プラズマ霧化

目次

固体の金属を完全な球形の粒子の雲に変える能力を持つことを想像してみてほしい。それが プラズマ霧化は、金属粉末の世界を一変させる革命的な技術です。しかし、それはいったい何であり、どのように機能するのでしょうか。シートベルトを締めてください。これから、このハイテク プロセスの魅力的な世界を詳しく見ていきます。

溶融金属からミクロの驚異まで

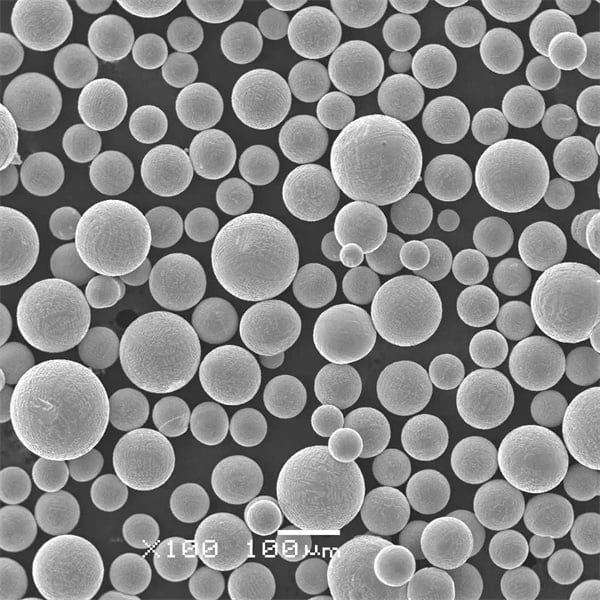

プラズマ噴霧法では、通常ワイヤー状の金属原料を非常に高温のプラズマ流で吹き付けます。温度は 10,000°C (18,000°F) を超えます。この高熱により金属は瞬時に溶け、溶融液滴に変わります。しかし、話はそれだけではありません。このプロセスでは、ガスや遠心力などのさまざまな噴霧技術を利用して、この溶融液滴を微細な金属粒子の霧に分解します。これらの粒子は空中で冷却されると急速に固まり、ほぼ完璧な球体の集合体、つまり切望される金属粉末になります。

その力 プラズマ霧化

プラズマ噴霧法は、水噴霧法やガス噴霧法などの他の金属粉末製造方法に比べて、非常に高品質の粉末を製造できるという点で優れています。その理由は次のとおりです。

- 純度のパワーハウス: プラズマ噴霧で達成される高温により、周囲の環境からの汚染のリスクが最小限に抑えられ、極めて純粋な金属粉末が得られます。これは、微量の不純物でも性能に大きな影響を与える可能性がある用途では非常に重要です。

- 球状の覇権: 凝固中に溶融液滴に作用する表面張力のおかげで、プラズマ噴霧化により球形度の高い粒子が生成されます。この一貫した形状により優れた流動性と充填密度が実現し、この粉末は 3D 印刷などの付加製造プロセスに最適です。

- フォースの微調整: プラズマトーチと噴霧パラメータを正確に制御することで、狭い粒度分布の粉末を作成できます。この一貫性は、均一な粒子サイズが最適なパフォーマンスに不可欠となる多くの用途にとって不可欠です。

特定金属粉

それでは、プラズマ噴霧法で作られた金属粉末のチャンピオンのいくつかを詳しく見ていきましょう。

1.チタン粉末: 優れた強度対重量比と優れた耐腐食性で知られるチタン粉末は、航空宇宙、医療用インプラント、高性能スポーツ用品の主力製品です。プラズマ噴霧チタン粉末は、優れた純度と一貫した球状形態を誇り、これらの品質が最も重要となる積層造形アプリケーションに最適です。

2.ニッケルパウダー ニッケルは多用途の金属で、硬貨や電池からジェットエンジンに使用される超合金まで、数え切れないほどの用途に使用されています。プラズマ噴霧ニッケル粉末は、材料特性の正確な制御が不可欠な粉末冶金などのプロセスに不可欠な、優れた流動性と充填密度を備えています。

