Vacuüm-inductie smelten

Inhoudsopgave

Overzicht

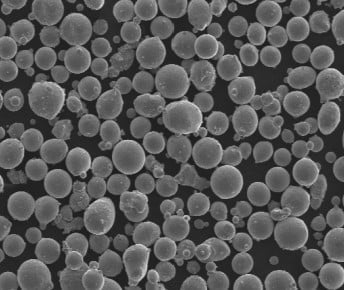

Vacuüm-inductie smelten (VIM) is een geavanceerd en zeer nauwkeurig proces dat wordt gebruikt om hoogwaardige metaallegeringen en poeders te produceren. Deze methode is cruciaal voor toepassingen die uitzonderlijke zuiverheid en nauwkeurige samenstelling vereisen, waardoor het essentieel is in sectoren zoals lucht- en ruimtevaart, medische apparatuur en high-performance engineering. Laten we dieper ingaan op de complexiteit van VIM en de processen, toepassingen, voordelen, nadelen en gedetailleerde informatie over verschillende metaalpoedermodellen die via deze techniek worden geproduceerd, verkennen.

Wat is vacuüm inductiesmelten?

Vacuüm-inductiesmelten omvat het smelten van metalen in een vacuümomgeving met behulp van elektromagnetische inductie. Deze techniek minimaliseert verontreiniging door gassen en onzuiverheden, waardoor de productie van metalen met superieure zuiverheid en homogeniteit wordt gegarandeerd. Door metalen onder vacuüm te smelten, voorkomt VIM oxidatie en maakt het nauwkeurige controle over de samenstelling van het eindproduct mogelijk.

Belangrijkste details van VIM:

- Proces: Smelten van metalen met behulp van elektromagnetische inductie in een vacuüm.

- Doel: Productie van metaallegeringen en poeders met een hoge zuiverheidsgraad.

- Toepassingen: Lucht- en ruimtevaart, medische apparatuur, hoogwaardige techniek.

Hoe vacuüminductiesmelten werkt

Stel je een hightechkeuken voor waar je je favoriete gerecht kookt in een perfect gecontroleerde omgeving, vrij van ongewenste geuren of verontreinigingen. Dat is VIM in een notendop, maar dan voor metalen! Het proces begint met het plaatsen van grondstoffen in een smeltkroes in de vacuümkamer. Een inductiespoel omringt de smeltkroes en genereert een magnetisch veld wanneer er een elektrische stroom doorheen gaat. Dit magnetische veld induceert wervelstromen in het metaal, waardoor het opwarmt en uiteindelijk smelt.

Zodra het metaal de gewenste temperatuur bereikt, kunnen legeringselementen worden toegevoegd om de specifieke vereiste samenstelling te bereiken. De vacuümomgeving zorgt ervoor dat er geen gassen in de smelt worden opgesloten, wat resulteert in een schonere en homogenere legering.

Soorten geproduceerde metalen en legeringen

VIM is veelzijdig en kan een breed scala aan metalen en legeringen produceren. Hier zijn enkele specifieke metaalpoedermodellen:

- Superlegeringen op nikkelbasis (bijv. INCONEL 718)

- Samenstelling: Nikkel, chroom, ijzer en andere elementen.

- Eigenschappen: Hoge sterkte, corrosiebestendigheid en uitstekende prestaties bij hoge temperaturen.

- Toepassingen: Turbinebladen, onderdelen voor de lucht- en ruimtevaart.

- Titaniumlegeringen (bijv. Ti-6Al-4V)

- Samenstelling: Titanium, aluminium, vanadium.

- Eigenschappen: Hoge sterkte-gewichtsverhouding, uitstekende weerstand tegen corrosie.

- Toepassingen: Lucht- en ruimtevaart, medische implantaten.

- Kobalt-chroomlegeringen (bijv. CoCrMo)

- Samenstelling: Kobalt, chroom, molybdeen.

- Eigenschappen: Hoge slijtvastheid, biocompatibiliteit.

- Toepassingen: Medische implantaten, tandheelkundige hulpmiddelen.

