Bloggen

alle collecties

3D Printed Test Coupons for Aerospace Certification

Introduction: The Critical Role of Test Coupons in Aerospace Qualification and the Rise of Additive Manufacturing The aerospace industry operates at the pinnacle of engineering, where performance, reliability, and safety are non-negotiable. Every component, from the smallest fastener to the largest structural element, undergoes rigorous scrutiny to ensure it can

3D Printing Pressure Valves in Corrosion-Resistant Alloys

Introduction: The Critical Role of Pressure Valves in Aerospace and the Rise of Additive Manufacturing The aerospace industry operates at the pinnacle of engineering, demanding components that perform flawlessly under extreme conditions. Among the most critical, yet often overlooked, are pressure valves. These intricate devices are the gatekeepers of fluid

Electronics Housings for Satellites 3D Printed in Al Alloys

The aerospace industry, particularly satellite manufacturing, operates at the cutting edge of technology, demanding components that are not only lightweight and robust but also capable of withstanding extreme environmental conditions. Electronics housings, the protective shells for sensitive satellite circuitry, are critical components that exemplify these demanding requirements. Traditionally manufactured through

Precision Sensor Mounts for Aerospace Applications

Introduction: Custom Aerospace Sensor Mounts – Precision in Extreme Environments In the demanding realm of aerospace, every component counts. From satellites orbiting the Earth to high-performance aircraft navigating the skies, the need for precision, reliability, and resilience under extreme conditions is paramount. Among the critical, yet often overlooked, components are

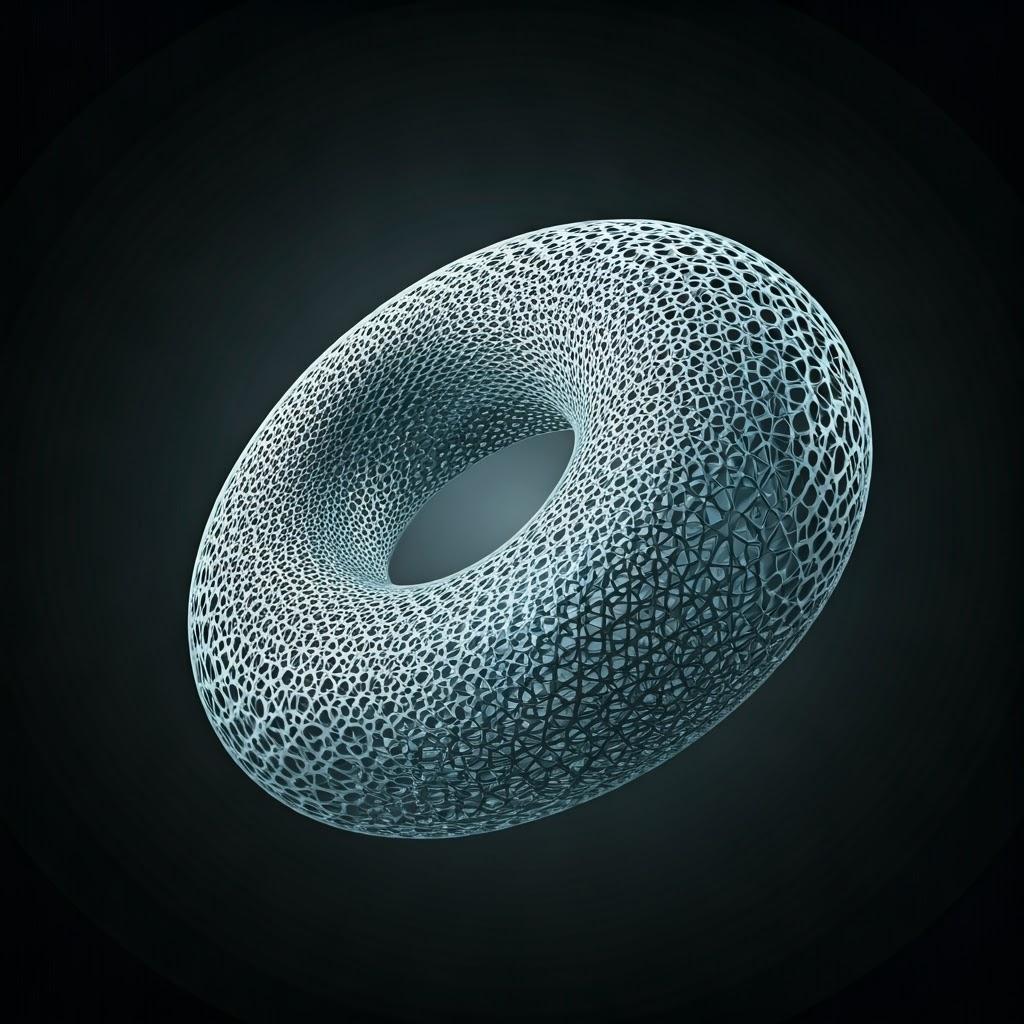

Vibration Damper Housings via 3D Printed Titanium

Introduction: Revolutionizing Aerospace Components with 3D Printed Titanium Damper Housings The aerospace industry stands at the vanguard of technological adoption, relentlessly pursuing innovations that enhance performance, safety, and efficiency. In this quest, materials and manufacturing processes play pivotal roles. Traditional methods, while reliable, often impose limitations on design complexity, material

