Części z superstopu do silników odrzutowych: drukowane 3D w USA

Spis treści

Wprowadzenie: Rola druku 3D w produkcji silników odrzutowych

Przemysł lotniczy przechodzi rewolucję produkcyjną, napędzaną przez wytwarzanie przyrostowe (AM)powszechnie znany jako Drukowanie 3D. Jednym z najważniejszych zastosowań tej technologii jest produkcja komponenty silników odrzutowych wykorzystujące nadstopy-Materiały specjalnie zaprojektowane, aby wytrzymać ekstremalne temperatury, wysokie ciśnienie i naprężenia mechaniczne.

Dlaczego druk 3D ma kluczowe znaczenie dla części silników odrzutowych?

- Geometrie złożone: Tradycyjna obróbka skrawaniem zmaga się ze skomplikowanymi projektami. druk 3D pozwala na zoptymalizowane, lekkie konstrukcje.

- Wydajność materiałowa: W przeciwieństwie do produkcji subtraktywnej, która marnuje materiał, druk 3D jest zasobooszczędny.

- Skrócony czas realizacji: Producenci z branży lotniczej i kosmicznej mogą przyspieszenie prototypowania i produkcji cykle.

- Najwyższa wydajność: Części z superstopów produkowane przez Selektywne topienie wiązką elektronów (SEBM) oraz Laserowa fuzja proszkowa (LPBF) wystawa wyjątkowa trwałość i odporność na ciepło.

Firmy takie jak Metal3DP są na czele tej transformacji, zapewniając precyzyjne rozwiązania do druku 3D z metalu dla zastosowania w lotnictwie, medycynie i motoryzacji. Dowiedz się więcej o Metal3DP możliwości druku 3D metali.

Trendy rynkowe: Wzrost produkcji addytywnej w przemyśle lotniczym i kosmicznym

The globalny rynek produkcji dodatków dla przemysłu lotniczego Oczekuje się, że wzrośnie w tempie CAGR z 20%+ w ciągu następnej dekady. Ekspansję tę napędza kilka czynników:

Kluczowe czynniki wpływające na branżę:

| Trend | Wpływ na przemysł lotniczy |

|---|---|

| Lekkość | Zmniejszenie masy samolotu poprawia wydajność paliwową. |

| Odporność łańcucha dostaw | Produkcja na żądanie łagodzi zakłócenia w dostawach. |

| Zrównoważony rozwój | Produkcja addytywna minimalizuje ilość odpadów materiałowych. |

| Optymalizacja wydajności | Superstopy zwiększają wydajność i żywotność silników odrzutowych. |

| Cyfrowa produkcja | Inżynierowie mogą szybko iterować i testować projekty. |

Zastosowanie nadstopów w silnikach odrzutowych

Nadstopy, takie jak Inconel 718, Inconel 625 i Hastelloy X są szeroko stosowane w komponentach silników odrzutowych, takich jak

- Łopatki turbiny

- Komory spalania

- Dysze wylotowe

- Wymienniki ciepła

Z gigantami lotniczymi, takimi jak Boeing, GE Aviation i Rolls-Royce intensywnie inwestując w badania nad drukiem 3Dprzyjęcie wytwarzanie przyrostowe metali ma gwałtownie wzrosnąć.

Metal3DP przyczynia się do tego wzrostu poprzez produkcję Wysokiej jakości proszki metali zoptymalizowany pod kątem zastosowań lotniczych. Poznaj ofertę Metal3DP zaawansowane proszki metalowe.

Kluczowe korzyści z drukowania 3D części silnika z superstopów

Przejście od tradycyjne odlewanie i kucie do drukowanie 3D części z nadstopów zapewnia szereg korzyści:

1. Redukcja masy & Efektywność paliwowa

- Struktury kratowe zmniejszają wagę o do 50% bez utraty wytrzymałości.

- Lżejsze silniki odrzutowe oszczędność paliwa i redukcja emisji dwutlenku węgla.

2. Odporność na wysokie temperatury

- Nadstopy wytrzymują temperatury przekraczające 1,000°C.

- Ulepszony rozpraszanie ciepła poprawia żywotność silnika.

3. Szybkie prototypowanie i dostosowywanie

- Inżynierowie mogą szybsze testowanie nowych projektów bez użycia drogiego oprzyrządowania.

- Personalizacja pozwala na modyfikacje silnika specyficzne dla linii lotniczych.