3.アルミニウム粉末: 軽量で成形しやすいアルミニウム粉末は、自動車産業や航空宇宙産業で軽量化のためにますます使用されています。プラズマ噴霧化により、アルミニウム粉末の高純度と狭い粒度分布が保証され、予測可能な機械的特性を持つ部品が生まれます。

4. コバルト粉末: 超合金や耐摩耗性切削工具の主要成分であるコバルト粉末は、プラズマ噴霧化によって大きな恩恵を受けます。このプロセスにより、優れた流動性を備えた高純度の粉末が得られ、堅牢で耐摩耗性に優れた部品の製造が可能になります。

5.銅粉: 銅は導電性に優れた金属で、電気用途では主力です。プラズマ噴霧銅粉末は優れた流動性と充填密度を備えているため、複雑な電子部品を作成するために使用される金属射出成形 (MIM) などのプロセスに最適です。

6. ステンレス鋼粉末: 強度、耐腐食性、手頃な価格を兼ね備えたステンレス鋼粉末は、さまざまな業界で広く使用されています。プラズマ噴霧化により、これらの粉末の粒子サイズと形態が一定になり、最終製品の機械的特性が予測可能になります。

7. インコネル粉末: 高性能ニッケルクロム超合金のファミリーであるインコネル粉末は、ジェットエンジン部品など、並外れた強度と耐熱性が要求される用途に不可欠です。プラズマ噴霧化により、これらの粉末は、過酷な条件に耐えるために必要な高純度と精密な粒子構造を備えています。

8.タングステン粉 密度が高く、非常に硬いタングステン粉末は、装甲メッキや高性能切削工具などの用途に使用されます。プラズマ噴霧により、不純物が最小限で粒度分布が制御されたタングステン粉末が生成されます。これは、望ましい硬度と耐摩耗性を実現するために不可欠です。

9.モリブデン粉末 モリブデンも高融点金属で、発熱体やその他の高温用途に使用されています。プラズマ噴霧により、モリブデン粉末の優れた純度と制御された粒子サイズが保証され、予測可能な熱特性と機械特性を備えた部品が生まれます。

10. タンタル粉末: 耐腐食性と生体適合性に優れたタンタル粉末は、医療用インプラントやコンデンサーでますます多く使用されています。プラズマ噴霧化により、医療機器の長期的な性能と生体適合性を確保するために不可欠な、制御された粒子構造を持つ高純度のタンタル粉末が得られます。

ビッグ 10 を超えて: 金属粉末の世界

プラズマ噴霧法の優れた点は、その汎用性にあります。このプロセスは、次のようなさまざまな金属から粉末を作成するために使用できます。

- ジルコニウム: 優れた中性子吸収特性のため、原子炉で使用されます。プラズマ噴霧化により、原子炉の安全で効率的な運転に不可欠なジルコニウム粉末の高純度が保証されます。

- ニオブ: 低温での強度と超伝導性で知られる貴重な合金元素です。プラズマ噴霧ニオブ粉末は、粒子サイズと形態を正確に制御できるため、超伝導アプリケーションで優れた性能を発揮します。

- マグネシウムだ: 最も軽い構造用金属であるマグネシウムは、航空宇宙などの重量に敏感な用途で注目を集めています。プラズマ噴霧化により、マグネシウム粉末の高純度と制御された多孔性が保証され、強度と重量の比率が最適化されます。

