Zagraniczne rozwiązania w zakresie wytwarzania przyrostowego

Spis treści

1. Introduction: The Rise of Overseas Additive Manufacturing Solutions

Additive manufacturing (AM), commonly known as 3D printing, has quickly become a cornerstone in advanced manufacturing sectors such as aerospace, automotive, medical devices, defense, and industrial tooling. As global demand surges, businesses are increasingly looking beyond their borders to source reliable, cost-effective, and high-performance additive manufacturing solutions.

In recent years, overseas additive manufacturing solution providers, particularly those in Asia and Europe, have gained prominence due to their ability to offer:

- Competitive pricing with high-quality output

- Broad material compatibility and innovation

- Skalowalne możliwości produkcyjne

- Customization for diverse industry applications

This shift is not just about cost reduction — it’s about accessing advanced technologies and materials that might not be available domestically. For B2B buyers, partnering with overseas additive manufacturing suppliers opens doors to innovation and strategic sourcing flexibility.

2. Global Market Trends and Growth Potential in Additive Manufacturing

The global additive manufacturing market is projected to reach $50+ billion by 2030, with CAGR estimates ranging from 20% to 25%. Key drivers include:

- Demand for rapid prototyping and custom parts

- Advancements in metal 3D printing

- Adoption in end-use production, not just prototyping

- Government and military investments

- Sustainability and waste reduction in manufacturing

Key Market Stats:

| Region | 3D Printing Market Size (2023) | Projected CAGR (2023–2030) |

|---|---|---|

| Ameryka Północna | $7.4 Billion | 21.0% |

| Europa | $6.2 Billion | 20.2% |

| Azja i Pacyfik | $5,9 miliarda | 23.3% |

| Reszta świata | $2,5 miliarda | 18.7% |

Emerging Trends in Overseas AM Markets:

- China and Southeast Asia are rapidly scaling production capacity and R&D in wytwarzanie przyrostowe metali.

- Europa remains a leader in precision engineering and regulatory compliance.

- India and South Korea are emerging as innovation centers for low-cost, high-efficiency AM systems.

For B2B buyers and distributors, this global expansion means more diverse sourcing options, more competitive pricing, and faster access to innovation.

3. Key Considerations When Sourcing Additive Manufacturing Solutions from Overseas

Before committing to an overseas AM supplier, businesses must evaluate several critical factors to ensure a successful partnership.

✅ Checklist for Overseas AM Supplier Evaluation:

| Kryteria | Dlaczego to ma znaczenie |

|---|---|

| Możliwości techniczne | Ensure compatibility with your industry’s application needs |

| Wiedza specjalistyczna w zakresie materiałów | Look for suppliers offering high-performance metal powders |

| Certyfikacja i zgodność | ISO, CE, FDA, and other relevant certifications |

| Logistics & Shipping Support | Faster lead times, export documentation, customs clearance |

| Post-Sales Support & Warranty | Critical for equipment maintenance and uptime |

| Language & Communication Skills | Smooth communication reduces project risks |

| Proven Export Experience | Suppliers experienced with B2B exports can simplify the process |

Red Flags to Watch Out For:

- Lack of verifiable case studies or references

- No in-house R&D or material testing

- Poor after-sales service or technical support

- Vague pricing or inconsistent lead times

By thoroughly vetting potential partners, B2B buyers can reduce supply chain risks and ensure long-term success with their overseas AM sourcing strategy.

4. Top 5 Overseas Additive Manufacturing Solution Providers

For B2B buyers, sourcing from top-performing overseas manufacturers ensures quality, consistency, and technological innovation. Below is a curated list of five highly reputable overseas additive manufacturing solution providers, all recognized for their production scale, industry credibility, and export capability.

🌍 Top 5 Overseas Additive Manufacturing Suppliers:

| Nazwa firmy | Siedziba główna | Specjalności | Obsługiwane branże |

|---|---|---|---|

| Metal3DP | China (Qingdao) | SEBM 3D printers, metal powders, AM solutions | Aerospace, Automotive, Medical, Tooling |

| EOS GmbH | Niemcy | Laser sintering systems, polymer & metal AM | Automotive, Aerospace, Consumer Goods |

| SLM Solutions | Niemcy | Laser-based metal AM machines | Przemysł lotniczy i kosmiczny, motoryzacja, energia |

| Farsoon Technologies | Chiny | Industrial polymer and metal 3D printers | Automotive, Aerospace, Mold Manufacturing |

| AddUp | Francja | PBF and DED systems, turnkey AM solutions | Aerospace, Defense, Heavy Industry |

Why These Suppliers Stand Out:

- Metal3DP: Offers full-stack AM solutions including wysokowydajne proszki metali and SEBM printers, ensuring tight integration between materials and hardware.