4. Oszczędność kosztów & Redukcja odpadów

- Tradycyjna obróbka powoduje straty do 80% surowca.

- Zastosowania produkcji addytywnej tylko niezbędna ilość proszkuobniżając koszty.

5. Zwiększona integralność strukturalna

- wystawa części drukowanych w 3D mniej defektów i zwiększona odporność na zmęczenie.

- Optymalizacja struktury ziarna zwiększa trwałość.

Porównanie: Konwencjonalne i drukowane w 3D części z nadstopów

| Cecha | Produkcja konwencjonalna | Wytwarzanie przyrostowe |

|---|---|---|

| Wydajność materiałowa | Wysoka ilość odpadów | Minimalna ilość odpadów |

| Czas realizacji | Tygodnie/miesiące | Dni |

| Złożoność | Ograniczone przez obróbkę | Nieograniczony |

| Siła i trwałość | Dobry | Doskonała struktura ziarna |

| Redukcja wagi | Ograniczony | Do 50% |

Wnioski

The integracja druku 3D w produkcji silników odrzutowych rewolucjonizuje przemysł lotniczy i kosmiczny. Wykorzystując wysokowydajne nadstopyfirmy mogą osiągnąć lżejsze, mocniejsze i bardziej oszczędne silniki.

Najlepsi dostawcy drukowanych w 3D nadstopów do silników odrzutowych w USA

The USA jest światowym liderem w przemyśle lotniczym produkcja addytywnaz wieloma firmami specjalizującymi się w metal Drukowanie 3D dla komponentów silników odrzutowychOto niektóre z nich najlepsi dostawcy:

1. GE Additive (oddział General Electric Aviation)

- Technologia: Topienie wiązką elektronów (EBM), bezpośrednie topienie laserowe metali (DMLM)

- Kluczowe produkty: Łopatki turbin, wykładziny spalania, wymienniki ciepła

- Znaczące osiągnięcia:

- Opracował światowy pierwsza wydrukowana w 3D dysza paliwowa z certyfikatem FAA.

- Zastosowania nadstopów, takich jak Inconel 718 i Hastelloy X dla części silników odrzutowych.

2. Produkcja addytywna Honeywell Aerospace

- Technologia: Laserowa fuzja proszkowa (LPBF)

- Kluczowe produkty: Komponenty płata, części komory spalania

- Znaczące osiągnięcia:

- Mocno zainwestował w produkcja dodatków metalowych dla przemysłu obronnego i samolotów komercyjnych.

- Pomyślnie wydrukowano wymienniki ciepła o złożonej geometrii.

3. Dział produkcji przyrostowej firmy Boeing

- Technologia: Selektywne topienie wiązką elektronów (SEBM), rozpylanie spoiwa

- Kluczowe produkty: Dysze wydechowe, łopatki turbin

- Znaczące osiągnięcia:

- Zastosowania Nadstopy tytanowo-glinowe tworzyć lżejsze i mocniejsze części silników odrzutowych.

- Praca nad druk 3D na żądanie do obsługi technicznej samolotów.

4. RTX (Raytheon Technologies - Pratt & Whitney)

- Technologia: Laserowa fuzja proszkowa (L-PBF)

- Kluczowe produkty: Tarcze turbin, łopatki wentylatorów

- Znaczące osiągnięcia:

- Koncentruje się na systemy napędowe hipersoniczne i nowej generacji przy użyciu druku 3D.

- Rozwijanie lekkie, wysokowytrzymałe komponenty z nadstopów.

5. Metal3DP - wysokowydajny partner w produkcji addytywnej

- Technologia: Fuzja wiązki elektronów w złożu proszkowym (EB-PBF), fuzja laserowa w złożu proszkowym (L-PBF)

- Kluczowe produkty: Wysoka precyzja proszki nadstopów i części silników drukowane w 3D

- Znaczące osiągnięcia:

