VIGA Maschinen

Inhaltsübersicht

Wenn wir über VIGA-Maschinentauchen wir in die Welt der fortschrittlichen Metallpulverproduktionstechnologie ein, die verschiedene Branchen revolutioniert hat. In diesem Artikel erfahren Sie alles, was Sie über VIGA-Maschinen wissen müssen – von einer Übersicht über detaillierte Spezifikationen und Anwendungen bis hin zu einem FAQ-Bereich. Also, los geht‘s!

Übersicht der VIGA-Maschinen

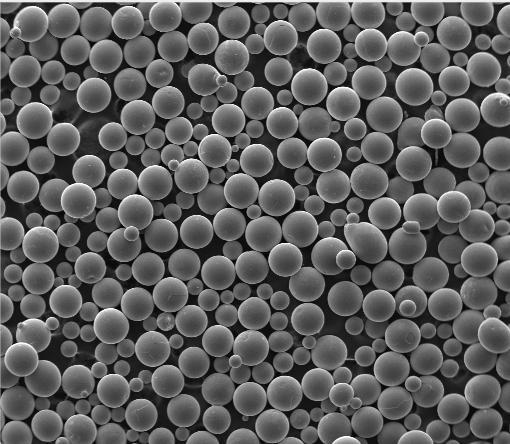

VIGA-Maschinen (Vakuum-Inertgas-Zerstäubung) sind hochmoderne Anlagen zur Herstellung hochwertiger Metallpulver. Diese Pulver sind entscheidend für Anwendungen in der Luft- und Raumfahrt, der Automobilindustrie, der Biomedizin und der additiven Fertigung. Die VIGA-Technologie zeichnet sich durch die Herstellung von Pulvern mit hervorragender Fließfähigkeit, sphärischer Form und kontrollierter Partikelgrößenverteilung aus.

Hauptmerkmale der VIGA-Maschinen

- Hochreine Metallpulver: VIGA-Maschinen arbeiten in einer Vakuum- oder Inertgasumgebung, wodurch die Kontamination minimiert wird.

- Sphärische Partikel: Sorgt für hervorragende Fließfähigkeit und Packungsdichte.

- Kontrollierte Partikelgröße: Einstellbare Zerstäubungsparameter für maßgeschneiderte Pulvereigenschaften.

- Große Auswahl an Materialien: Geeignet für verschiedene Metalle und Legierungen, einschließlich Titan, Edelstahl und Superlegierungen.

Arten und Modelle von Metallpulvern, hergestellt von VIGA Maschinen

Hier sind spezifische Metallpulvermodelle, die von VIGA-Maschinen hergestellt wurden, zusammen mit ihren Beschreibungen:

| Metallpulver-Modell | Zusammensetzung | Eigenschaften | Anwendungen |

|---|---|---|---|

| Ti-6Al-4V | Titan-Legierung | Hohe Festigkeit, korrosionsbeständig, biokompatibel | Luft- und Raumfahrt, medizinische Implantate |

| 316L-Edelstahl | Fe-Cr-Ni-Mo-Legierung | Ausgezeichnete Korrosionsbeständigkeit, gute mechanische Eigenschaften | Biomedizinische Geräte, maritime Anwendungen |

| IN718 | Superlegierung auf Nickelbasis | Hochwarmfest, oxidationsbeständig | Turbinenschaufeln, Luft- und Raumfahrtkomponenten |

| AlSi10Mg | Aluminium-Legierung | Leichtes Gewicht, gute thermische Eigenschaften | Automobilindustrie, Luft- und Raumfahrt |

| CoCrMo | Kobalt-Chrom-Molybdän-Legierung | Hohe Verschleißfestigkeit, biokompatibel | Medizinische Implantate, Zahnprothetik |

| CuCrZr | Kupfer-Chrom-Zirkonium-Legierung | Hohe elektrische Leitfähigkeit, gute mechanische Festigkeit | Elektrische Komponenten, Schweißelektroden |

