Bloggen

alle collecties

3D Printed Inverter Housings for Electric Vehicles

Introduction – The Rise of 3D Printed Inverter Housings in Electric Vehicles The electric vehicle (EV) revolution is rapidly transforming the automotive landscape, demanding innovation at every level of vehicle design and manufacturing. One critical component in the powertrain of an EV is the inverter, responsible for converting direct current

High-Temperature Exhaust Nozzles via 3D Printing

Introduction – The Critical Role of High-Temperature Exhaust Nozzles In demanding industries like aerospace, power generation, and high-performance automotive, turbine exhaust nozzles stand as critical components. These intricate parts are responsible for directing the high-velocity, high-temperature gases expelled from the turbine, playing a crucial role in the efficiency and performance

3D Printed Antenna Reflectors for Satellites

Introduction to 3D Printed Satellite Antenna Reflectors In the ever-evolving landscape of satellite technology, the demand for lightweight, high-performance, and geometrically complex components is constantly increasing. Among these critical components, the antenna reflector plays a pivotal role in signal transmission and reception. Traditionally manufactured using conventional methods, satellite antenna reflectors

Lightweight Suspension Links via Metal AM: Revolutionizing Automotive Performance

Introduction – The Evolution of Automotive Suspension and the Role of Metal 3D Printing The automotive industry has always been at the forefront of engineering innovation, constantly striving for enhanced performance, improved efficiency, and reduced weight. Among the critical components influencing these factors are suspension links, which play a vital

3D Printing Fuel Manifolds for Aerospace Engines

Introduction – The Ascent of Additive Manufacturing in Aerospace Fuel Systems The aerospace industry constantly demands innovation, pushing the boundaries of engineering to achieve greater efficiency, performance, and safety. Within this dynamic landscape, the manufacturing of critical engine components, such as fuel manifolds, is undergoing a significant transformation. Traditional manufacturing

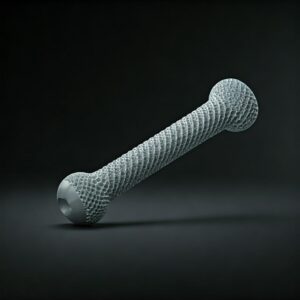

Custom Bone Screws via Metal 3D Printing: A New Era in Orthopedic Solutions

Introduction – Revolutionizing Orthopedics with Additive Manufacturing The landscape of orthopedic surgery is undergoing a significant transformation, driven by advancements in materials science and innovative manufacturing technologies. Among these groundbreaking developments, metal additive manufacturing, commonly known as metal 3D printing, stands out as a revolutionary force. This technology is enabling

3D Printed Inverter Housings for Electric Vehicles

Introduction – The Rise of 3D Printed Inverter Housings in Electric Vehicles The electric vehicle (EV) revolution is rapidly transforming the automotive landscape, demanding innovation

High-Temperature Exhaust Nozzles via 3D Printing

Introduction – The Critical Role of High-Temperature Exhaust Nozzles In demanding industries like aerospace, power generation, and high-performance automotive, turbine exhaust nozzles stand as critical

3D Printed Antenna Reflectors for Satellites

Introduction to 3D Printed Satellite Antenna Reflectors In the ever-evolving landscape of satellite technology, the demand for lightweight, high-performance, and geometrically complex components is constantly

Lightweight Suspension Links via Metal AM: Revolutionizing Automotive Performance

Introduction – The Evolution of Automotive Suspension and the Role of Metal 3D Printing The automotive industry has always been at the forefront of engineering

3D Printing Fuel Manifolds for Aerospace Engines

Introduction – The Ascent of Additive Manufacturing in Aerospace Fuel Systems The aerospace industry constantly demands innovation, pushing the boundaries of engineering to achieve greater

Custom Bone Screws via Metal 3D Printing: A New Era in Orthopedic Solutions

Introduction – Revolutionizing Orthopedics with Additive Manufacturing The landscape of orthopedic surgery is undergoing a significant transformation, driven by advancements in materials science and innovative

Ons product

HEET VERKOOPPRODUCT

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Metaalpoeders voor 3D printen en additieve productie

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731