- EOS: A pioneer in powder bed fusion with deep industry customization.

- SLM Solutions: Known for high-speed multi-laser systems.

- Farsoon: Competitive pricing and strong presence in APAC.

- AddUp: Offers hybrid manufacturing systems and robust post-processing tools.

✅ Tip for B2B Buyers: Look for suppliers with vertically integrated capabilities, including powder metallurgy, printer hardware, and application consulting. This reduces complexity and ensures better part quality.

5. Why More Distributors Are Turning to Chinese Additive Manufacturing Suppliers

China has emerged as a global powerhouse in additive manufacturing, not just for its scale and cost-efficiency, but for its rising technological innovation and export capabilities. Distributors across Europe, North America, and Southeast Asia are actively sourcing from Chinese AM companies due to several strategic benefits.

📈 Top Reasons Distributors Prefer Chinese AM Suppliers:

- Cost-Effective Equipment: Chinese AM hardware is often 20–40% more affordable without compromising on core functionalities.

- Materiały zaawansowane: Companies like Metal3DP offer innovative alloys such as TiAl, CoCrMo, and Ni-based superalloys.

- Export Expertise: Many Chinese suppliers have dedicated international sales and logistics teams.

- Mass Production Capabilities: High output volume with short lead times is ideal for distributors managing large inventories.

- Government-Backed R&D: China’s “Made in China 2025” policy heavily supports AM innovation, especially in metal 3D printing.

📋 Case Example: Metal3DP’s International Supply Chain Support

Metal3DP, headquartered in Qingdao, has successfully exported its additive manufacturing systems and powders to over 30 countries, providing end-to-end services including:

- Export documentation and custom clearance

- On-site installation and training

- Remote troubleshooting and spare parts supply

- Live demos and virtual consultations

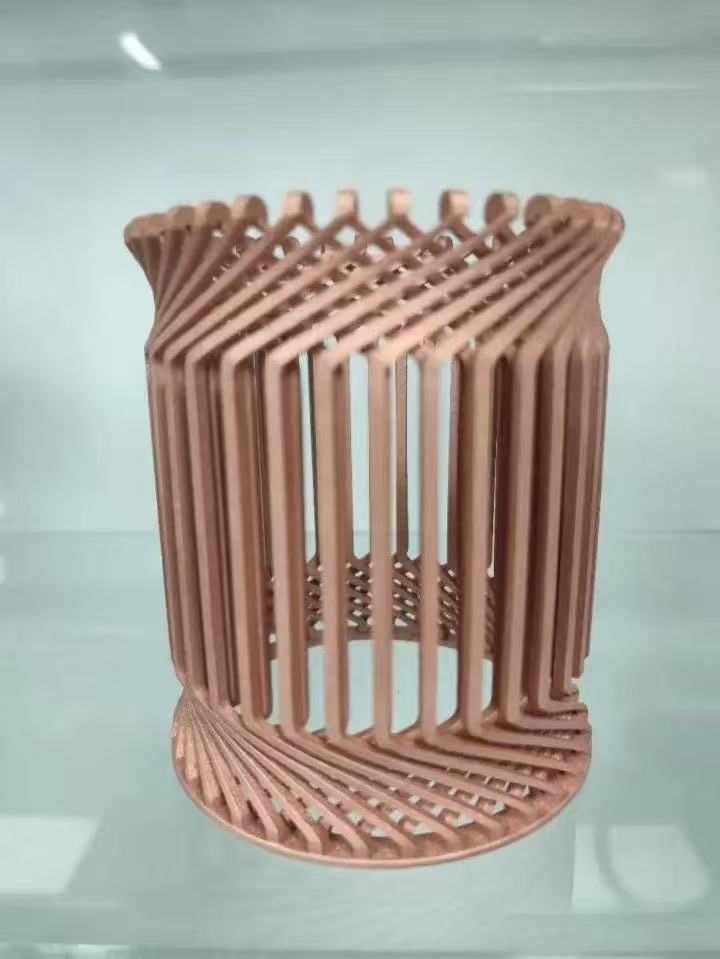

With its advanced powder production systems, Metal3DP supplies high-flowability, spherical metal powders optimized for laser and electron beam powder bed fusion processes — a critical differentiator for distributors seeking reliable materials.