| Martensitaushärtender Stahl (18Ni300) | Fe-Ni-Co-Mo-Ti-Legierung | Ultrahohe Festigkeit, gute Zähigkeit | Werkzeugbau, Hochleistungszahnräder |

| FeNiCo | Eisen-Nickel-Kobalt-Legierung | Magnetische Eigenschaften, gute mechanische Festigkeit | Magnetische Komponenten, Luft- und Raumfahrt |

| NiTi (Nitinol) | Nickel-Titan-Legierung | Formgedächtnis, Superelastizität | Medizinische Geräte, Aktoren |

| Hastelloy X | Nickel-Chrom-Molybdän-Legierung | Hohe Temperaturfestigkeit, korrosionsbeständig | Gasturbinenkomponenten, chemische Verarbeitung |

Anwendungen von VIGA-Maschinen

VIGA-Maschinen werden aufgrund ihrer Fähigkeit zur Herstellung hochwertiger Metallpulver in zahlreichen Branchen eingesetzt. Hier ist ein detaillierter Überblick über ihre Anwendungen:

| Industrie | Anwendungen |

|---|---|

| Luft- und Raumfahrt | Turbinenschaufeln, Strukturkomponenten, Befestigungselemente |

| Automobilindustrie | Leichtbaukomponenten, Motorenteile |

| Biomedizinische | Implantate, Prothesen, chirurgische Instrumente |

| Additive Fertigung | 3D-Druckpulver, Prototyping, komplexe Geometrien |

| Energie | Turbinenteile, Teile für Kernreaktoren |

| Elektronik | Leitpasten, magnetische Komponenten |

Vorteile von VIGA-Maschinen

- Hohe Reinheit und Sauberkeit: Der Betrieb in einer Vakuum- oder Inertgasumgebung reduziert die Verunreinigung und führt zu hochreinen Metallpulvern.

- Kontrollierte Partikelgrößenverteilung: Ermöglicht die Anpassung an bestimmte Anwendungen und verbessert die Leistung.

- Sphärische Partikel: Verbessert die Fließfähigkeit und Packungsdichte, was für die additive Fertigung entscheidend ist.

- Vielseitiges Materialsortiment: Kann eine Vielzahl von Metallen und Legierungen verarbeiten und ist daher für verschiedene Branchen geeignet.

Nachteile von VIGA Maschinen

- Hohe Anschaffungskosten: Die Anschaffung und Einrichtung von VIGA-Maschinen ist teuer.

- Komplexe Operation: Erfordert qualifiziertes Bedienpersonal und regelmäßige Wartung.

- Energieintensiv: Der Prozess erfordert viel Energie und erhöht die Betriebskosten.

Detaillierte Spezifikationen der VIGA-Maschinen

| Spezifikation | Einzelheiten |

|---|---|

| Materielle Leistungsfähigkeit | Titan, Edelstahl, Nickellegierungen, Aluminiumlegierungen, Kobalt-Chrom-Legierungen usw. |

| Zerstäubungsgas | Argon, Stickstoff, Helium |

| Betriebsdruck | Bis 150 bar |

| Partikelgrößenbereich | 10 – 200 Mikrometer |

| Produktionsrate | Bis zu 500 kg/Stunde |

| Vakuum Niveau | Bis zu 10^-5 mbar |

| Energieverbrauch | 100 – 500 kW |

| Kühlsystem | Wassergekühlt |

Vergleich der Vor- und Nachteile von VIGA Maschinen

| Vorteile | Benachteiligungen |

|---|---|

| Hochreine Metallpulver | Hohe Anschaffungskosten |

| Sphärische Partikel | Komplexe Operation |

| Kontrollierte Partikelgröße | Energieintensiv |

| Vielseitiges Materialspektrum | Erfordert qualifiziertes Personal |

| Ausgezeichnete Fließfähigkeit | Regelmäßige Wartung erforderlich |

FAQ

| Frage | Antwort |

|---|---|

| Wofür werden VIGA-Maschinen verwendet? | Herstellung hochwertiger Metallpulver für verschiedene Branchen, darunter die Luft- und Raumfahrt, die Automobilindustrie und die Biomedizin. |