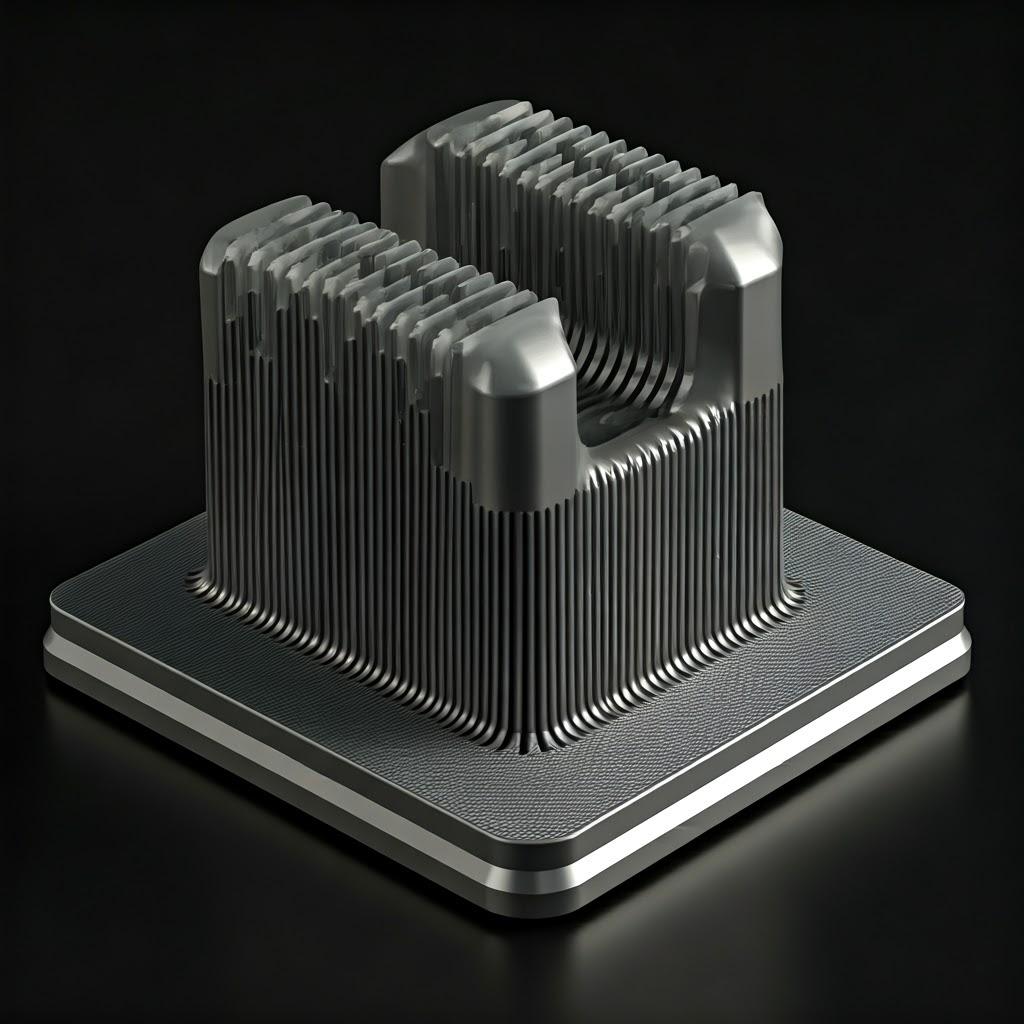

3D Printed Heat Dissipation Sinks for UAV Electronics

Introduction: The Critical Role of Thermal Management in Modern UAVs Unmanned Aerial Vehicles (UAVs), commonly known as drones, have transitioned from niche applications to indispensable tools across a multitude of sectors, including defense, surveillance, logistics, agriculture, and infrastructure inspection. This proliferation is driven by continuous advancements in miniaturization, sensor technology,

3D Printed Test Coupons for Aerospace Certification

Introduction: The Critical Role of Test Coupons in Aerospace Qualification and the Rise of Additive Manufacturing The aerospace industry operates at the pinnacle of engineering,

3D Printing Pressure Valves in Corrosion-Resistant Alloys

Introduction: The Critical Role of Pressure Valves in Aerospace and the Rise of Additive Manufacturing The aerospace industry operates at the pinnacle of engineering, demanding

Electronics Housings for Satellites 3D Printed in Al Alloys

The aerospace industry, particularly satellite manufacturing, operates at the cutting edge of technology, demanding components that are not only lightweight and robust but also capable

Precision Sensor Mounts for Aerospace Applications

Introduction: Custom Aerospace Sensor Mounts – Precision in Extreme Environments In the demanding realm of aerospace, every component counts. From satellites orbiting the Earth to

Vibration Damper Housings via 3D Printed Titanium

Introduction: Revolutionizing Aerospace Components with 3D Printed Titanium Damper Housings The aerospace industry stands at the vanguard of technological adoption, relentlessly pursuing innovations that enhance

3D Printed Heat Dissipation Sinks for UAV Electronics

Introduction: The Critical Role of Thermal Management in Modern UAVs Unmanned Aerial Vehicles (UAVs), commonly known as drones, have transitioned from niche applications to indispensable

Ons product

HEET VERKOOPPRODUCT

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Metaalpoeders voor 3D printen en additieve productie

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731