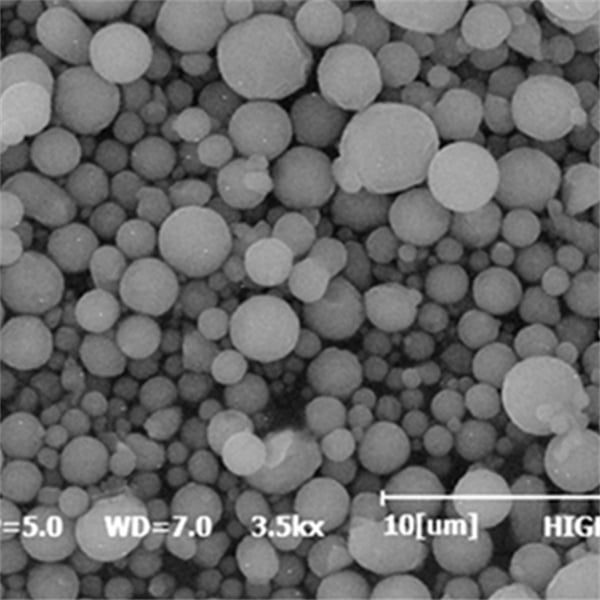

- Zaawansowany system wytwarzania proszku zapewnia wysoka kulistość i płynność.

- Materiały eksploatacyjne Wysokiej jakości proszki metali dla zastosowania silników odrzutowych.

- Zapewnia precyzyjne rozwiązania do produkcji addytywnej dla przemysłu lotniczego.

Chcesz poznać wysokowydajne proszki metali Metal3DP? Sprawdź naszą ofertę strona produktu.

Dlaczego firmy z branży lotniczej zwracają się w stronę produkcji addytywnej metali?

1. Większa swoboda projektowania i wydajność

- Złożone geometrie np. struktury kratowe i wewnętrzne kanały chłodzące są niemożliwe przy tradycyjnej obróbce.

- druk 3D umożliwia optymalizacja topologiizmniejszając waga przy zachowaniu wytrzymałości.

2. Szybsza produkcja i krótszy czas realizacji

| Metoda produkcji | Średni czas realizacji |

|---|---|

| Odlew tradycyjny | 8-16 tygodni |

| Obróbka CNC | 4-8 tygodni |

| Druk 3D | 1-3 tygodnie |

- Drukowanie na żądanie zmniejsza zależność od długich łańcuchów dostaw.

- Producenci OEM z branży lotniczej i kosmicznej może szybko wyprodukować części zamienne dla MRO (konserwacja, naprawy i remonty).

3. Doskonała wydajność materiału

- Nadstopy, takie jak Inconel 718 i Hastelloy X zapewniają najwyższą jakość odporność na ciepło, korozję i zmęczenie materiału.

- Produkcja addytywna poprawia strukturę ziarenprowadzące do trwalsze części do silników odrzutowych.

4. Redukcja kosztów & Zrównoważony rozwój

- Efektywność wykorzystania materiałów: Tradycyjne techniki odejmowania odpadów do 80% materiałupodczas gdy druk 3D wykorzystuje tylko wymaganą ilość.

- Oszczędność energii: The proces addytywny zużywa mniej energii w porównaniu do kucia i odlewania.

- Zmniejszony ślad węglowy: Lekki komponenty lotnicze zwiększają wydajność paliwową, zmniejszając emisje.

5. Sprostanie rosnącemu zapotrzebowaniu na samoloty nowej generacji

- The oczekuje się, że globalna flota samolotów podwoi się do 2040 roku.

- Druk 3D umożliwia szybszy rozwój systemów napędowych nowej generacji.

Dlaczego warto wybrać Metal3DP do produkcji wysokowydajnych części z nadstopów?

Metal3DP jest zaufany partner dla producentów z branży lotniczej i kosmicznej produkcja addytywna komponentów z nadstopów do silników odrzutowych. Oto dlaczego:

1. Wiodące w branży proszki metalowe

- Sferyczne proszki o wysokiej czystości dla zaawansowanych aplikacji lotniczych.

- Materiały superstopowe obejmują Inconel 718, TiAl, CoCrMo i Hastelloy X.

2. Zaawansowany system produkcji proszków

- Technologia atomizacji gazu i przygotowania zapewnić stały rozmiar proszku i wysoka płynność.

- Nasz system wytwarzania proszku tworzy stopy o niskiej zawartości tlenu i wysokiej sferyczności.

3. Precyzyjne rozwiązania do wytwarzania przyrostowego

- Fuzja elektronów w złożu proszkowym (EB-PBF) oraz Laserowa fuzja proszkowa (L-PBF) technologie dla wysoka dokładność i wytrzymałość.

- Usługi drukowania 3D na zamówienie dla przemysł lotniczy, medyczny i motoryzacyjny.