| Wie funktionieren VIGA-Maschinen? | Sie verwenden Vakuum oder Inertgas, um geschmolzenes Metall in feine Pulver mit kugelförmigen Partikeln zu zerstäuben. |

| Welche Metalle können VIGA-Maschinen verarbeiten? | Titan, Edelstahl, Nickellegierungen, Aluminiumlegierungen und mehr. |

| In welchem Partikelgrößenbereich liegen die hergestellten Pulver? | Normalerweise zwischen 10 und 200 Mikrometer. |

| Sind VIGA-Maschinen teuer? | Ja, die Anschaffungskosten sind hoch und reichen von $900.000 bis über $2.500.000. |

| Welche Vorteile bietet die Verwendung von VIGA-Maschinen? | Hohe Reinheit, kontrollierte Partikelgröße, hervorragende Fließfähigkeit und Vielseitigkeit bei der Materialverarbeitung. |

| Welche Branchen profitieren von VIGA-Pulvern? | Luft- und Raumfahrt, Automobilindustrie, Biomedizin, additive Fertigung, Energie und Elektronik. |

| Können VIGA-Maschinen Pulver für den 3D-Druck herstellen? | Ja, sie eignen sich hervorragend zur Herstellung hochwertiger Pulver für die additive Fertigung. |

| Benötigen VIGA-Maschinen eine besondere Wartung? | Ja, sie erfordern regelmäßige Wartung und qualifiziertes Bedienpersonal, um eine optimale Leistung zu gewährleisten. |

| Welche Zerstäubungsgase werden üblicherweise verwendet? | Zur Zerstäubung werden üblicherweise Argon, Stickstoff und Helium verwendet. |

Schlussfolgerung

VIGA-Maschinen stellen einen Höhepunkt der Metallpulverproduktionstechnologie dar und liefern hochwertige Pulver, die für die moderne Industrie unverzichtbar sind. Ihre Fähigkeit, sphärische, hochreine und präzise kontrollierte Pulver zu produzieren, macht sie für Anwendungen von der Luft- und Raumfahrt bis hin zu biomedizinischen Geräten unverzichtbar. Trotz ihrer hohen Anschaffungskosten und Komplexität bieten sie unübertroffene Vorteile hinsichtlich Materialeigenschaften und Leistung. Wenn Sie in die Produktion hochwertiger Metallpulver einsteigen möchten, kann das Verständnis und der Einsatz von VIGA-Maschinen entscheidend sein.

Teilen auf

MET3DP Technology Co., LTD ist ein führender Anbieter von additiven Fertigungslösungen mit Hauptsitz in Qingdao, China. Unser Unternehmen ist spezialisiert auf 3D-Druckgeräte und Hochleistungsmetallpulver für industrielle Anwendungen.

Fragen Sie an, um den besten Preis und eine maßgeschneiderte Lösung für Ihr Unternehmen zu erhalten!

Verwandte Artikel

Hochleistungs-Düsenschaufelsegmente: Revolutionierung der Turbineneffizienz mit 3D-Metalldruck

Mehr lesen "Über Met3DP

Aktuelles Update

Unser Produkt

KONTAKT US

Haben Sie Fragen? Senden Sie uns jetzt eine Nachricht! Wir werden Ihre Anfrage mit einem ganzen Team nach Erhalt Ihrer Nachricht bearbeiten.

Holen Sie sich Metal3DP's

Produkt-Broschüre

Erhalten Sie die neuesten Produkte und Preislisten

Metallpulver für 3D-Druck und additive Fertigung

UNTERNEHMEN

PRODUKT

cONTACT INFO

- Qingdao Stadt, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731