6. Why Choose Metal3DP as Your Trusted Overseas AM Partner

As competition intensifies in the additive manufacturing industry, businesses require partners who deliver not just machines or materials, but complete, integrated solutionsOto dlaczego Metal3DP stands out as a top overseas partner for B2B enterprises.

🔧 Core Strengths of Metal3DP

| Cecha | Korzyści dla kupujących B2B |

|---|---|

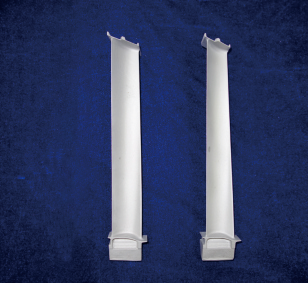

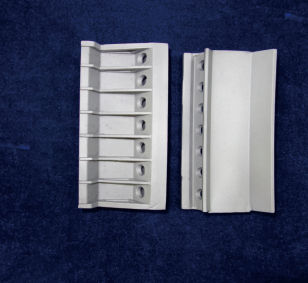

| SEBM (Selective Electron Beam Melting) Printers | High-volume, high-precision metal part production |

| Proprietary High-Sphericity Powders | Superior flowability, better packing density, fewer defects |

| Technologia atomizacji gazu i przygotowania | Produces powders with optimal morphology and particle size |

| Industry-Specific Material Portfolio | TiNi, Ti6Al4V, CoCrMo, Inconel — ready for aerospace & medical apps |

| Global Export Support Team | Seamless communication, shipping, and post-sales service |

🏭 Metal3DP’s Capabilities at a Glance:

- Print Volume: Among the largest in the industry, ideal for mission-critical parts in aerospace and automotive.

- Accuracy & Reliability: Precision within microns, tested under industrial stress conditions.

- Inżynieria aplikacji: Custom R&D and prototyping services offered to clients worldwide.

- Partnership Approach: Metal3DP actively collaborates with OEMs, research institutes, and manufacturers to co-develop tailored AM solutions.

📌 Relevant Internal Link:

Discover more about Metal3DP’s advanced printing methods and technologies by visiting the Metody drukowania strona.

“At Metal3DP, we don’t just sell machines — we enable transformation. From powder to part, we offer a complete ecosystem tailored for global B2B partners.” — Metal3DP Executive

7. How to Import Additive Manufacturing Equipment and Powders from Overseas

Importing additive manufacturing (AM) solutions — whether it’s metal 3D printers or high-performance powders — requires careful planning and the right supplier partnership. For B2B buyers, OEMs, and distributors, a structured import process ensures compliance, speed, and cost-efficiency.

📦 Step-by-Step Guide to Importing AM Equipment and Materials

| Krok | Działanie | Kluczowe kwestie |

|---|---|---|

| 1 | Identify the Right Supplier | Evaluate technical specs, export readiness, certifications |

| 2 | Request Quotation & Technical Data | Ask for datasheets, machine specs, powder MSDS, and compatibility |

| 3 | Confirm Incoterms & Shipping Terms | FOB, CIF, DDP — clarify who handles logistics and customs duties |

| 4 | Finalize Purchase Agreement | Include warranty, installation, training, and support terms |

| 5 | Arrange Payment & Production | Use secure payment terms (LC, TT), confirm lead time, QA process |

| 6 | Export Preparation by Supplier | Export docs: Commercial Invoice, Packing List, Bill of Lading, Certificate of Origin |

| 7 | Customs Clearance in Import Country | Work with a licensed customs broker |

| 8 | Installation, Onboarding & After-Sales Support | Ensure supplier provides technical onboarding, spare parts, and remote support |

✅ Metal3DP’s Streamlined Export Support

Metal3DP simplifies the import process for global partners through:

- Dedicated Export Team: Handles all necessary paperwork and logistics coordination

- CE-Certified Equipment: Meets international safety and compliance standards

- Virtual Training & Onboarding: For overseas customers unable to attend in-person sessions

- Warranty & After-Sales Support: Global support for parts, upgrades, and troubleshooting

Visit Metal3DP’s O nas page to learn more about their global service infrastructure and international partnerships.

“We’ve helped clients in over 30 countries seamlessly import AM systems and powders. Our logistics team reduces the complexity while our engineers ensure technical success.” — Metal3DP Export Manager

8. Conclusion: The Future of Cross-Border Additive Manufacturing Partnerships

The globalization of additive manufacturing is no longer a trend — it’s a necessity.