- Roestvrij staal (bijv. 316L)

- Samenstelling: IJzer, chroom, nikkel, molybdeen.

- Eigenschappen: Corrosiebestendigheid, mechanische sterkte.

- Toepassingen: Chirurgische instrumenten, maritieme toepassingen.

- Aluminiumlegeringen (bijv. AlSi10Mg)

- Samenstelling: Aluminium, Silicium, Magnesium.

- Eigenschappen: Lichtgewicht, goede thermische eigenschappen.

- Toepassingen: Auto-onderdelen, componenten voor de lucht- en ruimtevaart.

- Magnesiumlegeringen (bijv. AZ91D)

- Samenstelling: Magnesium, Aluminium, Zink.

- Eigenschappen: Lichtgewicht, zeer sterk.

- Toepassingen: Automobiel, elektronica.

- Koperlegeringen (bijv. CuCrZr)

- Samenstelling: Koper, chroom, zirkonium.

- Eigenschappen: Hoge elektrische geleidbaarheid, goede mechanische eigenschappen.

- Toepassingen: Elektrische onderdelen, warmtewisselaars.

- Gereedschapsstaal (bijv. M2-snelstaal)

- Samenstelling: IJzer, Wolfraam, Molybdeen, Chroom.

- Eigenschappen: Hoge hardheid, slijtvastheid.

- Toepassingen: Snijgereedschappen, mallen.

- Edelmetaallegeringen (bijv. PtIr)

- Samenstelling: Platina, Iridium.

- Eigenschappen: Hoge corrosiebestendigheid, goede mechanische eigenschappen.

- Toepassingen: Sieraden, medische apparatuur.

- Legeringen met hoge entropie (bijv. CoCrFeNiMn)

- Samenstelling: Kobalt, chroom, ijzer, nikkel, mangaan.

- Eigenschappen: Uitstekende mechanische eigenschappen, hoge corrosiebestendigheid.

- Toepassingen: Geavanceerde technische toepassingen.

Voordelen van Vacuüm-inductie smelten

Waarom wordt VIM zo hoog aangeschreven in de metallurgiewereld? Hier zijn enkele belangrijke voordelen:

- Hoge zuiverheid: De vacuümomgeving elimineert gasverontreiniging, wat resulteert in metalen met een uitzonderlijke zuiverheid.

- Precieze samenstelling: Maakt een nauwkeurige controle over de legeringselementen mogelijk, waardoor materialen met op maat gemaakte eigenschappen ontstaan.

- Verbeterde mechanische eigenschappen: Metalen die via VIM worden geproduceerd, vertonen superieure mechanische eigenschappen.

- Homogeniteit: Zorgt voor een gelijkmatige verdeling van legeringselementen door het metaal.

- Veelzijdigheid: Kan een breed scala aan metalen en legeringen smelten.

Nadelen van vacuüminductiesmelten

Zoals elk proces heeft VIM zijn nadelen. Hier zijn er een paar:

- Kosten: De apparatuur- en operationele kosten voor VIM zijn relatief hoog.

- Complexiteit: Het proces vereist geavanceerde technologie en expertise.

- Schaal: Meestal geschikt voor kleinere batchgroottes vergeleken met andere smeltmethoden.

Toepassingen van Vacuüm-inductie smelten

VIM is een game-changer in veel branches. Laten we de belangrijkste toepassingen ervan eens bekijken:

Lucht- en ruimtevaart:

- Componenten: Turbinebladen, motoronderdelen.

- Voordelen: Hoge temperatuurbestendigheid, duurzaamheid.

Medische hulpmiddelen:

- Componenten: Implantaten, chirurgische instrumenten.

- Voordelen: Biocompatibiliteit, corrosiebestendigheid.

Hoogwaardige techniek:

- Componenten: Onderdelen met hoge spanning, speciaal gereedschap.

- Voordelen: Sterkte, slijtvastheid.

