VIGA-machines

Inhoudsopgave

Als we het hebben over VIGA-machinesduiken we in een wereld van geavanceerde metaalpoederproductietechnologie die een revolutie teweeg heeft gebracht in verschillende industrieën. In dit artikel bespreken we alles wat je moet weten over VIGA-machines, van een overzicht tot gedetailleerde specificaties, toepassingen en zelfs een FAQ-sectie. Aan de slag dus!

Overzicht van VIGA-machines

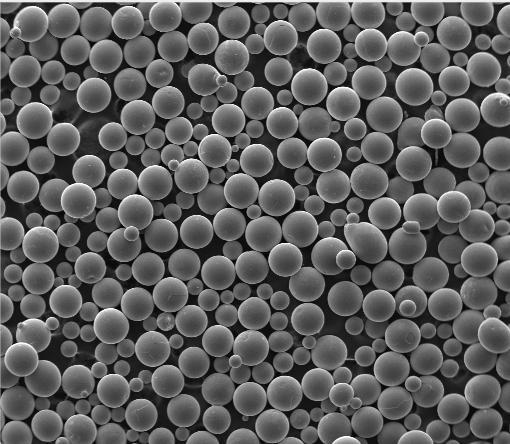

VIGA-machines (Vacuum Inert Gas Atomization) zijn geavanceerde apparatuur voor de productie van hoogwaardige metaalpoeders. Deze poeders zijn essentieel voor toepassingen in de ruimtevaart, automobielindustrie, biomedische industrie en additieve productie. De VIGA-technologie onderscheidt zich door de mogelijkheid om poeders te produceren met een uitstekende vloeibaarheid, sferische vorm en gecontroleerde deeltjesgrootteverdeling.

Belangrijkste kenmerken van VIGA-machines

- Hoogzuivere metaalpoeders: VIGA-machines werken in een vacuüm- of inerte gasomgeving, waardoor contaminatie tot een minimum wordt beperkt.

- Bolvormige deeltjes: Zorgt voor uitstekende vloeibaarheid en verpakkingsdichtheid.

- Gecontroleerde deeltjesgrootte: Instelbare verstuivingsparameters voor poedereigenschappen op maat.

- Breed scala aan materialen: Geschikt voor diverse metalen en legeringen, waaronder titanium, roestvrij staal en superlegeringen.

Soorten en modellen metaalpoeders geproduceerd door VIGA-machines

Hier vind je specifieke metaalpoedermodellen die worden geproduceerd door VIGA-machines, samen met hun beschrijvingen:

| Metaal Poeder Model | Samenstelling | Eigenschappen | Toepassingen |

|---|---|---|---|

| Ti-6Al-4V | Titaniumlegering | Hoge sterkte, corrosiebestendig, biocompatibel | Lucht- en ruimtevaart, medische implantaten |

| 316L roestvrij staal | Fe-Cr-Ni-Mo legering | Uitstekende corrosiebestendigheid, goede mechanische eigenschappen | Biomedische apparaten, mariene toepassingen |

| IN718 | Superlegering op nikkelbasis | Hoge temperatuursterkte, oxidatiebestendig | Turbinebladen, ruimtevaartcomponenten |

| AlSi10Mg | Aluminiumlegering | Lichtgewicht, goede thermische eigenschappen | Automobiel, ruimtevaart |

| CoCrMo | Kobalt-chroom-molybdeenlegering | Hoge slijtvastheid, biocompatibel | Medische implantaten, tandprotheses |

| CuCrZr | Koper-chroom-zirkonium legering | Hoge elektrische geleidbaarheid, goede mechanische sterkte | Elektrische componenten, laselektroden |

| Maragingstaal (18Ni300) | Fe-Ni-Co-Mo-Ti legering | Ultrahoge sterkte, goede taaiheid | Gereedschap, hoogwaardige tandwielen |

| FeNiCo | Ijzer-Nikkel-Kobalt legering | Magnetische eigenschappen, goede mechanische sterkte | Magnetische onderdelen, lucht- en ruimtevaart |

| NiTi (Nitinol) | Nikkel-Titanium legering | Vormgeheugen, superelasticiteit | Medische apparaten, actuatoren |

| Hastelloy X | Nikkel-chroom-molybdeenlegering | Hoge temperatuursterkte, corrosiebestendig | Onderdelen voor gasturbines, chemische verwerking |

Toepassingen van VIGA-machines

VIGA-machines worden in een groot aantal industrieën gebruikt vanwege hun vermogen om metaalpoeders van hoge kwaliteit te produceren. Hier volgt een gedetailleerde blik op hun toepassingen:

| Industrie | Toepassingen |

|---|---|

| Lucht- en ruimtevaart | Turbinebladen, structurele onderdelen, bevestigingsmiddelen |

| Automobiel | Lichtgewicht componenten, motoronderdelen |

| Biomedisch | Implantaten, protheses, chirurgische instrumenten |

| Additieve productie | 3D printen van poeders, prototyping, complexe geometrieën |

| Energie | Onderdelen van turbines, onderdelen van kernreactoren |

| Elektronica | Geleidende pasta's, magnetische componenten |

Voordelen van VIGA-machines

- Hoge zuiverheid en reinheid: Werken in een vacuüm of inerte gasomgeving vermindert vervuiling, wat leidt tot hoogzuivere metaalpoeders.