As industries seek faster prototyping, localized production, and material innovation, overseas AM partnerships are unlocking new levels of efficiency, customization, and scalability.

🔮 What the Future Holds:

- Decentralized Production: AM is enabling cross-border manufacturing hubs with reduced reliance on central factories.

- Innowacja materiałowa: High-entropy alloys, bio-compatible metals, and lightweight composites are being developed globally.

- AI + AM Integration: Smart systems will enhance defect prediction, print quality, and process efficiency.

- Green Additive Manufacturing: Reduced material waste and energy use make AM a sustainable alternative to traditional manufacturing.

🌍 Why It’s Time to Embrace Overseas AM

| Korzyści | Wpływ na nabywców B2B |

|---|---|

| Broader Supplier Base | Reduced risk, increased innovation |

| Efektywność kosztowa | Lower CAPEX and OPEX in sourcing machines and materials |

| Krótszy czas wprowadzania na rynek | Rapid prototyping and production cycles |

| Access to Specialized Alloys | Enables niche applications in aerospace, medical, and tooling |

| Global Collaboration | Co-development of next-gen applications with overseas partners |

For businesses ready to embrace the full potential of cross-border manufacturing, choosing a dependable, technologically advanced partner like Metal3DP is a strategic advantage.

9. FAQs: Common Questions About Overseas Additive Manufacturing Solutions

Here are some of the most frequently asked questions from B2B buyers and distributors exploring overseas AM solutions:

❓ Q1: Is it safe to import 3D printers and powders from China or other countries?

A: Yes, as long as the supplier has proven export experience, certifications (e.g., CE, ISO), and a track record of international clients. Metal3DP, for example, offers CE-certified equipment and manages full export processes for its global customers.

❓ Q2: How long does shipping typically take?

A: It depends on the destination country and Incoterms. Standard lead time for machine delivery is 4–6 weeks, while powders can be shipped in 1–2 weeks. Metal3DP provides real-time tracking and export documentation to speed up the process.

❓ Q3: What kind of post-sales support should I expect from an overseas supplier?

A: Leading overseas suppliers offer remote training, virtual installations, spare part availability, and multilingual support. Metal3DP provides live onboarding and a global technical support team.

❓ Q4: Can I request custom powder formulations for specific applications?

A: Absolutely. Metal3DP’s zaawansowane systemy produkcji proszków allow for custom alloy development based on customer needs — including biomedical, aerospace, and energy applications.

❓ Q5: What are the most common applications for overseas AM solutions?

A: Kluczowe zastosowania obejmują:

- Elementy konstrukcyjne dla przemysłu lotniczego

- Medical implants and devices

- Automotive prototyping and tools

- Energy sector turbine parts

- Custom industrial manufacturing

✅ Final Call-to-Action:

If your organization is looking to expand its additive manufacturing capabilities with reliable overseas solutions, we highly recommend exploring Metal3DP’s integrated systems and materials. From Drukarki SEBM do wysokiej jakości sferyczne proszki metalowe, Metal3DP is your trusted partner for industrial-grade 3D printing.

Odwiedź Strona produktu Metal3DP to explore our full range of additive manufacturing offerings or contact our team directly through our strona główna for a customized consultation.

Udostępnij

MET3DP Technology Co., LTD jest wiodącym dostawcą rozwiązań w zakresie produkcji addytywnej z siedzibą w Qingdao w Chinach. Nasza firma specjalizuje się w sprzęcie do druku 3D i wysokowydajnych proszkach metali do zastosowań przemysłowych.

Zapytaj o najlepszą cenę i spersonalizowane rozwiązanie dla Twojej firmy!

Powiązane artykuły

Wysokowydajne segmenty łopatek dysz: Rewolucja w wydajności turbin dzięki drukowi 3D w metalu

Czytaj więcej "

Drukowane w 3D mocowania dla samochodowych czujników radarowych: Precyzja i wydajność

Czytaj więcej "Informacje o Met3DP

Ostatnia aktualizacja

Nasz produkt

KONTAKT

Masz pytania? Wyślij nam wiadomość teraz! Po otrzymaniu wiadomości obsłużymy Twoją prośbę całym zespołem.

Proszki metali do druku 3D i produkcji addytywnej

PRODUKT

cONTACT INFO

- Miasto Qingdao, Shandong, Chiny

- [email protected]

- [email protected]

- +86 19116340731