Bloggen

alle collecties

3D Printed Suspension Components for EVs

Introduction: The Drive Towards Lightweighting and Performance in EV Suspensions The automotive industry is undergoing its most significant transformation in a century, driven by the accelerating shift towards electric mobility. Electric vehicles (EVs) are no longer a niche segment but are rapidly becoming mainstream, fueled by consumer demand, regulatory pressures,

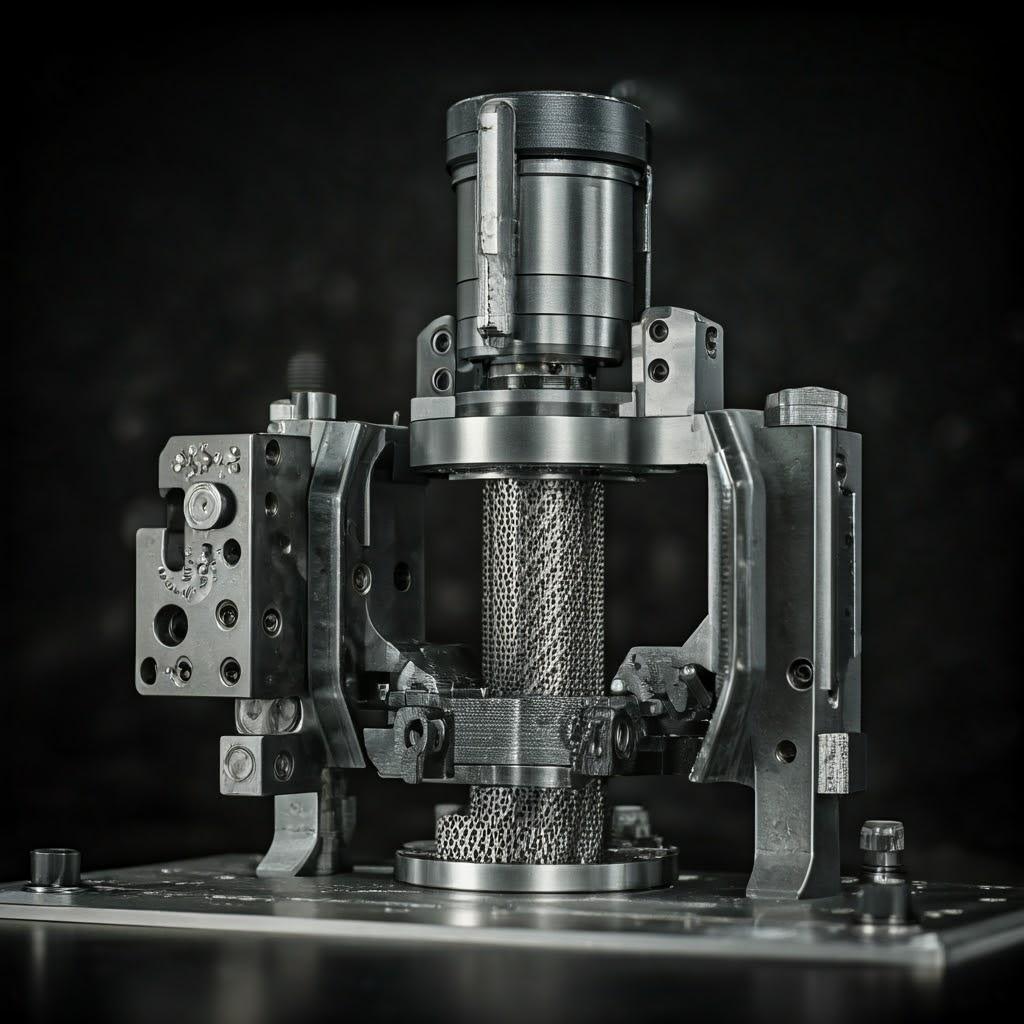

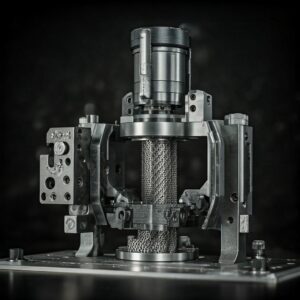

Custom Fixtures for Aerospace Testing via 3D Printing

Introduction: The Critical Role of Custom Test Fixtures in Aerospace Validation In the demanding world of aerospace engineering, failure is not an option. Every component, from the smallest fastener to the largest structural assembly, undergoes rigorous testing to ensure it meets stringent safety, performance, and reliability standards. Central to this

Linkage Arms 3D Printed for Dynamic Load Resistance

Introduction: The Critical Role of High-Stress Linkage Arms in Dynamic Systems Linkage arms are fundamental components in a vast array of mechanical systems, acting as the crucial connectors that transmit force and motion between different parts of an assembly. From the intricate mechanisms within robotic arms to the robust underpinnings

UAV Mounting Plates in Lightweight Aluminum

Introduction: Revolutionizing UAV Design with Advanced Mounting Plates The Unmanned Aerial Vehicle (UAV), or drone, sector is experiencing exponential growth, transforming industries from logistics and agriculture to surveillance and cinematography. At the heart of these sophisticated flying machines lies a complex interplay of components, each critical to performance, reliability, and

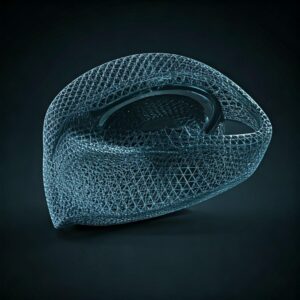

Rocket Fairing Connectors 3D Printed in Ti Alloys

The relentless pursuit of lighter, faster, and more cost-effective access to space places immense demands on every component within a launch vehicle system. Among the most critical, yet often overlooked, elements are the connectors used within the payload fairing assembly. These components play a vital role in maintaining structural integrity

Missile Fins 3D Printed with High-Strength Materials

Introduction: The Critical Role of Missile Fins in Aerospace & Defense Missiles, whether deployed for tactical advantage on the battlefield, strategic deterrence, or even peaceful space exploration launch systems, represent the pinnacle of aerospace engineering. Within these complex systems, every component plays a vital role, often operating under extreme conditions

3D Printed Suspension Components for EVs

Introduction: The Drive Towards Lightweighting and Performance in EV Suspensions The automotive industry is undergoing its most significant transformation in a century, driven by the

Custom Fixtures for Aerospace Testing via 3D Printing

Introduction: The Critical Role of Custom Test Fixtures in Aerospace Validation In the demanding world of aerospace engineering, failure is not an option. Every component,

Linkage Arms 3D Printed for Dynamic Load Resistance

Introduction: The Critical Role of High-Stress Linkage Arms in Dynamic Systems Linkage arms are fundamental components in a vast array of mechanical systems, acting as

UAV Mounting Plates in Lightweight Aluminum

Introduction: Revolutionizing UAV Design with Advanced Mounting Plates The Unmanned Aerial Vehicle (UAV), or drone, sector is experiencing exponential growth, transforming industries from logistics and

Rocket Fairing Connectors 3D Printed in Ti Alloys

The relentless pursuit of lighter, faster, and more cost-effective access to space places immense demands on every component within a launch vehicle system. Among the

Missile Fins 3D Printed with High-Strength Materials

Introduction: The Critical Role of Missile Fins in Aerospace & Defense Missiles, whether deployed for tactical advantage on the battlefield, strategic deterrence, or even peaceful

Ons product

HEET VERKOOPPRODUCT

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Metaalpoeders voor 3D printen en additieve productie

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731