- Gecontroleerde deeltjesgrootteverdeling: Maakt aanpassing voor specifieke toepassingen mogelijk, waardoor de prestaties verbeteren.

- Bolvormige deeltjes: Verbetert de vloeibaarheid en verpakkingsdichtheid, cruciaal voor additieve productie.

- Veelzijdig materiaalbereik: Kunnen een verscheidenheid aan metalen en legeringen verwerken, waardoor ze geschikt zijn voor diverse industrieën.

Nadelen van VIGA-machines

- Hoge initiële kosten: VIGA-machines zijn duur in aanschaf en installatie.

- Complexe werking: Vakkundige operators en regelmatig onderhoud vereist.

- Energie-intensief: Het proces vergt veel energie, waardoor de operationele kosten stijgen.

Gedetailleerde specificaties van VIGA-machines

| Specificatie | Details |

|---|---|

| Materiaalvermogen | Titanium, roestvrij staal, nikkellegeringen, aluminiumlegeringen, kobalt-chroomlegeringen, enz. |

| Vernevelingsgas | Argon, stikstof, helium |

| Bedrijfsdruk | Tot 150 bar |

| Deeltjesgroottebereik | 10 - 200 micron |

| Productie | Tot 500 kg/uur |

| Vacuümniveau | Tot 10^-5 mbar |

| Energieverbruik | 100 - 500 kW |

| Koelsysteem | Watergekoeld |

De voor- en nadelen van VIGA-machines

| Voordelen | Nadelen |

|---|---|

| Zeer zuivere metaalpoeders | Hoge initiële kosten |

| Bolvormige deeltjes | Complexe werking |

| Gecontroleerde deeltjesgrootte | Energie-intensief |

| Veelzijdig materiaalassortiment | Vakkundige operators vereist |

| Uitstekende stroombaarheid | Regelmatig onderhoud nodig |

FAQ

| Vraag | Antwoord |

|---|---|

| Waar worden VIGA-machines voor gebruikt? | Het produceren van hoogwaardige metaalpoeders voor diverse industrieën, waaronder lucht- en ruimtevaart, de auto-industrie en biomedische industrie. |

| Hoe werken VIGA-machines? | Ze gebruiken vacuüm of inert gas om gesmolten metaal te atomiseren tot fijne poeders met bolvormige deeltjes. |

| Welke metalen kunnen VIGA-machines verwerken? | Titanium, roestvrij staal, nikkellegeringen, aluminiumlegeringen en meer. |

| Wat is het bereik van de deeltjesgrootte van de geproduceerde poeders? | Gewoonlijk tussen 10 en 200 micron. |

| Zijn VIGA-machines duur? | Ja, ze hebben hoge initiële kosten, variërend van $900.000 tot meer dan $2.500.000. |

| Wat zijn de voordelen van het gebruik van VIGA-machines? | Hoge zuiverheid, gecontroleerde deeltjesgrootte, uitstekende vloeibaarheid en veelzijdigheid in materiaalverwerking. |

| Welke sectoren hebben baat bij VIGA-poeders? | Lucht- en ruimtevaart, auto-industrie, biomedische industrie, additive manufacturing, energie en elektronica. |

| Kunnen VIGA-machines poeders voor 3D-printen produceren? | Ja, ze zijn ideaal voor het produceren van poeders van hoge kwaliteit voor additieve productie. |

| Hebben VIGA-machines speciaal onderhoud nodig? | Ja, ze vereisen regelmatig onderhoud en bekwame operators om optimale prestaties te garanderen. |

| Wat zijn de meest gebruikte verstuivingsgassen? | Argon, stikstof en helium worden vaak gebruikt voor verneveling. |

Conclusie

VIGA-machines vertegenwoordigen een hoogtepunt in de metaalpoederproductietechnologie en leveren poeders van hoge kwaliteit die essentieel zijn voor de moderne industrie. Hun vermogen om sferische, hoogzuivere en nauwkeurig gecontroleerde poeders te produceren maakt ze van onschatbare waarde voor toepassingen variërend van lucht- en ruimtevaart tot biomedische apparaten. Ondanks hun hoge initiële kosten en complexiteit zijn de voordelen die ze bieden in termen van materiaaleigenschappen en prestaties ongeëvenaard. Als u zich wilt verdiepen in de productie van metaalpoeders van hoge kwaliteit, kan het begrijpen en gebruiken van VIGA-machines een revolutie betekenen.

Delen op

MET3DP Technology Co, LTD is een toonaangevende leverancier van additieve productieoplossingen met hoofdkantoor in Qingdao, China. Ons bedrijf is gespecialiseerd in 3D printapparatuur en hoogwaardige metaalpoeders voor industriële toepassingen.

Onderzoek om de beste prijs en een op maat gemaakte oplossing voor uw bedrijf te krijgen!

gerelateerde artikelen

Over Met3DP

Recente update

Ons product

NEEM CONTACT MET ONS OP

Nog vragen? Stuur ons nu een bericht! Na ontvangst van uw bericht behandelen wij uw verzoek met een heel team.

Metaalpoeders voor 3D printen en additieve productie

BEDRIJF

PRODUCT

contact informatie

- Qingdao-stad, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731