Soorten metalen en legeringen geproduceerd door VIM

| Metaal/legering | Samenstelling | Eigenschappen | Toepassingen |

|---|---|---|---|

| INCONEL-718 | Nikkel, chroom, ijzer | Hoge sterkte, corrosieweerstand | Turbinebladen, ruimtevaartcomponenten |

| Ti-6Al-4V | Titanium, aluminium, vanadium | Hoge sterkte-gewichtsverhouding, corrosieweerstand | Lucht- en ruimtevaart, medische implantaten |

| CoCrMo | Kobalt, chroom, molybdeen | Hoge slijtvastheid, biocompatibiliteit | Medische implantaten, tandheelkundige hulpmiddelen |

| 316L roestvrij staal | IJzer, chroom, nikkel, molybdeen | Corrosiebestendigheid, mechanische sterkte | Chirurgische instrumenten, maritieme toepassingen |

| AlSi10Mg | Aluminium, silicium, magnesium | Lichtgewicht, goede thermische eigenschappen | Auto-onderdelen, ruimtevaartonderdelen |

| AZ91D | Magnesium, aluminium, zink | Lichtgewicht, hoge sterkte | Automobiel, elektronica |

| CuCrZr | Koper, chroom, zirkonium | Hoge elektrische geleidbaarheid, goede mechanische eigenschappen | Elektrische onderdelen, warmtewisselaars |

| M2 Snelstaal | IJzer, wolfraam, molybdeen, chroom | Hoge hardheid, slijtvastheid | Snijgereedschappen, mallen |

| PtIr | Platina, Iridium | Hoge corrosiebestendigheid, goede mechanische eigenschappen | Sieraden, medische hulpmiddelen |

| CoCrFeNiMn | Kobalt, chroom, ijzer, nikkel, mangaan | Uitstekende mechanische eigenschappen, hoge corrosiebestendigheid | Geavanceerde technische toepassingen |

Toepassingen van VIM-geproduceerde metalen

| Industrie | Componenten | Voordelen |

|---|---|---|

| Lucht- en ruimtevaart | Turbinebladen, motoronderdelen | Hoge temperatuurprestaties, duurzaamheid |

| Medische apparaten | Implantaten, chirurgische instrumenten | Biocompatibiliteit, corrosiebestendigheid |

| Hoogwaardige techniek | Hoogspanningscomponenten, speciaal gereedschap | Sterkte, slijtvastheid |

Specificaties en normen

| Metaal/legering | Standaard | Cijfer | Specificatie |

|---|---|---|---|

| INCONEL-718 | ASTM B637 | Rang 1 | Hoge sterkte bij verhoogde temperaturen |

| Ti-6Al-4V | ASTM B348 | Niveau 5 | Hoge sterkte-gewichtsverhouding |

| CoCrMo | ASTM F1537 | Rang 1 | Hoge slijtvastheid |

| 316L roestvrij staal | ASTM A240 | Kwaliteit 316L | Corrosieweerstand |

| AlSi10Mg | ASTM B928 | Rang 1 | Lichtgewicht, goede thermische eigenschappen |

| AZ91D | ASTM B93 | Kwaliteit AZ91D | Lichtgewicht, hoge sterkte |

| CuCrZr | ASTM B224 | Rang 1 | Hoge elektrische geleidbaarheid |

| M2 Snelstaal | ASTM A600 | Klasse M2 | Hoge hardheid, slijtvastheid |

| PtIr | ASTM B563 | Rang 1 | Hoge corrosieweerstand |

| CoCrFeNiMn | ASTM E2209 | Rang 1 | Uitstekende mechanische eigenschappen |

Voor- en nadelen van Vacuüm-inductie smelten

Voordelen

| Voordeel | Beschrijving |

|---|---|

| Hoge zuiverheid | Verwijdert gasverontreiniging voor superieure zuiverheid. |

| Precieze compositie | Exacte controle over legeringselementen voor op maat gemaakte eigenschappen. |

| Verbeterde mechanische eigenschappen | Superieure mechanische eigenschappen in eindproducten. |

| Homogeniteit | Gelijkmatige verdeling van legeringselementen. |

| Veelzijdigheid | Geschikt voor een breed scala aan metalen en legeringen. |

Nadelen

| Nadeel | Beschrijving |

|---|---|

| Kosten | Hoge apparatuur- en operationele kosten. |

| Complexiteit | Vereist geavanceerde technologie en expertise. |

| Schaal | Meestal beperkt tot kleinere batchgroottes vergeleken met andere methoden. |