金属粉末のニュアンスを明らかにする

金属粉末に関しては、細部にこそ注意が必要です。考慮すべき重要なパラメータを以下にまとめました。

| パラメータ | 説明 | プラズマアトマイズ粉末の重要性 |

|---|---|---|

| 粒度分布 | 粉末に含まれるサイズの範囲 | プラズマ噴霧化により正確な制御が可能になり、最終製品の特性が一貫して予測可能になります。 |

| 球形度 | 粒子が完全な球体にどれだけ似ているか | プラズマ噴霧粉末の高い真球度により、優れた流動性と充填密度が保証されます。 |

| 表面積 | 粉末粒子の総表面積 | プラズマ噴霧は表面積に影響を与え、反応性や焼結挙動などの要因に影響を及ぼす可能性があります。 |

| 見かけ密度 | 単位体積当たりの粉末の重量 | プラズマ噴霧粉末の高い見かけ密度は、材料の効率的な使用と生産コストの削減につながります。 |

| 流動性 | パウダーの流れやすさ | プラズマ噴霧粉末の優れた流動性により、さまざまな用途で効率的な取り扱いと処理が可能になります。 |

| 化学組成 | 粉末の元素構成 | プラズマ噴霧化により汚染が最小限に抑えられ、予測可能な特性を持つ高純度の粉末が得られます。 |

サプライヤーと価格設定の状況

高品質の金属粉末の需要が高まるにつれて、 プラズマ霧化 サプライヤーは着実に増加しています。その概要は次のとおりです。

- 主要サプライヤー: プラズマ噴霧業界の有名企業としては、AP&C、Höganäs、PyroGenesis などがあります。これらの企業は、多様な用途に対応する幅広い金属粉末を提供しています。

- 価格動向: プラズマ噴霧粉末の価格は、特定の金属、粉末のグレード、および数量によって異なります。一般的に、高純度で微細な粉末は高額になります。

長所と短所を比較する

プラズマ原子化には数多くの利点がありますが、その限界を考慮することも重要です。

メリット

- 並外れた純度: 汚染を最小限に抑えることで、予測可能で信頼性の高い材料特性が得られます。

- 優れた真球度: 一貫した粒子形状により、優れた流動性と充填密度が保証されます。

- 正確なコントロール: カスタマイズされたプロセスパラメータにより、粒子のサイズと形態を制御できます。

- 幅広い素材: 多様な用途の幅広い金属に適用可能です。

デメリット

- 高いエネルギー消費: 強力なプラズマトーチには多大なエネルギー入力が必要であり、生産コストに影響を与えます。

- 複合機器: プラズマ原子化装置には高度な装置が必要となり、資本投資額が高くなります。

- 限定生産料金: 他の方法と比較すると、プラズマ原子化では特定の金属の生産速度が遅くなる可能性があります。

よくあるご質問

以下は、よくある質問である。 プラズマ霧化明瞭かつ簡潔な形式で答えた:

| 質問 | 答え |

|---|---|

| 他の粉末製造方法に比べてプラズマ噴霧法の利点は何ですか? | プラズマ噴霧化により、優れた純度、一貫した球形度、粒子サイズの正確な制御が可能になり、高性能の粉末が得られます。 |

| プラズマ噴霧金属粉末の用途にはどのようなものがありますか? | これらの粉末は、付加製造、粉末冶金、金属射出成形、その他さまざまな工業プロセスで使用されます。 |

| プラズマ噴霧粉末のコストに影響を与える要因は何ですか? | 特定の金属、粉末のグレード、および数量はすべて価格設定に影響します。 |

| プラズマ噴霧は環境に優しいプロセスですか? | プラズマ噴霧化のエネルギー消費は相当なものになる可能性があるものの、エネルギー効率を改善するための進歩が続けられています。さらに、生成される廃棄物が最小限に抑えられ、未使用の粉末をリサイクルできる可能性があることから、より持続可能なアプローチが実現します。 |

| プラズマ原子化の将来展望はどのようなものですか? | 高性能金属粉末の需要が高まるにつれて、プラズマ噴霧法は今後も成長を続けると予想されます。自動化、プロセス最適化、材料科学の進歩により、この技術の能力と効率はさらに向上する可能性があります。 |

シェアする

MET3DP Technology Co., LTDは、中国青島に本社を置く積層造形ソリューションのリーディングプロバイダーです。弊社は3Dプリンティング装置と工業用途の高性能金属粉末を専門としています。

関連記事

Met3DPについて

最新情報

製品

3Dプリンティングと積層造形用金属粉末