4. Doświadczenie w aplikacjach o znaczeniu krytycznym

- Nasze rozwiązania są wykorzystywane w łopatki turbin, wymienniki ciepła i komory spalania.

- Współpracujemy z firmy z branży lotniczej i kosmicznej wdrażają strategie produkcji dodatków nowej generacji.

5. Globalny zasięg i zaufana wiedza specjalistyczna

- Dziesięciolecia doświadczenia w wytwarzanie przyrostowe metali.

- Współpraca z wiodące firmy lotnicze i kosmiczne do przyspieszyć transformację cyfrową.

Dowiedz się więcej o specjalistycznej wiedzy Metal3DP w zakresie wytwarzanie przyrostowe metali.

Wnioski

The Stany Zjednoczone są domem dla jednych z najlepszych na świecie firm zajmujących się drukiem 3D w branży lotniczej i kosmicznejz Metal3DP odgrywający główną rolę w zaawansowana produkcja dodatków do metali dla części z nadstopu do silników odrzutowych.

Jak zamawiać niestandardowe, drukowane w 3D części z superstopów do silników odrzutowych?

Zamawianie niestandardowe komponenty silnika odrzutowego drukowane w 3D wymaga precyzji, specjalistycznej wiedzy i niezawodnego dostawcy. Przy Metal3DPusprawniamy proces, aby zapewnić wysokiej jakości części o krótkim czasie realizacji.

Proces zamawiania krok po kroku

| Krok | Opis |

|---|---|

| 1. Konsultacje & Zbieranie wymagań | Skontaktuj się z Metal3DP w sprawie wymagań projektowych, specyfikacji materiałowych i potrzeb w zakresie wydajności. |

| 2. Wybór materiału | Wybierz z wysokowydajne nadstopy jak Inconel 718, TiAl, CoCrMo i Hastelloy X. |

| 3. Projektowanie i optymalizacja | Nasi eksperci optymalizują model 3D dla produkcji addytywnej aby zwiększyć wytrzymałość, zmniejszyć wagę i poprawić odporność na ciepło. |

| 4. Prototypowanie i testowanie | Drukujemy przykładowe części przy użyciu Fuzja wiązki elektronów w złożu proszkowym (EB-PBF) lub fuzja laserowa w złożu proszkowym (L-PBF) do walidacji. |

| 5. Produkcja na pełną skalę | Po zatwierdzeniu rozpoczynamy produkcja na pełną skalęzapewniając ścisła kontrola jakości i integralność materiałów. |

| 6. Dostawa i wsparcie | Wysyłamy Twoje precyzyjnie zaprojektowane części do silników odrzutowych z pełną dokumentacją i wsparciem postprodukcyjnym. |

Dlaczego warto zamawiać w Metal3DP?

✅ Najwyższa w branży dokładność i niezawodność druku

✅ Zaawansowane proszki metali o wysokiej sferyczności i płynności

✅ Konfigurowalne rozwiązania do zastosowań lotniczych

✅ Krótki czas realizacji i globalna wysyłka

Jesteś zainteresowany zamówieniem? Skontaktuj się z Metal3DP już dziś aby omówić swój projekt.

Przyszłość druku 3D w przemyśle lotniczym i kosmicznym

1. Materiały nowej generacji & Nadstopy

- Rozwój nowych nadstopów wysokotemperaturowych dla samolotów hipersonicznych.

- Lżejsze i mocniejsze materiały dla zwiększenia wydajności paliwowej.

2. Silniki odrzutowe w pełni wydrukowane w 3D

- Firmy takie jak GE Aviation i Rolls-Royce eksplorują silniki odrzutowe w pełni wydrukowane w 3D.

- Przyszłe silniki mogą być wyposażone w zintegrowane struktury kratowe dla lepszego chłodzenia.

3. AI & Automatyzacja w produkcji przyrostowej

- Optymalizacja parametrów druku oparta na sztucznej inteligencji dla wyższa wydajność i mniej usterek.

- Zautomatyzowane techniki przetwarzania końcowego aby przyspieszyć produkcję.

4. druk 3D w konserwacji i naprawach statków powietrznych

- Drukowanie na żądanie na lotniskach aby skrócić czas przestojów.

- Części zamienne drukowane bezpośrednio na miejscu do szybkiej konserwacji samolotów.

