Blog

wszystkie kolekcje

Electric Motor Stator Housings using metal 3D printing

Introduction – The Critical Role of Electric Motor Stator Housings in Modern EVs The electric vehicle (EV) revolution is reshaping the automotive landscape, demanding innovation in every component, including the often-unsung hero: the electric motor stator housing. This critical component serves as the backbone of the electric motor, providing structural

3D Printing Bleed Valves: Revolutionizing Aerospace Fluid Control

Introduction In the demanding realm of aerospace engineering, every component plays a critical role in ensuring safety, efficiency, and performance. Among these vital parts are bleed valves, responsible for controlling the extraction of compressed air from various stages of the aircraft engine or other pneumatic systems. Traditionally manufactured through subtractive

Lightweight Satellite Solar Panel Mounts: Revolutionizing Aerospace Engineering with Metal 3D Printing

Introduction – The Critical Role of Lightweighting in Satellite Technology In the demanding realm of satellite technology, every gram counts. The relentless pursuit of lightweighting drives innovation across all satellite components, and solar panel mounts are no exception. These critical structures must securely deploy and orient solar arrays, the lifeline

Internal Cooling Structures

Introduction – The Critical Role of Advanced Cooling in Aerospace Applications The relentless pursuit of enhanced performance, increased efficiency, and miniaturization in the aerospace industry has placed unprecedented demands on thermal management systems. From the extreme heat generated within turbine engines and combustion chambers to the critical need to dissipate

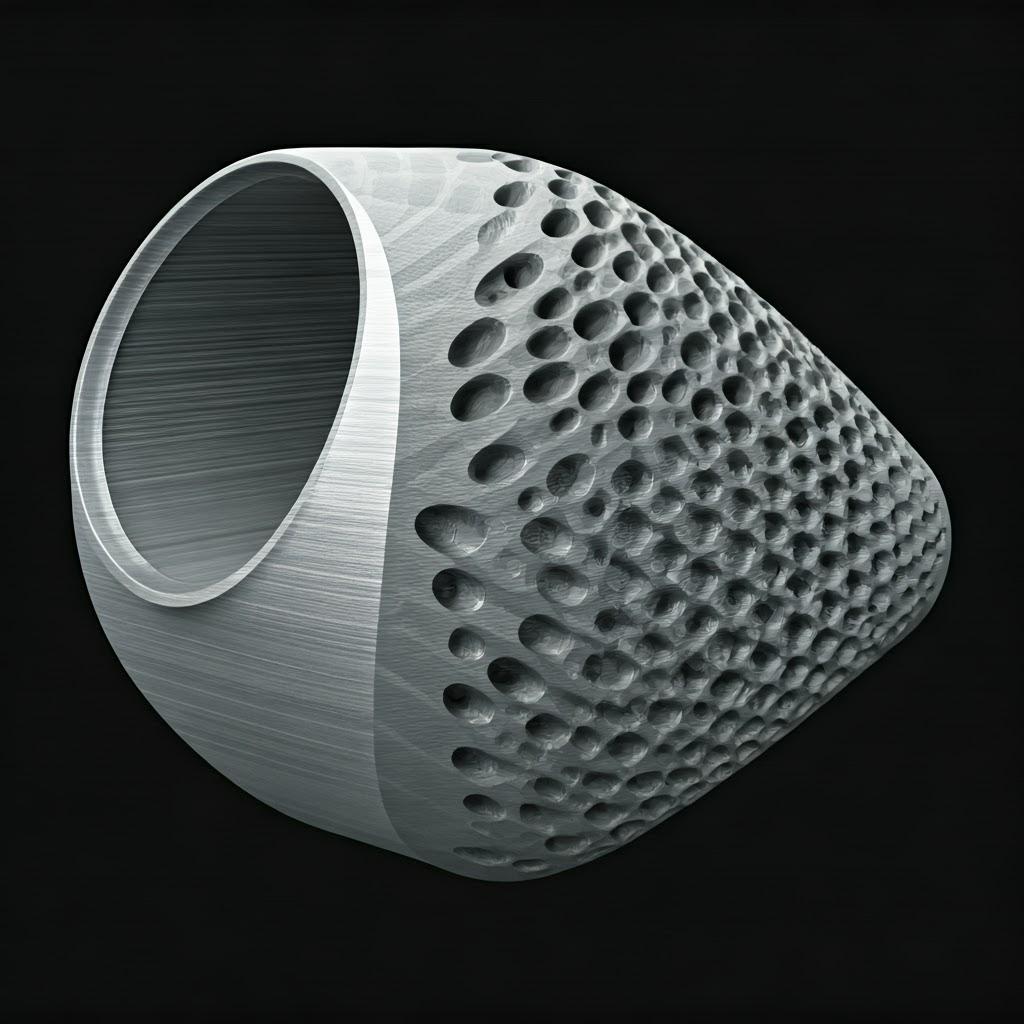

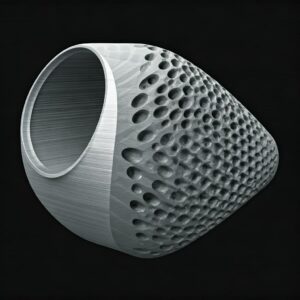

Additive Manufactured End Shields

Introduction – The Growing Importance of Advanced Materials in Electric Motors The electric motor industry is undergoing a significant transformation, driven by increasing demands for higher efficiency, lighter weight, and more compact designs across various sectors, including automotive, aerospace, and industrial automation. As these demands intensify, the role of advanced

3D Printed Exhaust Outlets

Introduction to 3D Printed Exhaust Outlets for Automotive Applications The automotive industry is constantly pushing the boundaries of innovation, seeking lighter, more efficient, and higher-performing components. Among these critical parts, the exhaust outlet plays a vital role in managing engine emissions and overall vehicle performance. Traditionally manufactured through processes like

Electric Motor Stator Housings using metal 3D printing

Introduction – The Critical Role of Electric Motor Stator Housings in Modern EVs The electric vehicle (EV) revolution is reshaping the automotive landscape, demanding innovation

3D Printing Bleed Valves: Revolutionizing Aerospace Fluid Control

Introduction In the demanding realm of aerospace engineering, every component plays a critical role in ensuring safety, efficiency, and performance. Among these vital parts are

Lightweight Satellite Solar Panel Mounts: Revolutionizing Aerospace Engineering with Metal 3D Printing

Introduction – The Critical Role of Lightweighting in Satellite Technology In the demanding realm of satellite technology, every gram counts. The relentless pursuit of lightweighting

Internal Cooling Structures

Introduction – The Critical Role of Advanced Cooling in Aerospace Applications The relentless pursuit of enhanced performance, increased efficiency, and miniaturization in the aerospace industry

Additive Manufactured End Shields

Introduction – The Growing Importance of Advanced Materials in Electric Motors The electric motor industry is undergoing a significant transformation, driven by increasing demands for

3D Printed Exhaust Outlets

Introduction to 3D Printed Exhaust Outlets for Automotive Applications The automotive industry is constantly pushing the boundaries of innovation, seeking lighter, more efficient, and higher-performing

Nasz produkt

PRODUKT GORĄCEJ SPRZEDAŻY

KONTAKT

Masz pytania? Wyślij nam wiadomość teraz! Po otrzymaniu wiadomości obsłużymy Twoją prośbę całym zespołem.

Proszki metali do druku 3D i produkcji addytywnej

PRODUKT

cONTACT INFO

- Miasto Qingdao, Shandong, Chiny

- [email protected]

- [email protected]

- +86 19116340731