Leveranciers en prijsinformatie

Toonaangevende leveranciers van VIM-apparatuur

| Leverancier | Assortiment | Prijzen | Regio |

|---|---|---|---|

| Inductotherm Groep | VIM-ovens, toebehoren | $100,000 – $1,000,000 | Wereldwijd |

| ALD-vacuümtechnologieën | VIM-systemen, maatwerkoplossingen | $150,000 – $2,000,000 | Wereldwijd |

| Seco/Warwick | VIM-ovens, aftersalesservice | $120,000 – $900,000 | Noord-Amerika, Europa |

| Consarc | VIM- en VAR-ovens | $200,000 – $1,500,000 | Wereldwijd |

| ECM-technologieën | VIM-systemen | $100,000 – $850,000 | Europa, Azië |

Vergelijking van VIM versus andere smeltmethoden

| Aspect | Vacuüm-inductiesmelten (VIM) | Boog smelten | Elektroslak-omsmelten (ESR) |

|---|---|---|---|

| Puurheid | Hoog vanwege vacuümomgeving | Gematigd | Hoog |

| Kosten | Hoog | Lager | Hoog |

| Complexiteit | Hoog | Gematigd | Hoog |

| Partijgrootte | Klein tot middelgroot | Middelgroot tot groot | Medium |

| Sollicitatie | Hoogwaardige legeringen | Algemeen doel | Toepassingen met hoge zuiverheid |

Veelgestelde vragen

| Vraag | Antwoord |

|---|---|

| Wat is vacuüminductiesmelten (VIM)? | VIM is een proces waarbij metalen worden gesmolten met behulp van elektromagnetische inductie in een vacuüm, om legeringen met een hoge zuiverheidsgraad te produceren. |

| Waarom VIM gebruiken in plaats van andere smeltmethoden? | VIM biedt superieure zuiverheid, nauwkeurige samenstellingscontrole en verbeterde mechanische eigenschappen. |

| Welke metalen kunnen met VIM worden geproduceerd? | VIM kan een breed scala aan metalen produceren, waaronder superlegeringen op nikkelbasis, titaniumlegeringen en meer. |

| Wat zijn de belangrijkste toepassingen van VIM? | Belangrijke toepassingen zijn onder meer onderdelen voor de lucht- en ruimtevaart, medische apparatuur en hoogwaardige technische onderdelen. |

| Wat zijn de nadelen van VIM? | Nadelen zijn onder meer de hoge kosten, de complexiteit en de doorgaans kleinere batchgroottes. |

| Wie zijn de toonaangevende leveranciers van VIM-apparatuur? | Belangrijke leveranciers zijn onder meer Inductotherm Group, ALD Vacuum Technologies en Seco/Warwick. |

| Hoe verhoudt VIM zich tot Arc Melting? | VIM biedt een hogere zuiverheid, maar is ook duurder en complexer dan Arc Melting. |

Conclusie

Vacuüm-inductiesmelten is een hoogtepunt van moderne metallurgie en biedt ongeëvenaarde zuiverheid en precisie in metaalproductie. De toepassingen ervan bestrijken kritieke industrieën waar prestaties en betrouwbaarheid niet onderhandelbaar zijn. Hoewel het gepaard gaat met hogere kosten en complexiteit, wegen de voordelen vaak op tegen deze uitdagingen, waardoor VIM een onschatbaar proces is in geavanceerde materiaalproductie.

Delen op

MET3DP Technology Co, LTD is een toonaangevende leverancier van additieve productieoplossingen met hoofdkantoor in Qingdao, China. Ons bedrijf is gespecialiseerd in 3D printapparatuur en hoogwaardige metaalpoeders voor industriële toepassingen.

Onderzoek om de beste prijs en een op maat gemaakte oplossing voor uw bedrijf te krijgen!

gerelateerde artikelen

Over Met3DP

Recente update

Ons product

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Metaalpoeders voor 3D printen en additieve productie

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731