5. Eksploracja kosmosu & Innowacje lotnicze i kosmiczne

- NASA i SpaceX używają produkcja addytywna silników rakietowych.

- Księżycowe i marsjańskie siedliska może być zbudowany przy użyciu metalowe struktury drukowane w 3D.

Poznaj zaawansowane technologie druku 3D Metal3DP dla przemysłu lotniczego i kosmicznego tutaj.

Najczęściej zadawane pytania: Najczęstsze pytania dotyczące drukowanych w 3D części z nadstopów

1. Jakie są najlepsze superstopy do druku 3D silników odrzutowych?

Do najczęściej stosowanych superstopów należą:

- Inconel 718 - Doskonała wytrzymałość i odporność na ciepło.

- Hastelloy X - Idealny do komór spalania i elementów układu wydechowego.

- Glinek tytanu (TiAl) - Lekka i odporna na wysokie temperatury.

2. Jak druk 3D wypada w porównaniu z tradycyjnym kuciem części do silników odrzutowych?

| Cecha | Tradycyjne kucie | Druk 3D |

|---|---|---|

| Czas realizacji | 8-16 tygodni | 1-3 tygodnie |

| Odpady materiałowe | 50-80% | Minimalny |

| Złożoność projektu | Ograniczony | Możliwe bardzo złożone geometrie |

| Efektywność kosztowa | Wysokie koszty oprzyrządowania | Niższe koszty narzędzi |

3. Czy wydrukowane w 3D części z superstopów mogą wytrzymać ekstremalne temperatury?

Tak! Nadstopy, takie jak Inconel 718 i Hastelloy X są zaprojektowane tak, aby wytrzymać temperatury powyżej 1000°Cdzięki czemu idealnie nadają się do zastosowania silników odrzutowych.

4. Czy druk 3D jest zatwierdzony przez FAA do zastosowań lotniczych?

Tak FAA (Federalna Administracja Lotnictwa) zatwierdziła kilka komponentów silników odrzutowych wydrukowanych w 3D, w tym:

- Dysze paliwowe

- Łopatki turbiny

- Wymienniki ciepła

5. Jak zapewnić jakość przy zamawianiu części lotniczych drukowanych w 3D?

Aby zagwarantować jakość:

- Pracuj z certyfikowani dostawcy jak Metal3DP.

- Użycie proszki metalowe o wysokiej czystości z stały rozmiar cząstek.

- Wykonanie badania nieniszczące (NDT) oraz analiza materiału.

Dowiedz się więcej o proszkach metali klasy lotniczej Metal3DP tutaj.

Wnioski i wezwanie do działania

Dlaczego Metal3DP jest najlepszym partnerem w zakresie druku 3D dla branży lotniczej i kosmicznej?

🚀 Ekspertyza w zakresie wysokowydajnych proszków metali i produkcji addytywnej

🚀 Najnowocześniejsze technologie druku do zastosowań w silnikach odrzutowych

🚀 Niestandardowe rozwiązania, krótkie terminy realizacji i globalna wysyłka

Szukam zaufany dostawca drukowanych w 3D nadstopowych części do silników odrzutowych? Skontaktuj się z Metal3DP już dziś aby omówić swój projekt!

Linki wewnętrzne dodane w części 3:

- Strona kontaktowa Metal3DP – Skontaktuj się z nami

- Metody druku 3D Metal3DP dla przemysłu lotniczego i kosmicznego – Poznaj technologie

- Proszki metali klasy lotniczej Metal3DP – Odkryj teraz

Udostępnij

MET3DP Technology Co., LTD jest wiodącym dostawcą rozwiązań w zakresie produkcji addytywnej z siedzibą w Qingdao w Chinach. Nasza firma specjalizuje się w sprzęcie do druku 3D i wysokowydajnych proszkach metali do zastosowań przemysłowych.

Zapytaj o najlepszą cenę i spersonalizowane rozwiązanie dla Twojej firmy!

Powiązane artykuły

Metal 3D Printed Subframe Connection Mounts and Blocks for EV and Motorsport Chassis

Czytaj więcej "

Metal 3D Printing for U.S. Automotive Lightweight Structural Brackets and Suspension Components

Czytaj więcej "Informacje o Met3DP

Ostatnia aktualizacja

Nasz produkt

KONTAKT

Masz pytania? Wyślij nam wiadomość teraz! Po otrzymaniu wiadomości obsłużymy Twoją prośbę całym zespołem.