet, um leitfähige Pfade und Verbindungen innerhalb von Mikroprozessoren zu erzeugen und so effiziente elektrische Verbindungen zwischen verschiedenen Komponenten sicherzustellen.

F4: Welche Vorteile bietet die Verwendung von Goldpulver in Halbleitern?

A4: Goldpulver bietet eine hervorragende Leitfähigkeit, ist nicht reaktiv und läuft nicht an oder korrodiert nicht, sodass es sich ideal für kritische Verbindungen eignet, bei denen Zuverlässigkeit und Langlebigkeit von entscheidender Bedeutung sind.

F5: Können Sie die Rolle von Wolframpulver in Halbleiterbauelementen erklären?

A5: Wolframpulver wird aufgrund seines hohen Schmelzpunkts und seiner Dichte in Halbleiterbauelementen verwendet, wodurch es sich für Hochtemperaturanwendungen wie Transistoren und Leistungsbauelemente eignet.

F6: Welche Faktoren beeinflussen die Wahl des Metallpulvers für eine bestimmte Halbleiteranwendung?

A6: Zu den Faktoren zählen die erforderliche elektrische und thermische Leitfähigkeit, der Schmelzpunkt, die Festigkeit, die Korrosionsbeständigkeit und spezifische Anwendungsanforderungen wie Gewicht und magnetische Eigenschaften.

F7: Gibt es Umweltbedenken bei der Verwendung von Metallpulvern in Halbleitern?

A7: Ja, die Herstellung und Entsorgung von Metallpulvern kann Auswirkungen auf die Umwelt haben. Um diese Auswirkungen zu minimieren, sind nachhaltige Praktiken und Recyclingmaßnahmen unerlässlich.

F8: Welchen Einfluss hat die Partikelgröße von Metallpulvern auf ihre Anwendung in Halbleitern?

A8: Die Partikelgröße beeinflusst die Oberfläche, Packungsdichte und elektrischen Eigenschaften der Metallpulver und somit ihre Leistung in Halbleiteranwendungen.

F9: Welche Herausforderungen gibt es bei der Verarbeitung von Metallpulvern für Halbleiter?

A9: Zu den Herausforderungen zählen das Erreichen einer gleichmäßigen Partikelgrößenverteilung, die Aufrechterhaltung einer hohen Reinheit, die Verhinderung von Oxidation und die Sicherstellung einer gleichbleibenden Qualität während der Produktion und Verarbeitung.

F10: Wo kann ich hochwertige Metallpulver für Halbleiteranwendungen kaufen?

A10: Hochwertige Metallpulver können von Lieferanten wie American Elements, NanoAmor, SkySpring Nanomaterials, Tekna und Goodfellow bezogen werden.

Teilen auf

MET3DP Technology Co., LTD ist ein führender Anbieter von additiven Fertigungslösungen mit Hauptsitz in Qingdao, China. Unser Unternehmen ist spezialisiert auf 3D-Druckgeräte und Hochleistungsmetallpulver für industrielle Anwendungen.

Fragen Sie an, um den besten Preis und eine maßgeschneiderte Lösung für Ihr Unternehmen zu erhalten!

Verwandte Artikel

Hochleistungs-Düsenschaufelsegmente: Revolutionierung der Turbineneffizienz mit 3D-Metalldruck

Mehr lesen "Über Met3DP

Aktuelles Update

Unser Produkt

KONTAKT US

Haben Sie Fragen? Senden Sie uns jetzt eine Nachricht! Wir werden Ihre Anfrage mit einem ganzen Team nach Erhalt Ihrer Nachricht bearbeiten.

Holen Sie sich Metal3DP's

Produkt-Broschüre

Erhalten Sie die neuesten Produkte und Preislisten

Metallpulver für 3D-Druck und additive Fertigung

UNTERNEHMEN

PRODUKT

cONTACT INFO

- Qingdao Stadt, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731